Professional Documents

Culture Documents

DM en

Uploaded by

dzan880Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DM en

Uploaded by

dzan880Copyright:

Available Formats

High Pressure Compressor Type DM

Peak Performance Compression Systems

Atlas Copco with its GREENFIELD product range is your specialist for high-pressure systems. With a century of experience in this business we have been able to maintain and even improve our strong market position providing total solutions from a single compressor to complete systems.

Today the GREENFIELD product range is the technology leader worldwide with its high-end premium products engineered in Switzerland. With a century of experience in high-pressure technology and the fact of thousands of compressors installed worldwide, the GREENFIELD product range is ready to serve your needs for peak performance and success in the market. Atlas Copco has global access to over 150 markets, which are served through our production facilities for high pressure compressor either in France, United States, India and China. This comprehensive Sales and Service Network assures our customers direct access to the most reliable and technologically advanced equipment available.

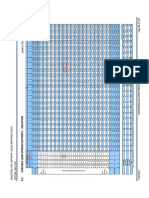

Flow Rate Diagramm

(typical for natural gas, 271 bara working pressure, 50 Hz) 240 220

Volume Flow [Nm3/h] (0 C; 1.013 bara)

200 180 160 140 120 100 80 60 40 20 1 1.5 2.5 5.0 7.0 14.0 26.0 40.0

Suction Pressure [ bara ]

DM Gas Compressor Technical Data, Dimensions

The DM Gas Compressor

The DM compressor range utilizes GREENFIELDs revolutionary oilfree high-pressure technology, which assures that oil neither contaminates the gas nor does oil disposal contaminate the environment. The hermetically sealed compressor-motor-unit with mangetic coupling ensures no gas losses to atmosphere. Due to the scotch yoke drive and antivibration pads the DM has a low vibration and noise level. The vertical arrangement allows an installation in an area of 0.7 m2 only. As the design for 2, 3, 4 or 5 stage units remains the same, the compressor blocks can be easily exchanged if suction pressure conditions or location of the installation changes.

Technical Data

Suction pressure: Working pressure: Flow rate: Motor power: Size: Weight: Gases: Applications: up to 40 bara up to 450 bara up to 210 Nm3 /h 30 kW (37 kW for D5M311.-GP) 900 x 740 x 1700 mm (L x W x H) approx. 800 kg Natural gas, processed biogas, hydrogen, noble gases, typical industrial gases, etc. CNG and hydrogen refuelling stations, bottle filling, breathing air, test and special applications, etc.

Dimensions

680 mm /26,77 inch 900 mm /35,43 inch

680 mm /26,77 inch 740 mm /29,13 inch

1700 mm /66,92 inch

Features and Options

Standard Features

2 5 stage oil-free compression Frame-mounted unit with vertical arrangement Scotch yoke principle (balanced forces) Hermetically sealed crankcase Working pressures up to 311 bara Electric Motor drive with magnetic coupling Zone 2 classification Stainless steel tubing and interstage air-cooler Set of gauges and safety valves on suction, interstage and discharge side Pressure transmitter on suction and discharge side Temperature transmitter on discharge side Set of separators with automatic condensate drain Direct driven cooling-air fan Antivibration pads PED /ATEX conformity

Available Standard Options*

Working pressures up to 450 bara Zone 1 classification (except D5M311.-GP) 3rd party inspection by TUeV

* Other non-standard options on request

Your Benefits

The DM All of the Benefits at a Glance:

Low space requirements, reduction of construction costs thanks to small foundations Highest reliability CNG compressor Oil-free compression resulting in no oil carry-over into the gas, no additional costs for lubricating oil or its disposal Ex-Zone 2 classification (TUeV) due to compressor-motor-unit with magnetic coupling No Methane emissions to atmosphere thanks to the hermetically sealed and pressure-tight crankcase Low space requirements due to vertical arrangement Extremely low vibration an noise level Reduced power consumption due to utilisation of suction pressure High efficiency, air-cooled Low compression ratios in the individual stages, resulting in low wear and low thermal loads Freedom from oil deposits means longer service life for valves and fittings Long intervals between maintenance Advanced maintenance concept for short downtimes Low total costs of ownership

GREENFIELD www.greenfield-comp.com

Part of the Atlas Copco Group

The design or specifications of the products described herein are subject to alterations or improvements without notice.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Safe Useof TelehandlersDocument86 pagesSafe Useof TelehandlersNicolae Burca100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- List Applicable WPS StructureDocument7 pagesList Applicable WPS StructureFerdie OSNo ratings yet

- History of Space ExplorationDocument11 pagesHistory of Space ExplorationSiddharth RajpriyeNo ratings yet

- Quay Wall Construction PDFDocument8 pagesQuay Wall Construction PDFdndudcNo ratings yet

- CASR Part 43 Amdt. 1 - Maintenance, Preventive Maintenance, Rebuilding and Alteration PDFDocument21 pagesCASR Part 43 Amdt. 1 - Maintenance, Preventive Maintenance, Rebuilding and Alteration PDFHarry Nuryanto100% (2)

- Buku Management Science PDFDocument248 pagesBuku Management Science PDFMuutiyara muti100% (1)

- 2017 Small Cell Solution OverviewDocument75 pages2017 Small Cell Solution OverviewRajibur Rahman100% (7)

- Temporary corrosion barg PSV selection for pneumatic simplex pumpDocument6 pagesTemporary corrosion barg PSV selection for pneumatic simplex pumpdzan880No ratings yet

- Egc CurveDocument18 pagesEgc Curvedzan880No ratings yet

- 717 - Buku Praktis OtomotifDocument89 pages717 - Buku Praktis OtomotifMathiasrobby090% (1)

- Guide To 4WDDocument18 pagesGuide To 4WDenselsoftware.comNo ratings yet

- Sample Air AuditDocument54 pagesSample Air Auditdzan880No ratings yet

- Glycol Dehydrators: Draft Oil and Gas Ozone Reduction Strategy - Presented at February 26, 2008 RAQC MeetingDocument4 pagesGlycol Dehydrators: Draft Oil and Gas Ozone Reduction Strategy - Presented at February 26, 2008 RAQC Meetingdzan880No ratings yet

- Spring HangerDocument1 pageSpring Hangerdzan880No ratings yet

- Cadenas PlasticasDocument530 pagesCadenas PlasticasYendrik Peluffo RiveraNo ratings yet

- 2012-03-09 Die Mercedes-Benz Dieselmotoren Powertrains Für Die Neue A - Und B-Klasse - ENDocument20 pages2012-03-09 Die Mercedes-Benz Dieselmotoren Powertrains Für Die Neue A - Und B-Klasse - ENFayez AlnamarnehNo ratings yet

- Weekly Geotech Report SummaryDocument4 pagesWeekly Geotech Report SummaryIndra Setiawan SunarjaNo ratings yet

- 5S Audit FormDocument1 page5S Audit FormStephi S. MontesdeocaNo ratings yet

- Aesolutions and Isa Sign Agreement To Provide Safety Cybersecurity and Alarm Management TrainingDocument2 pagesAesolutions and Isa Sign Agreement To Provide Safety Cybersecurity and Alarm Management TrainingBernardo Juvenil Celso Jr.No ratings yet

- THAI AVIATION ACCIDENT RECORDDocument33 pagesTHAI AVIATION ACCIDENT RECORDBobby Chipping100% (2)

- An Evaluation of Flat Carbon Steel Production of National Steel Corporation (NSC) From Its Privatization in 1995 To Its Liquidation in 1999 and Its Implications To The Country's Steel IndustryDocument293 pagesAn Evaluation of Flat Carbon Steel Production of National Steel Corporation (NSC) From Its Privatization in 1995 To Its Liquidation in 1999 and Its Implications To The Country's Steel IndustryArturo B. del AyreNo ratings yet

- Hicom 102 Technical Specs and Installation GuideDocument4 pagesHicom 102 Technical Specs and Installation Guidejunnior23No ratings yet

- Helicopter Charter Bucks TrendDocument2 pagesHelicopter Charter Bucks TrendAtlas HelicoptersNo ratings yet

- Nalgene Plastics Tech Guide 0209Document64 pagesNalgene Plastics Tech Guide 0209bkorecNo ratings yet

- Camapana de Humo Sin DuctosDocument4 pagesCamapana de Humo Sin DuctosBRIAN JULIAN GARCIA ALFONSONo ratings yet

- Catalogo de EspreasDocument44 pagesCatalogo de Espreasaxr1200No ratings yet

- CBP Study GuideDocument2 pagesCBP Study GuidedeepakbarhateNo ratings yet

- Linear Programming Simple Word ProblemsDocument2 pagesLinear Programming Simple Word ProblemsWendy Millheiser Menard0% (1)

- Project Report1Document154 pagesProject Report1RohitJoshiNo ratings yet

- Reading Sample Sappress 1517 Procurement With SAP MM Business User GuideDocument47 pagesReading Sample Sappress 1517 Procurement With SAP MM Business User GuideEdu RonanNo ratings yet

- Gangway Tower Preservation Procedure On SiteDocument4 pagesGangway Tower Preservation Procedure On SiteSalim Mohd RazNo ratings yet

- MercruiserfuelsystemDocument16 pagesMercruiserfuelsystemwguenonNo ratings yet

- Standard Schedules Information Manual Edition 30: Effective March 2020Document7 pagesStandard Schedules Information Manual Edition 30: Effective March 2020dsfakljafNo ratings yet

- Powerware 9170 Tower User Guide UPSDocument126 pagesPowerware 9170 Tower User Guide UPSgladdyloweNo ratings yet

- Ngo Online Brochure - June 2017Document4 pagesNgo Online Brochure - June 2017Shivani Dabas SihagNo ratings yet

- Sika®-Waterstop GDocument4 pagesSika®-Waterstop Gvertigo100% (1)

- OH100 Series TemplateDocument2 pagesOH100 Series TemplateRahul KumarNo ratings yet