Professional Documents

Culture Documents

Ultra Test Composite

Uploaded by

saptop39Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultra Test Composite

Uploaded by

saptop39Copyright:

Available Formats

NON-DESTRUCTIVE TESTING OF FIBRE REINFORCED COMPOSITES AND HONEYCOMB STRUCTURES

Brian Stephen Wong, Chua Fong Ming Ron Nanyang Technological University Singapore Ow Wing Yoong Defence Science Organisation National Laboratories Singapore Tui Chen Guan Republic of Singapore Airforce

ABSTRACT : This paper describes experiments conducted using various non-destructive testing techniques on carbon and glass fibre reinforced composites (FRC) and honeycomb structures. The advantages and disadvantages of each technique are described and all the techniques are compared. A radiograph of an impact damage on an FRC using an enhancing fluid of high radiographic absorption showed clearly the detailed delamination characteristics, this technique would be the best procedure for characterisation of defects. However the defect must be open to the surface to allow penetration of the enhancing fluid which is also toxic. The radiation is also dangerous. Mechanical impedance tests proved to be the most sensitive one sided test of delaminations between the skin and core of a honeycomb structure. Through transmission ultrasonic tests can also had equivalent sensitivity with this procedure. A and immersion C scan ultrasonic tests, the most widely used procedures, were conducted on on fibre reinforced composites. It was found possible to detect a one mm defect 0.3 from the specimen surface up to 3 mm below the surface. C scan enabled reasonably accurate determination of defect size. Test procedures for fibre reinforced composites have also been developed. Because immersion ultrasonic C scan cannot be used in situ, the lock-in thermography procedure has been compared with it. The sensitivity of the thermography which was found to be slightly less, was still adequate to recommend its use over ultrasonics because of its portability, remote inspection capability and speed of interrogation.

1.

INTRODUCTION

Fibre reinforced composite materials are being more and more used in numerous products. These products vary from consumer and sporting goods to aircraft and spacecraft components. In the latter components, honeycomb structures are also widely used and these may be fabricated from polymeric or metallic materials. Their increased use is due to that the fact that their properties can be tailored to satisfy a number of structural functions such as stiffness, toughness and strength which can be provided where they are needed. However until recently a deterrent to their use has been the concern that some difficult to detect defects may be present in the materials. Defects may result from the raw product such as fibres, matrix and prepregs, as well as due to poor bonding between the fibres and matrices and between individual lamina. Defects may also occur from in-service use such as low velocity impacts in aircraft structures. This paper focusses on the ability of non-destructive testing (NDT) techniques to be able to detect defects in composites. Table 1 summarises the capabilities of the major NDT techniques for defect detection. With reference to this table Yes indicates that the defects can be detected with the NDT technique and Some indicates lower sensitivity and less application than Yes. Fortunately the most serious defects such as delaminations, impact damage, debonds and resin cracks can be detected using several techniques.

Ultrasonics can be seen to be the powerful technique because of its sensitivity to all the defects shown. However other techniques need to be considered because of others advantages they may have. For example thermography is complete remote technique requiring no contact with the inspection surface and is also a fast testing procedure.

2.

RADIOGRAPHY

Radiography is based on differential absorption of penetrating radiation by the specimen being inspected. Defects or variations in the specimen composition will cause these absorption differences which can be recorded on film. Because the polmer matrix and some fibres such as carbon have low absorption to radiation good contrast is difficult to obtain and low kilovoltage (or low energy) radiation must be used. With radiography a better image of defects is produced than ultrasonics since visual two dimensional images are produced and it is nearly always possible to determine what has produced the image. To detect air-filled defects these need to have a dimension parallel to the radiation beam approximately equal to or greater than two per cent of the adjacent surrounding material. Using conventional radiography therefore delaminations are not detectable. Defects such as voids are detectable if large enough and certain fibre such as glass which have a much higher radiation absorption coefficient than the surrounding matrix are detectable. Therefore features such as volume fraction and fibre allignment can be determined. Much better contrast can be achieved by using radiographically opaque penetrants, for example tetrabormoethane (TBE), which has a much higher absorption coefficient than the composite materials. The defect, for example impact damage, must be open to the surface. This fluid is applied to the surface of the specimen before radiography. It is allowed to penetrate into the damaged regions for about 30 minutes before the excess penetrant is removed with absorbent cloth. The theory is that the radiation passing through the defect area is now absorbed much more than the surrounding areas and therefore the defect contrast is considerably enhanced. The technique even operates effectively on the normally undetectable delamination defects. Fig. 1 shows impact delamination and crack damage of a composite using this technique. The great detail and accurate delineation of the damage extremities can be clearly seen. In conclusion it can be deduced that radiography is the best non-destructive testing technique for characterisation of defects.

Fig. 1. A TBE Radiograph Of Impact Damage Of A Woven Glass Fibre Reinforced Composite

MECHANICAL IMPEDANCE INSPECTION

The mechanical impedance instrument utilizes an electronic transmitter and receiver, which acquires data from the material under test, analyses the data and presents it in graphic form on a cathode ray tube. To perform these functions the instrument uses a probe containing two piezo-electric crystals, one of which converts electrical signals into vibrations and, by the reverse procedure, the modified vibrations on the other crystal are converted back into electrical signals. The probe is utilized to apply a localized forced oscillation to the area under investigation. A defective area can be recognized from the different response it produces when compared with a non-defective area. One difference would be a reduced resonant frequency due to the reduced stiffness of the defective area. These responses can be deduced from the frequency spectrum displays produced by the instrument. The mechanical impedance technique is most sensitive to defects which are parallel to the structures surface e.g. skin-core disbonds in honeycomb structures. The ability of the technique to detect near surface defects in various specimens has been described (Adams and Cawley, 1988). In a structure, the layer of material above a disbond or delamination may be regarded as a plate that is being restrained around its edges. If the plate is being excited, it can resonate with the first mode being the

membrane resonance. From the vibration of a plate the first mode of the membrane resonant frequency for a plate fixed around its boundary is given by

Fr =

0.47h E . 2 r 12

(1)

where h = depth of the defect (in this case the skin thickness) r = defect radius E = Youngs modulus of the layer above the defect = density of the material = Poisson's ratio of the material above the defect The above equation represents the resonant frequency at the centre of the thin (membrane) circular plate. As a general guide, the defect diameter must be at least twenty times the skin thickness for this equation to be valid. The constant, 0.47, is the result of using a fixed boundary condition. Hence it is can be seen that for a given structure the membrane resonant frequency, Fr, at the centre of the defect is a function of the depth and size of the defect and its boundary conditions. Fig. 2 (Wong et al. 1996) shows resonant frequencies plotted against defect or discontinuity sizes. The specimens had aluminium skins and nomex cores. The defects were deliberately fabricated delaminations between the top skin and core. The delaminations were made from plastic inserts. The probe was placed over the top skin for the tests. The theoretical resonant frequencies derived from equation (1) agree well with the experimental values. The good agreement implies that for the autoclave cured aluminium skin specimens used in this paper (which is homogeneous and relatively stiff) it is possible to determine the diameter of the defects in the range of 40 mm to 90 mm in diameter from the resonant frequency recorded and the use of equation (1). This assumes that the defect would be circular or near circular in shape. The limitation exists because smaller defects have resonant frequencies above the 8 kHz maximum of the instrument used. For larger defects i.e. above 90 mm (3.6 in.) in diameter the rate of change of frequency with diameter then becomes too small for accurate assessment.

Fig. 2. Resonant Frequency Versus Discontinuity Size For Mechanical Impedance Tests An advantage of the technique over ultrasonics is that it does not require a couplant between the probe and specimen.

ULTRASONICS

Ultrasonic testing is the most widely used and most powerful procedure for inspecting fibre reinforced composites for internal defects. Fundamentally a probe with a piezoelectric crystal transmits ultrasonic pulses into the specimen and whenever a change in material acoustic impedance occurs the pulses are reflected back and received by the same or another crystal. Acoustic impedance is the material density multiplied by the ultrasonic velocity in the material. Appropriate instrumentation can display the information in various ways. The A scan display is similar to an oscilloscope display giving time of flight and reflection amplitude data. The C scan display requires the use of a rectilinear robot system and displays a pictorial plan view of the defects detected. A common technique is immersion testing where the transduced is coupled to the specimen with water. Contact testing is also possible where the probe is placed on the specimen with a viscous couplant being used between the probe and specimen. Fig. 2 shows an immersion C scan image of an impact damage defect on a honeycomb specimen. No damage is visible on the surface of the specimen. The specimen has a skin made of ten layers of carbon fibre prepreg material. In the figure image G1, G2 etc represents a defect between the first and second, second and third, etc prepreg layers. The delineation of the defect features and extremities can be observed. Also the interface between the core and surface skin of the honeycomb can be clearly observed showing the good adhesion between the two.

Fig. 3. C Scan Ultrasonic Images Of A Honeycomb Specimen With Image Damage In The Upper Skin Which Is Made Of Ten Layers Of Carbon Fibre Prepreg. Disadvantages of ultrasonics are it is slow testing procedure and the probe requires intimate contact with the test specimen. The sensitivity of ultrasonics to small defects is summarised in the next section.

THERMOGRAPHY

In Lock-in thermographic evaluation of materials, such as fibre reinforced composites, a sinusoidal thermal wave is directed at the surface of a specimen. Part of the wave penetrates into the specimen and will reflect from internal defects. The reflected wave will interfere with the surface wave. Changes in phase and amplitude of the surface interference pattern will enable defect characteristics to be determined. Fig. 4 (left hand image) shows the Lock-in thermographic phase image of the impact specimen in Fig. 3. The thermographic image can still show the general shape of the defect but its characteristics are not as clearly defined as by ultrasonic C scan.

Fig. 4 Lock-in image of a low impact damaged specimens (the left hand specimen was compared with an ultrasonic investigation) Fig. 5 shows that defects will produce positive or negative changes to the surface phase (value 0). Either can be used for defect detection. The defects are round delaminations artificially produced by inserting plastic sheets into the specimens. Small defects down to 1mm in size still can produce sufficient phase difference to produce good contrast for detectability. There are certain frequencies such as 0.025 Hz in the chart where no phase difference is produced because the returning wave is in phase with the incident wave. This blind frequency zone is narrow but should be avoided by experimental evaluation tests or testing at several frequencies. Frequencies giving maximum contrast should be selected for testing e.g 0.12 Hz in Fig. 4.

20 15 15 10 5 0 0 0.234 -5 -10 -10 -15 -15-15 -20 -20-20 -25 -30 -35 -28 -14 0.12 0.058 0.029 0.015 0.01 0.007 8 12 10 7 10

Defect Phase Difference

Large defects 20 to 60 mm Small defects 1 to 10 mm

Frequency (Hz)

Fig. 5. Phase Differences Caused By Defects

Fig. 6 shows that thermographic sensitivity is critically dependent on the defects depth with sensitivity decreasing linearly with defect depth. Lock-in phase thermography is shown to be more sensitive than the conventional reflection and through transmission thermography techniques. However all thermographic techniques are considerably less sensitive than ultrasonics which thermography is intended to replace. However thermography does have the advantages of remote testing of a large area quickly.

10

12 11 10 9 8 Diameter, mm 7 6 5 4 3 2 1 0 0 0.1 0.2

THERMOGRAGHICALLY NOT DETECTABLE REGION

DETECTABLE REGION

0.3

0.4

0.5

0.6

0.7

0.8

0.9 Depth, m m

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

LOCK IN METHOD TRANSMISSION METHOD REFLECTION METHOD ULTRASONIC DETECTABILITY LIMIT

Fig. 6. Comparison Of Various Testing Techniques

11

CONCLUSIONS

Radiography can show defect characteristics and extremities clearly but it is limited to certain techniques such as the TBE enhancement technique where the defect is open to the surface. The mechanical impedance is the most suitable technique for a one sided test of delaminations between the skin and core of a honeycomb specimen specimen. It is less sensitive than other techniques for other defects. The following table attempts a comparison between Lock-in Thermography and ultrasonic C scan for the detection of defects in fibre reinforced composites. Table 2 Summary Of A Comparison Between Thermography And Ultrasonic C Scan Near surface defects < 1 mm deep Defect sizing Smallest size detectable (mm) 1-2 Accuracy of depth measurement Detailed features of defect Not clear Noisiness of image Noisier than ultrasonics Clear

Lock-in thermo graphy Ultrasonic C scan

Size quite accurate Sizing accurate

Can determine ply layer ( 0.1mm)

Clear

Deep defects > 1 mm deep Defect sizing Smallest size detectable (mm) 8 Accuracy of depth measurement Detailed features of defect Not clear Noisiness of image Noisier than ultrasonics Clear

Lock-in thermo graphy Ultrasonic C scan

Size quite accurate Sizing accurate

Can determine ply layer ( 0.1mm)

Clear

7 1. 2.

REFERENCES Adams, R. D. and Cawly, P. D. A Review of Defect Types and Non-Destructive Testing Techniques for Composites and Bonded Joints, NDT International 21 (1988) pp 208-222. Wong, B. S., Guo, N., Tui, C. G. and Teng K. H. Mechanical impedance

12

3. 4.

inspection of aluminium honeycomb structures, Materials Evaluation, USA, (1996) Vol. 54, No. 12, pp. 1390-1396. Wong, B. S. and Tui, C. G. Thermographic Evaluation of Aerospace Materials, Aerospace Technology Seminar, Singapore, 1998. Wong, B. S., Tui, C. G., Low Bah Soon, Tan Peck Hui and Tan Kha Sheng Thermographic and Ultrasonic Evaluation of Composite Materials, Proceedings of Non-Destructive Testing 98, UK, 1998.

AUTHOR - BRIAN STEPHEN WONG

13

You might also like

- Ultrasonic Testing - Wikipedia PDFDocument26 pagesUltrasonic Testing - Wikipedia PDFKarthicWaitingNo ratings yet

- NDT UltrasonicDocument15 pagesNDT Ultrasonicromeoamu87No ratings yet

- Application Notes: Nondestructive Bond Testing For Aircraft CompositesDocument5 pagesApplication Notes: Nondestructive Bond Testing For Aircraft CompositesPDDELUCANo ratings yet

- ANDTBF - 06 NDT Training SyllabusDocument34 pagesANDTBF - 06 NDT Training SyllabusHeidi CoxNo ratings yet

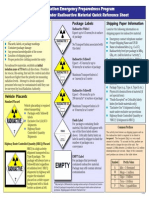

- Emergency Responder Fact Sheet - TransportationDocument2 pagesEmergency Responder Fact Sheet - TransportationS Pushya Mitra100% (1)

- PRR CalculationDocument4 pagesPRR CalculationnavitaNo ratings yet

- Quizelets PDFDocument9 pagesQuizelets PDFdiwakarNo ratings yet

- L Ru WrittenDocument12 pagesL Ru Writtenmadhunikhil100% (1)

- 109428-BS en 583-4-2002Document18 pages109428-BS en 583-4-2002Nensha KagasawaNo ratings yet

- List of StandardsDocument6 pagesList of StandardsShahazad ShaikNo ratings yet

- Visual Inspection ModulesDocument6 pagesVisual Inspection ModulesAgustine Setiawan100% (2)

- ISO 9916 1991 Aluminium and Magnesium Alloy Castings - Liquid Penetrant TestingDocument9 pagesISO 9916 1991 Aluminium and Magnesium Alloy Castings - Liquid Penetrant TestingJOSUE RIOSNo ratings yet

- Eddy Current InspectionDocument7 pagesEddy Current InspectionAl BorromeoNo ratings yet

- QZ EqDocument6 pagesQZ Eqgalati12345100% (1)

- Electromagnetic Testing-ASNT Level III S PDFDocument514 pagesElectromagnetic Testing-ASNT Level III S PDFRicardo Huanca TrejoNo ratings yet

- BS 4069-1982Document14 pagesBS 4069-1982Jithu KareemNo ratings yet

- PT PracticalDocument40 pagesPT PracticalShyam Sundar GayenNo ratings yet

- Accessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishDocument3 pagesAccessories For Magnetic Particle Inspection Brochure - Jan 15 - EnglishimahidaNo ratings yet

- Astm E1962 19Document4 pagesAstm E1962 19Mohamed AboelkhierNo ratings yet

- Radiograph FormulaDocument2 pagesRadiograph Formulaहेमंत कुमार मीणाNo ratings yet

- Nandtb PDFDocument1 pageNandtb PDFBalaji DharNo ratings yet

- Ect - Aerospace - OptimizedDocument30 pagesEct - Aerospace - OptimizedNguyen PhucNo ratings yet

- Topics On Nondestructive Evaluation: Automation, Miniature Robotics and Sensors Nondestructive Testing and EvaluationDocument103 pagesTopics On Nondestructive Evaluation: Automation, Miniature Robotics and Sensors Nondestructive Testing and EvaluationAli AlhaikNo ratings yet

- ASME SECTION VIII Ultrasonido CriteriosDocument1 pageASME SECTION VIII Ultrasonido CriteriosLorena Jimenez100% (1)

- Nortec Eddy CurrentDocument40 pagesNortec Eddy CurrentCss Sfaxien100% (2)

- Ferrite Measurement PDFDocument2 pagesFerrite Measurement PDFESWARANM91No ratings yet

- 20dB DropDocument84 pages20dB Dropphan hoang diepNo ratings yet

- 1100 Gorman RT-UT Presentation For CTMS Oct 07Document29 pages1100 Gorman RT-UT Presentation For CTMS Oct 07Sagar NaduvinamaniNo ratings yet

- LPT Spe QB 2Document6 pagesLPT Spe QB 2Aruchamy SelvakumarNo ratings yet

- Radiography Testing Level I and IIDocument16 pagesRadiography Testing Level I and IIJoshnewfoundNo ratings yet

- Nuclear UT - ISO - CD - 20890-1-2017Document39 pagesNuclear UT - ISO - CD - 20890-1-2017Anonymous 5qPKvmuTWCNo ratings yet

- Ecss Q ST 70 39c 1may2015Document72 pagesEcss Q ST 70 39c 1may2015melisbbNo ratings yet

- CINDE Course Calendar - Feb 3, 2016Document32 pagesCINDE Course Calendar - Feb 3, 2016PeterNo ratings yet

- DMTA 20015 01EN Rev M OmniScan MX and MX2 UserDocument230 pagesDMTA 20015 01EN Rev M OmniScan MX and MX2 UserPetr0% (2)

- Jaeger J1 EquivalentDocument2 pagesJaeger J1 Equivalentmukeshkbhatt100% (1)

- AGR Field Operations TD Focus-Scan Data SheetDocument2 pagesAGR Field Operations TD Focus-Scan Data SheetJeganeswaranNo ratings yet

- Ultrasonic TestingDocument52 pagesUltrasonic TestingSatheenaThiruvenkadamNo ratings yet

- Australian StandardDocument14 pagesAustralian StandardEsme P. W. LauNo ratings yet

- E 1065 - 99-UT-transdDocument22 pagesE 1065 - 99-UT-transdDemian PereiraNo ratings yet

- Radio GraphicDocument58 pagesRadio GraphicApex AesNo ratings yet

- Computed Tomographic (CT) Examination of Castings: Standard Practice ForDocument4 pagesComputed Tomographic (CT) Examination of Castings: Standard Practice ForEric GozzerNo ratings yet

- Standards of Radiography of WeldDocument133 pagesStandards of Radiography of Weldmsiddique1No ratings yet

- Tangential Radiography For The Wall Thickness Measurement of Process PipingDocument7 pagesTangential Radiography For The Wall Thickness Measurement of Process Pipingkirubha_karan2000No ratings yet

- BS EN ISO 9934-1 Current CalculationDocument3 pagesBS EN ISO 9934-1 Current Calculationbhavin178No ratings yet

- Eddy Current Testing Level Iii Questions in April 2012 These Questions May Also Again Repeat in The FollowingDocument5 pagesEddy Current Testing Level Iii Questions in April 2012 These Questions May Also Again Repeat in The FollowingMangalraj MadasamyNo ratings yet

- Multifilm Techinique PDFDocument7 pagesMultifilm Techinique PDFamitNo ratings yet

- 8.5 Curved Surface Correction (CSC) - Olympus IMSDocument4 pages8.5 Curved Surface Correction (CSC) - Olympus IMSTHIRU.SNo ratings yet

- 2017 Catalogue GBDocument131 pages2017 Catalogue GBCedric MercadoNo ratings yet

- BS en 9934-3Document21 pagesBS en 9934-3The Normal HeartNo ratings yet

- Calibration of Eddycon CL - ENGDocument36 pagesCalibration of Eddycon CL - ENGNathaniel LuraNo ratings yet

- MT Classroom Training HandbookDocument56 pagesMT Classroom Training HandbookaspoiaspoiNo ratings yet

- Application of Tandem Techniques With Contact Mono-Elements or Phased Array Probes: Simulation and ExperimentsDocument10 pagesApplication of Tandem Techniques With Contact Mono-Elements or Phased Array Probes: Simulation and ExperimentsAbd Rahman AliasNo ratings yet

- Transient Electromagnetic-Thermal Nondestructive Testing: Pulsed Eddy Current and Transient Eddy Current ThermographyFrom EverandTransient Electromagnetic-Thermal Nondestructive Testing: Pulsed Eddy Current and Transient Eddy Current ThermographyRating: 5 out of 5 stars5/5 (1)

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- Study of Commonly Encountered Defects in FRP Composites Through Air-Coupled Ultrasonic C-Scanning With Different Frequencies and WaveformsDocument7 pagesStudy of Commonly Encountered Defects in FRP Composites Through Air-Coupled Ultrasonic C-Scanning With Different Frequencies and WaveformsChirag AnandNo ratings yet

- Difference Between ISO and ASTM StandardsDocument5 pagesDifference Between ISO and ASTM StandardsNicholas Farrugia100% (4)

- A Risk Assessment Approach To Improve The Resilience of A Seaport System Using Bayesian Networks 2016 Ocean EngineeringDocument12 pagesA Risk Assessment Approach To Improve The Resilience of A Seaport System Using Bayesian Networks 2016 Ocean Engineeringsaptop39No ratings yet

- How To Use This BookletDocument7 pagesHow To Use This Bookletsaptop39No ratings yet

- Swan UseDocument135 pagesSwan Usesaptop39No ratings yet

- Iso 14125 1998Document10 pagesIso 14125 1998saptop39No ratings yet

- Tec482 PDFDocument39 pagesTec482 PDFsaptop39No ratings yet

- Principal Value With MatlabDocument1 pagePrincipal Value With Matlabsaptop39No ratings yet

- A Baq Us Execution ProcedureDocument1 pageA Baq Us Execution Proceduresaptop39No ratings yet

- WartsilaDocument92 pagesWartsilamohzainalabidin100% (2)

- IATTC 73 EPO Capacity PlanDocument5 pagesIATTC 73 EPO Capacity Plansaptop39No ratings yet

- Depliant Presentation AMASONE - v2Document2 pagesDepliant Presentation AMASONE - v2saptop39No ratings yet

- Ads Application Form 2012Document33 pagesAds Application Form 2012Cholis NurNo ratings yet

- Lecture 8 9 NotesDocument2 pagesLecture 8 9 Notessaptop39No ratings yet

- Outcome 35Document11 pagesOutcome 35Abhishek SharmaNo ratings yet

- OTC Paper 13210, 2001 Taco TerpstraDocument21 pagesOTC Paper 13210, 2001 Taco TerpstraParilla13No ratings yet

- (6 G) GuidanceDocument28 pages(6 G) Guidancesaptop39No ratings yet

- About CTIDocument3 pagesAbout CTIsaptop39No ratings yet

- About CTIDocument3 pagesAbout CTIsaptop39No ratings yet

- RSW SystemsDocument4 pagesRSW Systemssaptop39No ratings yet

- Fender Product LiteratureDocument8 pagesFender Product Literaturesaptop39No ratings yet

- Iso Kapal Layar - E - 2004-03-02Document29 pagesIso Kapal Layar - E - 2004-03-02saptop39No ratings yet

- RSW SystemsDocument4 pagesRSW Systemssaptop39No ratings yet

- Spin AkerDocument11 pagesSpin Akersaptop39No ratings yet

- Analysis of Existing Refrigeration Plants Onboard Fishing Vessels and Improvement PossibilitiesDocument8 pagesAnalysis of Existing Refrigeration Plants Onboard Fishing Vessels and Improvement PossibilitiesADRIANSF1No ratings yet

- Hirdostatic CurveDocument1 pageHirdostatic Curvesaptop39No ratings yet

- BrochureDocument6 pagesBrochuresaptop39No ratings yet

- Spin AkerDocument11 pagesSpin Akersaptop39No ratings yet

- 2Document2 pages2saptop39No ratings yet

- X19 CombatDocument1 pageX19 Combatsaptop39No ratings yet

- E127Document13 pagesE127UTshooterNo ratings yet

- Digital Control System Analysis and Design 4th Edition by Phillips ISBN Solution ManualDocument46 pagesDigital Control System Analysis and Design 4th Edition by Phillips ISBN Solution Manualraymond100% (23)

- Maths - 2B Imp QuestionsDocument93 pagesMaths - 2B Imp QuestionsBandaru Chiranjeevi100% (1)

- Assignment NM 2Document1 pageAssignment NM 2Sunny KashyapNo ratings yet

- SH 60 TD enDocument98 pagesSH 60 TD enCésar David Pedroza DíazNo ratings yet

- Economics 101: Interactive BrokersDocument11 pagesEconomics 101: Interactive BrokersDennys FreireNo ratings yet

- Time ResponseDocument105 pagesTime ResponseFrogie HuniebieNo ratings yet

- Huawei KPIs 10thsep2011Document15 pagesHuawei KPIs 10thsep2011Amr Mohamed Abd El-baryNo ratings yet

- More Than One Answer Is CorrectDocument182 pagesMore Than One Answer Is CorrectNikhil GandhiNo ratings yet

- ISCSI OptimizationDocument28 pagesISCSI OptimizationrahulhclNo ratings yet

- Cool Fire Manual 45M620N2UK-01Document198 pagesCool Fire Manual 45M620N2UK-01prejby91% (11)

- On The Coupling of Mechanics With Bioelectricity and Its Role in MorphogenesisDocument12 pagesOn The Coupling of Mechanics With Bioelectricity and Its Role in MorphogenesisVishvendraNo ratings yet

- Checklists For Quality Control For RCC WorkDocument4 pagesChecklists For Quality Control For RCC Workwaimaung100% (1)

- Handout 3 TMR4305 Lecture 13 09 2007Document5 pagesHandout 3 TMR4305 Lecture 13 09 2007sujaydsouza1987No ratings yet

- Electrolysis 4.1Document42 pagesElectrolysis 4.1Maham khanNo ratings yet

- 932qlg65vteb PDFDocument4 pages932qlg65vteb PDFMariaNo ratings yet

- The Law of CosinesDocument12 pagesThe Law of CosinesLei Xennia YtingNo ratings yet

- KPS Alignment Procedure & FormulaDocument4 pagesKPS Alignment Procedure & FormulaWidhyatmika RestuNo ratings yet

- Dental CementDocument74 pagesDental CementAisha samreenNo ratings yet

- King Fahd University of Petroleum & Minerals Department of Chemical EngineeringDocument5 pagesKing Fahd University of Petroleum & Minerals Department of Chemical Engineeringgood musicNo ratings yet

- Availability and ReachabilityDocument1 pageAvailability and ReachabilityAndre Syah FahmiNo ratings yet

- KEIYU NDT Ultrasonic TransducerDocument6 pagesKEIYU NDT Ultrasonic TransducersrgokuNo ratings yet

- Chapter 02 - Components of CADCAMCAE SystemsDocument35 pagesChapter 02 - Components of CADCAMCAE SystemsKeVal PaTelNo ratings yet

- Autoclave CatalogueDocument17 pagesAutoclave CatalogueUMARALEKSANA, CVNo ratings yet

- Lecture 2 - Inverse Laplace TransformsDocument3 pagesLecture 2 - Inverse Laplace TransformsAmirah MapandiNo ratings yet

- Module One 4 BAKERY INGREDIENTSDocument46 pagesModule One 4 BAKERY INGREDIENTSIhsan BadshaNo ratings yet

- APN-002 Protection and Control DevicesDocument10 pagesAPN-002 Protection and Control DevicesYusron MuhammadNo ratings yet

- Engineering Materials CE-105: ConcreteDocument27 pagesEngineering Materials CE-105: Concretenasir khanNo ratings yet

- ABM11 BussMath Q1 Wk3 ProportionsDocument12 pagesABM11 BussMath Q1 Wk3 ProportionsArchimedes Arvie Garcia100% (1)

- PumpsDocument8 pagesPumpskannagi198No ratings yet