Professional Documents

Culture Documents

CHE 426 Assignment Transient Response

Uploaded by

Farid SarrafOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHE 426 Assignment Transient Response

Uploaded by

Farid SarrafCopyright:

Available Formats

CHE 426 & Section # 02 | Assignment #6 | Sarraf, Farid | Page # /Total pages

1. A step change of magnitude 4 is introduced into a system having the transfer function

( )

( )

Y s

X s

=

2

10

1.6 4 s s + +

A. Determine (a) Percent overshoot, (b) Rise time, (c) Maximum value of Y(t), (d)

Ultimate value of Y(t), and (e) Period of oscillation. Use the following formulas:

Step response for , < 1.

Y(t)/10 = 1 exp

Overshoot = exp

2

1

t,

,

| |

|

|

\ .

f =

1

T

=

1

2t

2

1 ,

t

B. Determine graphically from Simulink the questions from (A).

2

1

1 ,

t

,

t

| |

|

\ .

2

2 1

1

sin 1 tan

t ,

,

t ,

( | |

| |

( | +

|

|

\ . (

\ .

R

1

R

2

A

1

A

2

h

1

h

2

Q

1

Q

2

20 ft /min

3

10 ft

3

CHE 426 & Section # 02 | Assignment #6 | Sarraf, Farid | Page # /Total pages

2. The two-tank system shown in Figure E-2 is

operating at steady state. At time t = 0, 10 ft

3

of

water is quickly added to the first tank.

Determine the maximum deviation in level (feet)

in both tanks from the ultimate steady-state value

and the time at which each maximum occurs.

Data: A

1

= A

2

= 10 ft

2

, R

1

= 0.1 ft/cfm, R

2

= 0.35

ft/cfm.

Note: Q

1

= h

1

/R

1

, if y(t) = o(0) (unit impulse)

then Y(s) = 1.

Figure E-2

CHE 426 & Section # 02 | Assignment #6 | Sarraf, Farid | Page # /Total pages

3.

1

Determine y(t = 0), y(t = 0.6), and y(t = ) if Y(s) =

1

s

2

25( 1)

2 25

s

s s

+

+ +

CHE 426 & Section # 02 | Assignment #6 | Sarraf, Farid | Page # /Total pages

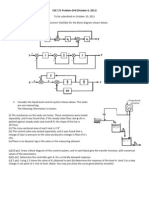

4. The two-tank liquid-level system shown in Figure E-3 is operating at steady state when a

step change is made in the flow rate to tank 1. The transient response is critically damped,

and it takes 1.0 min for the change in level of the second tank to reach 50 percent of the total

change.

If the ratio of the cross-sectional areas of the tanks is A

1

/A

2

= 2, calculate the ratio R

1

/R

2

.

Calculate the time constant for each tank. How long does it take for the change in level of the

first tank to reach 90 percent of the total change? Note: t

1

= t

2

for critical damping.

Figure E-3

R

1

R

2

A

1

A

2

h

1

h

2

Q

1

Q

2

Q

0

CHE 426 & Section # 02 | Assignment #6 | Sarraf, Farid | Page # /Total pages

5.

1

Sketch the response y(t) if Y(s) = exp(2s)/[s

2

+ 1.2s + 1]. Determine y(t) for t = 0, 1, 5,

.

6.

2

The two tanks shown in Fig. E-6 are connected in an interacting fashion. The system is

initially at steady state with q = 10 cfm. The following data apply to the tanks: A

1

= 1 ft

2

, A

2

= 1.25 ft

2

, R

1

= 1 ft/cfm, and R

2

= 0.8 ft/cfm.

(a) If the flow changes from 10 to 11 cfm according to a step change, determine

H

2

(s),i.e., the Laplace transform of H

2

where is the deviation in h

2

.

(b) Determine H

2

(1), H

2

(4), and H

2

().

Figure E-6

7. The two-tank heating process shown in Fig. E-7 consists of two identical, well-stirred

tanks in series. A flow of heat can enter tank 2. At time t = 0, the flow rate of heat to tank 2

suddenly increases according to a step function to 1000 Btu/min, and the temperature of the

inlet water Ti drops from 60

o

F to 52

o

F according to a step function. These changes in heat

flow and inlet water temperature occur simultaneously.

(a) Develop a block diagram that relates the outlet temperature of tank 2 to the inlet

temperature to tank 1 and the flow of heat to tank 2.

(b) Obtain an expression for T

2

(s)where T

2

is the deviation in the temperature of tank

2. This expression should contain numerical values of the parameters.

(c) Determine T2 (2) and T2 ().

(d) Sketch the response T

2

(t)versus t.

Initially, T

i

= T

1

= T

2

= 60

o

F and q = 0. The following data apply:

w = 250 lb/min

Holdup volume of each tank = 5 ft

3

Density of fluid = 50 lb/ft

3

Heat capacity of fluid = 1 Btu/(lb

o

F)

R

1

R

2

A

1

A

2

h

1 h

2

Q

2

Q

w

w

q

T

i

T

1 T

2

Tank 1 Tank 2

Figure E-7

8.

1

The overhead vapor from a depropanizer distillation column is totally condensed in a

water-cooled condenser at 120

o

F and 230 psig. The vapor is 98 mol % propane and 2 mol %

isobutene. The vapor design flow rate is 40,000 lb/h and average latent heat of vaporization

is 128 Btu/lb. Cooling water inlet and outlet temperatures are 75 and 100

o

F, respectively. The

condenser heat transfer area is 1000 ft

2

. The cooling water pressure drop through the

condenser at design rate is 50 psi. A linear-trim control valve (air-to-closed, when CO = 20

mA, PV = 15 psig) is installed in the cooling water line. The pressure drop over the valve is

25 psi at design with the valve half open. The process pressure is measured by an

electronic (4-20 mA) pressure transmitter whose range is 150-400 psig. An analog electronic

proportional controller with a gain of 2 is used to control process pressure by manipulating

cooling water flow. The electronic signal from the controller (CO) is converted into a

pneumatic signal in the I/P transducer.

a) Calculate the cooling water flow rate (gpm) at design conditions. Water density is 62.3

lb/ft

3

and 1 ft

3

= 7.48 gal.

b) If the cooling water flow rate is 250 gpm at design conditions, calculate the size

coefficient (C

v

) of the control valve.

c) Calculate the value of the signal PM at design condition.

d) Calculate the value of the signal PV at design conditions _________

e) Suppose the process pressure jumps 20 psi, determine value for CO.

9. Express the function given the graph in the t-domain

Reflux drum

PT PC

I/P

PM

SP

CO

PV

Control valve

Cooling

water

Condenser

Vapor

10. A thermometer having first-order dynamics with a time constant of 1 min is at 100

o

F. The

thermometer is suddenly placed in a bath at 110

o

F at t = 0 and left there for 0.167 min, after

which it is immediately returned to a bath at 100

o

F. Calculate the thermometer reading at t =

0.5 min.

You might also like

- Laplace Transforms and Process Control ProblemsDocument16 pagesLaplace Transforms and Process Control ProblemsSourav SutradharNo ratings yet

- Chapter 5 SolutionsDocument47 pagesChapter 5 Solutionskim0% (1)

- Aquino Lab06Document25 pagesAquino Lab06Ai RahNo ratings yet

- Problem 1.1ADocument23 pagesProblem 1.1AJohnathan Ortega MenesesNo ratings yet

- Applications of Laplace Transform Unit Step Functions and Dirac Delta FunctionsDocument8 pagesApplications of Laplace Transform Unit Step Functions and Dirac Delta FunctionsJASH MATHEWNo ratings yet

- CH E 511A: Separation Processes and Introduction To Particulate Technology LeachingDocument8 pagesCH E 511A: Separation Processes and Introduction To Particulate Technology LeachingKhayie Victoriano100% (1)

- Gate 1994 PDFDocument16 pagesGate 1994 PDFVammsy Manikanta SaiNo ratings yet

- Fluid Mechanics Assignment 3 KinematicsDocument2 pagesFluid Mechanics Assignment 3 KinematicsGunda Venkata SaiNo ratings yet

- Acre RTD ProblemsDocument10 pagesAcre RTD ProblemsHassan Al-AraimiNo ratings yet

- CH Process-CalculationsDocument11 pagesCH Process-CalculationsHrutik NimbalkarNo ratings yet

- Exam Weekly Exam5Document4 pagesExam Weekly Exam5Gab LibetarioNo ratings yet

- Assignment1 Cruz FrancisPaulo M MECp1Document3 pagesAssignment1 Cruz FrancisPaulo M MECp1Francis Paulo CruzNo ratings yet

- Cagayan State University: Republic of The PhilippinesDocument16 pagesCagayan State University: Republic of The PhilippinesblessaNo ratings yet

- 1 - Energy and Energy BalancesDocument135 pages1 - Energy and Energy BalancesHabib Al-Aziz100% (2)

- 1 Units and Dimensions 54Document24 pages1 Units and Dimensions 54SSNo ratings yet

- Experiment 4 Study On Dynamics of First Order and Second OrderDocument12 pagesExperiment 4 Study On Dynamics of First Order and Second OrderQastalani Ghazali100% (1)

- Prob SetDocument2 pagesProb SetLissa HannahNo ratings yet

- UNIFAC - Smith, VanNess, Abbott PDFDocument7 pagesUNIFAC - Smith, VanNess, Abbott PDFAlejandra InsuastyNo ratings yet

- Tuto Chap 3Document3 pagesTuto Chap 3Zakiyah Mohamed Razi50% (2)

- Fermenter design specificationsDocument38 pagesFermenter design specificationsMilton Dela Rosa JrNo ratings yet

- Numerical For Practice MidtermDocument3 pagesNumerical For Practice MidtermSiddhant SinhaNo ratings yet

- Tutorial 1 - SolutionDocument9 pagesTutorial 1 - SolutionerewrewrNo ratings yet

- CHE 312 Problem Set #2Document4 pagesCHE 312 Problem Set #2rkz93No ratings yet

- Solution To Homework #2 For Chemical Engineering ThermodynamicsDocument7 pagesSolution To Homework #2 For Chemical Engineering Thermodynamicsramesh pokhrel100% (1)

- C D D C: Topic 4 - The Collision Theory Example of Solved ProblemsDocument5 pagesC D D C: Topic 4 - The Collision Theory Example of Solved ProblemsesmassNo ratings yet

- Lec 15Document21 pagesLec 15durgesh patelNo ratings yet

- Math - Sequences, Series and Partial Fraction (Solution)Document4 pagesMath - Sequences, Series and Partial Fraction (Solution)Janjeremy2885No ratings yet

- Gate 2006 PDFDocument21 pagesGate 2006 PDFVammsy Manikanta SaiNo ratings yet

- KineticsOverviewbymongraal PDFDocument128 pagesKineticsOverviewbymongraal PDFMungur Dushyant RAiNo ratings yet

- Momentum Transport Operations External Flow Past Immersed BodiesDocument1 pageMomentum Transport Operations External Flow Past Immersed BodiesGerald LimNo ratings yet

- Chemical Reaction Engineering Exam QuestionsDocument8 pagesChemical Reaction Engineering Exam QuestionsSanthosh KumarNo ratings yet

- Rhodes Solutions ch9 PDFDocument5 pagesRhodes Solutions ch9 PDFJesus M. Arias ANo ratings yet

- LAB REPORT LeachingDocument4 pagesLAB REPORT LeachingKevinNo ratings yet

- Ot 5Document16 pagesOt 5ZZROTNo ratings yet

- Mass Transfer - II: Distillation Processes ExplainedDocument39 pagesMass Transfer - II: Distillation Processes ExplainedSMIT CHRISTIANNo ratings yet

- Membrane separation calculations for gaseous mixturesDocument2 pagesMembrane separation calculations for gaseous mixturesAsh YehiaNo ratings yet

- K Calibration of Venturi and Orifice MetersDocument13 pagesK Calibration of Venturi and Orifice MetersKitty VNo ratings yet

- Dynamic Behavior of First - Second Order SystemsDocument19 pagesDynamic Behavior of First - Second Order SystemsCuong TranNo ratings yet

- Quatech ProjectsDocument63 pagesQuatech ProjectsBlairEmrallafNo ratings yet

- (Differential Calculus, Integral Calculus, Differential Equations, Probability and StatisticsDocument7 pages(Differential Calculus, Integral Calculus, Differential Equations, Probability and Statisticskimuel demesaNo ratings yet

- Mass Transfer Operations: Gate PyqDocument62 pagesMass Transfer Operations: Gate PyqChandrashekharCSKNo ratings yet

- Solved Problem Ch3 PDFDocument4 pagesSolved Problem Ch3 PDFBen AhmedNo ratings yet

- Assignment 1 Basic of Heat TransferDocument2 pagesAssignment 1 Basic of Heat TransferAnkit MehrotraNo ratings yet

- Fourier Series MATLAB GUI P-Code Doc 011905Document7 pagesFourier Series MATLAB GUI P-Code Doc 011905Julio FerreiraNo ratings yet

- CHEMICAL ENGINEERING INSTRUMENTATION AND PROCESS CONTROL PROBLEMSDocument4 pagesCHEMICAL ENGINEERING INSTRUMENTATION AND PROCESS CONTROL PROBLEMSMarco SarmientoNo ratings yet

- MT 1subbuDocument40 pagesMT 1subbuVikas SachanNo ratings yet

- This Page Is Intentionally Left BlankDocument30 pagesThis Page Is Intentionally Left Blankdivakars100% (1)

- Albao Laboratory 1Document65 pagesAlbao Laboratory 1Shaun Patrick AlbaoNo ratings yet

- CT ratio error calculations and limitsDocument4 pagesCT ratio error calculations and limitsKamal NorlieNo ratings yet

- Isothermal Reactor DesignDocument3 pagesIsothermal Reactor Designنزار الدهاميNo ratings yet

- Extra Momentum Transfer QuestionsDocument5 pagesExtra Momentum Transfer QuestionsaNo ratings yet

- Ch12P1 VLE Models by Margules Van Laar and Wilson EquationsDocument2 pagesCh12P1 VLE Models by Margules Van Laar and Wilson Equationshana faqihNo ratings yet

- Introduction to Energy Balance ConceptsDocument25 pagesIntroduction to Energy Balance Conceptsnhalieza1067No ratings yet

- Applied Chemical Engineering CalculationsDocument7 pagesApplied Chemical Engineering Calculationsmbolantenaina100% (1)

- Problem DrillDocument3 pagesProblem DrillEina Scarlet0% (2)

- Homework-5 Root Locus-SOLUTIONSDocument17 pagesHomework-5 Root Locus-SOLUTIONSzakir abbasNo ratings yet

- Set 6 AnsDocument6 pagesSet 6 AnskietNo ratings yet

- Worksheet 2Document5 pagesWorksheet 2Theødřøš ÄbNo ratings yet

- Last Name, First CHE426Document3 pagesLast Name, First CHE426sumitNo ratings yet

- Set 8 AnsDocument14 pagesSet 8 AnsMuhammad RomzuddinNo ratings yet

- High Performance Swing Velocity Tracking Control of Hydraulic ExcavatorsDocument6 pagesHigh Performance Swing Velocity Tracking Control of Hydraulic ExcavatorsJack SonNo ratings yet

- Steel connection design check summaryDocument18 pagesSteel connection design check summaryDaniel TuerosNo ratings yet

- Electrical Fundamentals: What is Electricity and How is it MeasuredDocument76 pagesElectrical Fundamentals: What is Electricity and How is it MeasuredLaveen RaghunamNo ratings yet

- Balanced ForcesDocument21 pagesBalanced ForcesgaluhfahmiNo ratings yet

- Unit IIDocument17 pagesUnit IImansikakaniNo ratings yet

- Astm D4809Document9 pagesAstm D4809Kamruzaman MiahNo ratings yet

- Coulomb's Law Using Charged Pith BallsDocument20 pagesCoulomb's Law Using Charged Pith BallsRatul Das100% (4)

- Finite Element Analysis OBTDocument11 pagesFinite Element Analysis OBTSelvamuthu Kumaran60% (5)

- Development of AtomDocument32 pagesDevelopment of AtomRazel PanuncialNo ratings yet

- Moment Area Method Beam DeflectionsDocument52 pagesMoment Area Method Beam DeflectionsCamille Andrea SequitinNo ratings yet

- Radiant Floor Cooling SystemsDocument6 pagesRadiant Floor Cooling SystemsnikipshNo ratings yet

- Padhle 10th - Human Eye & The Colourful WorldDocument14 pagesPadhle 10th - Human Eye & The Colourful WorldDipak PatelNo ratings yet

- Nuclear Fusion in Stars Forms ElementsDocument3 pagesNuclear Fusion in Stars Forms ElementsEunice AcunaNo ratings yet

- Study of Alternator Power Delivery to an Infinite BusDocument5 pagesStudy of Alternator Power Delivery to an Infinite BusAsif KarimNo ratings yet

- SIMS analysis of solid surfacesDocument4 pagesSIMS analysis of solid surfacesimamuddeenNo ratings yet

- B.Tech Physics Course NIT Jalandhar Electrostatics Lecture 4Document30 pagesB.Tech Physics Course NIT Jalandhar Electrostatics Lecture 4Jaspreet Singh SidhuNo ratings yet

- Mechanics of Materials 71E44Document3 pagesMechanics of Materials 71E44OblackNo ratings yet

- What Is The Difference Between Coagulation and FlocculationDocument1 pageWhat Is The Difference Between Coagulation and FlocculationRuvindran Vasu100% (1)

- Influence of Elastic Foundations on Rotor DynamicsDocument8 pagesInfluence of Elastic Foundations on Rotor DynamicsVodanh Tieutot100% (1)

- High-Force Dynamic Mechanical Analysis (DMA) : Dynamic Characterization of Viscoelastic MaterialsDocument12 pagesHigh-Force Dynamic Mechanical Analysis (DMA) : Dynamic Characterization of Viscoelastic MaterialsDavid SimangunsongNo ratings yet

- APPLIED ENGINEERING MECHANICS EXAM QUESTIONSDocument4 pagesAPPLIED ENGINEERING MECHANICS EXAM QUESTIONSVishal PranavNo ratings yet

- James Ruse 2005 3U TrialDocument7 pagesJames Ruse 2005 3U TrialEmilyWongNo ratings yet

- Subject Code: PH 3151 Subject Title: Engineering Physics 05-03-2022 Max. Marks 100 Semester: I Time: 1:45 - 4:45 PMDocument1 pageSubject Code: PH 3151 Subject Title: Engineering Physics 05-03-2022 Max. Marks 100 Semester: I Time: 1:45 - 4:45 PMWittin PrinceNo ratings yet

- Mse630 f10 Hw1 SolDocument4 pagesMse630 f10 Hw1 SolLava Kumar BNo ratings yet

- Gas Pipeline Hydrodynamic Analysis Based On Beggs-Brill CorrelationDocument7 pagesGas Pipeline Hydrodynamic Analysis Based On Beggs-Brill CorrelationsriadelilaNo ratings yet

- Atomic Structure Revision NotesDocument5 pagesAtomic Structure Revision Notesapi-271128265No ratings yet

- This Study Resource Was: Transition CurvesDocument7 pagesThis Study Resource Was: Transition CurvesJoe NjoreNo ratings yet

- VCO 900 MHZ - 1 PDFDocument2 pagesVCO 900 MHZ - 1 PDFpu2ypvNo ratings yet

- Hydrogen Reduction Cobalt-Chromium Spinel Oxides. Stoichiometric Cobalt ChromiteDocument6 pagesHydrogen Reduction Cobalt-Chromium Spinel Oxides. Stoichiometric Cobalt ChromiteDuongNo ratings yet

- MSL Technical Guide 12 Assuring The Quality of Weighing ResultsDocument4 pagesMSL Technical Guide 12 Assuring The Quality of Weighing ResultsegemetsatisNo ratings yet