Professional Documents

Culture Documents

WPS - PQR As Per Is

Uploaded by

Niladri Sekhar MaitiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS - PQR As Per Is

Uploaded by

Niladri Sekhar MaitiCopyright:

Available Formats

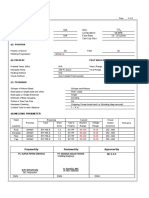

Welding Procedure Specification (WPS)

( Annexure E of IS 9595)

Project: Name of Work: Job No.: Unit:_____________________________________ Contractor: ____________________________

Work Order No. :_________________________ Date: Supporting PQR No. : Single or Multiple Pass : Machine Single or Multiple Arc : Welding position (s):

Specification No. : Welding Process: Manual

Material soecification : Grade of IS : Batch No/Cast No.

FOR INFORMATION ONLY

Electrode /Fillerwire Diameter. :

Thickness ( if pipe ,diabnere and wall thicknress):

Filler Metal Specification : Weld Metal Analysis :

Trade Name: Type of backing : Forhands or backhand:

FLUX OR SHIELDING GAS

Flux Trade Name or Composition: Inert Gas Composition Trade Name : Flow Rate : Is baking strip used : Preheat temperature range: Interpass temperature range Preheat Treatment:

WELDING TECHNIQUES

Joint Detail :

Amps : Electrode consumrd ( cm/m) : Currenr : Size of Reinforcment: Whether removed Inspection and test schedule :

Volts:

Polarity:

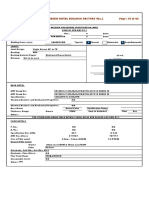

Procedure Qualification Record (PQR)

(Appendix A, Clause 8.1,Indian Standard: 7307(Part-1)-1972) Company Name: PQR No.: WPS No: Welding Process (es): Manufacturer's Name Weld preparation: Rev.: Rev.: Type(s): Date: Date:

Procedure No. Run sequence and complete weld dimensions:

(Sketch)(State method and fit-up) Dimensions of test piece: Wellding Position: Pre-heating and interpass temperature, method and control:

(Sketch) Parent Material(s): Position of test piece: Post-weld heat treatment temperature, method and control.:

Welding consumables Filler Material Make: Type: Composition: Size: Travel speed(mechanized welding): Weld Process(es): Additional Information: Drafted by date: Back Grouping: Type of flux: Composition of Gas: Flow rate: Shielding gas flux

You might also like

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Macro Examination StandardDocument4 pagesMacro Examination StandardMohd Akmal ShafieNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- WPQRDocument2 pagesWPQRsogleng100% (5)

- DP Format Bhel 1Document1 pageDP Format Bhel 1narayandasraikwar100% (1)

- Welder Continuity LogDocument3 pagesWelder Continuity Log942519100% (1)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Welder Qualification Report FormDocument1 pageWelder Qualification Report FormNanaba Nanayaw DwomohNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Welder Qualification RecordDocument1 pageWelder Qualification Recordtantri.hellyanti100% (1)

- 16 Electrode QualificationDocument11 pages16 Electrode QualificationAkhilesh Kumar67% (3)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- ET NDT Sample Test Report FormatDocument1 pageET NDT Sample Test Report Formatanas dwiNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- NDT Request FormDocument1 pageNDT Request FormSHANENo ratings yet

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- WPS ExampleDocument2 pagesWPS ExampleNur WijiantoNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- MPT Report FormatDocument1 pageMPT Report FormatRoshan ThomasNo ratings yet

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Document5 pagesWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Welding Visual Inspection FormatDocument2 pagesWelding Visual Inspection Formatgst ajah100% (3)

- Pqr-152 - Run SheetDocument38 pagesPqr-152 - Run SheetMAT-LIONNo ratings yet

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- DPI Test ReportDocument1 pageDPI Test Reportengsam777No ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- Magnetic Particle Test Quality Control and Inspection Report FormDocument1 pageMagnetic Particle Test Quality Control and Inspection Report FormRicardo MachadoNo ratings yet

- WPS - 007Document11 pagesWPS - 007MAT-LIONNo ratings yet

- Manufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoDocument2 pagesManufacturer'S Welding Procedure Specification Wps Wpsno: Rev No: Date: Page NoAMIT SHAHNo ratings yet

- DPT Report - FormatDocument1 pageDPT Report - Formatskc0% (1)

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- NDT Request Form: Project Quality Assurance & ControlDocument1 pageNDT Request Form: Project Quality Assurance & ControlIzar Irhamni, ST100% (1)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Pipe Wall Thickness - Report PDFDocument1 pagePipe Wall Thickness - Report PDFPetroNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- VT ReportDocument1 pageVT ReportBauyrzhanNo ratings yet

- Formato de ITP-estructuras Metalicas BOLT TORQUE TESTDocument1 pageFormato de ITP-estructuras Metalicas BOLT TORQUE TESTkrlitos24100% (1)

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocument3 pagesPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Weld RepairDocument2 pagesWeld RepairAnurag YadavNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- SAIC-LT-2007 LeaK Testing-Vacuum BoxDocument3 pagesSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamNo ratings yet

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument4 pagesPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Trinity Transformer PVT LTD: Liquidpenetrant Examination ReportDocument2 pagesTrinity Transformer PVT LTD: Liquidpenetrant Examination ReportipraoNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- Formato AWSDocument3 pagesFormato AWSDuverlyOrlandoMattaVásquezNo ratings yet

- Essar Constructions Ltd. Hazira.: List of FormatsDocument68 pagesEssar Constructions Ltd. Hazira.: List of Formatsravi00098No ratings yet