Professional Documents

Culture Documents

Hazard Communication, What Is

Uploaded by

asknishanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Communication, What Is

Uploaded by

asknishanCopyright:

Available Formats

What is

What is

Hazard Communication?

Hazard Communication?

The Occupational Safety and Health Administration (OSHA) developed the Hazard Communication Standard to assure that employees are made aware of and protected from hazardous substances at work. It requires employers to evaluate the presence and potential hazards of chemicals employees may be exposed to in their workplaces. It also requires employers to pass this information on to employees through employee training, material safety data sheets (MSDSs) and labels on containers or other identifying means. To best protect workers from injury/illness, employers should compile a master list of chemicals used in the facility. OSHA denes a hazardous chemical as any chemical that is a physical or health hazard. The list may be generated using a variety of information sources.

This publication is one in a series the Ohio Bureau of Workers Compensations (BWCs) Division of Safety & Hygiene publishes to address specic workplace safety and health concerns. Information contained in this publication is offered as suggestions to help safeguard you on the job. Each task presents its own special issues, so these guidelines cannot possibly cover every situation. If an injury occurs, BWC offers quick claims service to help you get back on the job as soon as possible or into rehabilitation when necessary. To download additional copies of this educational guide, please visit the Safety publications in the BWC library on our Web site at

Inventory

The rst step in developing a hazard communication program is to determine what hazardous substances are in the facility, and the only way to determine this is to inventory the entire facility. This must be a comprehensive listing of all hazardous or potentially hazardous substances present. During this procedure, list everything; judgments as to whether something is hazardous or not can be decided later. One way to accomplish the inventory is for you or a team to conduct a walk-through of the facility, department by department, and list all materials, whether hazardous or not. Look everywhere you think there may be materials that you will need to list. Get people from the different departments to assist you while you are in their areas. If using the team approach, record two separate lists and compare them when the listing is completed. To double-check, acquire any lists of materials that the safety manager, purchasing or warehousing may have, and add any materials not already listed to your inventory. Also review workers compensation claims and industrial hygiene reports to attempt to identify anything that may be an airborne contaminant. Dont forget to survey the workplace for any building materials stored on site. You must also consider byproducts produced by any processes in your facility. For example, carbon dioxide is given off by the fermentation process or fumes from welding operations. Employee-owned products also must be included on the inventory. Although the products belong to the employees, these items are on the companys premises, and workers are potentially exposed to any hazardous components they may contain. (This does not pertain to personal articles, such as cosmetics, medication, foodstuffs and other personal-use items.)

ohiobwc.com.

Ohio Bureau of Workers Compensation Division of Safety & Hygiene 13430 Yarmouth Drive Pickerington, OH 43147

1-800-OHIOBWC, press 2

1 BWCs Division of Safety & Hygiene

Revised June 2006

Other areas to include in the inventory are ofce and janitorial supplies, stationary containers and piping within the facility.

What is

2

Dont forget operations that may not be performed every day but involve hazardous substances either brought on the site or generated by the procedure itself. Examples include hazardous non-routine tasks and conned-space entry requirements. Remember, this inventory is not to determine quantity but what hazardous materials the organization has on site. While conducting this inventory, many organizations have discovered materials they no longer use or want to have on their sites. These materials must be disposed of properly in accordance with all local, state and federal regulations concerning hazardous materials.

Hazard Communication?

Hazard communication written program

The hazard communication written program outlines the process the company will use to protect its employees from the hazardous materials they must work with to perform their jobs. This is the plan that will drive the training required by the standard. The written program contains a number of elements, and these will be addressed one at a time. Policy statement Contains the organizations reasons it wants to comply with the hazard communication standard. This area should also state who is responsible, by name and position, for the plan, and its location and accessibility to the workers, their representatives and OSHA. The organization may include other concerns, such as organization philosophy, background and public image. Labeling Describes how materials will be labeled in the facility. This is where any in-house labeling system is described and where to list who is responsible for ensuring that this system is properly used. MSDSs Tells how the organization will maintain and make available to the employees and others the MSDSs pertinent to the safe performance of their jobs. This section should also state what procedure the company will follow if MSDSs from the manufacturer or supplier are not received. Again, someone should be named as having responsibility for this section of the plan. Employee training and information Will probably be the most detailed and comprehensive portion of the plan. Here the organization will spell out who is to receive what type of training and who will be responsible for conducting this training. This must include training on all aspects of the plan as well as how frequently this training will be conducted. Refresher training also will be covered in this part of the plan. List of hazardous materials Contains the list that you generated while conducting your inventory. Once more, this is where to specify who is responsible for maintaining this list and where it will be located. Hazardous non-routine tasks Addresses those tasks that need to be accomplished but not as part of the everyday routine. Examples include cleaning out vats or changing lters in ventilating systems. The organization must examine these processes and develop procedures to accomplish these in a safe manner.

Piping Details how the organization will deal with unlabeled piping systems in its facility. Although pipes are required to be labeled only where material is drawn off, its not a bad idea to label piping systems to facilitate maintenance and rapid identication of substances in an emergency. Informing contractors Spells out how the exchange of information on hazardous substances on multi-employer work sites will occur, as required by the standard. Remember to not only provide the contractors with the information they need to adequately train their employees about the hazardous substances in your facility but to obtain the information necessary to train your employees of the hazards the contractor may bring in to your site. Now that you have the essential elements of the plan and what those elements should contain, you might consider making sections in the plan that could change frequently. These sections usually include the list of hazardous materials and hazardous non-routine tasks. By including these as appendices, you can withdraw and update or modify them without changing the entire written plan.

What is

3

Hazard Communication?

Training

The best hazard communication program will not provide worker protection or meet the standards requirements without an effective and ongoing training program. Employers must provide workers with training on their program and the hazardous materials they will be exposed to in performing the work. This training can be divided into two categories: general and specic. General training is best described as training common to all organization employees as required by law and company policy. This training includes: The hazard communication standard; Specics of the organization written plan; How hazards will be communicated to the employees; What labeling system will be used; How to read and understand MSDSs, including pertinent terminology necessary for understanding. Specic training deals with specic hazardous substances in the workplace. These include: Characteristics of the hazardous substance, i.e., what does it look like? Is it a solid, liquid or vapor? How is its presence detected?; Physical and health hazards associated with the substance; Work practices or standard operating procedures used with the substance; Emergency action plans associated with the substance; Personal protective equipment required when using or while exposed to the substance; Non-routine task training; Results of any industrial hygiene monitoring within the work area. So, who must be trained? All employees should receive the general training, while specic training is generally limited to those workers who will handle or be exposed to the hazardous substances in the facility.

To start, train the existing employees of the company on both the general and specic training necessary to perform their jobs. Once the existing work force is trained, the following training is required: Give new employees all necessary training before they begin work; Provide temporary employees with the same training as permanent employees before they begin work; Conduct training for all employees on new substances that may present a hazard; Provide transferred employees additional specic training on hazards they will face in their new assignments; Give employees training on any new hazards associated with substances already in use in the facility; Retrain employees who have returned from either extended leaves or layoff; Conduct refresher training for all employees as needed. As far as the frequency of refresher training, employees with little or no exposure to hazardous substances may require refresher training only on an annual basis. But employees regularly exposed or exposed to substances with a high potential for harm may require much more frequent refresher training. After its determined who must be trained and what training must be given, decide who should do the training. Anyone knowledgeable of the hazard communication standard and the organization program can conduct the general training. This training could be accomplished during employee orientation or at any time prior to beginning work. Someone familiar with the particular hazards of the substances to which the workers will be exposed and the work practices that will be used should conduct the specic training. This can be accomplished by the rst-line supervisor or someone from the area where the worker will be assigned. After the training has been conducted, there must be a way to determine understanding. This could be a test or having the employees demonstrate their ability to safely perform the tasks required of them. Once the training has been completed, document the training and who has been trained. If you would like assistance in developing or reviewing your hazard communication plan, call the nearest BWC customer service ofce or 1-800-OHIOBWC. Visit BWCs Web site at www.ohiobwc.com.

What is

4

Hazard Communication?

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pile DrivingDocument78 pagesPile Drivingasknishan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cabinetmaking and Millwork Department GRADES 9-12Document21 pagesCabinetmaking and Millwork Department GRADES 9-12Tito Bustamante100% (1)

- Introduction To Osha GuideDocument61 pagesIntroduction To Osha GuideCesar BlNo ratings yet

- ICTAD Specifications For WorksDocument12 pagesICTAD Specifications For Workssanojani50% (8)

- Material Safety Data Sheet: RivanolDocument5 pagesMaterial Safety Data Sheet: RivanolIndHa Cua Cua100% (1)

- Irrigation Practices 4 PDFDocument4 pagesIrrigation Practices 4 PDFasknishanNo ratings yet

- Irrigation Practices 4 PDFDocument4 pagesIrrigation Practices 4 PDFasknishanNo ratings yet

- Irrigation Practices 2Document4 pagesIrrigation Practices 2asknishanNo ratings yet

- Irrigation Practices 3Document7 pagesIrrigation Practices 3asknishanNo ratings yet

- Irrigation Practices 3Document7 pagesIrrigation Practices 3asknishanNo ratings yet

- Irrigation Practices 5Document8 pagesIrrigation Practices 5asknishanNo ratings yet

- Rules: The Association of Consulting Engineers, Sri LankaDocument22 pagesRules: The Association of Consulting Engineers, Sri LankaasknishanNo ratings yet

- Challenging People's Challenge With Community Participation - Water Supply PerspectiveDocument6 pagesChallenging People's Challenge With Community Participation - Water Supply PerspectiveasknishanNo ratings yet

- Agency LawDocument3 pagesAgency LawasknishanNo ratings yet

- Professional EthicsDocument17 pagesProfessional EthicsasknishanNo ratings yet

- Member RegistrationDocument2 pagesMember Registrationasknishan0% (1)

- PMCDocument11 pagesPMCasknishanNo ratings yet

- රුවන්මැලි මහා සෑයDocument16 pagesරුවන්මැලි මහා සෑයdharmacharee_pirisa100% (1)

- Passport Normal A ApplicationDocument4 pagesPassport Normal A Applicationn2elNo ratings yet

- Tolstoy RanjithNaotunna PDFDocument111 pagesTolstoy RanjithNaotunna PDFasknishanNo ratings yet

- Laws of Sale of GoodsDocument1 pageLaws of Sale of GoodsasknishanNo ratings yet

- Johnson-LeBreton ORM 2004 PDFDocument20 pagesJohnson-LeBreton ORM 2004 PDFasknishanNo ratings yet

- බෞද්ධයා සහ බුද්ධ චරිතයDocument49 pagesබෞද්ධයා සහ බුද්ධ චරිතයMindStilledNo ratings yet

- Session 04 - 02 - Mr. P H Sarath Gamini - Cost of Water PDFDocument8 pagesSession 04 - 02 - Mr. P H Sarath Gamini - Cost of Water PDFasknishanNo ratings yet

- බෞද්ධයා සහ බුද්ධ චරිතයDocument49 pagesබෞද්ධයා සහ බුද්ධ චරිතයMindStilledNo ratings yet

- Http://dahamvila - Blogspot.comDocument91 pagesHttp://dahamvila - Blogspot.comDaham Vila BlogspotNo ratings yet

- Karma Vipaka (Sinhala)Document108 pagesKarma Vipaka (Sinhala)TRB94% (16)

- Aerial LiftDocument1 pageAerial LiftasknishanNo ratings yet

- Aerial LiftDocument1 pageAerial LiftasknishanNo ratings yet

- Fag2030 - Pripol 2030-LQ - (GD) - UsensdsDocument11 pagesFag2030 - Pripol 2030-LQ - (GD) - UsensdsHung TranNo ratings yet

- Afrd Work Rules-FinalDocument39 pagesAfrd Work Rules-Finalkarjoh2002No ratings yet

- Msds Petcoke RilDocument7 pagesMsds Petcoke Rilmurali_kmNo ratings yet

- Chock FastDocument25 pagesChock FastBrajko NikolaNo ratings yet

- Sulfuric Acid 93-Pct WT-SA15 SDSDocument6 pagesSulfuric Acid 93-Pct WT-SA15 SDSnitroxx7No ratings yet

- Eva MSDSDocument8 pagesEva MSDStahiriqbalalviNo ratings yet

- ECU Office of Environmental Health & Safety 211 South Jarvis ST, Suite 102 252-328-6166Document19 pagesECU Office of Environmental Health & Safety 211 South Jarvis ST, Suite 102 252-328-6166Lisandro Santos SilvaNo ratings yet

- MSDS For CorbolineDocument11 pagesMSDS For Corbolinesudeesh kumarNo ratings yet

- Material Safety Data Sheet: Section 1 - Product Identification and Company IdentificationDocument9 pagesMaterial Safety Data Sheet: Section 1 - Product Identification and Company IdentificationecoscribdNo ratings yet

- Bitumastic 50 MSDSDocument5 pagesBitumastic 50 MSDSglenleafNo ratings yet

- Antifoam 2 MSDSDocument11 pagesAntifoam 2 MSDSfructoraNo ratings yet

- Hydrogen Peroxide 50% - MsdsDocument12 pagesHydrogen Peroxide 50% - MsdsMohamed HalemNo ratings yet

- PsychologyDocument3 pagesPsychologynylalNo ratings yet

- Carbon ActivadoDocument6 pagesCarbon Activadojuan garciaNo ratings yet

- Evonik Ancamine 2049 - SDSDocument12 pagesEvonik Ancamine 2049 - SDStrường phạmNo ratings yet

- Viscosity - True Terpenes SDSDocument9 pagesViscosity - True Terpenes SDSBen AdlinNo ratings yet

- 2007 06 08 OA FEA Kalaeloa Asphalt TerminalDocument255 pages2007 06 08 OA FEA Kalaeloa Asphalt TerminalEsteban Lopez ArboledaNo ratings yet

- Hazard Communication: OSHA Office of Training and EducationDocument17 pagesHazard Communication: OSHA Office of Training and EducationArdian20No ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. IdentificationIsmael Enrique ArciniegasNo ratings yet

- Smi100406174 - 2.388 SDS 10115 Kopr-Kote® - SDS - Us - en - 2021-2-2Document8 pagesSmi100406174 - 2.388 SDS 10115 Kopr-Kote® - SDS - Us - en - 2021-2-2Luis Manuel Montoya RiveraNo ratings yet

- 2-Naphthol Safety SheetDocument8 pages2-Naphthol Safety SheetalonrabNo ratings yet

- Material Safety Data SheetDocument9 pagesMaterial Safety Data SheetjoeNo ratings yet

- MSDS - Sealing Compound Dowsil 732Document10 pagesMSDS - Sealing Compound Dowsil 732Muhammad ShofiudinNo ratings yet

- MSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDocument5 pagesMSDS - Fuel-Protect, Keep Clean Solution, For Diesel InjectorDaniel OlanoNo ratings yet

- Toluene Diisocyanate (Tdi) Msds enDocument11 pagesToluene Diisocyanate (Tdi) Msds enKameliza Saranghe Choi-siwon SujuelfNo ratings yet

- Human Resources Management Review SheetDocument34 pagesHuman Resources Management Review SheetIdil YorgancılarNo ratings yet

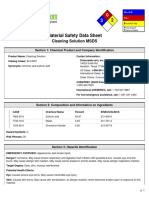

- Cleaning Solution MSDS: Section 1: Chemical Product and Company IdentificationDocument6 pagesCleaning Solution MSDS: Section 1: Chemical Product and Company Identificationfirman analisNo ratings yet