Professional Documents

Culture Documents

Engine Optimization.

Uploaded by

rishiraj87Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Optimization.

Uploaded by

rishiraj87Copyright:

Available Formats

arc

Automotive Research Center

NAC

Engine Optimization Methodologies: Tools and Strategies for Diesel Engine Design

George Delagrammatikas Dennis Assanis, Zoran Filipi, Panos Papalambros, Nestor Michelena

The University of Michigan May 24, 2000

Diesel Engine Optimization Methodologies

arc

Automotive Research Center BACKGROUND: VEHICLE AND ENGINE FUNDAMENTALS

NAC

ENGINE TUNING

INVERSE DESIGN

NOVEL TECHNOLOGIES

CVT, INJECTION TIMINGS

MAP SHAPING AND MATCHING

ENGINE FLEXIBILITY: COMPRESSION RATIO, CVT,HYBRID

TARGET CASCADING Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Motivation

Federal Regulations

Fuel economy (CAFE) Emissions (NOx, smog, and other pollutants)

Public Awareness

Green movement Global warming scare

Decrease Dependence on Foreign Oil

Avoid another oil crisis

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Objectives

Develop an engine optimization framework

21st century conventional and hybrid heavy truck

Implement techniques to conventional vehicle

Define a problem analytically Apply suitable driving cycle(s) Investigate location of use on engine map

Extend lessons learned to hybrid vehicle

How different are demands on engine and transmission? Need for a systems approach

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Euro III Steady State Test Procedure

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Power Demands on Engine

WHEEL

Torque, Speed at Wheel

Torque, Speed at Engine

ENGINE

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

HEV System Simulation Framework

Matlab-SIMULINK environment

FUEL (g/s)

ADVISOR

TORQUE

RPM

ENGINE FUEL DELIVERY LOOK-UP TABLE Parallel HEV Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Baseline Vehicle Parameters

Cummins M11-330 (246 kW) Diesel Engine Wheel/axle assembly for heavy truck Kenworth T400 Vehicle Standard heavy vehicle accessory loads Standard catalyst for CI engine Eaton Fuller RTLO-12610B 10-Speed Transmission Generic 10-spd constant efficiency gearbox Heavy Vehicle Powertrain Control Eaton Fuller RTLO-12610B 10-Speed Transmission Generic 10-spd constant efficiency gearbox

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Baseline Cummins Engine Map

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Driving Cycles Investigated

US06 REP05

FUDS

FHDS

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Engine Use Points for Various Cycles

US06 REP05

FUDS

FHDS

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Power Frequency for Each Cycle

US06 REP05

FUDS

FHDS

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Ideal BSFC Line Generation

Output Torque

Engine Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Benefits of Flexible Engine Designs Actual Transmission Case

Determine cumulative fuel throughput for each cycle investigated

Interpolate BSFC from engine map for every torque/speed combination for that given cycle Integrate all BSFCs from above step Find the total time that engine is producing power Mean effective BSFC = total BSFC/engine on time

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Ideal BSFC vs. Power Level

BSFC (g/kW-hr)

Power

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Benefits of Flexible Engine Designs Ideal Transmission Case

Find ideal BSFC transmission line on engine map used for a given cycle

Interpolate BSFC for every visited power level on the BSFC vs. Power graph Sum of all BSFCs is cumulative fuel throughput Mean effective BSFC = numerical average of total fuel throughput during time steps when engine is active

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Potential Benefits of Ideal CVT Design

140

Increase in Mean BSFC Per Cycle

120 100

4*BSFCmin

80 60 40 20 0 US06

2*BSFCmin

REP05

FUDS

FHDS

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Optimum Injection Timing Method

Using an optimization framework

Vary injection timing for every torque/speed combination (over 200 map points, ~100 executions per point) Computationally prohibitive

Parallel computer framework

Run as many maps as you want at different injection timings Coalesce data with a Matlab-based routine One map = ~5 minutes

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

Injection Timing Maps

NAC

Output Torque

Engine Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Optimum Injection Timing Map

Fueling Rate

Timing

RPM

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Variable Compression Ratio Engine

Hypothetical investigation of novel engine design

Find the ideal fuel consumption benefit Apply ideal transmission techniques from previous slides

Determine how BSFC can be optimized at various power levels

First maximize power density to find engines power upper bound Allow engine controller to change parameters that are not normally variable

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Problem Formulation

For each power level :

50, 100, 200, 300, 400, 500 kW

Minimize BSFC, subject to:

overall phi < 0.6 20% < percent premixed burn < 40% peak cylinder pressure < 150 bar

Variables:

Inlet manifold pressure Compression ratio Injection timing Fuel Engine speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

Same Engine - Different Maps

NAC

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

VCRE - Combined Map

TORQUE

RPM

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Ideal BSFC Line vs. Power Level

240 230

BSFC (g/kW-hr)

220 210 200 190 180 170 50 100 150 200 250 300 350 400 450 500

vcre_bsfc base_bsfc

Power (kW)

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Hybrid Powertrain Investigations

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Demands on Engine - CVT vs. 5-Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Demands on Motor - CVT vs. 5-Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Battery SOC - CVT vs. 5-Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Zero Delta SOC - CVT vs. 5-Speed

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Additional Hybrid Clustering Scenarios

60 40 20

Power-Assist Battery Recharge

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Future Directions

How realistic is the variable compression ratio engine for the driving cycles and vehicles we are considering? How can we better quantify the benefits of increased flexibility in transmission parameters? What are the effects of injection timing and variable valve timing on engine map characteristics? Is it better to cluster points around optimum power levels on an engine map or disregard that an engine can be described by a single map?

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Integration with Target Cascading

Parameterize engine torque curve Maximize engine turndown ratio while meeting mobility constraints Match maximum torque curve with a real engine defined by high fidelity model Use engine visitation points in conjunction with control strategies to meet BSFC and emissions targets Send results back to top level for verification and subsequent iteration

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Parameterized Max Torque Curve - I

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Parameterized Max Torque Curve - II

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Sample Torque Curves

Min cluster area

Min rated torque

Min rated power

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Engine Matching Subproblem

Diesel Engine Optimization Methodologies

arc

Automotive Research Center

NAC

Conclusions

High fidelity engine model can be used at different levels in the design process Methods have been illustrated on a variety of different engines Continue feed-backward work with ADVISOR and extend methodology to VESIM

Diesel Engine Optimization Methodologies

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Series 1000 and 1500: Year Model # Factory # Engine 1000 Series Engine ApplicationsDocument3 pagesSeries 1000 and 1500: Year Model # Factory # Engine 1000 Series Engine ApplicationsLilis FatimahNo ratings yet

- Akcela Aceites Fichas TecnicasDocument44 pagesAkcela Aceites Fichas TecnicasGUILLERMO SEGURANo ratings yet

- MF 8700-Brochure-English US 2014Document12 pagesMF 8700-Brochure-English US 2014Luka BornaNo ratings yet

- The Jatco CVT Power GlideDocument4 pagesThe Jatco CVT Power GlideHermawan 0103100% (1)

- Lecture 10 NptelDocument9 pagesLecture 10 Nptelmailsk123No ratings yet

- Đ Án Hyundai I10Document43 pagesĐ Án Hyundai I10Linh NhậtNo ratings yet

- Swift Equipment Specs 1 PDFDocument4 pagesSwift Equipment Specs 1 PDFShuaib KhedunNo ratings yet

- Btech ME Project On Regenerative Braking SystemDocument31 pagesBtech ME Project On Regenerative Braking SystemPRAVIN KUMAR NNo ratings yet

- Smart Machines. Serious ResultsDocument15 pagesSmart Machines. Serious ResultsMarcell MengyánNo ratings yet

- Leaflet Sienta 2021Document4 pagesLeaflet Sienta 2021郭哲宏No ratings yet

- SM 46 PDFDocument239 pagesSM 46 PDFEsteban OONo ratings yet

- Yamaha Nouvo PDFDocument1 pageYamaha Nouvo PDFtony rohman100% (1)

- Industrial TrainingDocument49 pagesIndustrial TrainingAlok AnandNo ratings yet

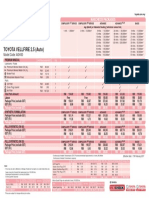

- Toyota Vellfire 2.5 (Auto) : Model Code: AGH30Document1 pageToyota Vellfire 2.5 (Auto) : Model Code: AGH30Arda Billy24No ratings yet

- Innovative Valve Train Systems: Technology Highlights and R&D Activities at FEVDocument8 pagesInnovative Valve Train Systems: Technology Highlights and R&D Activities at FEVAsrar AhmedNo ratings yet

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- Toyota Corolla Altis (2014)Document10 pagesToyota Corolla Altis (2014)alvinhaw98No ratings yet

- Portals Raybestos Files PM 1340 20161215 RPT Catalog Without Images ReducedDocument335 pagesPortals Raybestos Files PM 1340 20161215 RPT Catalog Without Images ReducedMohamed AhmedNo ratings yet

- Automatic Gear Shifting in 2 WheelerDocument21 pagesAutomatic Gear Shifting in 2 WheelerJilly ArasuNo ratings yet

- 0AW (Multitronic) : Longitudinal FWD CVT 8 Speed (Electronic Control)Document4 pages0AW (Multitronic) : Longitudinal FWD CVT 8 Speed (Electronic Control)mcgyver972No ratings yet

- Automotive FundamentalsDocument53 pagesAutomotive FundamentalssebsrayNo ratings yet

- Special Connectors For CAT501SDocument6 pagesSpecial Connectors For CAT501SHernan PosadaNo ratings yet

- CVT FWD (Electronic Control With Converter) (Toyota Belta, Ractis, Vitz), XA-10LN (Suzuki)Document3 pagesCVT FWD (Electronic Control With Converter) (Toyota Belta, Ractis, Vitz), XA-10LN (Suzuki)Ibn e siddique100% (1)

- CVT Transmission Part2Document8 pagesCVT Transmission Part2ryba1100% (1)

- PGO BR 150 (RexonaVn - Com)Document72 pagesPGO BR 150 (RexonaVn - Com)Bogdan StefanNo ratings yet

- Continuously Variable Transmission - CVTDocument18 pagesContinuously Variable Transmission - CVTPratheep Srinivas100% (3)

- Mitsubishi Jf011e TrannyDocument8 pagesMitsubishi Jf011e Trannydatdcb100% (1)

- Alto Automotive Catalog 20199Document548 pagesAlto Automotive Catalog 20199RodolfoNo ratings yet

- Preliminary Design ReportDocument28 pagesPreliminary Design ReportpankajNo ratings yet

- New Toyota WigoDocument2 pagesNew Toyota Wigoasieee chimmyNo ratings yet