Professional Documents

Culture Documents

Eng Tips

Uploaded by

Saad NaumanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng Tips

Uploaded by

Saad NaumanCopyright:

Available Formats

I can only answer the aspect ratio in general terms, apart from Mechanica.

I believe that my general statements apply to Mechanica also, but as it has been a long time since I've used that code, I can't be 100% sure.

Finite elements end up being sorted out mathematically through their idealized shape (in the case of a quadrilateral element, it is first idealized as a perfect square). This idealized shape is then "linked" to the actual element geometry through shape functions. This is significant because these shape functions break down if the actual geometry of the element seriously diverges from the idealization. This results in "bad answers"

The number that I have most heard for a reasonable aspect ratio is <5.0, meaning the longest edge of an element should not be greater than 5 times that of the shortest. Obviously, one would like this number to be as close to 1.0 as often as possible (meaning all edges are the same length--closer to the idealized shape). However, that is generally not practical. The general rule is always build the best meshes in the areas of greatest concern.

One thing about Mechanica which may effect details of deciding aspect ratio (although I don't think it does) is the fact that Mechanica utilizes polynomial elements. I don't think that p-elements change any of the statements which I have made on this posting. However, if somebody who knows Mechanica feels differently, PLEASE correct me on this point

What is shear locking? This is not intended to be an exhaustive discussion, so my apologies to the hardcore solid mechanicians; this is intended to explain in easiest terms this phenomenon. Take the example which I earlier gave of the cantilever beam. Solid elements cannot "bend", per se. So for a single solid element in cantilever bending, (where the x's are the nodes) Let's presume I hold the left vertical face fixed and apply a bending moment to the right side: The original and deformed configurations would look like: ORIGINAL x x becomes x x x x x DEFORMED x

If this is a fully-integrated 1st order element, the "bending" displacement plays itself out as a contraction of the bottom portion and an extension of the top portion of the element. Hence, the bending mode effectively can only be reacted by a shear mode in the element. One could calculate the strain at the top and bottom of a cantilever beam. If a solid element in bending has a strain of +e on the top face and -e on the bottom face, the energy due to this is much less than the energy due to shearing of that same amount. However, the solid element can ONLY react this load condition via shear. These parasitic shear stresses result in an overly-stiff element. For first-order fullyintegrated elements, this can introduce significant error for a coarse mesh. This overly-stiff behavior is referred to as shear locking. Rahulsrp suggests using reduced-integration elements to avoid this; however, they present their own unique problems in that they have no hourglass stiffness. They have no way of resisting this shear behavior, therefore they have spurious zero-energy shear modes, which can propogate through the mesh. The way to get around these issues: 1) Use 2nd order elements 2) Use a finer mesh--a fine mesh will eventually converge to the "correct" solution 3) Some codes have special fully-integrated elements which account for this behavior. They are sometimes referred to as "incompatible modes" elements. And despite rahulsrp's statement, you CAN in fact use solid elements for "thin" structures; you just need a fine enough mesh and need to be able to maintain reasonable element ratios (after all, "thin" is a relative term). As previously stated, once one has addressed these two issues, it is generally much more computationally expensive to use "solid" elements instead of "shells". Just so there is no confusion: one CAN use solids for these thin structures, but I would recommend using shell elements instead for most cases. Finite elements end up being sorted out mathematically through their idealized shape (in the case of a quadrilateral element, it is first idealized as a perfect square). This idealized shape is then "linked" to the actual element geometry through shape functions. This is significant because these shape functions break down if the actual geometry of the element seriously diverges from the idealization. This results in "bad answers" The number that I have most heard for a reasonable aspect ratio is <5.0, meaning the longest edge of an element should not be greater than 5 times that of the shortest. Obviously, one would like this number to be as close to 1.0 as often as possible (meaning all edges are the same length--closer to the idealized shape). However, that is generally not practical. The general rule is always build the best meshes in the areas of greatest concern. One thing about Mechanica which may effect details of deciding aspect ratio (although I don't think it does) is the fact that Mechanica utilizes polynomial elements. I don't think that p-elements change any of the statements which I have made on this posting. However, if somebody who knows Mechanica feels differently, PLEASE correct me on this point

There does not exist a limit for this, to my knowledge. Often people refer to the 1:10 thickness:element dimension, but this is in fact a reference to the thickness and model dimension. I have not encountered a reference to any limits such as this with regards to element formulation (note that some classes of problems may however have a limit; I just don't know of a general "rule"). MECH works with p-elements and not with the conventional h-elements. P-Elements increase the polynomial orders from 1 (equivalent to linear conventional finite elements) up to 9th order ! This results in a lot of advantages: - each solid element can handle bending, torsion and shear - the element limits can vary for the - aspect ratio up to 1:30 !!! - edge angles from 5 to 175 deg !!! - edge turn up to 95 deg (p-elements follow exactly the underlying geometry, so a hole or similar can be represented as a minimum by four (4!!) element-edges - therefore tetrahedal automatic meshing is no problem; stresses and displacements can be recieved as precise as you wish by defining a numerical quality (convergence) of e.g. 5 % - that is thin structures can be calculated very good; example: we calcualted structures with 1 mm thick walls and an diameter of about 800 mm with 110,000 solid elements and 4.8 Mio. DOF !! To rigid connections: since Version 2000i2 (actual is version 2001) rigid connections can be defined and used. The use of beams is not necessary any more. Answers this some of your points ?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Presentasi Free VibrationDocument48 pagesPresentasi Free VibrationadiNo ratings yet

- Simple Stress and StrainDocument41 pagesSimple Stress and Strainsaritha0003No ratings yet

- ME108 Lab7Document8 pagesME108 Lab7Nick RendaNo ratings yet

- On Bottom Stability Using 3D Dynamic Modelling OTC 27727 MS PDFDocument21 pagesOn Bottom Stability Using 3D Dynamic Modelling OTC 27727 MS PDFMuhammad Rafiq RavinNo ratings yet

- PED Ch1Document17 pagesPED Ch1dpatel 2310No ratings yet

- Design For Steel Structures (Jackets)Document12 pagesDesign For Steel Structures (Jackets)Kathia Lorena Espinoza RojasNo ratings yet

- Lec34 PDFDocument15 pagesLec34 PDFRitu SinghNo ratings yet

- Lattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015Document12 pagesLattice-Boltzmann Analysis of Three-Dimensional Ice Shapes Naca 23012 2015Miliani AhmedNo ratings yet

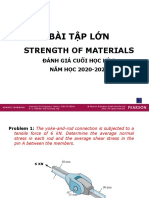

- Đề Bài tập lớn - Môn Strength of MaterialsDocument10 pagesĐề Bài tập lớn - Môn Strength of MaterialsDinh leNo ratings yet

- Mechanical Vibrations Chapter 1Document15 pagesMechanical Vibrations Chapter 1Danyal ChaudhryNo ratings yet

- Lecture Notes Chapter 1 Intro Sept 5Document22 pagesLecture Notes Chapter 1 Intro Sept 5Reb1990No ratings yet

- Solutions 2 PHYSICS 2Document6 pagesSolutions 2 PHYSICS 2MARIAMA SILLAHNo ratings yet

- 1 s2.0 S0020740323007178 MainDocument49 pages1 s2.0 S0020740323007178 MainsobhanNo ratings yet

- Underwater Explosins by ColeDocument464 pagesUnderwater Explosins by Colexiaotaoscribd100% (1)

- Some Salient Features of The Time-Averaged Ground Vehicle WakeDocument34 pagesSome Salient Features of The Time-Averaged Ground Vehicle WakeJulietaDanielaNo ratings yet

- Electromagnetic Fields & Waves (BEB20303) Chapter 1: Electrostatic FieldDocument32 pagesElectromagnetic Fields & Waves (BEB20303) Chapter 1: Electrostatic FieldAFiqah Nazirah JailaniNo ratings yet

- Torsion Spring DesignDocument3 pagesTorsion Spring DesignsohamkoliNo ratings yet

- Sheet1: CIRCULAR Bellows Design Analysis (UNREINFORCED)Document4 pagesSheet1: CIRCULAR Bellows Design Analysis (UNREINFORCED)Raji SuriNo ratings yet

- Thesis Sample, EUROCODEDocument151 pagesThesis Sample, EUROCODEelias workuNo ratings yet

- KCS - CTDocument8 pagesKCS - CTakıle neseNo ratings yet

- 100 QuestionsDocument189 pages100 Questionsasdfsd2345No ratings yet

- 2.1 Duct Design PP 1Document42 pages2.1 Duct Design PP 1quoc khanh NgoNo ratings yet

- Chapter 12 Numerical Simulation: The Stream Function - Vorticity MethodDocument22 pagesChapter 12 Numerical Simulation: The Stream Function - Vorticity Methodbhassan 2007No ratings yet

- ME 4953.009 Gas Dynamics Syllabus Spring 2015, Rev. BDocument7 pagesME 4953.009 Gas Dynamics Syllabus Spring 2015, Rev. Bxxxtoyaxxx0% (1)

- Agitated VesselsDocument12 pagesAgitated VesselsFren2008100% (11)

- Biswas Academy: A2 PhysicsDocument21 pagesBiswas Academy: A2 PhysicsAshiq MehmoodNo ratings yet

- Contact AngleDocument3 pagesContact AngleIman AimanNo ratings yet

- 2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Document11 pages2D Finite Element Analysis of Rubber Pad Forming Process: October 2016Rui MatiasNo ratings yet

- The Forced Vibration of A Three-Layer, Damped Sandwich Beam With Arbitrary Boundary ConditionsDocument13 pagesThe Forced Vibration of A Three-Layer, Damped Sandwich Beam With Arbitrary Boundary Conditionsmusic freakNo ratings yet