Professional Documents

Culture Documents

Manual Version 3.4

Uploaded by

pjvansandwykCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Version 3.4

Uploaded by

pjvansandwykCopyright:

Available Formats

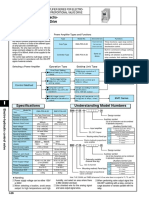

SYL-2342, SYL-2352 PID TEMPERATURE CONTROLLER

INSTRUCTION MANUAL

Version 4.5

AUBER INSTRUMENTS WWW.AUBERINS.COM

2011.12 P1/8

Instruction Manual

1. Specification

Input type

Thermocouple(TC): K, E, S, N, J, T, B, WRe5/26

RTD(Resistance temperature detector): Pt100, Cu50

DC Voltage: 0~5V, 1~5V, 0~1V,

-100~100mV, -20~20mV, -5~5V, 0.2~1V.

DC current : 0~10mA, 1~20mA, 4~20mA. (use external

shunt resistor for higher current)

Input range Please see section 4.7 for detail.

Accuracy

0.2% Full scale: RTD, linear voltage, linear current and

thermocouple input with ice point compensation or Cu50

copper compensation.

0.2%Full scale or 2 C: thermocouple input with internal

automatic compensation.

Note: for thermocouple B, the measurement accuracy of

0.2% can only be guaranteed when input range is between

600~1800 C.

Response time

0.5s (when FILt=0)

Display resolution 1 C, 1 F; or 0.1 C

Control mode

Fuzzy logic enhanced PID control

On-off control

Manual control

Output mode

Relay contact (NO): 250VAC/7A, 120V/10A, 24VDC/10A

SSR voltage output: 12VDC/30mA

Alarm output Relay contact. 250VAC/1A, 120VAC/3A, 24V/3A

Alarm function

Process high alarm, process low alarm, deviation high

alarm, and deviation low alarm

Manual function Automatic/Manual bumpless transfer

Power supply 85~260VAC/50~60Hz

Power consumption 5 Watt

Ambient temperature 0~50C, 32~122F

Dimension 48 x 48 x100 mm (WxHxD)

Mounting cutout 45 x 45 mm

2. Available Configurations Caution

This controller is intended to control equipment under normal operating

conditions. If failure or malfunction of the controller may lead to abnormal

operating conditions that may result in personal injury or damage to the

equipment or other property, devices (limit or safety controls) or systems

(alarm or supervisory) intended to warn of or protect against failure or

malfunction of the controller must be incorporated into and maintained as

part of the control system.

Installing the rubber gasket supplied will protect the controller front panel

from dust and water splash (IP54 rating). Additional protection is needed

for higher IP rating.

This controller carries a 90-day warranty. This warranty is limited to the

controller only.

Model Control output Ramp/soak option

SYL-2342 Relay contact output No

SYL-2352 SSR control output No

SYL-2342P Relay contact output Yes

SYL-2352P SSR control output Yes

All the models listed in table 1 are 1/16 DIN size with dual-alarm outputs.

Table 1. Controller models

3. Terminal Wiring

Figure 1. Wiring diagram

3.1 Sensor connection

Please refer to table 3 for the input sensor type (Sn) setting codes. The initial

setting for input is for a K type thermocouple. Set Sn to the right sensor code

if another sensor type is used.

3.1.1 Thermocouple

The thermocouple should be connected to terminals 4 and 5. Make sure that

the polarity is correct. There are two commonly used color codes for the K

type thermocouple. US color code uses yellow (positive) and red (negative).

Imported DIN color code uses red (positive) and green/blue (negative). The

temperature reading will decrease as temperature increases if the connection

is reversed.

When using ungrounded thermocouple that is in touch with a large

conductive subject, the electromagnetic field picked up by the sensor tip

might be too large for the controller to handle, the temperature display will

change erratically. In that case, connecting the shield of thermocouple to

terminal 5 (circuit ground of the controller) might solve the problem. Another

option is to connect the conductive subject to terminal 5.

3.1.2 RTD sensor

For a three-wire RTD with standard DIN color code, the two red wires should

be connected to the terminals 3 and 4. The white wire should be connected

to terminal 5. For a two-wire RTD, the wires should be connected to terminals

4 and 5. Jump a wire between terminals 3 and 4. Set controller input type, Sn

to 21.

3.1.3 Linear input (V, mV, mA or resistance)

V and mA current signal inputs should be connected between terminals 2

and 5. Terminal 2 is positive.

mV signal inputs should be connected between terminals 4 and 5. Terminal 4

is positive. For resistance inputs, short terminals 3 and 4, then connect

resistance inputs between terminals 4 and 5.

3.2 Power to the controller

The power cables should be connected to terminals 9 and 10. Polarity does

not matter. It can be powered by 85- 260V AC power source. Nei t her a

transformer nor jumper is needed to wire it up. For the sake of consistency

with the wiring example described later, we suggest you connect the hot wire

to terminal 9 and neutral to 10.

+

+

1

2

3

13 14 6

7

8

9

10

4

5

AL1 AL2

AC

85~260V

SSR

+

-

Model SYL-2352, SYL-2352P

RTD

R

R

W

TC

mA

V

-

+

+

1

2

3

13 14 6

7

8

9

10

4

5

RTD

R

R

W

TC

mA

V

AL1 AL2

AC

85~260V

Out

Model SYL-2342, SYL-2342P

+

-

+

AUBER INSTRUMENTS

WWW.AUBERINS.COM

2011.12 P2/8

3.3 Control output connection

The SSR control output of the controller SYL-2352 provides a 12V DC signal

that can control up to 5 SSRs in parallel. The rel ay out put of the controller

SYL-2342 can be used to turn on a contactor or a solenoid valve. It can drive

a smal l heater di rectl y i f the heater draws l ess than 10 Ampere when

connected to 120V AC power source. For applications needing two control

outputs, such as one for heating and another for cooling, relays AL1 or AL2

can be used for the second output with on/off control mode. Please see

Figure 11 for details.

3.3.1 Connecting the load through SSR (for SYL-2352)

Connect terminal 7 to the positive input and terminal 8 to the negative input of

the SSR. See Figure 8 and 9 for details.

3.3.2 Connecting the load through a contactor (for SYL-2342)

Assuming the controller is powered by 120V AC and the contactor has a 120V

AC coil, jump a wire between terminals 8 and 9. Connect terminal 7 to one

lead of the coil and terminal 10 to the other lead of the coil. Please see Figure

7 for example.

3.3.3. Connecting the heater (or cooler) directly from the internal relay

Assuming the controller and the load (heater or cooler) are powered by the

same voltage. Jump a wire from terminal 9 to 8. Connect terminal 7 to the one

lead of the load and terminal 10 to the other lead of the load. Please see

Figure 6 and 11 for details.

3.4 For first time users without prior experience with PID controllers, the

following notes may prevent you from making common mistakes.

3. 4. 1 Power to the heat er does not flow through terminal 9 and 10 of the

controller. The controller consumes less than 2 watts of power. It only

provides a control signal to the relay. Therefore, wires in the 18 to 26 gauge

range should be used for providing power to terminals 9 and 10. Thicker wires

may be more difficult to install.

3.4.2 The control relay outputs (for SYL-2342), -AL1 and AL2, are dry single

pole switches. They do not provide power by themselves. Please see Figure

6, 7 and 11 for how they are wired when providing a 120V output (or when

output voltage is the same as the power source for the controller). If the load

of the relay requires a different voltage than that for the controller, another

power source will be needed. See Figure 10 for examples.

3.4.3 SSR output power does not come from the input of the SSR. The output

of the SSR is a single pole switch between terminals 1 and 2 of the SSR. The

input of the SSR is for control, or triggering the SSR. (Please note we are

talking about the SSR itself, not the SSR control output of the controller).

When switching a North American 240V AC power, the heater will be live

even when the SSR is off. Users should install a double pole mechanical

switch to the power input.

3.4.4. For all controller models listed in this manual, the power is controlled by

regulating the duration of on time for a fixed period of time. It is not controlled

by regulating amplitude of the voltage or current. This is often referred as time

proportional control. e.g. If the cycle rate is set for 100 seconds, a 60% output

means controller will switch on the power for 60 seconds and off for 40

seconds (60/100=60%). Almost all high power control systems use time

proportional control because amplitude proportional control is too expensive

and inefficient.

4. Front Panel and Operation

QPV display: Indicates the sensor read out, or process value (PV).

SV display: Indicates the set value (SV) or output value (%).

AL1 indicator: It lights up when AL1 relay is on.

AL2 indicator: It lights up when AL2 relay is on.

A-M indicator: The light indicates that the controller is in manual mode. For

the controllers with the Ramp/Soak option, this light indicates that the

program is running.

Output indicator: It is synchronized with control output (terminal 7 and 8),

and the power to the load. When it is on, the heater (or cooler) is

powered.

SET key: When it is pressed momentarily, the controller will switch the

lower (SV) display between set value and percentage of output. When

pressed and held for two seconds will put the controller into paramet er

setting mode.

Automatic/Manual function key (A/M) /Data shift key

Decrement key : Decreases numeric value of the setting value.

Increment key : Increases numeric value of the setting value.

4.1 Display Status

Figure 2. Front panel

Display mode 1: When the power is turned on, the upper display window

shows the measured value (PV) and the lower window shows the four-digit set

value (SV).

Display mode 2: Press the SET key to change the display status into mode 2.

The upper display window shows the measured value (PV) and the lower

windows shows the output value. This picture shows the output percentage is

60% when in Automatic (PID) control mode. If parameter A-M=1 (see table 2),

pressing the A/M key will switch the controller between PID and Manual

control mode with the output unchanged. -This bumpless transfer allows the

controller to be switched between manual and automatic mode without the

output suddenly 'bumping' to a different value.

Display mode 3: Press the SET key for 2 seconds to enter the display mode

3. This mode allows users to change the system parameters.

4.2 Basic Operation

4.2.1 Changing set value (SV)

Press the or key once, and then release it. The decimal point on the

lower right corner will start to flash. Press the or key to change SV until

the desired value is displayed. If the change of SV is large, press the A/M key

to move the flashing decimal point to the desired digit that needs to be

changed. Then press the or key to start changing SV from that digit.

The decimal point will stop flashing after no key is pressed for 3 seconds. The

changed SV will be automatically registered without pressing the SET key.

Figure 3. Display modes

3

4

5

6

1

2

7 8 9 10

8888

8888

Power on

8 0 0.0

8 0 0.5

Display mode 1

8 0 0.0

A 6 0

8 0 0.0

M 60 means

output value=60%

on manual mode

Display mode 2

1 0 0 5

ALM1 (high limit alarm)=1005

Display mode 3

2S

+

Next parameter

M 6 0

A L M1

SET

SET

SET

A/M

SET A/M

A 60 means

output value=60%

on Automatic mode

PV

SV

PV

PV

AUBER INSTRUMENTS WWW.AUBERINS.COM

2011.12 P3/8

4.2.2 Display change

Press the SET key to change the display mode. The display can be changed

between display modes 1 and 2.

4.2.3 Manual/Automatic mode switch

Bumpless switching between PID mode and Manual mode can be performed

by pressing the A/M key. The A-M LED will light up when the controller is in

Manual mode. In Manual mode, the output amplitude can be increased or

decreased by pressing and (display mode 2).

Please note that manual control is initially disabled (A/M=2). To activate

the manual control, set A/M=0 or 1.

4.2.4 Parameter Setup Mode

When the display mode is 1 or 2, press SET and hold for roughly 2 seconds

until the parameter setup menu is displayed (display mode 3). Please refer to

4.3 for how to set the parameters.

4.3 Setup flow chart

Figure 4. System setup flow chart

SET

PV

SV

2S

SET

SET

SET

SET

SET

SET

SET

ALM1

Process high alarm

HY-1

9 9 9 9

Hy-1

Deviation high alarm

HY-2

9 9 9 9

Hy-2

Deviation low alarm

HY

0.3

Hy

Hysteresis band

AT

3

At

Control mode

I

1 0 0 0

I

Integral time

P

5 0 0

P

Proportional constant

SET

SET

SET

SET

SET

SET

SET

SET

t

2

t

Cycle time

SN

0

Sn

Input type

DP

0

dP

Decimal point position

Baud

9 6 0 0

Baud

Communication baud

filt

0

FILT

PV input filter

A-M

2

A-M

Running status

SET

SET

SET

SET

SET

SET

SET

SET

P-SH

2 5 0 0

P-SH

Display high limit

Pb

0.0

Pb

Input offset

Op-A

0

OP-A

Output mode

outL

0

OutL

Output low limit

OUtH

1 0 0

OutH

Output high limit

AL-P

1 7

AL-P

Alarm output definition

COOL

1 0

Cool

System function selection

Addr

1

Addr

Communication address

d

1 2 0

d

Derivative time

P-SL

- 1 0 0

P-SL

Display low limit

SET

SET

EP1-EP8

ALM1

1 0 0

ALM2

5 0

ALM2

Process low alarm

Locw

8 0 8

Lock

Configuration privilege

Code Description Setting Range Initial Setting Remarks

ALM1 Process high alarm -1999~+9999 C or F 100

ALM2 Process low alarm -1999~+9999 C or F 50

Hy-1 Deviation high alarm 0~9999 C or F 9999

Hy-2 Deviation low alarm 0~9999 C or F 9999

Hy Hysteresis Band

0~200.0 C or F

or 0~2000 for linear input

0.3 See 4.4.2

At Auto tuning

0~3. Set to 1 or 2 to start

auto tuning

3 See 4.4.3

I Integral time 0~9999 1000

P Proportional Constant 1~9999 % 500

d Derivative Time 0~2000 120

t Cycle time 2~125

2 for SSR

20 for relay

See 4.6

Sn Input type 0~37 0 (K type TC) See 4.7

dP Decimal point position 0~3 0 See 4.8

P-SL Display low limit -1999~+9999 C or F -100

P-SH Display high limit -1999~+9999 C or F 2500

Pb Input offset

-1999~+4000

-1999~+9999 C or F

0.0 See 4.10

OP-A Output mode 0~2 0 See 4.11

OUTL Output low limit 0~110 % 0

OUTH Output high limit 0~110 % 100

AL-P Alarm output definition 0-31 17 See 4.13

COOL

System function

selection

0~15 10

For heating and

F display, see 4.14

Addr Communication address 0~20 1 Ignore this setting

bAud Communication baud rate 0~19200 9600 Ignore this setting

FILt PV input filter 0~20 0 See 4.15

A-M

Automatic/Manual

status

0. Manual

1. Automatic

2. Manual suppressing

2

Manual control is

disabled. Set to 1 to

activate. See 4.16

LocK Configuration privilege 0~9999 808

All parameters are

unlocked. See 4.17

EP1-EP8

Field parameter

definition

nonE ~ A-M nonE

To be defined by

user. See 4.17

See 4.4.1

See 4.5.1

See 4.9

See 4.12

4.4.1 Alarm parameters

This controller offers four types of alarm, ALM1, ALM2, Hy-1, Hy-2.

ALM1: High limit absolute alarm. If the process value is greater than the

value specified as ALM1+Hy (Hy is the Hysteresis Band), then the alarm

will turn on. It will turn off when the process value is less than ALM1-Hy.

ALM2: Low limit absolute alarm. If the process value is less than the value

specified as ALM2-Hy, then the alarm will turn on, and the alarm will turn

off if the process value is greater than ALM2+Hy.

Hy-1: Deviation high alarm. If the temperature is above SV+Hy-1 +Hy,

the alarm will turn on, and the alarm will turn off if the process value is less

than SV+Hy-1 -Hy (we will discuss the role of Hy in the next section)

Hy-2: Deviation low alarm. If the temperature is below SV-Hy-2 -Hy, the

alarm will turn on, and the alarm will turn off if the temperature is greater

than SV-Hy-2 +Hy.

4.4 Parameter Setting

Table 2. System parameters

While in the parameter setup mode, use and to modify a digit and use

A/M to select the digit that needs to be modified. Press the A/M and SET key

at t he same t i me to exit the parameter setup mode. The instrument will

automatically exit if no key is pressed for 10 seconds. Figure 4 is the setup

flow chart.

Pl ease note the changed parameter will be automatically registered without

pressing the SET key. If the controller is locked ( see 4.17) , only limited

parameters (or no parameters) can be changed.

AUBER INSTRUMENTS WWW.AUBERINS.COM

2011.12 P4/8

The things you should know about alarm

1) Absolute alarm and deviation alarm

High (or low) limit absolute alarm is set by the specific temperatures that the

alarm will be on. Deviation high (or low) alarm is set by how many degrees

above (or below) the control target temperature (SV) that the alarm will be on.

e.g. Assuming ALM1=1000 F, Hy-1=5 F, SV=700 F. When the probe

temperature (PV) is above 705, the deviation alarm will be on. When the

temperature is above 1000 F, the process high alarm will be on. Later, when

SV changes to 600 F, the deviation alarm will be changed to 605 but process

high alarm will remain the same. Here the Hysteresis Band (Hy) setting is

ignored. Please see 4.5.2 for details.

2) Alarm Suppression feature

Sometimes, user may not want the low alarm to be turned on when starting

the controller at a temperature below the low alarm setting. The Alarm

Suppression feature will suppress the alarm from turning on when the

controller is powered up (or SV changes). The alarms can only be activated

after the PV has reached SV.

This feature is controlled by the B constant of the COOL parameter (see 4.14).

The default setting is alarm suppression on. If you use the AL1 or AL2 relay for

a control application that needs it to be active as soon as the controller is

powered up, you need to turn off the alarm suppression by setting B=0.

3) Assignment of the relays for the alarms

AL1 and AL2 are the name of the two relays used for alarm output. AL1 is the

alarm relay 1 and AL2 is alarm relay 2. Please do not confuse the relays with

alarm parameter ALM1 (process high alarm) and ALM2 (process low alarm).

Either the AL1 or the AL2 can be used for any of the four alarms. AL-P (alarm

output definition) is a parameter that allows you to select the relay(s) to be

activated when the alarm set condition is met.

You can set all four alarms to activate the one relay (AL1 or AL2), but you

cant activate both relays for with just one alarm.

4) Display of the alarm

When AL1 or AL2 relay is activated, the LED on the upper left will light up. If

you have multiple alarms assigned to a single relay, you might want to know

which alarm activated the relay. This can be done by setting the E constant in

the AL-P parameter (see 4.13). When E=0, the bottom display of the controller

will alternately display the SV and the activated alarm parameter.

5) Activate the AL1 and AL2 by time instead of temperature

For the controllers with the ramp and soak function (SYL-2342P and SYL-

2352P), AL1 and AL2 can be activated when the process reaches a specific

time. This is discussed in the section 3.7 of Supplementary Instruction Manual

for ramp/soak option.

4.4.2 Hysteresis Band Hy

The Hysteresis Band parameter Hy is also referred as Dead Band, or

Differential. It permits protection of the on/off control from high switching

frequency caused by process input fluctuation. Hysteresis Band parameter is

used for on/off control, 4-alarm control as well as the on/off control at auto

tuning. For example: 1) When controller is set for on/off heating control mode,

the output will turn off when temperature goes above SV+Hy and on again

when it drops to below SV-Hy. 2) If the high alarm is set at 800 F and

hysteresis is set for 2 F, the high alarm will be on at 802 F (ALM1+Hy) and

off at 798 F (ALM1-Hy).

Please note that the cycle time can also affect the action. If the temperature

passes the Hy set point right after the start of a cycle, the controller will not

respond to the Hy set point until the next cycle. If cycle time is set to 20

seconds, the action can be delay as long as 20 seconds. Users can reduce

the cycle time to avoid the delay.

tuning from the front panel is inhibited to prevent accidental re-starting of the

auto tuning process. To start auto tuning again, set At=1 or At=2.

4.5 Control action explanations

4.5.1 PID

Please note that because this controller uses fuzzy logic enhanced PID

control software, the definition of the control constants (P, I and d) are

different than that of the traditional proportional, integral, and derivative

parameters.

In most cases the fuzzy logic enhanced PID control is very adaptive and may

work well without changing the initial PID parameters. If not, users may need

to use auto-tune function to let the controller determine the parameters

automatically. If the auto tuning results are not satisfactory, you can manually

fine-tune the PID constants for improved performance. Or you can try to

modify the initial PID values and perform auto tune again. Sometimes the

controller will get the better parameters.

The auto-tune can be started in two ways. 1) Set At=2. It will start

automatically after 10 seconds. 2) Set At=1. Then you can start the auto-tune

any time during the normal operation by pressing the A/M key. During auto

tuning, the instrument executes on-off control. After 2-3 times on-off action,

the microprocessor in the instrument will analyze the period, amplitude,

waveform of the oscillation generated by the on-off control, and calculate the

optimal control parameter value. The instrument begins to perform accurate

artificial intelligence control after auto tuning is finished. If you want to exit

from auto tuning mode, press and hold the (A/M) key for about 2 seconds

until the blinking of "At" symbol is stopped in the lower display window.

Generally, you will only need perform auto tuning once. After the auto tuning

is finished. The instrument will set parameter At to 3, which will prevent the

(A/M) key from triggering auto-tune. This will prevent an accidental repeat of

the auto-tuning process.

(1) Proportional constant P

Please note the P constant is not defined as Proportional Band as in the

traditional model. Its unit is not in degrees. A larger constant results in larger

and quicker action, which is the opposite of the traditional proportional band

value. It also functions in the entire control range rather than a limited band.

If you are controlling a very fast response system (>1 F/second) that fuzzy

logic is not quick enough to adjust, set P=1 will change the controller to the

traditional PID system with a moderate gain for the P.

(2) Integral time I

Integral action is used to eliminate offset. Larger values lead to slower action.

Increase the integral time when temperature fluctuates regularly (system

oscillating). Decrease it if the controller is taking too long to eliminate the

temperature offset. When I =0, the system becomes a PD controller.

(3) Derivative time D

Derivative action can be used to minimize the temperature over-shoot by

responding to its rate of change. The larger the number, the faster the action.

4.4.3 Control mode At

At=0 On/off control. It works like a mechanical thermostat. It is suitable for

devices that do not like to be switched at high frequency, such as motor and

valves. See 4.5.2 for details.

At=1 Gets the controller ready to start the Auto tuning process by pressing the

A/M key.

At=2 Start auto tuning. The function is the same as starting auto tuning from

front panel.

At=3 This configuration is automatically set after auto tuning is done. Auto

4.5.2 On/off control mode

It is necessary for inductive loads such as motors, compressors, or solenoid

valves that do not like to take pulsed power. It works like a mechanical

thermostat. When the temperature passes the set point, the heater (or

cooler) will be turned off. When the temperature drops back to below the

hysteresis band (Hy) the heater will turn on again.

To use the On/off mode, set At=0. Then, set the Hy to the desired range

based on control precision requirements. Smaller Hy values result in tighter

temperature control , but al so cause the on/off acti on to occur more

frequently.

PV

SV

SV-Hy

100

97

Relay On

When heating, At=0

If PV(SV-Hy), relay on

If PV(SV+Hy), relay off

(SV=100, Hy=3)

Figure 5. On/off control mode

SV+Hy 103

AUBER INSTRUMENTS

2011.12 P5/8

Sn code Input device Display range (C) Display range (F)

0 K (thermocouple) -50~+1300 -58~2372

1 S(thermocouple) -50~+1700 -58~3092

2 WRe (5/26) (thermocouple) 0~2300 32~4172

3 T (thermocouple) -200~350 -328~662

4 E (thermocouple) 0~800 32~1472

5 J (thermocouple) 0~1000 32~1832

6 B (thermocouple) 0~1800 32~3272

7 N (thermocouple) 0~1300 32~2372

20 Cu50 (RTD) -50~+150 -58~302

21 Pt100 (RTD) -200~+600 -328~1112

26 0~80

27 0~400

28 0~20mV

29 0~100 mV

30 0~60 mV

31 0~1V

32

0.2~1V

4-20mA (w/ 50 Resistor)

33

1~5V

4~20mA (w/ 250 Resistor)

34 0~5V

35 -20~+20mV

36 -100~+100mV

37 -5V~+5V

-1999~+9999 Defined by user

with P-SL and P-SH

4.7 Input selection code for Sn

Table 3. Code for Sn and its range.

4.12 Output range limits OUTL and OUTH

OUTL and OUTH allow you set the output range low and high limit.

OUTL is a useful feature for a system that needs to have a minimum amount

of power as long as the controller is powered. e.g. If OUTL=20, the controller

will maintain a minimum of 20% power output even when input sensor failed.

OUTH can be used when you have an overpowered heater to control a small

subject. e.g. If you set the OUTH=50, the 5000 watt heater will be used as

2500W heater (50%) even when the PID wants to send 100% output.

4.13 Alarm output definition AL-P

Parameter AL-P may be configured in the range of 0 to 31. It is used to

define which alarms (ALM1, ALM2, Hy-1 and Hy-2) is output to AL1 or

AL2. Its function is determined by the following formula:

AL-P=AX1+BX2+CX4+DX8+EX16

If A=0, then AL2 is activated when Process high alarm occurs;

If A=1, then AL1 is activated when Process high alarm occurs;

If B=0, then AL2 is activated when Process low alarm occurs;

If B=1, then AL1 is activated when Process low alarm occurs;

If C=0, then AL2 is activated when Deviation high alarm occurs;

If C=1, then AL1 is activated when Deviation high alarm occurs;

If D=0, then AL2 is activated when Deviation low alarm occurs;

If D=1, then AL1 is activated when Deviation low alarm occurs;

If E=0, then alarm types, such as ALM1 and ALM2 will be displayed

alternatively in the lower display window when the alarms are on. This makes

it easier to determine which alarms are on.

If E=1, the alarm will not be displayed in the lower display window (except for

orAL). Generally this setting is used when the alarm output is used for

control purposes.

For example, in order to activate AL1 when a Process high alarm occurs,

trigger AL2 by a Process low alarm, Deviation high alarm, or Deviation low

alarm, and not show the alarm type in the lower display window, set A=1,

B=0, C=0, D=0, and E=1. Parameter AL-P should be configured to:

AL-P=1X1+0X2+0X4+0X8+1X16=17 (this is the factory default setting)

Note: Unlike controllers that can be set to only one alarm type (either

absolute or deviation but not both at same time), this controller allows both

alarm types to function simultaneously. If you only want one alarm type to

function, set the other alarm type parameters to maximum or minimum

(ALM1, Hy-1 and Hy-2 to 9999, ALM2 to 1999) to stop its function.

4.14 COOL for Celsius, Fahrenheit, Heating, and Cooling Selection

Parameter COOL is used to set the display unit, heating or cooling, and

alarm suppression. Its value is determined by the following formula:

COOL=AX1+BX2+CX8

A=0, reverse action control mode for heating control.

4.5.3. Manual mode

Manual mode allows the user to control the output as a percentage of the

total heater power. It is like a dial on a stove. The output is independent of the

temperature sensor reading. One application example is controlling the

strength of boiling during beer brewing. You can use the manual mode to

control the boiling so that it will not boil over to make a mess. The manual

mode can be switched from PID mode but not from On/off mode. This

controller offers a bumpless switch from the PID to manual mode. If the

controller outputs 75% of power at PID mode, the controller will stay at 75%

when it is switched to the manual mode, until it is adjusted manually. See

Figure 3 for how to switch the display mode. The Manual control is initially

disabled (A/M=2). To activate the manual control, set A/M=0 or 1.

4.6 Cycle time t

It is the time period (in seconds) that the controller uses to calculate its

output. e.g. When t=2, if the controller decides output should be 10%, the

heater will be on 0.2 second and off 1.8 seconds for every 2 seconds. Smaller

t values result in more precision control. For SSR output, t is set at the

minimum (2 seconds). For relay or contactor output, it should be set longer to

prevent contacts from wearing out too soon. Normally it is set to 20~ 4 0

seconds.

4.8 Decimal point setting dP

1) In case of thermocouple or RTD input, dP is used to define temperature

display resolution.

dP=0, temperature display resolution is 1 C (F).

dP=1, temperature display resolution is 0.1 C . The 0.1 degree resolution is

only available for Celsius display. The temperature will be displayed at the

resolution of 0.1 C for input below 1000 C and 1 C for input over 1000 C.

2) For linear input devices (voltage, current or resistance input, Sn=26-37)

Table 4. dP parameter setting

4.9 Limiting the control range, P-SH and P-SL

1) For temperature sensor input, the P-SH and P-SL values define the set

value range. P-SL is the low limit, and P-SH is the high limit.

e.g. Sometimes, you may want to limit the temperature setting range so that

the operator cant set a very high temperature by accident. If you set the P-

SL=100 and P-SH =130, operator will only be able to set the temperature

between 100 and 130.

2) For linear input devices, P-SH and P-SL are used to define the display

span. e.g. If the input is 0-5V. P-SL is the value to be displayed at 0V and P-

SH is the value at 5V.

4.10 Input offset Pb

Pb is used to set an input offset to compensate the error produced by the

sensor or input signal itself.

For example, if the controller displays 5 C when probe is in ice/water mixture,

setting Pb=-5, will make the controller display 0 C.

4.11 Output definition OP-A

This parameter is not used for this model. It should not be changed.

dP Value 0 1 2 3

Display format 0000 000.0 00.00 0.000

WWW.AUBERINS.COM

TC

AUBER INSTRUMENTS

2011.12 P6/8

4.17 Lock up the settings, field parameter EP and parameter LocK

To prevent the operator from changing the settings by accident, you can lock

the parameter settings after initial setup. You can select which parameter can

be viewed or changed by assigning one of the field parameters to it. Up to 8

parameters can be assigned into field parameter EP1-EP8. The field

parameter can be set to any parameter listed in Table 2, except parameter EP

itself. When LocK is set to 0, 1, 2, and so on, only parameters or setting

values of program defined in an EP can be displayed. This function can speed

up parameter modification and prevent critical parameters (like input, output

parameters) from being modified.

If the number of field parameters is less than 8, then define the first unused

parameter as none. For example, if only ALM1 and ALM2 need to be modified

by field operators, the parameter EP can be set as following:

LocK=0, EP1=ALM1, EP2=ALM2, EP3=nonE.

In this case, the controller will ignore the field parameters from EP4 to EP8. If

field parameters are not needed after the instrument is initially adjusted,

simply set EP1 to nonE.

Lock code 0, 1 and 2 will give the operator limited privileges to change some

of the parameters that can be viewed. Table 5 shows the privileges

associated with each lock code.

Table 5. LocK parameter

5. Wiring examples

5.1 Controlling the load directly with internal relay

N

1 13 14 6

2

3

4

5

7

8

9

10

L

120VAC

Heater

Fuse

SYL-2342

Figure 6. SYL-2342 or SYL-2342P control the heater directly by the

internal relay of the controller. The heater must consume less current than

the internal relays maximum rating (7A at 240VAC and 10A at 120VAC).

LocK value SV Adjustment EP1-8 Adjustment Other parameters

0 Yes Yes Locked

1 Yes No Locked

2 No Yes Locked

3 and up No No Locked

808 unlocked

5.3 Controlling the load via SSR

Figure 8. SYL-2352 or SYL-2352P with RTD input. This is a typical wiring for

controlling the temperature of a tank of liquid with high precision.

The RTD sensor can offer accuracy within a fraction of a degree . The SSR

allows the heater to be switched at higher frequency for better stability. It also

has longer life time than the electromechanical relay. A proper heat sink is

needed when the SSR switches >8A of current. For wiring a 240V heater,

please see 5.4.

A=1, direct action control mode for cooling control.

B=0, without alarm suppressing when turned on or when set point changes.

B=1, alarm suppressing at power up or set point changes.

C=0, display unit in C.

C=1, display unit in F.

The factory setting is A=0, B=1, C=1 (heating, with alarm suppression, display

in Fahrenheit). Therefore,

COOL=0X1+1X2+1X8=10

To change from Fahrenheit to Celsius display, set COOL=2

4.15 Input digital filter FILt

If measurement input fluctuates due to noise, then a digital filter can be used

to smooth the input. FILt may be configured in the range of 0 to 20.

Stronger filtering increases the stability of the readout display, but causes

more delay in the response to change in temperature. FILt=0 disables the

filter.

4.16 Manual and Automatic Mode Selection A-M

Parameter A-M is for selecting automatic or manual control mode.

A-M=0, manual control mode

A-M=1, automatic control mode (either PID or On/off control)

A-M=2, automatic control mode, in this state manual operation is prohibited

This parameter functions differently for controllers with the ramp/soak function

(see supplemental manual for details).

5.2 Controlling the load via external contactor

Figure 7. SYL-2342 or SYL-2342P with thermocouple input and external

relay output. This is a typical wiring for oven and kiln.

Note: to limit the control temperature range instead of completely locking it,

please refer to section 4.9.

+

-

WWW.AUBERINS.COM

Using the external contactor allows users to control higher power loads than

the internal relay can handle. It is also easy to service. If the contacts of the

relay wear out, it is more economical to replace them than to repair the

controller. In this example, we assume the coil voltage of the contactor is the

same as the voltage of the controller power supply. The voltage of power

supply for alarm is 120V AC. Note: You dont have to wire or set the alarm

to control the temperature. It is just to show how the alarm can be wired.

SSR

N

1 13 14 6

2

3

4

5

7

8

9

10

L

120V AC

Heater

Fuse

SYL-2352

120VAC buzzer

3

4

2

1

+

-

R

T

D

R

R

W

N

C

o

n

t

a

c

t

o

r

TC

+

-

1 13 14 6

2

3

4

5

7

8

9

10

L

120VAC

H

e

a

t

e

r

Fuse

SYL-2342

120VAC

buzzer

L

N

120VAC

120VAC

buzzer

TC

AUBER INSTRUMENTS

2011.12 P7/8

TC

N

1 13 14 6

2 7

8

9

10

L

120VAC

Refrigerator

Fuse

SYL-2342

3

4

5

Bulb

+

-

Figure 11. A refrigerator connected to SYL-2342 directly

This is an example for beer fermentation. The refrigerator is driven by the

internal relay of the controller directly. Please note that the internal relay

output (terminals 7 and 8) is not powered by itself. A power supply must

be used to drive the external relay. The refrigerator must consume less

current than the internal relays maximum rating (7A at 240V AC and 10A at

120V AC). The bulb (l ess than 100-300 W) is for heating. The example is

setup to have the heater to turn on when temperature drops to below 60 F

and turns off at 64 F. The refrigerator will turn on when temperature is above

69 F and turn off at 65 F.

Set up for the controller

1) Hy = 2.0. Set both hysteresis band for heater and cooler to 2 degree.

2) COOL=9. Set the controller to cooling mode, no alarm suppression,

Fahrenheit temperature unit display.

3) AT=0. Set the controller main output to on/off control mode for refrigerator

compressor control

4) ALM2=62. Set the low limit alarm to 62 F. Heater will be on at 60 F

(ALM2-Hy) and off at 64 F (ALM2+Hy)

5) SV=67. Refrigerator will be on at 69 F (SV+Hy) and off at 65 F (SV-Hy).

SSR

L2

1 13 14 6

2

3

4

5

7

8

9

10

L1

240VAC

Heater

Fuse

SYL-2352

3

4

2

1

+

-

Figure 9. This is the essentially the same wiring example as 5.3, except the

heater and controller are powered by 240V AC. An alarm is not installed in

this example.

R

T

D

R

R

W

5.4 Controlling the load via SSR, 240VAC example

5.5 Controlling a 24V valve

N

1 13 14 6

2

3

4

5

7

8

9

10

L

120VAC

Fuse

SYL-2342

Figure 10. SYL-2342 or SYL-2342P with thermocouple input. This is a typical

wiring set up for a 24V gas, hot water valve, or a contactor with 24V coil

voltage.

+

-

S

24VAC

Solenoid valve

5.6 Cooling and heating with the same controller

WWW.AUBERINS.COM

AUBER INSTRUMENTS

2011.12 P8/8

Quick Guide for SYL-2342, 2352

1. Wiring

1) Power to the controller. Connect the 85-260V AC power to terminals 9 and

10.

2) Control output connection. Connect terminals 7 and 8 for output.

3) Sensor connection. For thermocouples, connect the positive wire to terminal

4, the negative to terminal 5. For a three-wire RTD with standard DIN color

code, connect the two red wires to terminals 3 and 4, and connect the white

wire to terminal 5. For a two-wire RTD, connect the wires to terminals 4 and 5.

Then, jump a wire between terminals 3 and 4.

2. Set sensor type

Set Sn to 0 for a K type thermocouple (default), 5 for a J type thermocouple,

and 21 for a Pt100 RTD.

3. Switching between automatic and manual mode

Set A-M=1 to active manual mode. Press the A/M key to switch between

automatic and manual mode.

4.Changing the temperature scale from Fahrenheit to Celsius.

Change COOL from 10 to 2 (for heating mode).

5 Setting the controller for cooling control.

For cooling control, set COOL=11 to display Fahrenheit; set COOL=3 to

display Celsius.

6. Setting target temperature (SV)

Press the or key once, and then release it. The decimal point on the

lower right corner will start to flash. Press the or key to change SV until

the desired value is displayed. The decimal point will stop flashing after no key

is pressed for 3 seconds. You can press the A/M key to move the flashing

decimal point to the desired digit that needs to change. Then press the or

key to change SV starting from that digit.

7. Auto-tune

You can use the auto-tune function to determine the PID constants

automatically.

There are two ways to start auto-tuning:

1) Set At=2. It will start automatically after 10 seconds.

2) Set At=1. Then during the normal operation, press the A/M key to start the

auto-tune.

The instrument will perform accurate artificial intelligence control after auto

tuning is finished.

7 On/off mode

Set At=0 to active the on/off control mode.

Set the Hysteresis Band parameter Hy to be a desired value.

8. Error Message and trouble shooting

8.1 Display orAL

This is an input error message. The possible reasons are: the sensor is not

connected correctly; the input setting is wrong type; or the sensor is defective.

In this case, the instrument terminates its control function automatically, and

the output value is fixed according to the parameter OUTL. If this happens

when using thermocouple sensor, you can short terminal 4 and 5 with a copper

wire. If the display shows ambient temperature, the thermocouple is defective.

If it still displays orAL, check the input setting, Sn, to make sure it is set to the

right thermocouple type. If the Sn setting is correct, the controller is defective.

For RTD sensors, check the input setting first because most controllers are

shipped with the input set for thermocouples. Then check the wiring. The two

red wires should be connected to terminals 3 and 4. The clear wire should be

connected to terminal 5.

8.2 No heating

When the controller output is set for relay output, the O U T LED is

synchronized with output relay. If heat is not output when it is supposed to,

check the OUT LED first . If it is not lit, the controller parameter settings are

wrong. If it is on, check the external switching device (if the relay is pulled-in, or

the SSRs red LED is on). If the external switching device is on, then the

problem is either the external switching device output, its wiring, or the heater.

If the external switching device is not on, then the problem is either the

controller output, or the external switch device.

8.3 Poor Accuracy

Please make sure calibration i s done by immersing the probe in liquid.

Comparing the reference in air is not recommended because response time of

the sensor depends on its mass. Some of our sensors have response time

>10 minutes in the air. When the error is larger than 5 F, the most common

problem is an improper connection between the thermocouple and the

controller. The thermocouple needs to be connected directly to the controller

unless a thermocouple connector and extension wire is used. Copper wire or

a thermocouple extension wire with the wrong polarity connected on the

thermocouple will cause the reading to drift more than 5 F.

8.4 On on/off mode, although hysteresis is set to 0.3, the unit is running

5 degrees above and below.

If the Hy is very small and temperature changes very quickly, users will need

to consider the delay of the cycle time (the parameter t). For example, if cycle

time is 20 seconds, when the temperature passes the SV+Hy after the

beginning of a 20 seconds cycle, the relay will not act until the start of the next

cycle 20 seconds later. Users may change the cycle time to a smaller value,

such as 2 seconds, to get better precision control.

WWW.AUBERINS.COM

Auber Instruments

730 Culworth, Alpharetta, GA 30022

www.auberins.com

e-mail: info@auberins.com Tel: 770-569-8420

You might also like

- Secrets in NumbersDocument26 pagesSecrets in Numbersmdkafzal100% (5)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- String Harmonics in Ravel's Orchestral WorksDocument97 pagesString Harmonics in Ravel's Orchestral WorksYork R83% (6)

- Barrons High Frequency Words With Syn & AntonymsDocument48 pagesBarrons High Frequency Words With Syn & Antonymsbharatluvs100% (4)

- PZO9401 Second Darkness Players Guide PDFDocument36 pagesPZO9401 Second Darkness Players Guide PDFAllan ChuaNo ratings yet

- DC/DC Converter Operation GuideDocument6 pagesDC/DC Converter Operation GuidesaeidraminaNo ratings yet

- PID Temp. ControllerDocument8 pagesPID Temp. ControllerHowardgfNo ratings yet

- Temperature Controller: User'S ManualDocument32 pagesTemperature Controller: User'S ManualkmpoulosNo ratings yet

- O The Beat 1 - TBDocument164 pagesO The Beat 1 - TBJulliana SantosNo ratings yet

- 4ps QuestionnaireDocument3 pages4ps QuestionnaireFlorante De Leon67% (3)

- Syl 2372Document8 pagesSyl 2372Ismael 8877No ratings yet

- Auber Instruments PID Temperature Controller ManualDocument5 pagesAuber Instruments PID Temperature Controller ManualEektor BonillaNo ratings yet

- Syl 151Document4 pagesSyl 151Boris KozjanNo ratings yet

- Syl-1512A2 Pid Temperature Controller Instruction Manual Instruction ManualDocument5 pagesSyl-1512A2 Pid Temperature Controller Instruction Manual Instruction ManualTony GaryNo ratings yet

- Electronic RelaysDocument21 pagesElectronic Relayslopablito24No ratings yet

- Im PK 1603Document32 pagesIm PK 1603James James MorrisonNo ratings yet

- The Sussex VT1: As Interpreted by Les Carpenter G4CNHDocument27 pagesThe Sussex VT1: As Interpreted by Les Carpenter G4CNHrogerio pessanha dos santosNo ratings yet

- .J N I - .J N - P U1 0 S : 0Document15 pages.J N I - .J N - P U1 0 S : 0Montse TovarNo ratings yet

- MTB Oi 4-12Document19 pagesMTB Oi 4-12JerNo ratings yet

- SYL-2342 ManualDocument8 pagesSYL-2342 ManualAbu SaifNo ratings yet

- H1000e I Ema-Emc PDFDocument4 pagesH1000e I Ema-Emc PDFNguyen Van ChungNo ratings yet

- Lg42pc5dh Ul Chassis Pa75cDocument38 pagesLg42pc5dh Ul Chassis Pa75cdann222No ratings yet

- DTB ManualDocument13 pagesDTB ManualJorge BurbanoNo ratings yet

- LD-B10-10 Temperature Controller User GuideDocument22 pagesLD-B10-10 Temperature Controller User GuideFareh KhanNo ratings yet

- Lock Out Relay PDFDocument10 pagesLock Out Relay PDFshaikhsajid242No ratings yet

- SG808 ManualDocument2 pagesSG808 ManualzzmeoneNo ratings yet

- Telemecanique PDFDocument60 pagesTelemecanique PDFMario PerezNo ratings yet

- N121-132A Servocontroller Power Supply SpecsDocument6 pagesN121-132A Servocontroller Power Supply Specsnm2007kNo ratings yet

- LM2852 Synchronous BuckDocument14 pagesLM2852 Synchronous BuckAndrew CavanaughNo ratings yet

- Universal 16 Amp Self Excited Automatic Voltage Regulator ManualDocument9 pagesUniversal 16 Amp Self Excited Automatic Voltage Regulator ManualJuan José Tovar Pérez100% (1)

- LG TV 29fu6rsd (RS) Chassis Cw62d, Service ManualDocument22 pagesLG TV 29fu6rsd (RS) Chassis Cw62d, Service Manualjazjcl3269No ratings yet

- LM45B LM45C SOT-23 Precision Centigrade Temperature SensorsDocument9 pagesLM45B LM45C SOT-23 Precision Centigrade Temperature SensorsTuấn ThiệnNo ratings yet

- Design Ideas - 6598372 - 555 Timer Drives 7 LEDsDocument5 pagesDesign Ideas - 6598372 - 555 Timer Drives 7 LEDsTony ClelandNo ratings yet

- Op - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Document3 pagesOp - Tc544a - Tc244ax - Tc344ax - Dtc204a-2 - Dtc324a-2 - Op294-V05 - 04-07-13Raja VeluNo ratings yet

- Product Features: Control ModeDocument6 pagesProduct Features: Control ModeYudha J MalmsteenNo ratings yet

- Triple Power SupplyDocument2 pagesTriple Power SupplymankylyNo ratings yet

- 7XV5662!2!5AD10 Manual Ziehl TR600 enDocument10 pages7XV5662!2!5AD10 Manual Ziehl TR600 enEddy Fernando Queca CadizNo ratings yet

- 48 50a-3wDocument28 pages48 50a-3wtecairNo ratings yet

- TV LG Plasma 42PB4DA Manual de ServicioDocument42 pagesTV LG Plasma 42PB4DA Manual de Servicioteack09100% (1)

- Varlogic NRC12Document56 pagesVarlogic NRC12ViverSharinganUchihaNo ratings yet

- TC620 TC621 5V, Dual Trip Point Temperature Sensors: Features General DescriptionDocument6 pagesTC620 TC621 5V, Dual Trip Point Temperature Sensors: Features General Descriptionmiki983No ratings yet

- Dual Half Bridge Driver: Multipower BCD TechnologyDocument9 pagesDual Half Bridge Driver: Multipower BCD TechnologyDan EsentherNo ratings yet

- Syy155415 CPDocument3 pagesSyy155415 CPdanutzugheNo ratings yet

- BM2596Document9 pagesBM2596Anton AdrianNo ratings yet

- Advanced Monolithic Systems: Rohs CompliantDocument8 pagesAdvanced Monolithic Systems: Rohs CompliantWilliam BlackNo ratings yet

- LM2585Document32 pagesLM2585Anonymous uBxUcNd58No ratings yet

- Abb Combiflex Stator Earth Fault RelayDocument2 pagesAbb Combiflex Stator Earth Fault RelayumeshbhamidiNo ratings yet

- XP2-R Power and Reverse Power RelayDocument14 pagesXP2-R Power and Reverse Power RelayRam RKNo ratings yet

- DTA Manual UsuarioDocument12 pagesDTA Manual Usuario99lea99No ratings yet

- Electronic Pressure Switch & Transmitter: General SpecificationDocument4 pagesElectronic Pressure Switch & Transmitter: General Specificationhuu thanh nguyenNo ratings yet

- DAC0808 8-Bit D/A Converter: Literature Number: SNAS539ADocument14 pagesDAC0808 8-Bit D/A Converter: Literature Number: SNAS539AomNo ratings yet

- RTD Module PDFDocument4 pagesRTD Module PDFbuianhtuan1980No ratings yet

- Description: Eagle Quantum Premier Agent Release Module EQ2500ARMDocument2 pagesDescription: Eagle Quantum Premier Agent Release Module EQ2500ARMFernando Zambrano San Martín0% (1)

- Ucc3580 4Document20 pagesUcc3580 4vanhuong87No ratings yet

- 150KHz, 3A Step Down Voltage Switching Regulators DatasheetDocument10 pages150KHz, 3A Step Down Voltage Switching Regulators DatasheetAlfredo Valencia RodriguezNo ratings yet

- LM334Document26 pagesLM3342567daNo ratings yet

- Coleman RV 12 Volt Thermistat ACDocument18 pagesColeman RV 12 Volt Thermistat ACsthoma20100% (1)

- Automatic Temperature Controller Using Lm35Document18 pagesAutomatic Temperature Controller Using Lm35siddhantgurung4171% (14)

- SCR w5 enDocument10 pagesSCR w5 enAji Beni LastomoNo ratings yet

- IC Regulated Power Supply TutorialDocument8 pagesIC Regulated Power Supply TutorialGugun GunawanNo ratings yet

- TMP 35 GDocument16 pagesTMP 35 GWeslley FariaNo ratings yet

- Adr 132 BDocument5 pagesAdr 132 Btandin tshewangNo ratings yet

- Datasheet lm3914Document29 pagesDatasheet lm3914antonioNo ratings yet

- 50 Important Quotes You Should Pay Attention To in Past The Shallows Art of Smart EducationDocument12 pages50 Important Quotes You Should Pay Attention To in Past The Shallows Art of Smart EducationSailesh VeluriNo ratings yet

- Toan Bo Cac Bai Ktra E11CBDocument13 pagesToan Bo Cac Bai Ktra E11CBNguyễn Thị Huyền Phương0% (1)

- VC3 TranslationDocument313 pagesVC3 TranslationFuyuki Maxwell ArashiNo ratings yet

- Physics: PAPER 1 Multiple ChoiceDocument20 pagesPhysics: PAPER 1 Multiple Choicelulz.l.n.sNo ratings yet

- Progressivism Lesson 3 The PresidentsDocument3 pagesProgressivism Lesson 3 The Presidentsapi-302923213No ratings yet

- Kamala Das Poetry CollectionDocument0 pagesKamala Das Poetry CollectionBasa SwaminathanNo ratings yet

- Edith Bonomi CV SummaryDocument1 pageEdith Bonomi CV SummaryEdithNo ratings yet

- Frawley David - Wisdom of The Ancient Seers Mantras of The Rig VedaDocument140 pagesFrawley David - Wisdom of The Ancient Seers Mantras of The Rig Vedadbbircs100% (1)

- Mathematical Language and Symbols ExplainedDocument5 pagesMathematical Language and Symbols Explainedcyra6flores6verderaNo ratings yet

- MKTG10001Document38 pagesMKTG10001Jessica KokNo ratings yet

- Balay Dako Menu DigitalDocument27 pagesBalay Dako Menu DigitalCarlo -No ratings yet

- 11th Commerce Mathematics and Statistics Part II Maharashtra BoardDocument10 pages11th Commerce Mathematics and Statistics Part II Maharashtra BoardTanmay Gholap100% (3)

- Engineering Properties of Soil PDFDocument55 pagesEngineering Properties of Soil PDFJam Apizara Chaizalee100% (1)

- SLI ProfileThe title "TITLE SLI Profile" is less than 40 characters and starts with "TITLEDocument3 pagesSLI ProfileThe title "TITLE SLI Profile" is less than 40 characters and starts with "TITLEcringeNo ratings yet

- Crane's Manual - CV ValuesDocument14 pagesCrane's Manual - CV Valuesnghiemta18No ratings yet

- Aircrew Standards Manual FY2015 V1Document211 pagesAircrew Standards Manual FY2015 V1Anonymous Pb39klJ100% (1)

- Chapter 16-Analyzing Qualitative DataDocument3 pagesChapter 16-Analyzing Qualitative DataLiko Pah TuafNo ratings yet

- Irish Chapter 6 Causes of DeathDocument8 pagesIrish Chapter 6 Causes of DeathIrish AlonzoNo ratings yet

- History of English - IntroductionDocument58 pagesHistory of English - IntroductionPaul Edward GuevarraNo ratings yet

- Community-Acquired Pneumoniaandhospital-Acquiredpneumonia: Charles W. Lanks,, Ali I. Musani,, David W. HsiaDocument15 pagesCommunity-Acquired Pneumoniaandhospital-Acquiredpneumonia: Charles W. Lanks,, Ali I. Musani,, David W. HsiaMajo EscobarNo ratings yet

- Ra 6770Document8 pagesRa 6770Jamiah Obillo HulipasNo ratings yet

- SAP Training Program Proposal for StudentsDocument2 pagesSAP Training Program Proposal for StudentsAjay KumarNo ratings yet

- Discourse and PragmaticsDocument10 pagesDiscourse and PragmaticsDebby NatasyaNo ratings yet

- MC Data Dig Graphic Organizer 1Document5 pagesMC Data Dig Graphic Organizer 1api-461486414No ratings yet