Professional Documents

Culture Documents

Quality Plan

Uploaded by

hjgajjarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Plan

Uploaded by

hjgajjarCopyright:

Available Formats

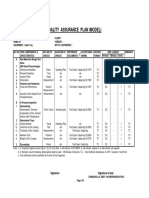

STANDARD MANUFACTURING QUALITY PLAN

CODE : SMQP/1 PRODUCT : TRANSMISSION TOWERS ITEM : TOWER ACCESSORIES SECTION : FINAL INSPECTION & TESTING

S. No. 1.0 1.1 1.1.1 Component/ operation & description of test RAW MATERIALS Structural Steel (MS & HT) (Angles, Plates, Pipes & Bars) Visual check for surface finish Min. of 5% of total lot One sample per 400 MT or as per Customers Requirement. One sample per 400 MT or as per Customers requirement. Min. of 5% of total lot Customer Specs. or equiv. International Standards Customer Specs. or equiv. International Standards Customer Specs. or equiv. International Standards Customer Specs. or equiv. International Standards

ABRAJ-tec

REVISION NO : 09 PAGE ISSUE NO: 01 PAGE NO : 01 of 03 DATE OF ISSUE: 28.12. 2004

Ref. Doc. & Acceptance norm Testing Agency Remarks

Sampling plan

Ref.AITE/MAQP/01

1.1.2

Physical properties

Suppliers works/ or Third party Testing lab Suppliers works/ or third party Testing lab

ABRAJ-tec

Verification of Mill Test Certificates of main producers Verification of Mill Test Certificates of main producers Ref. AITE/MAQP/01

1.1.3

Chemical properties

1.1.4 1.2 1.2.1

Dimensional checks & Sectional Tolerances Hardware Visual Check

5% of total lot

Based on P.O. or ASTM A325 or equivalent Std. Based on P.O. or ASTM A325 or equivalent Std. Customers Spec.

ABRAJ-tec

Review of records at the time of final inspection Verification of Certificates issued by the manufacturer

1.2.2

Dimensional & Thread pitch Check Fitment INPROCESS INSPECTION Fabrication Marking, Stamping and Cropping (Cutting)

1% of total lot

ABRAJ-tec

1.2.3 2.0 2.1 2.1.1

1% of total lot

ABRAJ-tec

1st piece and every 50th piece

Customers Spec./ Dwgs. & Stds. Stamping letter size 10 or 16mm

ABRAJ-tec

Ref. ABRAJ-TEC AITE/MAQP/01 and As per Clients requirement

STANDARD MANUFACTURING QUALITY PLAN

CODE : SMQP/1 PRODUCT : TRANSMISSION TOWERS ITEM : TOWER ACCESSORIES SECTION : FINAL INSPECTION & TESTING

S. No. 2.1.2 2.1.3 Component/ operation & description of test Punching/ Drilling Notching Sampling plan

REVISION NO : 09 PAGE ISSUE NO: 01 PAGE NO : 02 of 03 DATE OF ISSUE: 28.12. 2004

Ref. Doc. & Acceptance norm Customers requirements/ Standards. Customers requirements/ Standards Tolerance +5mm on lengths of cut As per drawing/Stds. Tolerance +5mm on lengths of cut As per drawing Testing Agency

ABRAJ-tec

Remarks

1st piece and random basis 1st piece and random basis

ABRAJ-tec

Tolerance is allowed provided it does not functionally have any adverse affect - do

2.1.4

Heel Cutting

1st piece and random basis 1st piece and random basis 1st piece and random basis 100% Random basis

ABRAJ-tec

2.1.5 2.1.6

Bending Welding a).Fillet size

ABRAJ-tec

b).Visual examination c).Dye Penetration Test

Customers Specs./ Approved drawings &Welding Procedure Specn/ Welding Stds. -do-do-

ABRAJ-tec

Review of records at the time of final inspection

ABRAJTEC ABRAJTEC or Third party inspn. ABRAJTEC

2.1.7

Final Inspection of fabricated Parts

Random basis

Verify:- parameters from 2.1.1 to 2.1.5 - Straightness of members - Holes & edges to be free from burrs - Complete planned qty. availability Approved Dwg. Bill of Materials Interchangeability of bolted members to be verified

2.2

Prototype/ Model Assembly

One structure of each type

ABRAJTEC

BOM to be finalized on approval of prototype structure. Individual part nos. to be specified on the final drawing.

STANDARD MANUFACTURING QUALITY PLAN

CODE : SMQP/1 PRODUCT : TRANSMISSION TOWERS ITEM : TOWER ACCESSORIES SECTION : FINAL INSPECTION & TESTING

S. No. 3 Component/ operation & description of test Galvanizing Sampling plan

REVISION NO : 09 PAGE ISSUE NO: 01 PAGE NO : 03 of 03 DATE OF ISSUE: 28.12. 2004

Ref. Doc. & Acceptance norm Galvanizing should be done only at reputed/ reliable Units. Visual inspection: Loose particles not Permitted Acid pickling and Chromatisation ASTM: A 123 or other applicable International Stds. Remarks Galvanizing is a Farmed out operation.

3.1

Surface Preparation a) Sand blasting (in case of large members) or b) Pickling (in case of small members) Random basis All inspections related Galvanizing to be performed by the Vendor and certificate to be issued for compliance with requirements.

(farmed out) (farmed out)

3.2

Dipping (Galvanizing)

3.3

Receipt inspection after Galvanizing a) Visual inspection b) Coating thickness Random 2% Random basis No brittle coatings. Uniform coatings. Steel (>5mm) > 85 Threaded parts > 43 Or per ASTM: A123 or other applicable Internatl Standards As per ASTM: A123 or other equivalent Approved drawings or as agreed with the customer. Approved drawings/ Specs. As per Clients Requirements or AITE/ MAQP/ 01. Packing List * For exports: Small cleats, gussets, hardware to be packed & strapped separately * Wt. of each bundle or pallet could be between 600-2000kg * Equal length items can be bundled together Verification of Vendors certificate for conformance with International Stds.

c) Adhesion Test 4.0

Random basis

FINAL INSPECTION a) Identification Marks b) Dimensional/ Visual c) Packing/ Bundling d) Quantity checks

Random basis Random basis Random basis 100%

You might also like

- Quick Reference CardDocument3 pagesQuick Reference Cardaslam.ambNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AQPP Check List NewDocument17 pagesAQPP Check List NewSuresh KumarNo ratings yet

- Acdb FQPDocument9 pagesAcdb FQPAnonymous vcadX45TD7No ratings yet

- Bay Marshalling BoxesDocument4 pagesBay Marshalling BoxesSimbu ArasanNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- BOQ 2 BedroomDocument83 pagesBOQ 2 BedroomOgunfolaji Rasheed100% (1)

- L&T ECCD Inspection & Test Plan for Structural WorksDocument4 pagesL&T ECCD Inspection & Test Plan for Structural Worksmanu_gite100% (2)

- LOCTITE - Threadlocking - GuideDocument7 pagesLOCTITE - Threadlocking - Guidedavorp1402No ratings yet

- AC7102.1D Nadcap Audit Criteria For BrazingDocument11 pagesAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- Control PlanDocument6 pagesControl PlanAustin ChinNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- Quality Manual: For Carolina Precision Manufacturing, LLC IndexDocument27 pagesQuality Manual: For Carolina Precision Manufacturing, LLC IndexhjgajjarNo ratings yet

- NDT Magnetic Particle Inspection ProcedureDocument7 pagesNDT Magnetic Particle Inspection ProcedureCharlesNo ratings yet

- Contractor QAP for HT Breaker PanelDocument1 pageContractor QAP for HT Breaker Panelmadhu_bedi12No ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- SKF Bearing Installation and MaintenanceDocument146 pagesSKF Bearing Installation and MaintenanceDefinal ChaniagoNo ratings yet

- Estimation of The ProjectDocument89 pagesEstimation of The ProjectNaga PrasanthNo ratings yet

- 0040 10 - R1Document39 pages0040 10 - R1tinhNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- SO238051 Test Report CMT0036Document10 pagesSO238051 Test Report CMT0036mpedraza-1No ratings yet

- (Centrifugal Pump Calculation For DM PW Water To R-401Document20 pages(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNo ratings yet

- Balance Grades As Per ISO 1940Document0 pagesBalance Grades As Per ISO 1940ADITYA_PATHAKNo ratings yet

- History of CFD Work in IndiaDocument10 pagesHistory of CFD Work in IndiajoemonjacobNo ratings yet

- Free Siemens NX (Unigraphics) Tutorial - Surface ModelingDocument53 pagesFree Siemens NX (Unigraphics) Tutorial - Surface Modelingitltechnology73% (11)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- GMW 14670 - May 2007 - Organic Coat For Finish WheelsDocument4 pagesGMW 14670 - May 2007 - Organic Coat For Finish WheelsatulmkaushalNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- Castings NDE Guide PDFDocument24 pagesCastings NDE Guide PDFAdityaJainNo ratings yet

- Sedimentation: Engr. Nadeem Karim BhattiDocument23 pagesSedimentation: Engr. Nadeem Karim BhattiEngr Sarang Khan100% (1)

- The Global Commitment 2021 Progress ReportDocument39 pagesThe Global Commitment 2021 Progress ReportComunicarSe-ArchivoNo ratings yet

- CementingTools NS 1 A4 WatermarkedDocument7 pagesCementingTools NS 1 A4 Watermarkedislam atifNo ratings yet

- Material Requirements For Machine Parts: ProcurementstandardDocument7 pagesMaterial Requirements For Machine Parts: ProcurementstandardtomognNo ratings yet

- PS 3103Document9 pagesPS 3103JayeshNo ratings yet

- Performance Test Results Gmt900Document7 pagesPerformance Test Results Gmt900Lupita LupitaNo ratings yet

- R05323 P 001a X009 0042 PDFDocument464 pagesR05323 P 001a X009 0042 PDFcquibajoNo ratings yet

- Radiographic Examination of Piping Welds According To EN: IssueDocument6 pagesRadiographic Examination of Piping Welds According To EN: Issuebth8320No ratings yet

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- WC059 AMG Metal Non Drainable Louver Test - MSRKDocument9 pagesWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.No ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- Inspection & Testing Requirements: FITTINGS: For Use in HOT TAP And/or Stopple Operations Wet &Document1 pageInspection & Testing Requirements: FITTINGS: For Use in HOT TAP And/or Stopple Operations Wet &aqisNo ratings yet

- CSCS Rods & BracketsDocument66 pagesCSCS Rods & BracketsshuklahouseNo ratings yet

- Materials System SpecificationDocument5 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Qap Rap PDFDocument1 pageQap Rap PDFtrushalpanchalNo ratings yet

- Ts Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencyDocument1 pageTs Remarks: of Raw Materials Item Manufacture System / Requiremen Thicknes S (Min. MM) Resin % Glass % Testing FrequencySaud PathiranaNo ratings yet

- QSQR S7-36-2014enDocument11 pagesQSQR S7-36-2014enDiego CamargoNo ratings yet

- SM 001 SRV SpecDocument5 pagesSM 001 SRV Specvardan_vardanNo ratings yet

- 42crmo4 Raw Material Specification Document: Doc Ref CSMEP/RMSPC/0001 Date 24.08.2013 Issue Rev 1.0 Page No 1 of 4Document4 pages42crmo4 Raw Material Specification Document: Doc Ref CSMEP/RMSPC/0001 Date 24.08.2013 Issue Rev 1.0 Page No 1 of 4mass3444No ratings yet

- Integrated Management System Certificate of Galvanizing: Test Result Name of Zinc Used and PercenatgeDocument1 pageIntegrated Management System Certificate of Galvanizing: Test Result Name of Zinc Used and Percenatgebahar62_iutNo ratings yet

- MS-4052 Rev. HDocument4 pagesMS-4052 Rev. HGuri GuriNo ratings yet

- InspectorDocument5 pagesInspectorVictor DvornikovNo ratings yet

- MS-4005 - Rev - DDocument5 pagesMS-4005 - Rev - DEngenharia APedroNo ratings yet

- QSQR+S7 48 2020 1Document8 pagesQSQR+S7 48 2020 1مرکز پژوهش متالورژی رازی RMRCNo ratings yet

- ASTM - A 903 - Steel Castings, Surface Acceptance Standards - MT - PTDocument2 pagesASTM - A 903 - Steel Castings, Surface Acceptance Standards - MT - PTGeorge Hdlc100% (1)

- Radiographic Examination of Piping Welds According To EN: IssueDocument6 pagesRadiographic Examination of Piping Welds According To EN: IssueEdAlmNo ratings yet

- Technical Requirements for Storage Tank PlatesDocument1 pageTechnical Requirements for Storage Tank PlatesAnkit KumarNo ratings yet

- Piping Components Spec for Low Temp ServiceDocument6 pagesPiping Components Spec for Low Temp ServiceFlorante NoblezaNo ratings yet

- Section 08500 Windows Rev 0Document35 pagesSection 08500 Windows Rev 0Our SalahEddineNo ratings yet

- V 341001Document1 pageV 341001mdkakhanNo ratings yet

- Pulley Manufacturing ProceduresDocument4 pagesPulley Manufacturing ProceduresVijayakumar SamyNo ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- Astm A874Document3 pagesAstm A874DendeNo ratings yet

- Kuwait Lab Tests Zinc Coating ThicknessDocument3 pagesKuwait Lab Tests Zinc Coating Thicknessm.aliNo ratings yet

- Checklist For Tank No 1Document2 pagesChecklist For Tank No 1sathi11189No ratings yet

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 pagesCPPP Self Assessment Spot Welding (QHB037G) 1broNo ratings yet

- 0 Material Inspection SlideDocument116 pages0 Material Inspection SlideMinh VuuNo ratings yet

- PW-3 Part Design For Ultrasonic Welding (Single PGS) HRDocument8 pagesPW-3 Part Design For Ultrasonic Welding (Single PGS) HRhjgajjarNo ratings yet

- Centrifuges Manual NewDocument19 pagesCentrifuges Manual NewhjgajjarNo ratings yet

- Joint Design SonitekDocument4 pagesJoint Design SonitekhjgajjarNo ratings yet

- Danfoss PF000G102Document212 pagesDanfoss PF000G102abby_nipaNo ratings yet

- Thermal Staking Design Guide Pgs PDFDocument4 pagesThermal Staking Design Guide Pgs PDFdiego_mtzNo ratings yet

- Tools For Fasteners Rivit CatalogueDocument72 pagesTools For Fasteners Rivit CataloguehjgajjarNo ratings yet

- Manufacturing of A Ball-BearingDocument12 pagesManufacturing of A Ball-Bearingvalentinp3No ratings yet

- Relationship of TQM and Business Performance With Mediators of SPC, Lean Production and TPMDocument6 pagesRelationship of TQM and Business Performance With Mediators of SPC, Lean Production and TPMhjgajjarNo ratings yet

- 14-07-17 SpeedMill PLUS Eng WEB GeschuetztDocument4 pages14-07-17 SpeedMill PLUS Eng WEB GeschuetzthjgajjarNo ratings yet

- In 175Document15 pagesIn 175hjgajjarNo ratings yet

- Santos Vijande, Alvarez GonzalezDocument21 pagesSantos Vijande, Alvarez Gonzalezmohsin_khan_mmkNo ratings yet

- Product Quality. A Guide For Small and Medium-Sized EnterprisesDocument56 pagesProduct Quality. A Guide For Small and Medium-Sized EnterprisesNedzminaNo ratings yet

- Laboratory centrifuge guideDocument6 pagesLaboratory centrifuge guideJustin HernandezNo ratings yet

- Quality Function Deployment - A Comprehensive ReviewDocument25 pagesQuality Function Deployment - A Comprehensive ReviewgschiroNo ratings yet

- Hermle Z-320 - User Manual PDFDocument29 pagesHermle Z-320 - User Manual PDFhjgajjarNo ratings yet

- Full Robotics PDFDocument29 pagesFull Robotics PDFmajesticdharma1985No ratings yet

- Ie 450 PP 7Document30 pagesIe 450 PP 7hjgajjarNo ratings yet

- TQM For Manufacturing ExcellenceDocument15 pagesTQM For Manufacturing ExcellencerudypatilNo ratings yet

- TQM Practices Impact on Market OrientationDocument13 pagesTQM Practices Impact on Market OrientationhjgajjarNo ratings yet

- 10 1371-Journal Pcbi 1003686 g002Document1 page10 1371-Journal Pcbi 1003686 g002hjgajjarNo ratings yet

- Supply Chain Management and TQMDocument4 pagesSupply Chain Management and TQMMahesh KannanNo ratings yet

- Minggu 2 1 Engineering Mathematics Differential EquationsDocument39 pagesMinggu 2 1 Engineering Mathematics Differential EquationshjgajjarNo ratings yet

- Chaos, Solitons & Fractals: Oliver StrebelDocument12 pagesChaos, Solitons & Fractals: Oliver StrebelhjgajjarNo ratings yet

- C70Document3 pagesC70Jorge Luis Arevalo LopezNo ratings yet

- Modeling Relationships in Scatter PlotsDocument45 pagesModeling Relationships in Scatter PlotsSiddarth Kalyan100% (1)

- Chapte4 ZamznDocument24 pagesChapte4 ZamznAHMED DARAJNo ratings yet

- Ask Astrologer Report - Specific Answer To Major Concern of LifeDocument8 pagesAsk Astrologer Report - Specific Answer To Major Concern of LifecyberastroNo ratings yet

- Director Contract Management in Florida North Carolina Resume Thomas CzajaDocument3 pagesDirector Contract Management in Florida North Carolina Resume Thomas CzajaThomas CzajaNo ratings yet

- Working Principle Iwind Wind TurbinesDocument25 pagesWorking Principle Iwind Wind TurbinesKarbonKaleNo ratings yet

- Parts Catalogue: Nova L5-L6Document69 pagesParts Catalogue: Nova L5-L6juanjoserodriguezalzNo ratings yet

- Heat Transfer Through Extended SurfacesDocument16 pagesHeat Transfer Through Extended SurfaceschawarepNo ratings yet

- Cardiovascular SystemDocument40 pagesCardiovascular SystemDouglas Jacques100% (1)

- Emc SCADA PresentationDocument36 pagesEmc SCADA Presentationerode els erodeNo ratings yet

- Comprehensive Land Use Plan in Municipality of TigbauanDocument4 pagesComprehensive Land Use Plan in Municipality of TigbauanmaygracedigolNo ratings yet

- Silo Surface Area CalculationDocument3 pagesSilo Surface Area CalculationVIC EngineersNo ratings yet

- Business Operations Group AssignmentDocument7 pagesBusiness Operations Group Assignmentankit gangeleNo ratings yet

- Processing and Characterization of Recycled Poly (Ethylene Terephthalate) BlendsDocument3 pagesProcessing and Characterization of Recycled Poly (Ethylene Terephthalate) BlendsJason WilliamsNo ratings yet

- xtp471 Kcu116 QuickstartDocument2 pagesxtp471 Kcu116 QuickstartIoan TivgaNo ratings yet

- ALL-Q (Coenzyme Q10) Plus - PDSDocument3 pagesALL-Q (Coenzyme Q10) Plus - PDSMarlon2370No ratings yet

- Abinash Master SeminarDocument51 pagesAbinash Master SeminarAGRICULTURE BOYNo ratings yet

- Tactile Internet MSC V2Document28 pagesTactile Internet MSC V2hendNo ratings yet

- BX 560GDocument20 pagesBX 560Gmacanipharoldf6220No ratings yet

- Training Programmers. Reniforcementptx145525Document9 pagesTraining Programmers. Reniforcementptx145525nkalaiNo ratings yet

- Your First ProgramDocument7 pagesYour First ProgramJosephat MugumbaNo ratings yet

- How The World Was Created (Panayan)Document25 pagesHow The World Was Created (Panayan)Mary Kris De AsisNo ratings yet