Professional Documents

Culture Documents

Lams Group 6 Lashing and Securing of Timber Deck Cargo

Uploaded by

rochbcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lams Group 6 Lashing and Securing of Timber Deck Cargo

Uploaded by

rochbcCopyright:

Available Formats

LAMS ASSIGNMENT FOR COC1&2 CARGOWORK(MA2024) GROUP MEMBERS: ROCH BRANDON CHARLES (GRP 34) KAW CHEE WAI

(GRP 33) VICKNESWARAN M. (GRP 33) GANESH KUMAR (GRP 33) LASHING AND SECURING OF TIMBER DECK CARGO

It is important to realise that Regulation 44 of the International Convention of Load Lines 1966, still applies to the 1991 IMO timber deck cargo Code, but the spacing of the transverse lashings within the Code, although still determined by height, does not permit an interpolation between cargo heights of 4m and 6m. The straightforward interpretation of such spacing applies to a compact stow of square-ended bundles (flush at both ends) or near square-ended bundles in the following manner: Each package (along the sides, that is) shall be secured by at least two transverse lashings spaced 3m apart for heights not exceeding 4m above the weather-deck at sides. For heights above 4m the spacing shall be 1.5m above the weather-deck at sides. When timber in the outboard stow is in lengths less than 3.6m the spacing of the lashings shall be reduced as necessary (to comply with the requirement for each package to be secured by at least two transverse lashings). The stowage of timber deck cargo should be tight and compact. Where packages are involved, they should be square-ended (flush) at both ends so far as this is possible. Broken stowage and unused spaces should be avoided. There is no absolute requirement for uprights to be used for packaged timber cargo although some national administrations may insist on their use when lashing arrangements are not otherwise fully satisfactory. Bundles of regular form when stowed in stepped-in truncated, pyramid fashion will not benefit from uprights, even if they are fitted. The IMO Code does not allow uprights to be used instead of lashings. Where uprights are used they are in addition to the full number of lashings properly pitched and of full strength. The use of uprights when carrying logs on deck is a necessary requirement, and it is most important always to rig and attach hog wires between such uprights. The uprights strength relies upon the weight of logs above the hog wires. This rule applies whenever hog wires are rigged even with packaged timber. Never use uprights without rigging hog wires. When a full timber cargo is carried on deck and the ship is loaded to the timber load line, the statical stability curve may be derived from the cross curves of stability which have been computed taking into account the timber deck cargo. When the timber deck cargo is not correctly stowed, due to deficient height or other reason, the statical stability curve must be derived from the cross curves computed for the ship without timber deck cargo. Wires or chains used for lashings should have a break load of not less than 13.6 tonnes force (133kN). With wire and grips the IMO Code of Safe Practice for Ships Carrying Timber Deck Cargoes recommends that four grips per eye are used, and if that recommendation is followed with the eye made up around a thimble the holding power of the eye will be not less than 90% NBL, so a 6x24 galvanised wire rope of 19mm diameter will fully comply with the Codes strength requirements. Where thimbles are not used, the slip-load of an eye properly made up, will be about 70% of the wires

nominal strain. At sea, all lashing and securing arrangements should be tended daily, adjusting as necessary to take up any slack which may occur as the cargo settles.

Always rig hog wires when using the deck side uprights for logs, packages and loose timber

Rigging hog wires for deck-stowed log cargo, as required by the IMO Code of Safe Practice for Ships Carrying Timber Deck Cargoes, 1991

The correct use of wiggle-wires through snatch blocks used to bind and consolidate the log stow independent of the number and pitch of crosslashings required. Photo shows chain cross-lashings pitched 3m apart for stow not exceeding 4m in height above the weatherdeck at the ships side

You might also like

- Mooring Systems: Securing Ships to Piers & WharvesDocument12 pagesMooring Systems: Securing Ships to Piers & WharvesKarim Abd Elaziz100% (2)

- Cummins Electronic Governor ManualDocument1 pageCummins Electronic Governor ManualElectro Allied Engineering Services100% (2)

- Cuplok Scaffold System: User GuideDocument11 pagesCuplok Scaffold System: User Guideezzularab100% (1)

- Web Slings-Cintas CERTEXDocument34 pagesWeb Slings-Cintas CERTEXleonardo_barros_48No ratings yet

- Scaffold Erection GuidanceDocument14 pagesScaffold Erection GuidanceRauf Akchurin67% (3)

- Drum Handlingstorage Installation GuidelineDocument12 pagesDrum Handlingstorage Installation GuidelineShubham Baderiya100% (1)

- 2008 RCL Accepting Steel Coils ProceduresDocument8 pages2008 RCL Accepting Steel Coils ProceduresMauricio Gomes de BarrosNo ratings yet

- Operation Maintenance Manual PDFDocument28 pagesOperation Maintenance Manual PDFbulentbulutNo ratings yet

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 pagesDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- Timber Deck Cargoes: Regional Maritime UniversityDocument33 pagesTimber Deck Cargoes: Regional Maritime UniversityMahami M ProsperNo ratings yet

- Carefully Carry Timber CargoesDocument6 pagesCarefully Carry Timber Cargoescptmehmetkaptan100% (2)

- 8 Scaffolding SafetyDocument12 pages8 Scaffolding SafetygbogboiweNo ratings yet

- Power Grid Training ReportDocument43 pagesPower Grid Training ReportManasvi Dhariwal80% (5)

- The Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsFrom EverandThe Knot Book - Knots, Bends and Hitches - A Guide for Sailors, Adventurers and HobbyistsNo ratings yet

- Technical Wire RopesDocument17 pagesTechnical Wire RopesAdrian CantaragiuNo ratings yet

- IMO Code Timber Deck Cargoes and Bulk Oil Cargo ShipsDocument6 pagesIMO Code Timber Deck Cargoes and Bulk Oil Cargo ShipsMorganNo ratings yet

- Medical Equipment TroubleshootingDocument28 pagesMedical Equipment TroubleshootingNarendran Ravi80% (5)

- Tractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookFrom EverandTractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookRating: 5 out of 5 stars5/5 (2)

- Bulk Carrier ConstructionDocument5 pagesBulk Carrier Constructionreuben ephraim100% (2)

- Hawser Operating ManualDocument14 pagesHawser Operating ManualFaisal AwanNo ratings yet

- Ac Machines Lab ManualDocument102 pagesAc Machines Lab ManualAshwin Gopinath100% (3)

- Timber Deck CargoesDocument12 pagesTimber Deck CargoeschristieSINo ratings yet

- 3.structural Damages During Cargo Operations DAY 3Document16 pages3.structural Damages During Cargo Operations DAY 3cicileana100% (1)

- Anchoring Systems & ProceduresDocument21 pagesAnchoring Systems & ProceduresPushkar Lamba100% (1)

- RAILWAYS, Ballast and SleepersDocument94 pagesRAILWAYS, Ballast and SleepersGulraizNo ratings yet

- Flat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Document25 pagesFlat Rack Loading Guidelines 5-28 (NCB Revised Mod 2)Shane Anderson100% (1)

- Drivers Daily Check Sheet Log Sheet Mileage SheetDocument2 pagesDrivers Daily Check Sheet Log Sheet Mileage Sheetronscofield94% (18)

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- Timber Deck CargoesDocument6 pagesTimber Deck CargoesGauravRaiNo ratings yet

- VCBDocument19 pagesVCBmadan_153No ratings yet

- Mooring Equipment GuidelinesDocument3 pagesMooring Equipment GuidelinesJason Roberts100% (1)

- Comparing Traction and Hydraulic ElevatorsDocument17 pagesComparing Traction and Hydraulic ElevatorsPankaj Mahata83% (6)

- Container Lashing WebDocument16 pagesContainer Lashing WebSined SinedNo ratings yet

- Timber Notes PH 1 Class 2Document16 pagesTimber Notes PH 1 Class 2Yash SaxenaNo ratings yet

- 13 Timber Deck Cargoes (II)Document24 pages13 Timber Deck Cargoes (II)Kyaw Zin LynnNo ratings yet

- Load LineDocument3 pagesLoad LineNelum PereraNo ratings yet

- Hapag-LLoyd Flatracks Lashing Guide Nov 2015Document3 pagesHapag-LLoyd Flatracks Lashing Guide Nov 2015Allen Alex LalisNo ratings yet

- L5-Cargo Gears (Part 2)Document13 pagesL5-Cargo Gears (Part 2)Ganesh Bharath KumarNo ratings yet

- Code of Safe Practice For Ships Carrying Timber Deck CargoesDocument30 pagesCode of Safe Practice For Ships Carrying Timber Deck CargoesAldy MaitaNo ratings yet

- The Maintenance of Permanent Way: Part 'A' General InstructionsDocument8 pagesThe Maintenance of Permanent Way: Part 'A' General Instructionslakshmi dileepNo ratings yet

- Handling and Securing Steel CoilsDocument3 pagesHandling and Securing Steel CoilsdharmawanNo ratings yet

- Dabchick Association of South Africa: Measurement Procedure For Dabchick Class BoatsDocument4 pagesDabchick Association of South Africa: Measurement Procedure For Dabchick Class BoatskilpsNo ratings yet

- Precautions for handling PSC sleepersDocument9 pagesPrecautions for handling PSC sleepersSWRNo ratings yet

- Emergency Towing ArrangementDocument9 pagesEmergency Towing ArrangementManishNo ratings yet

- Unit6 DerrickDocument20 pagesUnit6 DerrickPratham PandeyNo ratings yet

- Chevron-JO Lift Procedure For TubularsDocument1 pageChevron-JO Lift Procedure For TubularszhiqianxuNo ratings yet

- Box Culvert Handling and Jointing Instructions 2020 PDFDocument3 pagesBox Culvert Handling and Jointing Instructions 2020 PDFHpeso EmohseNo ratings yet

- TowingDocument17 pagesTowingALP ASLANNo ratings yet

- Guide to restraining concrete panels and beamsDocument18 pagesGuide to restraining concrete panels and beamsStuart EdwardsNo ratings yet

- 13.roll OnDocument20 pages13.roll OnFaye-Ann CristobalNo ratings yet

- 9.15 Underhung Scaffold.Document3 pages9.15 Underhung Scaffold.AfshadNo ratings yet

- Military Occupational Information - PPTX Rey Mark Jay LupinaDocument13 pagesMilitary Occupational Information - PPTX Rey Mark Jay LupinaReymark Jay LupinaNo ratings yet

- CLO3Document9 pagesCLO3saifNo ratings yet

- 2.1.4.5 How To Maintenance of Cargo GearDocument26 pages2.1.4.5 How To Maintenance of Cargo Gear4pv6gkwvc9No ratings yet

- UDN500 - Chap-5 - Sleeper TypesDocument23 pagesUDN500 - Chap-5 - Sleeper Typesmuhammad aliNo ratings yet

- LWR - Permitted LocationsDocument14 pagesLWR - Permitted LocationsG. S. YadavNo ratings yet

- Lec 9 BallastDocument88 pagesLec 9 BallastNisha NishaNo ratings yet

- User S Manual Synthetic Mooring TailsDocument13 pagesUser S Manual Synthetic Mooring TailsGökhan UlukuzNo ratings yet

- CrossLam Unloading Handling Storage 2017Document13 pagesCrossLam Unloading Handling Storage 2017Vasilis LappasNo ratings yet

- Flatrack RackcardDocument2 pagesFlatrack RackcardSergiy KovernikNo ratings yet

- 015chapter 14 Koepe Friction HoistsDocument14 pages015chapter 14 Koepe Friction HoistsWahyu Dwi AgustianNo ratings yet

- Technical Information Sheet: Lashing PointsDocument2 pagesTechnical Information Sheet: Lashing PointsSebastian ZarzyckiNo ratings yet

- Risk Watch Vol 08 2 PDFDocument4 pagesRisk Watch Vol 08 2 PDFkahl983No ratings yet

- Effective Mooring2222Document37 pagesEffective Mooring2222Red SkiNo ratings yet

- Deck Cargo Handling GuideDocument35 pagesDeck Cargo Handling GuideInnocentvishwaNo ratings yet

- FOCLaying ProceduresDocument10 pagesFOCLaying ProceduresjahanzaibNo ratings yet

- Proclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalFrom EverandProclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalNo ratings yet

- Operational Write Up - SCRDocument10 pagesOperational Write Up - SCRZahoor AhmedNo ratings yet

- LT3751 - Cap Charger ControllerDocument34 pagesLT3751 - Cap Charger Controllerdinamik2tNo ratings yet

- Arduino DC MotorDocument12 pagesArduino DC MotorJohn Clifford Ambaic JayomaNo ratings yet

- 6679gs Mosfet Canal PDocument6 pages6679gs Mosfet Canal PMarta_d_eNo ratings yet

- DK-17 PlanoDocument2 pagesDK-17 PlanoodeiviNo ratings yet

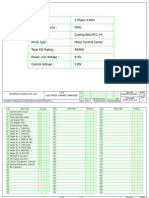

- ELEC PANEL LISTDocument21 pagesELEC PANEL LISTjsrplc7952No ratings yet

- Sanmotion AC Servo PYO Series Instruction ManualDocument370 pagesSanmotion AC Servo PYO Series Instruction ManualsunhuynhNo ratings yet

- Design and Fabrication of Coconut de HuskingDocument5 pagesDesign and Fabrication of Coconut de HuskingKenneth LorenzoNo ratings yet

- 2017 Lista de Preturi Aeronave Ulm Tecnam 1490263678 PDFDocument12 pages2017 Lista de Preturi Aeronave Ulm Tecnam 1490263678 PDFMari DawoodNo ratings yet

- HDMI Switch 4KDocument4 pagesHDMI Switch 4Ksudhir DNo ratings yet

- BOQ Plumbing+HvacDocument3 pagesBOQ Plumbing+HvacOmar MhmmadNo ratings yet

- Thumm 4.506.13 e 506H 4 G1 2Document1 pageThumm 4.506.13 e 506H 4 G1 2luc sherdNo ratings yet

- 8251 Programmable Communication InterfaceDocument14 pages8251 Programmable Communication Interfacesukantho sikderNo ratings yet

- Jamec Air FittingsDocument18 pagesJamec Air Fittingsgoeez1No ratings yet

- S1r9a9m9 Water CarDocument7 pagesS1r9a9m9 Water Carapi-372572650% (2)

- Calculating Conductor Impedance for a 3-Phase Pole ConfigurationDocument12 pagesCalculating Conductor Impedance for a 3-Phase Pole ConfigurationJonatan Lopez RodriguezNo ratings yet

- High Frequency Off Grid Solar InverterDocument1 pageHigh Frequency Off Grid Solar InverterHanibal АтанасовNo ratings yet

- Accessing I/O DevicesDocument33 pagesAccessing I/O DevicesKishore SKNo ratings yet

- Manual Pulidora 9 Milwaukee Serial B43CD15010643Document36 pagesManual Pulidora 9 Milwaukee Serial B43CD15010643M Vega Vega Mahecha0% (1)

- Power Bridge Rectifiers: FeaturesDocument3 pagesPower Bridge Rectifiers: FeaturesFatumaNo ratings yet

- Ina - Permaglide - InformationsDocument3 pagesIna - Permaglide - Informationsnunesalessandro1975No ratings yet

- How To Install Somfy MotorsDocument6 pagesHow To Install Somfy MotorsJuary99No ratings yet