Professional Documents

Culture Documents

Detergent Flushing

Uploaded by

SamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detergent Flushing

Uploaded by

SamCopyright:

Available Formats

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 1of 35

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

LIST OF CONTENTS

PLANT DETAILS

OBJECTIVE

PROPOSAL

SERVICES REQUIRED

SAFETY PRECAUTIONS

EMERGENCY PROCEDURES

STATE OF THE PLANT

METHOD

COMPLETION CRITERIA

APPENDICES

DRAWINGS

LOG SHEETS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 2of 35

1.0

1.1

1.2

1.3

1.4

2.0

3.0

3.1

PLANT DETAILS

The Pre-Boiler system consists of Condensate system, Drip

system, Feed water system and Extraction steam lines to

Regenerative Heaters.

Condensate system comprises 3 nos. of Condensate

Extraction Pumps, Low Pressure Heaters, Gland steam cooler,

Drain cooler, Deaerator, connecting pipelines including excess

condensate line upto condensate storage Tank.

Feed water system comprises 1 no. Motor driven and 2 Nos.

Turbo driven Boiler Feed Pumps, their Booster pumps and

recirculation lines, High Pressure Heaters, their connecting

pipelines upto Economizer inlet. RH & SH spray lines are also

included for the purpose of flushing.

Drip system comprises the shell side of all LP and HP Heaters

and the Drip lines.

OBJECTIVE

To remove dirt, oil, grease etc., from the Condensate, Feed

water, Drip and Extraction steam lines of HP & LP Heaters,

using a non-ionic detergent, prior to putting these systems in

regular service. This is to ensure flow of clean condensate

and feed water to the Boiler.

PROPOSAL

Temporary Circulation Pumps (4 nos) each having a capacity

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 3of 35

3.2

3.3

3.4

3.4.1

of 200 T/hr at 20 Kg/sq cm shall be used in this activity.

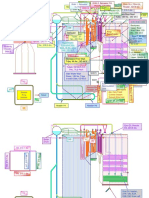

Drawings at pages 13, 14 & 15 provide the layout of

connections between temporary and permanent systems.

Flushing shall be carried out in four separate stages using

fresh detergent in each stage.

The four stages are:

Stage-I: Feed lines

Stage-II: Condensate lines & Drip lines of HP Heaters 5A

& 5B

Stage-III: Extraction steam lines and Drip lines of HP

Heaters

Stage-IV: Extraction steam lines and Drip lines of LP

Heaters

Each system shall be suitably sub-divided into various sub

circuits to cover all the lines and components.

STAGE - I

Sub Stage IA

Mixing Tank - Circulation Pumps - BFP suction lines (of one

BFP at a time) - Booster Pump suction line - Feed Storage

Tank - Recirculation lines - Temporary line - Mixing Tank

Sub Stage IB

Mixing Tank - Circulation Pumps - discharge line of BFP -

Bypass lines of HP Heaters - Feed control station - point near

economizer inlet valve - Mixing Tank

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 4of 35

3.4.2

3.4.3

Sub Stage IC

Mixing Tank - Circulation Pumps - SH Spray & RH Spray lines

- Attemperation station - Mixing Tank

STAGE - II

Sub Stage IIA

Mixing Tank - Circulation Pumps - Condensate discharge line

- Gland Steam Condenser bypass - CPU bypass - Deaerator

level control station - Drain Cooler & LP Heater 1 bypass - LP

Heater 2 bypass - LP Heater 3 bypass upto a point before

Deaerator - Drip line of HP Heater 5A to Deaerator - HP

Heater 5A shell - Alternate drain of HP Heater 5A - Mixing

Tank

Loop from Gland Steam Condenser - excess condensate

return - Mixing Tank is also to be included

Sub Stage IIB

Mixing Tank - Circulation Pumps - condensate discharge line

- Gland Steam Condenser - CPU bypass - Deaerator level

control station - Drain Cooler - LP Heater 1 bypass - LPH 2

bypass - LPH 3 bypass upto a point before Deaerator - Drip

line of HP Heater 5B to Deaerator - HP Heater 5B shell -

Alternate drain of HP Heater 5B - Mixing Tank

STAGE - III

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 5of 35

Sub Stage IIIA

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 5B - HP Heater 5B shell - alternate drip line of HP

Heater 5B - Mixing Tank

Sub Stage IIIB

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 5B - HP Heater 5B shell - Drip line between HP

Heaters 5B & 6B - HP Heater 6B shell - Alternate drip line of

HP Heater 6B - Mixing Tank

Sub Stage IIIC

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 6B - HP Heater 6B shell - alternate drip line of HP

Heater 6B - Mixing Tank

Sub Stage IIID

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 5A - HP Heater 5A shell - alternate drip line of HP

Heater 5A - Mixing Tank

Sub Stage IIIE

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 5A - HP Heater 5A shell - Drip line between HP

Heaters 5A & 6A - HP Heater 6A shell - alternate drip line of

HP Heater 6A - Mixing Tank

Sub Stage IIIF

Mixing Tank - Circulation Pumps - Extraction line of HP

Heater 6A - HP Heater 6A shell - alternate drip line of HP

Heater 6A - Mixing Tank

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 6of 35

3.4.4

3.5

3.5.1

STAGE IV

Sub Stage IVA

Mixing Tank - Circulation Pump - Extraction line of LP Heater

3 - LP Heater 3 shell - alternate drain line of LP Heater 3 -

Mixing Tank

Sub Stage IVB

Mixing Tank - Circulation Pump - Extraction line of LP Heater

2 - LP Heater 2 shell - alternate drain line of LP Heater 2 -

Mixing Tank

Sub Stage IVC

Mixing Tank - Circulation Pump - Extraction line of LP Heater

3 - LP Heater 3 shell - drain line between LPH 3 and LP

Heater 2 - LP Heater 2 shell - alternate drain line of LP Heater

2 - Mixing Tank

Sub Stage IVD

Mixing Tank - Circulation Pump - Extraction line of LP Heater

2 - LP Heater 2 shell - drip line between LP Heater 2 and LP

Heater 1 - LP Heater 1 shell - drip line between LP Heater 1

and Drain Cooler - drip line between Drain cooler and Flash

Tank - Mixing Tank.

In each stage the following activities shall be carried out:

Open circuit Mass Flushing of each sub stage with cold water

for 1 hour or till the effluent is visibly clear, whichever is

later.

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 7of 35

3.5.2

3.5.3

3.5.4

3.5.5

Closed circuit Mass Flushing of each sub stage with cold

water for 1 hour and draining. If the effluent is not visibly

clear this shall be repeated once more.

Closed circuit Mass Flushing of each sub stage with hot water

for 2 hours and draining. If the effluent is not visibly clear

this shall be repeated once more.

Closed circuit Detergent Flushing of each sub stage for 4

hours.

Rinsing of the entire system. Rinsing shall be declared

complete based on analytical results as detailed in the

completion criteria.

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 8of 35

3.5.6

3.6

Passivation of individual circuit for 8 hours.

After successful completion of Detergent flushing the

permanent system shall be isolated from the temporary

system and released for normalization.

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 9of 35

4.0

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

SERVICES REQUIRED

Availability of approximately 5000 Tons of DM water for the

entire operation.

Availability of nonionic detergent:

Rinopol - Jet 100% OR Sumisol - N 100%

Estimated quantity - 1000 Litres

Required concentration - 0.05%

Availability of following chemicals for Passivation:

i) Hydrazene Hydrate (minimum 80% concentration) - 800

Kg

(IS: 12086 / 1991)

ii) Liquor Ammonia (minimum 25% concentration) - 400 Kg

(IS: 799 / 1985)

Availability of 4 Nos. of temporary circulation pumps having

200 T/Hr capacity at 20 Kg/sq cm. (Motor rating - 180 KW)

Availability of Temporary Tank of 40m

3

capacity.

Availability of power supply to temporary circulation pumps.

Availability of adequate lighting in all workings areas.

Availability of reliable communication system such as walkie-

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 10of 35

4.9

4.10

talkie sets, telephones etc.

Availability of laboratory facility for analysis of flushing water

etc.

Availability of required manpower.

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 11of 35

5.0

5.1

5.2

5.3

5.4

6.0

6.1

6.2

6.3

SAFETY PRECAUTIONS

Readiness of staircases, platforms, hand-rails, approaches etc

as decided jointly in advance by BHEL and NTPC at site

should be ensured.

First aid kit should be available during the process.

Safety and protection equipments like hand gloves, eye

protection equipments, helmets etc should be available

during the process.

Service water should be made available near the activity

area.

EMERGENCY PROCEDURES

The testing team should be aware of the procedures to be

followed in case of accident involving injury to personnel.

The team conducting the flushing activity should be aware of

the operating procedures of fire extinguishers for quenching

minor fires.

An operator should be posted in the pump area and

instructed that he should trip the circulation pumps in the

event of emergency being notified to him by observers.

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 12of 35

7.0

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

STATE OF THE PLANT

Hydrotest of the entire system to be flushed is declared

complete.

All the regenerative equipment are installed in position and

temporary pipe line connections as per schemes is complete.

BFPs, their booster pumps and CEPs are bypassed suitably

with temporary piping.

Suction and discharge ends of BFPs and CEPs are capped to

prevent entry of flushing fluid into the pump.

BFP suction strainer elements are removed before flushing.

All the valves in the steam lines to and from Deaerator are

closed.

Installation of circulation pumps, mixing tank and connected

temporary piping along with pressure gauges is complete.

All HP Heaters safety valves are removed and blanks are

provided with a inch valve for air venting. Temperature

stubs in extraction steam lines for LP Heaters may be used

for venting of LP Heaters. While carrying out the flushing of

shell sides of HP and LP Heaters, care is to be taken for

proper venting of heaters for proper filling.

Safety valves of LP heaters are erected in position. This is

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 13of 35

7.10

7.11

7.12

7.13

7.14

7.15

required to release the pressure in the system, in case the

pressure exceeds the set value during the operation due to

any unforeseen reasons.

All the cutting and welding work on instrument tapping points

are complete up to isolating root valves.

All the orifices, flow nozzles, control valves and NRV internals

are removed and a check list is prepared. Spool pieces are

provided wherever required.

All the instruments except those required during flushing are

isolated.

All permanent supports are provided for all the pipelines

before starting the flushing.

Temporary Mixing Tank is provided with 2 nos of Level

Indicators.

The bore of the temporary pipelines should preferably be the

same as that used in the permanent system.

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 14of 35

8.0

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

METHOD

Flushing shall be carried out in four stages as detailed in

proposal.

The stage to be flushed is lined up.

The system is filled with DM water by running temporary

circulation pumps and circulation is established.

Cold DM water is circulated in all the sub loops. Continuous

filling, circulation and draining is continued through each sub

stage for one hour or till the effluent becomes visibly clear. .

Closed circuit mass flushing with cold DM water is started and

continued for one hour through each sub stage. The system is

then drained. If the effluent is not visibly clear then this

process is repeated once more.

Steam is admitted into the mixing tank and water

temperature is raised to 60

0

C. Closed circuit hot DM water

circulation is done through each sub stage for two hours and

the system is drained. If the effluent is not visibly clear then

this process is repeated once more.

System is refilled with DM water by running circulation pumps

and circulation is established.

Steam is admitted into the mixing tank and water

temperature is raised to 60

0

C. Rinopol - Jet 100% or Sumisol

STATUS

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 15of 35

8.9

8.10

8.11

8.12

8.13

8.14

8.15

8.16

8.17

- N 100% is added in mixing tank to achieve the solution

concentration of 0.05%.

The solution is circulated in each of the loops for a minimum

duration of four hours. During circulation make up is given as

per the system requirement and the solution temperature is

kept at 60

0

C.

On completion of detergent circulation in all the loops

continuous make up and draining is carried out in all the

loops one by one for a duration of Fifteen minutes in each

loop.

The system is drained completely and filled again with DM

water.

DM water is circulated in each loop for half an hour once

again.

The system is drained completely.

The system is rinsed with DM water by continuous filling and

draining till the conductivity and oil parameters meet the

values specified in completion criteria.

The system is drained completely.

The system is filled with DM water and circulation is

established. Water temperature is raised to 60

0

C by

admitting steam in the mixing tank.

Hydrazine and Ammonia are added to get 200 ppm Hydrazine

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 16of 35

8.18

8.19

8.19.1

8.19.2

8.19.3

8.19.4

and pH of water between 9.5 and 10.0. Temperature of the

solution is raised to 80

0

C by steam admission in mixing tank.

Circulation is maintained for Eight hours through each sub

stage at this temperature.

The system is completely hot drained. All vent valves and

Feed Storage Tank manholes are opened to aerate the

system.

POST FLUSHING OPERATION

All the temporary connections are removed from the

permanent scheme.

It is checked that all the pipelines and connections are as per

the final scheme.

Deaerator is drained, jointly inspected and cleaned

thoroughly.

After welding of flow nozzles in BFP suction lines, the suction

lines are flushed by draining water from Deaerator for half an

hour through each line. For this purpose temporary pipe

connections are made from suction of each BFP to drain pit.

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 17of 35

9.0

10.0

COMPLETION CRITERIA

DM water rinsing after chemical flushing is considered

complete when conductivity of drained water is less than 10

micro mhos / cm and oil content is NIL.

APPENDICES

LOG SHEET # 1

LOG SHEET # 2

LOG SHEET # 3

LOG SHEET # 4

LOG SHEET # 5

STATU

S

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 18of 35

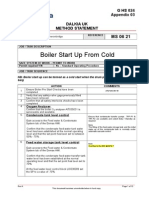

LOG SHEET # 1

Unit :

Activity: Detergent Flushing of Stage I

S

No.

Activity

Duration

Start

Date /

Time

Finish

Date /

Time

Remarks

1. Open circuit flushing

of sub stage IA with

cold water

1 Hr Flushing is continued

for 1 hour OR till the

effluent is visibly clear

2. Open circuit flushing

of sub stage IB with

cold water

1 Hr -do-

3. Open circuit flushing

of sub stage IC with

cold water

1 Hr -do-

4. Closed circuit flushing

of sub stage IA with

cold water

1 Hr -do-

5. Closed circuit flushing

of sub stage IB with

cold water

1 Hr -do-

6. Closed circuit flushing

of sub stage IC with

cold water

1 Hr -do-

7. Complete draining of

the system

8. Refilling of the

System and

establishing

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 19of 35

circulation

9. Raising the water

temperature to 60

0

C

10. Closed circuit flushing

of sub stage IA with

hot water

2 Hrs Flushing is continued

for 2 hours OR till the

effluent is visibly clear

11. Closed circuit flushing

of sub stage IB with

hot water

2 Hrs -do-

12. Closed circuit flushing

of sub stage IC with

hot water

2 Hrs -do-

13. Complete draining of

the system

14. Refilling of the

System and

establishing

circulation

15. Raising the water

temperature to 60

0

C

and addition of

detergent

16. Circulation of

detergent solution in

sub stage IA

4 Hrs

17. Circulation of

detergent solution in

sub stage IB

4 Hrs

18. Circulation of

detergent solution in

sub stage IC

4 Hrs

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 20of 35

19. Continuous make up

& draining of sub

stage IA

15 min

20. Continuous make up

& draining of sub

stage IB

15 min

21. Continuous make up

& draining of sub

stage IC

15 min

22. Draining the

complete system &

refilling with DM

water

23. Circulation of DM

water in sub stage

IA

1 Hr

24. Circulation of DM

water in sub stage

IB

1 Hr

25. Circulation of DM

water in sub stage

IC

1 Hr

26. Draining the system

completely

27. Refilling of the

System and

establishing

circulation

28. Rinsing of sub stage

IA with DM water by

continuous filling &

Rinsing is considered

complete when water

conductivity is less

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 21of 35

draining than 10 micro mhos /

cm and oil content is

nil.

29. Rinsing of sub stage

IB with DM water by

continuous filling &

draining

-do-

30. Rinsing of sub stage

IC with DM water by

continuous filling &

draining

-do-

31. Draining of the

system

32. Refilling of the

system and

establishing

circulation

33. Raising of water

temp to 60

0

C and

adding Hydrazene &

Ammonia

Hydrazene content

should be 200 ppm

and ammonia is added

to get pH of 9.5 to 10

34. Raising of the

solution temp to

80

0

C and passivation

of sub stage IA

8 Hrs

35. Passivation of sub

stage IB

8 Hrs

36. Passivation of sub

stage IC

8 Hrs

37. Hot draining of the

system

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 22of 35

LOG SHEET # 2

Unit :

Activity: Detergent Flushing of Stage II

S

No.

Activity Duration Start

Date /

Time

Finish

Date /

Time

Remarks

1. Open circuit flushing

of sub stage IIA with

cold water

1 Hr Flushing is continued

for 1 hour OR till

effluent is visibly

clear

2. Open circuit flushing

of sub stage IIB with

cold water

1 Hr -do-

3. Closed circuit

flushing of sub stage

IIA with cold water

1 Hr -do-

4. Closed circuit

flushing of sub stage

IIB with cold water

1 Hr -do-

5. Complete draining of

the system

6. Refilling of the

System and

establishing

circulation

7. Raising the water

temperature to 60

0

C

8. Closed circuit 2 Hrs Flushing is continued

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 23of 35

flushing of sub stage

IIA with hot water

for 2 hours OR till

effluent is visibly

clear

9. Closed circuit

flushing of sub stage

IIB with hot water

2 Hrs -do-

10. Complete draining of

the system

11. Refilling of the

system and

establishing

circulation

12. Raising water temp

to 60

0

C and addition

of detergent

13. Circulation of

detergent solution in

sub stage IIA

4 Hrs

14. Circulation of

detergent solution in

sub stage IIB

4 Hrs

15. Continuous make up

& draining of sub

stage IIA

15 min

16. Continuous make up

& draining of sub

stage IIB

15 min

17. Draining of the

complete system &

refilling with DM

water

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 24of 35

18. Circulation of DM

water in sub stage

IIA

1 Hr

19. Circulation of DM

water in sub stage

IIB

1 Hr

20. Complete draining of

system

21. Refilling of the

System and

establishing

circulation

22. Rinsing of sub stage

IIA with DM water by

continuous filling &

draining

Rinsing is considered

complete when

water conductivity is

less than 10 micro

mhos / cm and oil

content is nil

23. Rinsing of sub stage

IIB with DM water by

continuous filling &

draining

-do-

24. Draining of the

system

25. Refilling of the

system and

establishing

circulation

26. Raising of water

temp to 60

0

C and

addition of

Hydrazene content

should be 200 ppm

and ammonia is

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 25of 35

Hydrazene &

Ammonia

added to get pH of

9.5 to 10

27. Raising the solution

temp to 80

0

C and

passivation of sub

stage IIA

8 Hrs

28. Passivation of sub

stage IIB

8 Hrs

29. Hot draining of the

system

LOG SHEET # 3

Unit :

Activity: Detergent Flushing of Stage III

S

No.

Activity Durat

ion

Star

t

Dat

e /

Tim

e

Finish

Date /

Time

Remarks

1. Open circuit flushing of

sub stage IIIA with cold

water

1 Hr Flushing is continued

for 1 hour OR till the

effluent is visibly clear

2. Open circuit flushing of

sub stage IIIB with cold

water

1 Hr -do-

3. Open circuit flushing of

sub stage IIIC with cold

water

1 Hr -do-

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 26of 35

4. Open circuit flushing of

sub stage IIID with cold

water

1 Hr -do-

5. Open circuit flushing of

sub stage IIIE with cold

water

1 Hr -do-

6. Open circuit flushing of

sub stage IIIF with cold

water

1 Hr -do-

7. Closed circuit flushing of

sub stage IIIA with cold

water

1 Hr Flushing is continued

for 1 hour OR till the

effluent is visibly clear

8. Closed circuit flushing of

sub stage IIIB with cold

water

1 Hr -do-

9. Closed circuit flushing of

sub stage IIIC with cold

water

1 Hr -do-

10. Closed circuit flushing of

sub stage IIID with cold

water

1 Hr -do-

11. Closed circuit flushing of

sub stage IIIE with cold

water

1 Hr -do-

12. Closed circuit flushing of

sub stage IIIF with cold

water

1 Hr -do-

13. Complete draining of the

system

14. Refilling of the System

and establishing

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 27of 35

circulation

15. Raising the water

temperature to 60

0

C

16. Closed circuit flushing of

sub stage IIIA with hot

water

2 Hrs Flushing is continued

for 2 hours OR till the

effluent is visibly clear

17. Closed circuit flushing of

sub stage IIIB with hot

water

2 Hrs -do-

18. Closed circuit flushing of

sub stage IIIC with hot

water

2 Hrs -do-

19. Closed circuit flushing of

sub stage IIID with hot

water

2 Hrs -do-

20. Closed circuit flushing of

sub stage IIIE with hot

water

2 Hrs -do-

21. Closed circuit flushing of

sub stage IIIF with hot

water

2 Hrs -do-

22. Complete draining of the

system

23. Refilling of the System

and establishing

circulation

24. Raising the water

temperature to 60

0

C and

addition of detergent

25. Circulation of detergent

solution in sub stage IIIA

4 Hrs

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 28of 35

26. Circulation of detergent

solution in sub stage IIIB

4 Hrs

27. Circulation of detergent

solution in sub stage IIIC

4 Hrs

28. Circulation of detergent

solution in sub stage IIID

4 Hrs

29. Circulation of detergent

solution in sub stage IIIE

4 Hrs

30. Circulation of detergent

solution in sub stage IIIF

4 Hrs

31. Continuous make up &

draining of sub stage

IIIA

15

min

32. Continuous make up &

draining of sub stage

IIIB

15

min

33. Continuous make up &

draining of sub stage

IIIC

15

min

34. Continuous make up &

draining of sub stage

IIID

15

min

35. Continuous make up &

draining of sub stage

IIIE

15

min

36. Continuous make up &

draining of sub stage IIIF

15

min

37. Draining of complete

system & refilling with

DM water

38. Circulation of DM water 1 Hr

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 29of 35

in sub stage IIIA

39. Circulation of DM water

in sub stage IIIB

1 Hr

40. Circulation of DM water

in sub stage IIIC

1 Hr

41. Circulation of DM water

in sub stage IIID

1 Hr

42. Circulation of DM water

in sub stage IIIE

1 Hr

43. Circulation of DM water

in sub stage IIIF

1 Hr

44. Complete draining of

system

45. Refilling of the system

and establishing

circulation

46. Rinsing of sub stage

IIIA with DM water by

continuous filling &

draining

Rinsing is considered

complete when

conductivity is less

than 10 micro mho/

cm and oil content is

nil

47. Rinsing of sub stage

IIIB with DM water by

continuous filling &

draining

-do-

48. Rinsing of sub stage

IIIC with DM water by

continuous filling &

draining

-do-

49. Rinsing of sub stage -do-

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 30of 35

IIID with DM water by

continuous filling &

draining

50. Rinsing of sub stage IIIE

with DM water by

continuous filling &

draining

-do-

51. Rinsing of sub stage IIIF

with DM water by

continuous filling &

draining

-do-

52. Draining of the system

53. Refilling the system and

establishing circulation

54. Raising of water temp to

60

0

C and adding

Hydrazene & Ammonia

Hydrazene content

should be 200 ppm

and ammonia is

added to get pH of

9.5 to 10

55. Raising of solution

temp to 80

0

C and

passivation of sub

stage IIIA

8 Hrs

56. Passivation of sub

stage IIIB

8 Hrs

57. Passivation of sub

stage IIIC

8 Hrs

58. Passivation of sub

stage IIID

8 Hrs

59. Passivation of sub

stage IIIE

8 Hrs

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 31of 35

60. Passivation of sub

stage IIIF

8 Hrs

61. Hot draining of the

system

LOG SHEET # 4

Unit :

Activity: Detergent Flushing of Stage IV

S

No.

Activity Duration Start

Date /

Time

Finish

Date /

Time

Remarks

1. Open circuit flushing

of sub stage IVA

with cold water

1 Hr Flushing is continued

for 1 hour OR till the

effluent is visibly clear

2. Open circuit flushing

of sub stage IVB

with cold water

1 Hr -do-

3. Open circuit flushing

of sub stage IVC

with cold water

1 Hr -do-

4. Open circuit flushing

of sub stage IVD

with cold water

1 Hr -do-

5. Closed circuit

flushing of sub stage

IVA with cold water

1 Hr Flushing is continued

for 1 hour OR till the

effluent is visibly clear

6. Closed circuit

flushing of sub stage

IVB with cold water

1 Hr -do-

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 32of 35

7. Closed circuit

flushing of sub stage

IVC with cold water

1 Hr -do-

8. Closed circuit

flushing of sub stage

IVD with cold water

1 Hr -do-

9. Complete draining of

the system

10. Refilling of the

System and

establishing

circulation

11. Raising the water

temperature to 60

0

C

12. Closed circuit

flushing of sub stage

IVA with hot water

2 Hrs Flushing is continued

for 2 hours OR till the

effluent is visibly clear

13. Closed circuit

flushing of sub stage

IVB with hot water

2 Hrs -do-

14. Closed circuit

flushing of sub stage

IVC with hot water

2 Hrs -do-

15. Closed circuit

flushing of sub stage

IVD with hot water

2 Hrs -do-

16. Complete draining of

the system

17. Refilling of the

system and

establishing

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 33of 35

circulation

18. Raising of water

temp to 60

0

C and

addition of detergent

19. Circulation of the

detergent solution in

sub stage IVA

4 Hrs

20. Circulation the

detergent solution in

sub stage IVB

4 Hrs

21. Circulation the

detergent solution in

sub stage IVC

4 Hrs

22. Circulation the

detergent solution in

sub stage IVD

4 Hrs

23. Continuous make up

& draining of sub

stage IVA

15 min

24. Continuous make up

& draining of sub

stage IVB

15 min

25. Continuous make up

& draining of sub

stage IVC

15 min

26. Continuous make up

& draining of sub

stage IVD

15 min

27. Draining of the

complete system &

refilling with DM

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 34of 35

water

28. Circulation of DM

water in sub stage

IVA

1 Hr

29. Circulation of DM

water in sub stage

IVB

1 Hr

30. Circulation of DM

water in sub stage

IVC

1 Hr

31. Circulation of DM

water in sub stage

IVD

1 Hr

32. Complete draining of

the system

33. Rinsing of sub stage

IVA with DM water

by continuous filling

& draining

Rinsing is considered

complete when water

conductivity is less

than 10 micro mhos /

cm and oil content is

nil

34. Rinsing of sub stage

IVB with DM water

by continuous filling

& draining

-do-

35. Rinsing of sub stage

IVC with DM water

by continuous filling

& draining

-do-

36. Rinsing of sub stage

IVD with DM water

-do-

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 35of 35

by continuous filling

& draining

37. Draining of the

system

38. Refilling the system

with DM water and

establishing

circulation

39. Raising of water

temp to 60

0

C and

addition of

Hydrazene &

Ammonia

Hydrazene content

should be 200 ppm

and ammonia is

added to get pH of

9.5 to 10

40. Raising the solution

temp to 80

0

C and

passivation of sub

stage IVA

8 Hrs

41. Passivation of sub

stage IVB

8 Hrs

42. Passivation of sub

stage IVC

8 Hrs

43. Passivation of sub

stage IVD

8 Hrs

44. Hot draining of the

system

LOG SHEET # 5

Station: NTPC-

VINDHYACHAL-ST-III

BHEL Ref No: PW/TSX/VIN/TUR-CS/001/REV00

NTPC Ref No:

Plant area:

TURBINE & AUXILARIES

Document- Type

COMMISSIONING SCHEDULE

COMMISSIONING SCHEDULE FOR

DETERGENT FLUSHING OF PREBOILER AND CONDENSATE SYSTEM

Signatures

BHEL

NTPC

Page 36of 35

Details of Chemicals used during the process

Unit :

S

No.

System Activity Name of

Chemical

used

Quantity

1. Feed water

2. Condensate

3. Ex steam lines & Drip

lines of HP Heaters

4. Ex steam lines & Drip

lines of LP Heaters

Remarks:

You might also like

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Turbine ErectionDocument131 pagesTurbine ErectionSam92% (12)

- Generator CommissioningDocument90 pagesGenerator CommissioningSam94% (18)

- KWU Text GoverningDocument43 pagesKWU Text GoverningSam100% (2)

- Music GcseDocument45 pagesMusic GcseAimee DohertyNo ratings yet

- Boiler Erection PDFDocument44 pagesBoiler Erection PDFShankar Jha100% (1)

- KWU Turbine SystemDocument90 pagesKWU Turbine Systemvenukumare100% (6)

- Design & Construction Features of TurbogeneratorsDocument92 pagesDesign & Construction Features of TurbogeneratorsArpit Kumar100% (1)

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- Water Circulation SystemDocument37 pagesWater Circulation SystemSam50% (2)

- TTPS Divisions GuideDocument34 pagesTTPS Divisions GuideRamanand bharadwajNo ratings yet

- CobolDocument224 pagesCobolrahulravi007No ratings yet

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- 2.final Energy EfficiencyDocument29 pages2.final Energy EfficiencyVandana VanuNo ratings yet

- Sixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFDocument19 pagesSixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFSunil100% (1)

- Abrasive Blast Nozzle Catalog: Bringing Ceramic Technology To Industry Boride P Roduct SDocument46 pagesAbrasive Blast Nozzle Catalog: Bringing Ceramic Technology To Industry Boride P Roduct SSamsu SamsNo ratings yet

- The Order of Historical Time: The Longue Durée and Micro-HistoryDocument17 pagesThe Order of Historical Time: The Longue Durée and Micro-HistoryGeorgia KoutaNo ratings yet

- DuctDocument100 pagesDuctSam100% (2)

- RHH and LTSH links overviewDocument4 pagesRHH and LTSH links overviewrpshvjuNo ratings yet

- L-03 Spring Loaded Foundation-PresentationDocument34 pagesL-03 Spring Loaded Foundation-PresentationSam100% (1)

- Turbine Operation PMIDocument43 pagesTurbine Operation PMInikesh ranjan100% (1)

- Automatic Turbine TestorDocument26 pagesAutomatic Turbine TestorSam100% (2)

- Generator ClassDocument93 pagesGenerator ClassSam100% (5)

- Auxiliary Power Supply System OverviewDocument21 pagesAuxiliary Power Supply System Overviewpramod_nandaNo ratings yet

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNo ratings yet

- Performance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFDocument9 pagesPerformance Analysis of Surface Condenser in 525MW Thermal Power Plant PDFJeeEianYannNo ratings yet

- B-Asic of Super Critical Boiler (660mw)Document48 pagesB-Asic of Super Critical Boiler (660mw)Arvind Shukla100% (1)

- Procedure For Commissioning of Auxiliary Prds SystemDocument14 pagesProcedure For Commissioning of Auxiliary Prds SystemJackSparrow86100% (1)

- 2nd Control of BoilerDocument14 pages2nd Control of BoilerMuanifNo ratings yet

- Disclosure To Promote The Right To InformationDocument22 pagesDisclosure To Promote The Right To InformationJGD123No ratings yet

- Jindal Power SOP Load Shedding RelayDocument4 pagesJindal Power SOP Load Shedding RelayChandramani PatelNo ratings yet

- Cold Startup Procedure 250 MWDocument7 pagesCold Startup Procedure 250 MWPrudhvi RajNo ratings yet

- Introduction To Turbovisory InstrumentsDocument40 pagesIntroduction To Turbovisory InstrumentsSam0% (1)

- NK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraDocument28 pagesNK - 008 Approved Procedure For STEAM BLOWING of North KaranpuraHimanshu ChaturvediNo ratings yet

- StepsDocument62 pagesStepsSam100% (1)

- A320 CBT Test 1 PDFDocument107 pagesA320 CBT Test 1 PDFCesarNo ratings yet

- Turbine Working & ItsComponentsDocument88 pagesTurbine Working & ItsComponentsHimanshu spoliaNo ratings yet

- 500mw Checking and Setting of Hydraulic and ElectroDocument15 pages500mw Checking and Setting of Hydraulic and Electrothangarajm1984No ratings yet

- SDH TechnologyDocument26 pagesSDH TechnologyJayesh SinghalNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- Automatic Turbine Tester EeDocument17 pagesAutomatic Turbine Tester EeSam100% (1)

- Role of Maintenance in Boiler Energy ConservationDocument125 pagesRole of Maintenance in Boiler Energy ConservationkkannanmtpsNo ratings yet

- NeedsDocument66 pagesNeedsSamNo ratings yet

- Boiler fouling and slagging prevention with intelligent sootblowingDocument8 pagesBoiler fouling and slagging prevention with intelligent sootblowingSuganya LokeshNo ratings yet

- HP Bypass Valve Data SheetDocument8 pagesHP Bypass Valve Data Sheetcasno4427No ratings yet

- Infrastructure in Power Project 1Document51 pagesInfrastructure in Power Project 1SamNo ratings yet

- Equipment at HPSDocument60 pagesEquipment at HPSSam100% (1)

- CC PumpsDocument38 pagesCC PumpsvijaykrishnatennetiNo ratings yet

- Curtis CatalogDocument9 pagesCurtis CatalogtharngalNo ratings yet

- L-2 Presentation Gen Mech AuxDocument36 pagesL-2 Presentation Gen Mech AuxSam100% (1)

- To Reduce Auxiliary PowerDocument15 pagesTo Reduce Auxiliary PowerMohit GuptaNo ratings yet

- VSLP 1×135MW Power Plant Turbine RulesDocument148 pagesVSLP 1×135MW Power Plant Turbine RulesSakthi Sekar CbiNo ratings yet

- MS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Document12 pagesMS 06 21 - Boiler Startup Frim Cold (Rev A - 03.01.12)Prakash WarrierNo ratings yet

- TG Referal DatapediaDocument20 pagesTG Referal Datapediajp mishraNo ratings yet

- ATTDocument3 pagesATTforu_kkkNo ratings yet

- Dec 09Document35 pagesDec 09Krishnan SanthanarajNo ratings yet

- NTPC Rihand Standard Checklist:: System CommissioningDocument3 pagesNTPC Rihand Standard Checklist:: System Commissioningsrigirisetty208No ratings yet

- APHDocument3 pagesAPHMallinatha PNNo ratings yet

- CCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Document7 pagesCCTV Locations For 2 X 520 MW, IPP, HNPCL, Vishakhapatnam: BTG Unit-1Rupesh SinhaNo ratings yet

- NTPC Vindhyachal ReportDocument13 pagesNTPC Vindhyachal Reportblackswan_07No ratings yet

- Auxiliary Power Consumption Reduction in Thermal Power StationsDocument3 pagesAuxiliary Power Consumption Reduction in Thermal Power StationsbarunNo ratings yet

- Dokumen - Tips Coordinated Master Control in Thermal Power PlantDocument40 pagesDokumen - Tips Coordinated Master Control in Thermal Power Plant150819850No ratings yet

- Thermal insulation wool mattress quality standardsDocument4 pagesThermal insulation wool mattress quality standardsjagan100% (1)

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- Lalitpur Superthermal Power Project - 3 X 660 MWDocument10 pagesLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNo ratings yet

- 2 HP WTR Hdr-Seal Trough FlushingDocument10 pages2 HP WTR Hdr-Seal Trough Flushingsekhar_ntpcNo ratings yet

- Difficulties FacedDocument6 pagesDifficulties FacedJackSparrow86No ratings yet

- O & M Manual Ut-13000 - Dalmia DSP Unit-1Document62 pagesO & M Manual Ut-13000 - Dalmia DSP Unit-1ranjan shiveshNo ratings yet

- Essential Interlocks and Protections for Feed Water and Condensate SystemsDocument18 pagesEssential Interlocks and Protections for Feed Water and Condensate SystemsSanjay GuptaNo ratings yet

- EID PARRY TURBINE POOR VACUUMDocument4 pagesEID PARRY TURBINE POOR VACUUMCharu ChhabraNo ratings yet

- Soot BlowerDocument6 pagesSoot BlowerSamNo ratings yet

- WRITE UP ON AUTOMATIC TURBINE TESTERDocument14 pagesWRITE UP ON AUTOMATIC TURBINE TESTERlp mishraNo ratings yet

- Boiler Light-Up PrerequisitesDocument3 pagesBoiler Light-Up PrerequisitesmallavscNo ratings yet

- Gland Steam Pressure For ReferenceDocument5 pagesGland Steam Pressure For ReferencebalajimechanicalNo ratings yet

- R&RDocument15 pagesR&Rajitseth1050% (2)

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Document74 pagesPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Mohit MalikNo ratings yet

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDocument41 pagesBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNo ratings yet

- 09 ATRS - STDDocument45 pages09 ATRS - STDSam100% (1)

- CW, CWR & CWX Pumps Installation, Operation and Maintenance ManualDocument20 pagesCW, CWR & CWX Pumps Installation, Operation and Maintenance ManualNadeemNo ratings yet

- Technical Diary Turbine KSKDocument31 pagesTechnical Diary Turbine KSKdreamboy87100% (1)

- ID FD PA Logic SystemDocument11 pagesID FD PA Logic SystemThirumalNo ratings yet

- Bhel Pipe Color Code-Aa10630 1Document7 pagesBhel Pipe Color Code-Aa10630 1Vamsikrishna LakamsaniNo ratings yet

- Ind Bharat Energy (Utkal) LTD (English)Document11 pagesInd Bharat Energy (Utkal) LTD (English)Prateek DubeyNo ratings yet

- Kawasaki's Presentation on FGD and SCR SystemsDocument20 pagesKawasaki's Presentation on FGD and SCR Systemsjitendrashukla10836No ratings yet

- Final YearDocument51 pagesFinal YearAnand Kumar0% (1)

- How To Deal Emergencies in Thermal Power PlantDocument4 pagesHow To Deal Emergencies in Thermal Power PlantEr Mahendra KeshriNo ratings yet

- FANS: Types, Features, Selection FactorsDocument15 pagesFANS: Types, Features, Selection FactorsgvprambabuNo ratings yet

- Aux Steam SystemDocument14 pagesAux Steam Systemsanjeevchhabra100% (1)

- FeedwaterDocument55 pagesFeedwaternaresh977977No ratings yet

- An Ode To SilenceDocument1 pageAn Ode To SilenceSamNo ratings yet

- Recording, Reporting of OutputDocument30 pagesRecording, Reporting of OutputSam100% (3)

- User PPT Acmotors1Document88 pagesUser PPT Acmotors1SamNo ratings yet

- Overview of Hydro Power ProjectDocument21 pagesOverview of Hydro Power ProjectSamNo ratings yet

- Ppe DisDocument12 pagesPpe DisSam100% (1)

- Accident - Causes & FactorsDocument38 pagesAccident - Causes & FactorsSam100% (1)

- Feedwater SystemDocument70 pagesFeedwater SystemishanpahwaNo ratings yet

- Causes, Factors, CostDocument37 pagesCauses, Factors, CostSamNo ratings yet

- 1 Elect ActuatlorDocument29 pages1 Elect ActuatlorSamNo ratings yet

- Biogen 2021Document12 pagesBiogen 2021taufiq hidNo ratings yet

- ASP Flashcards - QuizletDocument36 pagesASP Flashcards - QuizletRehman MuzaffarNo ratings yet

- DC Machines Chapter SummaryDocument14 pagesDC Machines Chapter SummaryMajad RazakNo ratings yet

- c1Document19 pagesc1vgnagaNo ratings yet

- F 2786538d6cdc0bb1Document245 pagesF 2786538d6cdc0bb1Daniel HarutyunyanNo ratings yet

- Rodi TestSystem EZSDI1 Iom D603Document25 pagesRodi TestSystem EZSDI1 Iom D603Ricardo AndradeNo ratings yet

- 1.11 CHEM FINAL Chapter 11 Sulfuric AcidDocument21 pages1.11 CHEM FINAL Chapter 11 Sulfuric AcidSudhanshuNo ratings yet

- Astm D5501Document3 pagesAstm D5501mhmdgalalNo ratings yet

- Metacentric Height: From Wikipedia, The Free EncyclopediaDocument6 pagesMetacentric Height: From Wikipedia, The Free EncyclopediaВладимир ШевченкоNo ratings yet

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDocument16 pagesGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNo ratings yet

- Ferrites and AccessoriesDocument11 pagesFerrites and AccessoriesMaulik ShahNo ratings yet

- Database Classification TypesDocument10 pagesDatabase Classification TypesBhiea Mische MatilacNo ratings yet

- Unit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharDocument18 pagesUnit 3: Databases & SQL: Developed By: Ms. Nita Arora Kulachi Hansraj Model School Ashok ViharAthira SomanNo ratings yet

- DbintfcDocument80 pagesDbintfchnr.uninstallNo ratings yet

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioNo ratings yet

- CS 102 Programming Fundamentals Lecture NotesDocument14 pagesCS 102 Programming Fundamentals Lecture NotesOkay OkayNo ratings yet

- Bash 101 Hacks PDFDocument5 pagesBash 101 Hacks PDFAmira A MarreiNo ratings yet

- IMChap 014 SDocument14 pagesIMChap 014 STroy WingerNo ratings yet

- Visualizing Interstellar WormholesDocument14 pagesVisualizing Interstellar WormholesFranciscoNo ratings yet

- Uncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)Document5 pagesUncompacted Void Content of Fine Aggregate (As Influenced by Particle Shape, Surface Texture, and Grading)ROBERTO MIRANDANo ratings yet

- Haidarali-MR-2011-PhD-Thesis 01 PDFDocument378 pagesHaidarali-MR-2011-PhD-Thesis 01 PDFIbrahim KhanNo ratings yet