Professional Documents

Culture Documents

For Uplode Type 316 Schedule 10s Allowable Working Pressure

Uploaded by

prashantms1481Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Uplode Type 316 Schedule 10s Allowable Working Pressure

Uploaded by

prashantms1481Copyright:

Available Formats

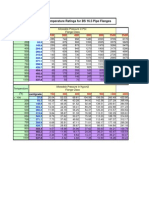

STAINLESS STEEL WELDED PIPE

TYPE 316 SCHEDULE 10S ALLOWABLE WORKING PRESSURE

ALLOWABLE WORKING PRESSURES

FOR A-312 WELDED PIPE

TEMPERATURE F.

MAX. STRESS

425

to 300

400

500

600

650

TYPE 316

Schedule 10S

700

750

800

1150

1200

1250

1300

1350

1400

1450 1500

20000 19300 17900 17000 16700 16300 16100 15900 15700 15500 15400 15300 14500 12400 9600

7400

5500

4100

3100

2300

1700 1300

NOM.

SCH. NOM.

PIPE

NO. WALL.

SIZE

850

900

950

1000

1050

1100

ALLOWABLE WORKING PRESSURES PSIG

10S

.083

2767

2670

2476

2352

2310

2255

2227

2200

2172

2144

2130

2117

2006

1715

1356

1024

761

587

429

318

235

180

10S

.083

2213

2136

1981

1881

1848

1804

1782

1760

1737

1715

1704

1693

1605

1372

1085

819

609

454

343

255

188

144

10S

.109

2321

2240

2077

1973

1938

1892

1888

1845

1822

1799

1787

1775

1683

1439

1137

859

638

476

360

267

197

151

10S

.109

1839

1774

1646

1563

1535

1496

1480

1462

1443

1425

1416

1406

1333

1140

901

680

506

377

285

211

156

120

10S

.109

1608

1550

1438

1365

1341

1309

1293

1277

1261

1245

1237

1229

1165

996

787

594

442

329

249

185

137

104

10S

.109

1285

1240

1150

1092

1073

1047

1034

1022

1009

996

969

983

932

797

630

475

353

263

199

148

109

84

10S

.120

1169

1128

1046

993

976

952

941

929

917

906

900

894

847

725

573

432

321

240

181

134

99

76

10S

.120

960

926

859

816

802

782

773

763

754

744

739

734

696

595

470

355

264

197

149

110

82

62

10S

.120

840

811

752

714

701

685

676

668

659

651

647

643

609

521

412

311

231

172

130

97

71

55

10S

.120

747

721

668

635

623

609

601

594

586

579

575

571

541

463

366

276

205

153

116

86

63

49

10S

.134

674

651

604

573

563

550

543

538

529

523

519

516

489

418

330

250

185

138

105

78

57

44

10S

.134

566

547

507

481

473

462

456

450

445

439

438

433

411

351

278

210

156

116

88

65

48

37

10S

.148

480

464

430

408

401

392

387

382

377

372

370

368

348

298

235

178

132

96

74

55

41

31

10

10S

.165

430

415

385

365

359

350

346

342

337

333

331

329

312

266

211

159

118

88

67

49

37

28

12

10S

.180

395

381

354

336

330

322

318

314

310

306

304

302

287

245

194

148

109

81

61

45

34

26

14

10S

.188

376

363

337

320

314

306

303

299

295

291

290

288

273

233

184

139

103

77

58

43

32

24

16

10S

.188

329

317

294

260

275

268

265

262

258

255

253

252

239

204

161

122

90

67

51

38

28

21

18

10S

.188

292

282

262

249

244

238

235

232

230

227

225

224

212

181

143

108

80

60

45

34

25

19

20

10S

.218

305

295

273

259

255

249

246

243

240

237

235

233

221

189

150

113

84

63

47

35

26

20

24

10S

.250

292

281

261

248

244

238

235

232

229

226

225

223

211

181

143

108

80

60

45

34

25

19

The Allowable Stress Values used are as shown in Appendix "A" of ANSI B31.3-1993 for welded

pipe to ASTM A-312 having a weld joint factor of .80.

The Stress Values at all temperatures above 1000F apply only when the carbon is 0.04% or higher.

TA CHEN INTERNATIONAL, INC. | Excellence in Execution | www.tachen.com

You might also like

- Washout Valve and Air Valve SizingDocument3 pagesWashout Valve and Air Valve SizingA.ANo ratings yet

- Dynaflo DP 60hz CatalogDocument44 pagesDynaflo DP 60hz Catalognpclap67% (3)

- Airbus: Process and Material SpecificationDocument25 pagesAirbus: Process and Material SpecificationJorge OrtegaNo ratings yet

- Corrosion Under InsulationDocument28 pagesCorrosion Under InsulationNurulFatimahalzahra100% (7)

- Type 316 Schedule 10s Allowable Working PressureDocument1 pageType 316 Schedule 10s Allowable Working Pressureprashantms1481No ratings yet

- Pressure-Temperature Ratings for Steel Pipe FlangesDocument1 pagePressure-Temperature Ratings for Steel Pipe FlangesPaulusIwanNo ratings yet

- Pressure and temperature ratings for carbon steel pipeDocument1 pagePressure and temperature ratings for carbon steel pipeCharu ChhabraNo ratings yet

- Typical 1St-4Th Floor Plan L (2-) 05: StairsDocument1 pageTypical 1St-4Th Floor Plan L (2-) 05: Stairsnak_osNo ratings yet

- SCALE - 1: 100: Lift Machine RoomDocument1 pageSCALE - 1: 100: Lift Machine RoomPrathamesh SalviNo ratings yet

- Pressure-Temperature ratings of alloy steel pipeDocument1 pagePressure-Temperature ratings of alloy steel pipeCharu ChhabraNo ratings yet

- KT PenstockDocument24 pagesKT Penstockbenliney100% (1)

- Pressure Temperature With ChartDocument1 pagePressure Temperature With ChartVasundharaLimayeNo ratings yet

- Stainless Steel Pipes - Pressure RatingsDocument3 pagesStainless Steel Pipes - Pressure RatingsExsan OthmanNo ratings yet

- Mouvex Abaque Series Peristaltic Hose Pump Spec SheetDocument3 pagesMouvex Abaque Series Peristaltic Hose Pump Spec SheetAnkur BhargavaNo ratings yet

- A106B Pressure ChartDocument1 pageA106B Pressure ChartJon LawsonNo ratings yet

- Table F2-1.15 Pressure-Temperature Ratings For Group 1.15 MaterialsDocument1 pageTable F2-1.15 Pressure-Temperature Ratings For Group 1.15 MaterialsPanchal ShaileshNo ratings yet

- SVL606 Stainless Steel Safety Valve: DescriptionDocument4 pagesSVL606 Stainless Steel Safety Valve: DescriptionalejjavierdelgadoNo ratings yet

- Maximum Allowable Non-Shock PressureDocument2 pagesMaximum Allowable Non-Shock PressureWaqas WaqasNo ratings yet

- Table F2-1.14 Pressure-Temperature Ratings For Group 1.14 MaterialsDocument1 pageTable F2-1.14 Pressure-Temperature Ratings For Group 1.14 MaterialsPanchal ShaileshNo ratings yet

- Table F2-1.17 Pressure-Temperature Ratings For Group 1.17 MaterialsDocument1 pageTable F2-1.17 Pressure-Temperature Ratings For Group 1.17 MaterialsPanchal ShaileshNo ratings yet

- Table F2-1.9 Pressure-Temperature Ratings For Group 1.9 MaterialsDocument1 pageTable F2-1.9 Pressure-Temperature Ratings For Group 1.9 MaterialsPanchal ShaileshNo ratings yet

- Pressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004Document3 pagesPressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004alikajbafNo ratings yet

- Ansi B16.5 Bolt Torque (FT.-LBS) For 7500psi Gasket Seating Stress For Raised Faced Flanges Pressure ClassesDocument2 pagesAnsi B16.5 Bolt Torque (FT.-LBS) For 7500psi Gasket Seating Stress For Raised Faced Flanges Pressure ClassesJhoseph RoqueNo ratings yet

- Table F2-1.10 Pressure-Temperature Ratings For Group 1.10 MaterialsDocument1 pageTable F2-1.10 Pressure-Temperature Ratings For Group 1.10 MaterialsPanchal ShaileshNo ratings yet

- Pressure Temperature Ratings GuideDocument4 pagesPressure Temperature Ratings GuideCURRITOJIMENEZNo ratings yet

- Hot TappingDocument6 pagesHot TappingbravoalfadeltaNo ratings yet

- @@ Water Tubing 1Document1 page@@ Water Tubing 1starykltNo ratings yet

- Deepak Valves Price List 20.11.2012Document2 pagesDeepak Valves Price List 20.11.2012ShrikantNo ratings yet

- No3anchor Pool TWDocument2 pagesNo3anchor Pool TWlomasbigNo ratings yet

- Flange ClassDocument3 pagesFlange ClassBSFNo ratings yet

- Temperature Flange Class 150 300 400 Gage Pressure (Psi)Document3 pagesTemperature Flange Class 150 300 400 Gage Pressure (Psi)Acid HadiNo ratings yet

- 3 - 10 Ref - Table For Type TDocument2 pages3 - 10 Ref - Table For Type TCharu ChhabraNo ratings yet

- PVC Cables FinolexDocument8 pagesPVC Cables FinolexMaria DenetNo ratings yet

- Table F2-1.13 Pressure-Temperature Ratings For Group 1.13 MaterialsDocument1 pageTable F2-1.13 Pressure-Temperature Ratings For Group 1.13 MaterialsPanchal ShaileshNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- Vitomax 200HSDocument14 pagesVitomax 200HSDamir ĆavarNo ratings yet

- Weight: Stockless AnchorDocument1 pageWeight: Stockless AnchorJuliana Gil RodriguezNo ratings yet

- Model 30 Dry Gas FilterDocument4 pagesModel 30 Dry Gas FiltercartarNo ratings yet

- CaterpillarDiesel Generator Specifications and DimensionsDocument1 pageCaterpillarDiesel Generator Specifications and DimensionsaldandanalNo ratings yet

- Flow Cal. Intervalve BVDocument3 pagesFlow Cal. Intervalve BVf_riseNo ratings yet

- GAIL HDPE and LLDPE price list for MaharashtraDocument6 pagesGAIL HDPE and LLDPE price list for MaharashtraindramaniNo ratings yet

- Flange Tables PDFDocument6 pagesFlange Tables PDFTomhang No HangNo ratings yet

- Flange P T TablesDocument6 pagesFlange P T Tablesquocan4386No ratings yet

- Flange Tables PDFDocument6 pagesFlange Tables PDFtpelly7No ratings yet

- 100 SeriesDocument5 pages100 Seriesfathur2107No ratings yet

- Asean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Document1 pageAsean Centre For Biodiversity (Acb) Proposed Acb Office Building Lower Ground Floor Finishes 0Vince Bagsit PolicarpioNo ratings yet

- All Wiley-Blackwell JournalsDocument454 pagesAll Wiley-Blackwell JournalsSeif EddineNo ratings yet

- Pages From Vacuum - Condensers-8Document1 pagePages From Vacuum - Condensers-8boeiniNo ratings yet

- Grip Type U-BoltsDocument1 pageGrip Type U-BoltsPaul QueenNo ratings yet

- Flang TempDocument1 pageFlang Temps_bikassNo ratings yet

- Achech Gate GlobeDocument31 pagesAchech Gate GlobeberusleeNo ratings yet

- Structural steel assemblies and dimensionsDocument1 pageStructural steel assemblies and dimensionszgrouproNo ratings yet

- Stainless Steel Pressure RatingDocument1 pageStainless Steel Pressure RatingJatinder SondhiNo ratings yet

- Optimize your COBRA-TDC check valve SEO with this 40-character titleDocument7 pagesOptimize your COBRA-TDC check valve SEO with this 40-character titleGogyNo ratings yet

- Rezimi Rada GlodalaDocument2 pagesRezimi Rada GlodalaPetar HosticNo ratings yet

- Cases Will Remain Available For Use Until Annulled by The Applicable Standards CommitteeDocument5 pagesCases Will Remain Available For Use Until Annulled by The Applicable Standards CommitteeMMD Siddhiranj 335MWNo ratings yet

- Table F2-3.16 Pressure-Temperature Ratings For Group 3.16 MaterialsDocument1 pageTable F2-3.16 Pressure-Temperature Ratings For Group 3.16 MaterialsPanchal ShaileshNo ratings yet

- RMG by Honeywell BD 277 Hi-Flo GB 2010-10Document8 pagesRMG by Honeywell BD 277 Hi-Flo GB 2010-10Jorge Henostroza IntiNo ratings yet

- Cat01 BaDocument11 pagesCat01 BaTemporiusNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- Section 089000 - Louvers and VentsDocument17 pagesSection 089000 - Louvers and VentsNeeskens D'melloNo ratings yet

- bLOCKS PDFDocument16 pagesbLOCKS PDFHoang Diep PhanNo ratings yet

- SH Catalogue - Plastic & OralDocument13 pagesSH Catalogue - Plastic & OralSaqibullah ShahzadNo ratings yet

- 00 PR SP 00001 - 2 Wet Hydrogen Sulphide (H2S) Service SpecificationDocument12 pages00 PR SP 00001 - 2 Wet Hydrogen Sulphide (H2S) Service SpecificationStevanNikolicNo ratings yet

- Viking Pumps PDFDocument11 pagesViking Pumps PDFlavascudoNo ratings yet

- 2017-Katalog-4400UK Hydraulic Hoses Fittings And-Equipment CAT 4400 UKNEWDocument608 pages2017-Katalog-4400UK Hydraulic Hoses Fittings And-Equipment CAT 4400 UKNEWfia c.lNo ratings yet

- 001 Lca Standard ComponentsDocument4 pages001 Lca Standard ComponentsYUCARIE HIGUCHINo ratings yet

- 05 - (直动电磁阀)SVP8 x 08 Series (February 2007)Document4 pages05 - (直动电磁阀)SVP8 x 08 Series (February 2007)陆军No ratings yet

- Fontaine Aquanox 2016Document6 pagesFontaine Aquanox 2016MarceloNo ratings yet

- Bombas Centífugas KSBDocument12 pagesBombas Centífugas KSBkarmencitaconk4035No ratings yet

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- NI 0133 (English)Document112 pagesNI 0133 (English)Cebrac ItatibaNo ratings yet

- Jeddah Office and Contact DetailsDocument38 pagesJeddah Office and Contact DetailsArun Chandra Babu100% (1)

- ISSA Ship Store Catalogue ISSA Weicon Katalog Velle 1317834688Document12 pagesISSA Ship Store Catalogue ISSA Weicon Katalog Velle 1317834688hiệp đìnhNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- BS en 13445 2 2021 Unfired Pressure Vessels Part 2Document94 pagesBS en 13445 2 2021 Unfired Pressure Vessels Part 2muhammad hadiNo ratings yet

- TH 150Document12 pagesTH 150Minh Hong PhamNo ratings yet

- 3S Fall Arrestor For Vertical Wire Rope Protection SystemDocument14 pages3S Fall Arrestor For Vertical Wire Rope Protection SystemangelNo ratings yet

- GATE PSU Study Material Plant Design Economics PDFDocument14 pagesGATE PSU Study Material Plant Design Economics PDFBathula KasiNo ratings yet

- Mil STD 248dDocument157 pagesMil STD 248dTom Giles67% (3)

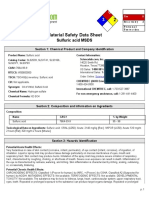

- Msds Asam Sulfat InggrisDocument7 pagesMsds Asam Sulfat InggrisNiko yuga ade putraNo ratings yet

- ASTM A240-A240M-05aDocument12 pagesASTM A240-A240M-05aNadhiraNo ratings yet

- A 890 - A 890M - 99 R03Document4 pagesA 890 - A 890M - 99 R03AjimKe'enNo ratings yet

- Marflex Deepwell Pump Brochure v3 PDFDocument7 pagesMarflex Deepwell Pump Brochure v3 PDFJ.C. ZhangNo ratings yet

- ECO AUDIT STEAM IRONDocument7 pagesECO AUDIT STEAM IRONUlisses Heredia0% (1)

- Autoclave CatalogueDocument12 pagesAutoclave CataloguecristianoclemNo ratings yet

- Pipe Code SpecsDocument4 pagesPipe Code Specsfrenskiran100% (1)