Professional Documents

Culture Documents

Types of Propellers and Their Construction

Uploaded by

Zhenyan ChenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Types of Propellers and Their Construction

Uploaded by

Zhenyan ChenCopyright:

Available Formats

Propeller, Types of Propellers and Construction of Propellers

by Anish 4 December 2010 3 Comments A propeller is a rotating fan like structure which is used to propel the ship by using the power generated and transmitted by the main engine of the ship. The transmitted power is converted from rotational motion to generate a thrust which imparts momentum to the water, resulting in a force that acts on the ship and pushes it forward. A ship propels on the basis of Bernoullis principle and Newtons third law. A pressure difference is created on the forward and aft side of the blade and water is accelerated behind the blades. The thrust from the propeller is transmitted to move the ship through a transmission system which consists of a rotational motion generated by the main engine crank shaft, intermediate shaft and its bearings, stern tube shaft and its bearing and finally by the propeller itself.

Material and Construction of Propeller Marine propellers are made from corrosion resistant materials as they are made operational directly in sea water which is a corrosion accelerator. The materials used for making marine propeller are alloy of aluminium and stainless steel. Other popular materials used are alloys of nickel, aluminium and bronze which are 10~15 % lighter than other materials and have higher strength. The construction process of the propeller includes attaching a number of blades to the hub or boss by welding or forging in one piece. Forged blades are highly reliable and have greater strength but are expensive as compare to welded ones. A marine propeller is constructed by sections of helicoidal surfaces acting together to rotate through water with a screw effect. Types of Propeller Propellers are be classified on the basis of several factors. The classification of different types of propellers is shown below: A) Classification by Number of Blades Attached: Propeller blades may vary from 3 blade propeller to 4 blade propeller and sometimes even 5 blade propeller. However, the most commonly used are 3 blades and 4 blade propellers. 3 blade propeller:

A 3 blade propeller has following characteristics: The manufacturing cost is lower than other types. - Are normally made up of aluminium alloy. - Gives a good high speed performance. - The acceleration is better than other types. - Low speed handling is not much efficient. 4 blade propeller:

A 4 blade propeller has following characteristics: - The manufacturing cost is higher than 3 blade propellers. - 4 blade propellers are normally made up of stainless steel alloys. - Have better strength and durability. - Gives a good low speed handling and performance. - Has a better holding power in rough seas. - 4 blade propeller provides a better fuel economy than all the other types. 5 blade propeller:

A 5 blade propeller has following characteristics: - Manufacturing cost is higher of all. - Vibration is minimal from all the other types. - 5 blade propellers have better holding power in rough seas. B) Classification By pitch of the blade: Pitch of a propeller can be defined as the displacement that a propeller makes for every full revolution of 360 The classification of the propellers on the basis of pitch is as follows. . Fixed Pitch Propeller: The blades in fixed pitch propeller are permanently attached to the hub. The fixed pitch type propellers are casted and the position of the blades and hence the position of the pitch is permanently fixed and cannot be changed during the operation. Fixed pitch propellers are robust and reliable as the system doesnt incorporate any mechanical and hydraulic connection as in Controlled Pitch Propeller (CPP). The manufacturing, installation and operational costs are lower than controlled pitch propeller (CPP) type. The manoeuvrability of fixed pitch propeller is also not as good as CPP. Controllable Pitch Propeller: In Controlled Pitch type propeller, it is possible to alter the pitch by rotating the blade about its vertical axis by means of mechanical and hydraulic arrangement. This helps in driving the propulsion machinery at constant load with no reversing mechanism required as the pitch can be altered to match the required operating condition. Thus the manoeuvrability improves and the engine efficiency also increases.

This drawback includes the possibility of oil pollution as the hydraulic oil in the boss which is used for controlling the pitch may leak out. It is a complex and expensive system from both installation and operational point. Moreover, the pitch can get stuck in one position, making it difficult to manoeuvre the engine.

You might also like

- 4 Blades PropellersDocument12 pages4 Blades PropellersFernando Raúl LADINONo ratings yet

- United States Patent: (22l Fned' Lan' 14' 1974 Tivelyg' On Iopposite Sides Thereoftgare Disposezi Betvi/jeenDocument12 pagesUnited States Patent: (22l Fned' Lan' 14' 1974 Tivelyg' On Iopposite Sides Thereoftgare Disposezi Betvi/jeenاحمد عبدالكريمNo ratings yet

- United States Patent: SimpsonDocument5 pagesUnited States Patent: Simpsonاحمد عبدالكريمNo ratings yet

- Sept. 3, 1940.: Filed May 9, 1958Document7 pagesSept. 3, 1940.: Filed May 9, 1958احمد عبدالكريمNo ratings yet

- June 5, 1923. 1,457,961: Filed April 13, 1921 5 Sheets-Sheet 1Document17 pagesJune 5, 1923. 1,457,961: Filed April 13, 1921 5 Sheets-Sheet 1cll1968No ratings yet

- Browning Proto US1457961Document17 pagesBrowning Proto US1457961apoorva singhNo ratings yet

- Nomencleature of PropellerDocument2 pagesNomencleature of PropellerPavan KishoreNo ratings yet

- Design and Analysis of Propeller BladeDocument6 pagesDesign and Analysis of Propeller Bladechethan mahadevNo ratings yet

- Get. 31, 1944. I I G - Munro 2,361,409: Filed Dec. 2, 1943Document4 pagesGet. 31, 1944. I I G - Munro 2,361,409: Filed Dec. 2, 1943احمد عبدالكريمNo ratings yet

- 1978 ITTC Performance PredictionDocument31 pages1978 ITTC Performance PredictionqursenNo ratings yet

- DNV CN41-5Document9 pagesDNV CN41-5Constantinos IvNo ratings yet

- ITTC - Recommended Procedures: Performance, Propulsion 1978 ITTC Performance Prediction MethodDocument31 pagesITTC - Recommended Procedures: Performance, Propulsion 1978 ITTC Performance Prediction MethodAlfredoLopezNo ratings yet

- Draft Survey - Bulk Vessels LoadingDocument5 pagesDraft Survey - Bulk Vessels LoadingSoubam Luxmibai100% (1)

- Analysis and Design of Ship StructureDocument76 pagesAnalysis and Design of Ship StructureRicardo Pizá FernándezNo ratings yet

- Lehm0028 00Document4 pagesLehm0028 00Aidel MustafaNo ratings yet

- WA2-1-Jurgens - Voith Schneider Propeller (VSP) - Investigations of TH PDFDocument11 pagesWA2-1-Jurgens - Voith Schneider Propeller (VSP) - Investigations of TH PDFAndre OliveiraNo ratings yet

- Propeller Terminology - Michigan Wheel MarineDocument9 pagesPropeller Terminology - Michigan Wheel Marinerafael espinosa semperNo ratings yet

- RudderDocument33 pagesRuddertribleprinceNo ratings yet

- In-Service Performance of Aluminum Structural DetailsDocument114 pagesIn-Service Performance of Aluminum Structural DetailsMahdiNo ratings yet

- INDIAN MARITIME UNIVERSITY NSTL Lab reportDocument4 pagesINDIAN MARITIME UNIVERSITY NSTL Lab reportAnkit GhoshNo ratings yet

- Us 1001260Document5 pagesUs 1001260mehdi parsNo ratings yet

- Tanker stability report analysisDocument42 pagesTanker stability report analysisNikola DjordjevicNo ratings yet

- Modelmaker Revision02Document43 pagesModelmaker Revision02AngelNo ratings yet

- Self Propulsion Tests: Marine Engineering 2019Document23 pagesSelf Propulsion Tests: Marine Engineering 2019Yalqa RizqiNo ratings yet

- Design and Construction of High Speed, Hard Chine Planing HullDocument8 pagesDesign and Construction of High Speed, Hard Chine Planing Hullkhristc15No ratings yet

- Stability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactDocument6 pagesStability Calculation - Immersing: Loadcase - Immersing Damage Case - IntactfahmiNo ratings yet

- Propeller Testing and Performance CurvesDocument6 pagesPropeller Testing and Performance CurvespothirajkalyanNo ratings yet

- Michigan Wheel Propeller GeometryDocument18 pagesMichigan Wheel Propeller GeometryAdelia PratiwiNo ratings yet

- Tuning A Twin-Screw Rudder InstallationDocument6 pagesTuning A Twin-Screw Rudder Installationaeromexpower2009No ratings yet

- Types of Rudders Used For ShipsDocument8 pagesTypes of Rudders Used For Shipsนัทเดช เรืองสวนNo ratings yet

- Loadings Affecting On Boats and Small Craft: Markku Hentinen 2016Document12 pagesLoadings Affecting On Boats and Small Craft: Markku Hentinen 2016notengofffNo ratings yet

- Strength of Marine Propeller BladesDocument23 pagesStrength of Marine Propeller BladesLijo Thoams100% (3)

- Design of Propulsion Systems For High-Speed CraftDocument17 pagesDesign of Propulsion Systems For High-Speed Craftaeromexpower2009No ratings yet

- Arquitectura Naval para IngenierosDocument109 pagesArquitectura Naval para IngenierosRafael Medina100% (1)

- Operation & Maintenance ManualDocument21 pagesOperation & Maintenance ManualMohammed BasionyNo ratings yet

- Ship Design Concept From NarcikiDocument6 pagesShip Design Concept From NarcikiFerdy Fer DNo ratings yet

- Jack Up TestDocument3 pagesJack Up TestGermán AguirrezabalaNo ratings yet

- 3512B B 861bkW 1155bhp 1200rpmDocument6 pages3512B B 861bkW 1155bhp 1200rpmFernandez Gonzalo100% (1)

- Propulsion ExperimentDocument21 pagesPropulsion ExperimentJayElfNo ratings yet

- ON APPLICATION OF PARAMETRIC METHOD FOR DESIGN OF PLANING CRAFTDocument11 pagesON APPLICATION OF PARAMETRIC METHOD FOR DESIGN OF PLANING CRAFTsowole olantunNo ratings yet

- Saddle Wear Plate DesignDocument2 pagesSaddle Wear Plate DesignsterlingNo ratings yet

- Hydrodynamic Design andDocument36 pagesHydrodynamic Design andMini DangNo ratings yet

- But What Is A Fixed Pitch Propeller or The FPP?Document7 pagesBut What Is A Fixed Pitch Propeller or The FPP?Baso AmirullahNo ratings yet

- Damen Stan Tender: General Deck Lay-OutDocument2 pagesDamen Stan Tender: General Deck Lay-Outvov1302No ratings yet

- High Speed Propulsion SystemsDocument14 pagesHigh Speed Propulsion SystemsVu ThongNo ratings yet

- Modern Marine Internal Combustion Engines A Technical and Historical Overview 1st Ed 9783030497484 9783030497491 CompressDocument395 pagesModern Marine Internal Combustion Engines A Technical and Historical Overview 1st Ed 9783030497484 9783030497491 Compressilliashapshalov38No ratings yet

- PromasDocument3 pagesPromasbagci_1No ratings yet

- Hydrodynamic Support PresentationDocument108 pagesHydrodynamic Support PresentationAnonymous 95XksLBPZNo ratings yet

- 45m Ferry Equipment List Rev 1Document3 pages45m Ferry Equipment List Rev 1bdthanhvkct100% (1)

- PropellerDocument25 pagesPropellerNima ConquistadorNo ratings yet

- Co Axial Propeller 2dDocument30 pagesCo Axial Propeller 2dKalai SelvanNo ratings yet

- Co Axial PropellerDocument31 pagesCo Axial PropellerKalai SelvanNo ratings yet

- PROPELLERSDocument53 pagesPROPELLERSMohd akifNo ratings yet

- Types of PropellersDocument13 pagesTypes of PropellersNEXNo ratings yet

- How Ships Steer: Rudder and Propeller TypesDocument25 pagesHow Ships Steer: Rudder and Propeller TypesNikz Masbate100% (2)

- Types of Propellers and MaterialsDocument3 pagesTypes of Propellers and MaterialsMariza Margueritte VillacampaNo ratings yet

- High Speed MArine VehiclesDocument11 pagesHigh Speed MArine VehiclesAnonymous e3ceN15No ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Importance of TextbookDocument16 pagesImportance of TextbookZhenyan ChenNo ratings yet

- Countable NounsDocument1 pageCountable NounsZhenyan ChenNo ratings yet

- Maintaining Fire Safety Equipment and SuppliesDocument20 pagesMaintaining Fire Safety Equipment and SuppliesZhenyan ChenNo ratings yet

- Captain's Maritime VocabularyDocument16 pagesCaptain's Maritime VocabularyZhenyan ChenNo ratings yet

- Captain's Maritime VocabularyDocument16 pagesCaptain's Maritime VocabularyZhenyan ChenNo ratings yet

- STCW Guide EnglishDocument78 pagesSTCW Guide EnglishBenja87100% (7)

- MarEng Grammar LIST OF IRREGULAR VERBSDocument3 pagesMarEng Grammar LIST OF IRREGULAR VERBSZhenyan ChenNo ratings yet

- Maintaining Fire Safety Equipment and SuppliesDocument20 pagesMaintaining Fire Safety Equipment and SuppliesZhenyan ChenNo ratings yet

- Captain's Maritime English Vocabulary II-02Document30 pagesCaptain's Maritime English Vocabulary II-02Zhenyan ChenNo ratings yet

- Familiarization TrainingDocument3 pagesFamiliarization TrainingZhenyan ChenNo ratings yet

- China's Actions in Hunt For Jet Are Seen As Hurting As Much As HelpingDocument5 pagesChina's Actions in Hunt For Jet Are Seen As Hurting As Much As HelpingZhenyan ChenNo ratings yet

- Foreign Teacher WantedDocument2 pagesForeign Teacher WantedZhenyan ChenNo ratings yet

- A Good Guide To Being A Bad GirlDocument3 pagesA Good Guide To Being A Bad GirlZhenyan ChenNo ratings yet

- 游轮词汇Document4 pages游轮词汇Zhenyan ChenNo ratings yet

- AIS WorksDocument1 pageAIS WorksZhenyan ChenNo ratings yet

- Cambridge English Proficiency (CPE) Use of English 1Document1 pageCambridge English Proficiency (CPE) Use of English 1Zhenyan ChenNo ratings yet

- IAMU Newsletter2006Document37 pagesIAMU Newsletter2006Zhenyan ChenNo ratings yet

- Citadels No Absolute Guarantee of Crew Security Against PiratesDocument1 pageCitadels No Absolute Guarantee of Crew Security Against PiratesZhenyan ChenNo ratings yet

- SRI CHAITANYA EDUCATIONAL INSTITUTIONS JR AIIMS S60 NEET-2024 SCHEDULEDocument5 pagesSRI CHAITANYA EDUCATIONAL INSTITUTIONS JR AIIMS S60 NEET-2024 SCHEDULEteen's teamNo ratings yet

- Aci-207.1r (1996) PDFDocument42 pagesAci-207.1r (1996) PDFFernando HerediaNo ratings yet

- Ip21 Hw10 SolDocument4 pagesIp21 Hw10 Sol吳昭亮No ratings yet

- B.sc. Electronics Honours SyllabusDocument10 pagesB.sc. Electronics Honours Syllabussiddhartharay007No ratings yet

- Design Wall NH-51Document46 pagesDesign Wall NH-51Navarun VashisthNo ratings yet

- 20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartDocument3 pages20Mnv6 Hollow Bar: Iso Stocked Sizesiso ChartretrogradesNo ratings yet

- Corrosion and Its Control NFDocument93 pagesCorrosion and Its Control NFAayu JainNo ratings yet

- Effect of Silica Fume On Mechanical Properties of High-Strength ConcreteDocument11 pagesEffect of Silica Fume On Mechanical Properties of High-Strength ConcreteMmm HhhhNo ratings yet

- Designand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationDocument17 pagesDesignand Performanceof Soft Ground Improvement Using PVDwithandwithout Vacuum ConsolidationShadabNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Heat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisDocument9 pagesHeat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisNhacaNo ratings yet

- Mini VRFDocument34 pagesMini VRFPaulo Vitor Santos100% (1)

- Section 3,4: Bending Deformation, Strain and Stress in BeamsDocument20 pagesSection 3,4: Bending Deformation, Strain and Stress in BeamsRasool AkhterianNo ratings yet

- 6 InertingDocument9 pages6 InertingHasan CosalevNo ratings yet

- Fluid Flow OperationDocument2 pagesFluid Flow OperationShubham imtsNo ratings yet

- Development of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsDocument10 pagesDevelopment of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsJulio BetancurNo ratings yet

- Semiconductor Assembly ProcessDocument22 pagesSemiconductor Assembly Processlabacahin100% (1)

- Film Coat of Ciprofloxacin Using HPC Ans PovidoneDocument67 pagesFilm Coat of Ciprofloxacin Using HPC Ans Povidonemohamed basheirNo ratings yet

- Determination of Copper by AASDocument18 pagesDetermination of Copper by AASWan ShamNo ratings yet

- Efficiency Improvement of Flat Plate Solar Collector Using ReflectorDocument6 pagesEfficiency Improvement of Flat Plate Solar Collector Using ReflectorAnonymous iHJPiQI7No ratings yet

- Centifugal+Chiller+ (1000+ +10000+kW) MideaDocument35 pagesCentifugal+Chiller+ (1000+ +10000+kW) MideaevrimkNo ratings yet

- Presentation VDocument51 pagesPresentation VGagan SrivastavaNo ratings yet

- Di Bella Et Al 2004Document13 pagesDi Bella Et Al 2004Emilio Patané SpataroNo ratings yet

- Doctoral Thesis by S ChaterjeeDocument159 pagesDoctoral Thesis by S ChaterjeeSaikat ChaterjeeNo ratings yet

- OK Tubrod 15.14Document1 pageOK Tubrod 15.14Tiberiu MunteanuNo ratings yet

- Coulomb's LawDocument6 pagesCoulomb's LawAarush MishraNo ratings yet

- Laws of MotionDocument5 pagesLaws of Motionkatie4834No ratings yet

- Activity Session 5 Earth Science ConseminoDocument32 pagesActivity Session 5 Earth Science ConseminoFatimah D. Rubin-Cansancio100% (2)

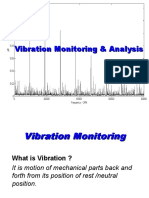

- Vibration Monitoring AnalysisDocument102 pagesVibration Monitoring AnalysisAlangghya Susatya Adigama100% (1)

- Alfa Laval Separartor s937 System DescriptionDocument14 pagesAlfa Laval Separartor s937 System DescriptionIgors VrublevskisNo ratings yet