Professional Documents

Culture Documents

DK9322 0810 0036

Uploaded by

Alex David EliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DK9322 0810 0036

Uploaded by

Alex David EliCopyright:

Available Formats

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

Keywords M-Bus level converter counter consumption measurement serial interface energy measurement EN 1434 EN 13757 flow measurement calorimetry IEC 870 EN 1434-3 Building Automation

M-Bus connection for energy and consumption meters via TwinCAT

This application example from the Building Automation Sub-bus Systems series describes the basic principles of M-Bus and the functionality and integration of a PC as an M-Bus master via the TwinCAT PLC M-Bus library from Beckhoff. Through serial data transmission an M-Bus master can read up to 250 energy and consumption meters. The bus line is connected to an M-Bus line via a serial interface (Bus Terminal, EtherCAT Terminal or COM port) and a level converter as a master. The M-Bus is predominately used in buildings and properties with a large number of end users.

1.

The M-Bus

The M-Bus (metering bus) is a fieldbus for logging, analyzing, optimizing and controlling energy and process data. It is as used as a standardized system for reading energy and consumption meters or other end devices or actuators. Signals are transferred serially from the connected slaves (measuring devices) to a master via a reverse polarity protected two-wire line. Depending on the application the data are stored or prepared for further processing. The field devices can be supplied with power via the bus cable. M-Bus is a typical single-master bus, in which the master requests and picks up the data from the slaves. With a primary address space of 250 addresses, up to 250 slaves can be connected to a master. Via modem interfaces, large distances can be covered in order to bring together modular extensions or complex systems. The M-Bus system is predominately used by operating companies supplying a large number of end users (e.g. industrial and technology parks, trade shows, building management systems, etc.). Meanwhile the M-Bus has become established as a separate standard in EN 13757. This standard describes the M-Bus for application via a two-wire bus (part 2) and for radio transmission (part 4). However, standardization at the protocol level is

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

incomplete. The data telegram features a freely available segment which manufacturers can use for transferring various (nonstandardized) data or control characters. Before using new slaves it is therefore important to verify compatibility with the evaluation unit. All manufacturers of M-Bus meters offer downloadable specifications of the M-Bus protocols for their meters.

2.

Typical field devices

The field devices used for M-Bus are typically meters for measuring tasks within a building. Examples of field devices include heat meters, water meters, hot water meters, electricity meters, pulse meters, switching devices, and heating cost distributors. A distinction is made between the reading mode. For local reading only one meter is connected, for remote reading several meters are integrated. The following data transfer options are available, depending on the reading type. The transfer protocol according to IEC 870 and EN1434-3 is used for all transfer routes.

2.1

Local reading (single meter)

one optical interface (EN 61107 section 3.2) one inductive interface (CEN TC176/WG4) one 20 mA current loop, CL (EN 61107 section 3.1)

2.2

Remote reading (several meters)

one two-wire fieldbus, meter bus (CEN TC176/WG4) one 11-bit modem radio system (433 or 868 MHz)

3.

Master versions

The master can be an independent device or a PC with level converter. It reads the data of the connected field devices at configurable intervals and stores the meter readings permanently. All Industrial and Embedded PCs from Beckhoff can be used as a master in conjunction with TwinCAT software. The Beckhoff Bus Terminal Controllers from the BC and BX series (except for BCxx50) can also be used as a master, although in this case the limited transfer rates, the limited multi-tasking functionality and the longer cycle times must be taken into account. In addition, the program memory and, consequently the mapping is limited depending on the Bus Terminal Controller, so the number of meters that can be read is limited as a result. Notes regarding the use of devices from the Beckhoff BC/BX series: M-Bus devices may deliver very large values (that may exceed the DWord value range) and are therefore output in string format. Conversion to the Real format may result in inaccuracies or even invalid values. Conversion to the LReal format is therefore preferable. This approach is not available on controllers from the BC/BX series. If the values have to be provided in a number format, controllers from the BC/BX series are unsuitable if those values exceed the DWord value range.

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

4.

Topologies

Devices can be connected to M-Bus in a strand or star topology. For each strand a master and a level converter is required. The maximum number of meters per segment is 250. Larger systems can be formed and cascaded with the aid of repeaters.

Slave Slave Slave

M-Bus master Slave Slave Slave Slave Slave Slave Slave

Slave

M-Bus master

Slave

Slave Slave

Slave

Slave

Fig. 1

Possible M-Bus topologies

One of the factors limiting the size of an M-Bus network is the wire cross-section. Wiring of an existing building is very complex and expensive, which is why in such applications radio solutions with lower infrastructure costs tend to be used. When configuring an M-Bus topology it should be noted that the plug connectors of the bus cable are not standardized, which may result in complications if components from different manufacturers are used.

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

4.1

Laying system, cross-section and cable lengths

The lower the line resistance, the longer the cable can be. However, as a basic rule the cross-section should not be less than 0.5 mm (#20 AWG). Transmission errors may occur if the maximum cable length is exceeded or if the cable cross-section is too small. A normal telephone cable of type J-Y(ST)Y n x 2 x 0.8 mm (#20 AWG standard twisted-pair) can be used. Figure 2 shows the number of M-Bus devices that can be connected in relation to the cable length of the M-Bus.

Number of M-Bus devices depending on the cable length

300 250

M-Bus devices

200 150 100 50 0

2 x 2 x 0.6 mm (2 x 2 x #19 AWG) 2 x 2 x 0.8 mm (2 x 2 x #18 AWG) 3 x 1.5 mm (3 x #16 AWG)

(1 00 64 0)

28 00 0)

56 00 1)

84 00 2)

(4

(8

(1

(1

(3

(6

total cable length [m] (ft)

Fig. 2 Number of M-Bus devices

5.

Communication

M-Bus is a single-master bus based on serial data transmission. The master queries the meters via the bus by modulating the supply voltage: A logical 1 corresponds to a signal level of 36 V DC, a logical 0 is represented by 24 V DC. This ensures that the power supply for the slaves can take place via the bus. The slave responds to the master by modulating its current consumption: 1.5 mA corresponds to logical 1, logical 0 is detected between 11 and 20 mA. Data transfer rates of 300 to 9,600 baud are possible, in some cases more than 9,600 baud. The maximum possible transfer rate of a meter depends on the manufacturer. The user must therefore check which baud rate can be used for all connected field devices within a strand. In delivery state (unparameterized) many slaves are set to 2,400 baud as standard.

(9

(1

47 00 63 )

92 00 1)

20 00 2)

31 00 23 )

14 00 83 )

45

15

25

10

20

30

35

40

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

Two addressing modes are possible: With primary addressing the master sends a request for data transmission to the end device 1...250. The addressed slave responds with a standard dataset, which in the simplest case consists of the meter reading, measured medium, device type, serial number and manufacturers code. Secondary addressing can be used to extend the address space of M-Bus. With secondary addressing the master sends a request for data transmission to all end devices via the special address 253. Individual end devices are addressed via serial number, manufacturers code and medium. The addressed slave responds with the standard dataset.

6.

Power supply

The power supply of the slaves and the master is manufacturer-dependent. A wide range of options is available, including 230 V AC external, 30 V DC external, 30 V DC integrated, etc. In addition there are battery-powered field devices which do not require a power supply connection. In this case the operator should be aware that each meter reading reduces the service life of the battery.

7.

TwinCAT PLC M-Bus library: PC as an M-Bus master with connected level converter

TwinCAT supports the M-Bus with a dedicated library: TwinCAT PLC M-Bus. Via a level converter, up to 250 slaves can be connected to any PC in a suitable topology (star or strand). Devices from different manufacturers can be operated on the same bus. The M-Bus library only evaluates data with variable data structure that are identified by a leading low byte. The TwinCAT PLC M-Bus library supports the serial interfaces KL6001, KL6021 (Bus Terminals) and EL6001, EL6021 (EtherCAT Terminals), and the PC-COM port. The interfaces are connected with an M-Bus level converter (e.g. from Relay), from which the individual slaves are connected (reverse polarity protected) via a two-wire line. The TwinCAT PLC M-Bus library currently does not support secondary addressing, which is possible with M-Bus for extending the address space. (The link to download the M-Bus library just described is at the end of the document)

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

Water meter

FB_MBUS_...

m Water

Address 0...249

FB_MBUS_...

Gas meter

m Gas

FB_MBUS_...

Electricity meter

kWh Energy

M-Bus level converter RS232 RS485

Heat meter

FB_MBUS_...

kWh Heat

Pulse meter

FB_MBUS_... Pulse

COM interface

FB_MBUSPcCom

FB_MBUS_KL60xx

KL6001 KL6021

EL6001 EL6021

FB_MBUS_EL60xx

CX1010

BX9000 Ethernet

BC9000 with KL6001

Fig. 3

Integration of M-Bus devices via level converters and serial interfaces

7.1

Benefits for the user

The function blocks are object-oriented and characterized by a self-contained, more or less complex function. The user configures the input parameters through which the function block is adapted individually to its task within the associated system. Thanks to strongly object-oriented encapsulation of complex system functions within one function block, comprehensive system programs can be set up with a few function blocks. The blocks are linked to each other via a small number of PLC variables. The status of all objects is indicated through a large number of different output variables at the function blocks. This simplifies the connection of HMI and visualization systems.

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

For system operators this has the following advantages for system setup and operation: faster system program development faster parameterization and commissioning of the systems guarantee of a very large range of system functions at all times improved readability of programs (prerequisite for long-term maintainability and expandability of the systems) improved reusability of templates for systems or system components faster familiarization of personnel simple extension of existing systems better program documentation Notice: A link to an overview of all meter blocks (meters supported by the TwinCAT PLC M-Bus library) can be found at the end of this document. Beckhoff can create new meter blocks at short notice. To this end, Beckhoff requires a sample device and an M-Bus protocol description from the device manufacturer.

8.

Serial interfaces (RS232/RS485) from Beckhoff

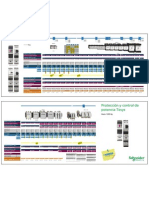

The following Beckhoff Bus Terminals and EtherCAT Terminals are available for integrating an M-Bus strand:

Baud rates of the RS232/RS485 interfaces from Beckhoff

KL6001 KL6021 300 600 1,200 2,400 4,800 9,600 19,200 1,200 2,400 4,800 9,600 19,200 4,800 9,600 19,200 38,400 57,600 115,200 2,400 4,800 9,600 19,200 38,400 57,600 115,200 2,400 4,800 9,600 19,200 38,400 57,600 115,200 KL6031/KL6041 EL6001/EL6002 EL6021/EL6022 COM-Port PC 50/75/110 150/300/600 1,200 2,400 4,800 9,600 19,200 38,400 57,600 115,200 230,400 460,800

Tab. 1

Serial interfaces from Beckhoff

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

Since M-Bus can handle transfer rates between 300 and 9,600 baud, the user must ensure that the transfer rate of the terminal matches the transfer rate of the connected slaves when selecting an interface. The higher the selected baud rate, the shorter the cycle time has to be. Below 1,200 baud only the PC-COM port is recommended.

8.1

Process image

The process image of the KL6001 and KL6021 interface terminals is set to 3 bytes as standard. Since the process image of the M-Bus library has 5 bytes, the terminal mapping must be configured from 3 to 5 bytes with KS2000 Bus Terminal configuration software. To simplify the configuration Beckhoff offers special versions of the terminals (KL6001-0020 and KL6021-0020), which feature a 5-byte process image as standard.

9.

Practical example

A typical area of application for M-Bus-based consumption data acquisition is in decentralized buildings. Individual production areas within a factory site are equipped with separate acquisition points. A suitable media meter is integrated for each building element. The data are collected in a control center and managed centrally. This provides the advantage that duplicate data management is avoided and the data are archived at a central location. Consumption data acquisition in distributed buildings

m kWh

Building management

m kWh

BMS

Ethernet

m kWh

m kWh

Fig. 4

The building management system is the central switching point for all buildings that are networked with Ethernet.

Each building acts as a separate data acquisition unit: Via the Beckhoff CX1010 Embedded PC with integrated Ethernet interface the data can then be made available to a central building management system. This enables the local data to be available directly in the individual systems as well as centrally. This principle significantly reduces the engineering effort and keeps the data management transparent.

For application notes see disclaimer on the last page

Beckhoff New Automation Technology

TwinCAT

Application Note DK9322-0810-0036 TwinCAT, Building Automation

Another typical practical example is error-free meter reading at short notice when a change of tenants occurs, while safeguarding the privacy of the tenants. Remote reading enables electronic data acquisition with minimum manpower requirements (reduction of reading errors) and speedy further processing (compiling of statistics, invoicing, etc.).

TwinCAT PLC Library M-Bus www.beckhoff.com/english/twincat/twincat_plc_m_bus.htm Documentation of M-Bus library at Beckhoff Information System http://infosys.beckhoff.com/content/1033/tcplclibmbus/html/tcplclibmbus_einleitung.htm Overview of supported M-Bus counter http://infosys.beckhoff.com/content/1033/tcplclibmbus/html/tcplclibmbus_programmierung.htm Building Automation www.beckhoff.com/building Overview serial interfaces K-Bus www.beckhoff.com/english/bus_terminal/sonder.htm Overview serial interfaces EtherCAT www.beckhoff.com/english/ethercat/sonder.htm Relay GmbH www.relay.de/frame_3fach_e.htm

This publication contains statements about the suitability of our products for certain areas of application. These statements are based on typical features of our products. The examples shown in this publication are for demonstration purposes only. The information provided herein should not be regarded as specific operation characteristics. It is incumbent on the customer to check and decide whether a product is suit-able for use in a particular application. We do not give any warranty that the source code which is made available with this publication is complete or accurate. This publication may be changed at any time with-out prior notice. No liability is assumed for errors and/or omissions. Our products are described in detail in our data sheets and documentations. Product-specific warnings and cautions must be observed. For the latest version of our data sheets and documentations please visit our website (www.beckhoff.com). Beckhoff Automation GmbH, August 2010 The reproduction, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

Beckhoff New Automation Technology

You might also like

- M-Bus 012Document36 pagesM-Bus 012Voicu StaneseNo ratings yet

- LEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYDocument30 pagesLEED - v4.1 - ID - C - Guide - For - April - 2023 - ENERGYTomaszNo ratings yet

- TRACE3DPlus - Standard - 140 - Results PDFDocument146 pagesTRACE3DPlus - Standard - 140 - Results PDFMelvin SanchezNo ratings yet

- Catalogue General enDocument31 pagesCatalogue General enzhyhhNo ratings yet

- Cadprofi 2021 enDocument67 pagesCadprofi 2021 enPetru CorduneanuNo ratings yet

- Virbyg J-1Document6 pagesVirbyg J-1Anonymous xFV7bg7Q100% (1)

- Donaldson Torit - Easy Duct Master Cataloguel PDFDocument32 pagesDonaldson Torit - Easy Duct Master Cataloguel PDFtylerstearnsNo ratings yet

- NordCAD 3.1Q User ManualDocument24 pagesNordCAD 3.1Q User ManualsundarNo ratings yet

- Equest Tutorial v364 PDFDocument151 pagesEquest Tutorial v364 PDFRaniPaviNo ratings yet

- Distance From Sprinkler To HangerDocument1 pageDistance From Sprinkler To Hangerahmaborashed100% (1)

- Iti Bcu 570 GBDocument116 pagesIti Bcu 570 GBJos AngelNo ratings yet

- For Modelling LEED (Version-1)Document11 pagesFor Modelling LEED (Version-1)Zaw Moe KhineNo ratings yet

- Energy-efficient gas heaters for commercial spacesDocument66 pagesEnergy-efficient gas heaters for commercial spacesdfsddsNo ratings yet

- How To Import Data From Template Projects: QB Tip 001Document3 pagesHow To Import Data From Template Projects: QB Tip 001maheshNo ratings yet

- Autocad Mep 2009Document132 pagesAutocad Mep 2009haneefaparokot100% (1)

- Ashrae DatabaseDocument81 pagesAshrae Databasesam100% (1)

- 4MCAD-EN ManualDocument404 pages4MCAD-EN ManualolgfNo ratings yet

- CYPEFIRE Sprinklers ManualDocument33 pagesCYPEFIRE Sprinklers Manualrukesh104100% (2)

- Installation Guide V1.3: Intrinsic Safety Box: Serial Isolator and Power Supply For CorusDocument13 pagesInstallation Guide V1.3: Intrinsic Safety Box: Serial Isolator and Power Supply For CorusOmar Orlando KranevitterNo ratings yet

- LEED V4 - BDC - Reference Guide - EA p2 - Minimum Energy PerformanceDocument3 pagesLEED V4 - BDC - Reference Guide - EA p2 - Minimum Energy PerformanceTrần TùngNo ratings yet

- Pipe Spooling in Fabrication CADmepDocument3 pagesPipe Spooling in Fabrication CADmepsambasivammeNo ratings yet

- Thermal Comfort in Green BuildingDocument22 pagesThermal Comfort in Green BuildingThắm PhạmNo ratings yet

- Low Heating Costs: QB Tip 001Document8 pagesLow Heating Costs: QB Tip 001maheshNo ratings yet

- Hap Ehelp 024Document6 pagesHap Ehelp 024Abed NaemNo ratings yet

- Basic Training Workbook SettingsDocument8 pagesBasic Training Workbook SettingsIvonn OchoaNo ratings yet

- KB Duct 2019 CatalogDocument60 pagesKB Duct 2019 CatalogRajendraPrajapat100% (1)

- Autocad Mep 2009Document120 pagesAutocad Mep 2009haneefaparokotNo ratings yet

- Add An Optional Design Standard Property To Flanges in Plant 3DDocument3 pagesAdd An Optional Design Standard Property To Flanges in Plant 3DgeorgD2010No ratings yet

- OpenStudio Product Overview 1 enDocument15 pagesOpenStudio Product Overview 1 enPaco De Peco EdmspjpNo ratings yet

- 16798-3 Vdı 6022Document25 pages16798-3 Vdı 6022Gıda GündemiNo ratings yet

- MBus 03 eDocument26 pagesMBus 03 eVoicu StaneseNo ratings yet

- Meteonorm ManualDocument58 pagesMeteonorm ManualSam Fisher100% (2)

- Daikin AHU Integration KitDocument4 pagesDaikin AHU Integration Kiterdo mandanaNo ratings yet

- LEED and ASHRAE 90.1 2007 and 2010 App G PRM - User Guide: March 2019Document46 pagesLEED and ASHRAE 90.1 2007 and 2010 App G PRM - User Guide: March 2019Jotham King DennisNo ratings yet

- Hap Ehelp 009 1Document3 pagesHap Ehelp 009 1maheshNo ratings yet

- Energy Savings of 8% From ANSI/ASHRAE/IES Standard 90.1-2016Document65 pagesEnergy Savings of 8% From ANSI/ASHRAE/IES Standard 90.1-2016demet cioncaNo ratings yet

- Using Hap460 For LeedDocument6 pagesUsing Hap460 For LeedSid KherNo ratings yet

- Agregar Componentes AutoCAD Plant 3DDocument8 pagesAgregar Componentes AutoCAD Plant 3DystasvNo ratings yet

- Open StudioDocument18 pagesOpen Studiotajudeen_372461273No ratings yet

- Manual AvicadDocument676 pagesManual AvicadOlivia BlanaruNo ratings yet

- Openstudio 1.7.0 Basic Workflow Guide: Openstudio Sketchup Plug-InDocument52 pagesOpenstudio 1.7.0 Basic Workflow Guide: Openstudio Sketchup Plug-InEdmundo Sahd NetoNo ratings yet

- Actuator Catalogue CompleteDocument22 pagesActuator Catalogue Completeprashantsingh0450% (2)

- AutoCAD Customization Guide 2012Document592 pagesAutoCAD Customization Guide 2012katherxNo ratings yet

- EnergyPlus Energy Simulation Software - Learn More About OpenStudioDocument2 pagesEnergyPlus Energy Simulation Software - Learn More About OpenStudiosoljah818No ratings yet

- Bolt Length Calculations in Plant 3D 2013Document3 pagesBolt Length Calculations in Plant 3D 2013ystasvNo ratings yet

- Sistemi Segnalazione Ostacoli VoloDocument13 pagesSistemi Segnalazione Ostacoli VoloAnonymous 1aHRPIIFfINo ratings yet

- Josam SS Drain GuideDocument28 pagesJosam SS Drain GuidetuzlucayirNo ratings yet

- Pipe Support CalculationDocument1 pagePipe Support CalculationNethru0% (1)

- PD Cen-Tr 16798-2-2019 - (2021-04-20 - 11-25-29 Am)Document92 pagesPD Cen-Tr 16798-2-2019 - (2021-04-20 - 11-25-29 Am)acmm59383No ratings yet

- Flammable Gas Mixing and Detection in HVAC Ducts - Industrial Fire Journal - Fire & Rescue - Hemming Group LTDDocument3 pagesFlammable Gas Mixing and Detection in HVAC Ducts - Industrial Fire Journal - Fire & Rescue - Hemming Group LTDAnonymous 1AAjd0No ratings yet

- KRANTZ ProductsDocument38 pagesKRANTZ Productsduuk73No ratings yet

- Energyplus Vs EquestDocument84 pagesEnergyplus Vs EquestAbdry50No ratings yet

- Valves and Actuators Catalog North America F 27855 7 PDFDocument444 pagesValves and Actuators Catalog North America F 27855 7 PDFAlvaro YépezNo ratings yet

- Ashrae 90.1 Tabelas e ComentáriosDocument12 pagesAshrae 90.1 Tabelas e ComentáriosEmerson Borges SantanaNo ratings yet

- Calefaccion Solar SolvisDocument44 pagesCalefaccion Solar SolvisjomarmaeNo ratings yet

- Integrating Submeters With Building Management Systems For Energy Efficiency and Cost SavingsDocument8 pagesIntegrating Submeters With Building Management Systems For Energy Efficiency and Cost SavingsDon Roseller DumayaNo ratings yet

- BACnet Energy MeterDocument5 pagesBACnet Energy MeterSophia SmithNo ratings yet

- SmpsDocument5 pagesSmpscalvarez_5No ratings yet

- BECKHOFF B U S T E R M I N A L CONFIGURATIONDocument63 pagesBECKHOFF B U S T E R M I N A L CONFIGURATIONbehnamatgNo ratings yet

- UMG96S EnglishDocument8 pagesUMG96S EnglishDaniel EneaNo ratings yet

- Instruction - Manual - GRBL - Controller - V1 - 2 J TECHDocument11 pagesInstruction - Manual - GRBL - Controller - V1 - 2 J TECHAlex David EliNo ratings yet

- NAZA-M Quick Start Guide v1.26 enDocument33 pagesNAZA-M Quick Start Guide v1.26 enjsmith46No ratings yet

- Siemens 317t Gs Sinamics s120Document84 pagesSiemens 317t Gs Sinamics s120Alex David EliNo ratings yet

- F550 User Manual v2.0 enDocument9 pagesF550 User Manual v2.0 enSin BanderaNo ratings yet

- Sigue Line AsDocument6 pagesSigue Line AsAlex David EliNo ratings yet

- Desplegable TesysDocument2 pagesDesplegable TesysAlex David EliNo ratings yet

- Desplegable TesysDocument2 pagesDesplegable TesysAlex David EliNo ratings yet

- Planning Procedure Quality SystemDocument4 pagesPlanning Procedure Quality SystemMacelNo ratings yet

- Dell XPS L502X ManualDocument59 pagesDell XPS L502X ManualNonitus OctingentiNo ratings yet

- AuditDocument8 pagesAuditsai raoNo ratings yet

- Z1 ManualDocument6 pagesZ1 ManualIvana JazidzijaNo ratings yet

- Data Assest Management System (DAMS)Document32 pagesData Assest Management System (DAMS)Greg WiedemanNo ratings yet

- 2500 VA 230V safety isolation transformerDocument1 page2500 VA 230V safety isolation transformerpadminittNo ratings yet

- LTE Network Issue Analysis Guideline V1Document29 pagesLTE Network Issue Analysis Guideline V1Amir Miftahudin100% (1)

- Pom Assignment EditedDocument21 pagesPom Assignment EditedKarl Gio GonocruzNo ratings yet

- Minggu 4 - JavascriptDocument58 pagesMinggu 4 - Javascriptcikiaaulia anisNo ratings yet

- Tc7200.u User Manual Eng v17 PDFDocument83 pagesTc7200.u User Manual Eng v17 PDFalbertNo ratings yet

- 1-Check List CF PumpDocument2 pages1-Check List CF PumpStarla HillNo ratings yet

- BS 10 Flange PDFDocument6 pagesBS 10 Flange PDFmozammilNo ratings yet

- Job Description Safety & HealthDocument1 pageJob Description Safety & HealthNiz IsmailNo ratings yet

- Powerpac HC Power Supply: Instruction ManualDocument26 pagesPowerpac HC Power Supply: Instruction ManualSebastian Martinez CuautencoNo ratings yet

- Pdvsa: Engineering Design ManualDocument7 pagesPdvsa: Engineering Design ManualRafael GarciaNo ratings yet

- 06-086-098 Weld Ring GasketsDocument13 pages06-086-098 Weld Ring GasketsRitesh VishambhariNo ratings yet

- Hydrotesting Quad Joint PipesDocument15 pagesHydrotesting Quad Joint PipesTrust EmmaNo ratings yet

- CR 6Document672 pagesCR 6Francisco José Fontelles ObelenisNo ratings yet

- A F E S: Process Piping: Pipeline Metering Stations 670.204Document3 pagesA F E S: Process Piping: Pipeline Metering Stations 670.204puwarin najaNo ratings yet

- lmp91000 PDFDocument36 pageslmp91000 PDFCleberNogueiraBorgesNo ratings yet

- 15 Au50es ManualDocument9 pages15 Au50es ManualluisNo ratings yet

- 3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDocument7 pages3-Case Study Understanding and Improving ESP Reliability in SAGD Wells With High Dogleg SeverityDorianNo ratings yet

- PSVDocument32 pagesPSVAhtsham Ahmad100% (2)

- 121 130 Lead2Pass Latest Free Oracle 1Z0 060 Dumps (51 60) Download!Document5 pages121 130 Lead2Pass Latest Free Oracle 1Z0 060 Dumps (51 60) Download!mahendra.lal71373No ratings yet

- Introduction To Pipe SupportDocument63 pagesIntroduction To Pipe SupportAkhil Joseph100% (4)

- BS 6399 PDFDocument22 pagesBS 6399 PDFTeoh ChunliNo ratings yet

- Thrush S2R R-1340 Maintenence ManualDocument227 pagesThrush S2R R-1340 Maintenence Manualarizonaflyer1_732976100% (1)

- Activity 7.4.2: Challenge DHCP and NAT ConfigurationDocument5 pagesActivity 7.4.2: Challenge DHCP and NAT ConfigurationLorena Sierra BNo ratings yet

- Firstlook Manual SenxDocument22 pagesFirstlook Manual SenxschraeubleNo ratings yet

- Vtu Tea-1 J2EE Notes Ch-3Document17 pagesVtu Tea-1 J2EE Notes Ch-3junaidnizNo ratings yet