Professional Documents

Culture Documents

Emulan Types

Uploaded by

razamehdi3Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emulan Types

Uploaded by

razamehdi3Copyright:

Available Formats

Technical Information

TI/ES 1047 e August 1994 (DFC)

Emulan types

Supersedes edition dated October 1989

Emulan A

Emulan OP 25

Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan

AF AT 9 EL ELP NP 2080 OC OG OK 5

Emulan Emulan Emulan Emulan Emulan Emulan Emulan

OU P PO TO 2080 TO 3070 TO 4070 TO 5070

Nonionic emulsifiers for the chemical and allied industries

Specialty Chemicals

Emulan types

Chemical nature

Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan Emulan

A AF AT 9 EL ELP NP 2080 OC OG OK 5 OP 25 OU P PO TO 2080 TO 3070 TO 4070 TO 5070

Oleic acid ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Castor oil ethoxylate Castor oil ethoxylate Alkylphenol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Alkylphenol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Alkylphenol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate Fatty alcohol ethoxylate

Properties

Emulan NP 2080, Emulan P, Emulan PO, Emulan TO 2080, Emulan TO 3070, Emulan TO 4070 and Emulan TO 5070 are all clear, colourless liquids. Emulan OK 5 is a clear or cloudy, colourless liquid. Emulan A and Emulan ELP are clear, yellowish liquids. Emulan EL is a cloudy, yellowish liquid. Emulan AF, Emulan AT 9, Emulan OC, Emulan OP 25 and Emulan OU are all colourless, waxy solids. Emulan OG is supplied in the form of colourless, waxy, micronized beads. The most important properties of the Emulan types are listed in the table overleaf.

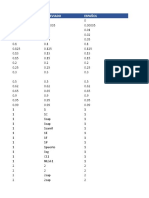

Emulan Physical form Concentration Water content Cloud point (DIN 53917) in BDG solution in water in saline solution pH (5 % in water) Density (23 C) Bulk density Dropping point Setting point Solidification point Melting point Viscosity (23 C, Brookfield, LVT, 60 rpm) Acid number (DIN 53402) Saponification number (DIN 53401) Surface tension (DIN 53914, 1 g/l in distilled water, 23 C, applying Harkins-Jordan correction) Hydrophilic-lipophilic balance (W. C. Griffin) g/cm3 g/l C C C C mPa s mg KOH/g mg KOH/g % % C C C

A Liquid ca. 100 ca. 52 ca. 7 ca. 0.98 <5 <5 ca. 20 ca. 70 ca. 0 ca. 110

AF Paste ca. 100 ca. 65 ca. 7 ca. 0.90 (60 C) ca. 43 ca. 38 ca. 44 ca. 15 (60 C) ca. 0 ca. 0

AT 9 Paste ca. 100 ca. 87 ca. 68 ca. 55 ca. 7 ca. 0.95 (60 C) ca. 33 ca. 31 ca. 33 ca. 20 (60 C) ca. 0 ca. 0

EL Liquid ca. 97 ca. 3 ca. 71 ca. 7 ca. 1.07 ca. 16 ca. 8 ca. 1500 ca. 1 ca. 60

ELP Liquid ca. 100 ca. 51 ca. 7 ca. 1.01 <5 <5 ca. 30 ca. 700 ca. 1 ca. 100

NP 2080 Liquid ca. 80 ca. 20 ca. 85 ca. 7 ca. 1.09 ca. 5 <5 ca. 6 ca. 500 ca. 0 ca. 0

mN/m

ca. 33 ca. 11

ca. 39 ca. 11

ca. 35 ca. 13

ca. 40 ca. 14

ca. 38 ca. 11

ca. 38 ca. 16

OC Paste ca. 100 ca. 90 ca. 7 ca. 1.02 (60 C) ca. 50 ca. 35 ca. 52 ca. 60 (60 C) ca. 0 ca. 0

OG Solid ca. 100 ca. 92 ca. 7 ca. 600 ca. 52 ca. 34 ca. 50 ca. 80 (60 C) ca. 0 ca. 0

OK 5 Liquid ca. 100 ca. 62 ca. 7 ca. 0.96 ca. 6 <5 ca. 60 ca. 0 ca. 0

OP 25 Paste ca. 100 ca. 88 ca. 7 ca. 1.06 (60 C) ca. 37 ca. 26 ca. 37 ca. 100 (60 C) ca. 0 ca. 0

OU Paste ca. 100 ca. 90 ca. 7 ca. 1.02 (60 C) ca. 50 ca. 35 ca. 52 ca. 60 (60 C) ca. 0 ca. 0

P Liquid ca. 100 ca. 52 ca. 7 ca. 0.92 ca. 5 <5 ca. 6 ca. 30 ca. 0 ca. 0

PO Liquid ca. 100 ca. 46 ca. 7 ca. 1.03 <5 <5 ca. 20 ca. 300 ca. 0 ca. 0

TO 2080 Liquid ca. 80 ca. 20 ca. 93 ca. 7 ca. 1.07 ca. 12 <5 ca. 3 ca. 400 ca. 0 ca. 0

TO 3070 Liquid ca. 70 ca. 30 ca. 92 ca. 7 ca. 1.08 ca. 12 <5 ca. 0 ca. 1500 ca. 0 ca. 0

TO 4070 Liquid ca. 70 ca. 30 ca. 92 ca. 7 ca. 1.09 ca. 15 ca. 7 ca. 2 ca. 1400 ca. 0 ca. 0

TO 5070 Liquid ca. 70 ca. 30 ca. 90 ca. 7 ca. 1.09 ca. 16 ca. 7 ca. 4 ca. 2100 ca. 0 ca. 0

ca. 39 ca. 17

ca. 40 ca. 17

ca. 27 ca. 10

ca. 39 ca. 17

ca. 39 ca. 17

ca. 28 ca. 11

ca. 28 ca. 11

ca. 35 ca. 16

ca. 39 ca. 17

ca. 41 ca. 18

ca. 41 ca. 18

The above information is correct at the time of going to press. It does not necessarily form part of the product specification. A detailed product specification is available from your local BASF representative.

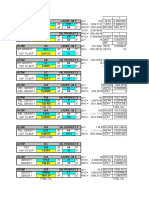

Solubility of 10 % solutions of Emulan at 23 C Emulan Distilled water Potable water Caustic soda, 5 % Hydrochloric acid, 5 % Saline solution, 5 % Petroleum oils Ethanol Aromatic hydrocarbons A + + + AF a + + AT 9 + + EL + + + + + /a + a ELP a + + NP 2080 + + + + + + OC + + + + + a +

The above table shows the solubility of 10 % solutions of the various Emulan types at 23 C. + = Clear solution a = Cloudy solution = Insoluble

OG + + + + + +

OK 5 +/a + a

OP 25 + + + + + /a + +

OU + + + + + a +

P + + a

PO + + +

TO 2080 + + + + + +

TO 3070 + + + + + +

TO 4070 + + + + + +

TO 5070 + + + + + +

The relationship between viscosity and temperature is always an important point to consider when Emulan types are to be stored or delivered. The following tables show the viscosity of the Emulan types as a function of temperature and concentration. Viscosity (mPa s) as a function of temperature Emulan 0 C 10 C 20 C 30 C 40 C 50 C 60 C A ca. 290 ca. 160 ca. 100 ca. 50 ca. 30 ca. 25 ca. 15 AF > 10 5 > 10 5 > 10 5 > 10 5 3600 ca. 20 ca. 15 AT 9 > 10 5 > 10 5 > 10 5 ca. 3500 ca. 90 ca. 40 ca. 20 EL > 10 5 > 10 5 ca. 5000 ca. 1000 ca. 600 ca. 200 ca. 150 ELP ca. 7000 ca. 1500 ca. 1000 ca. 350 ca. 200 ca. 150 ca. 80 NP 2080 ca. 11000 ca. 4500 ca. 1000 ca. 250 ca. 120 ca. 50 ca. 40 OC > 10 5 > 10 5 > 10 5 > 10 5 ca. 800 ca. 100 ca. 60

The rate at which the Emulan types dissolve can be increased by adding alcohols, glycols and other solubilizers. Some of the Emulan types form a gel when they are diluted with water, as can be seen from the following table. Viscosity (mPa s) at 23 C as a function of concentration Emulan Water content 0% 10 % 20 % 30 % 40 % 50 % 60 % 70 % 80 % 90 % A ca. 70 ca. 110 ca. 230 ca. 360 ca. 500 ca. 850 ca. 1900 ca. 200 ca. 35 ca. 20 AF > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 9000 ca. 4000 ca. 1000 AT 9 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 1000 < 10 EL ca. 1500 ca. 1500 ca. 2100 ca. 12000 ca. 23000 ca. 74000 ca. 12000 ca. 130 ca. 15 < 10 ELP ca. 700 ca. 1000 ca. 1700 ca. 2600 ca. 2000 ca. 1600 ca. 900 ca. 400 ca. 90 ca. 25 NP 2080 ca. 500 ca. 450 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 35 < 10 < 10 OC > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 1000 ca. 200 ca. 60 ca. 25

OG > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 110 ca. 80

OK 5 ca. 5200 ca. 600 ca. 100 ca. 40 ca. 30 ca. 25 ca. 15

OP 25 > 10 5 > 10 5 > 10 5 > 10 5 ca. 300 ca. 150 ca. 100

OU > 10 5 > 10 5 > 10 5 > 10 5 ca. 800 ca. 100 ca. 60

P > 10 5 ca. 140 ca. 40 ca. 25 ca. 20 ca. 15 ca. 10

PO ca. 5000 ca. 950 ca. 400 ca. 120 ca. 70 ca. 35 ca. 30

TO 2080 > 10 5 ca. 8000 ca. 1100 ca. 240 ca. 130 ca. 70 ca. 50

TO 3070 > 10 5

TO 4070 > 10 5

TO 5070 > 10 5

ca. 12000 ca. 23000 > 10 5 ca. 3000 ca. 1000 ca. 500 ca. 200 ca. 100 ca. 10000 ca. 16000 ca. 1000 ca. 600 ca. 200 ca. 100 ca. 1800 ca. 1200 ca. 400 ca. 200

OG > 10 5 > 10 5 > 10 5

OK 5 ca. 60

OP 25 ca. 100

OU > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 1000 ca. 200 ca. 60 ca. 25

P ca. 30 ca. 50 ca. 200 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5

PO ca. 300 ca. 300 ca. 9000 > 10 5 > 10 5 ca. 4000 ca. 450 ca. 200

TO 2080 ca. 400 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 70 ca. 20 ca. 10

TO 3070 ca. 1500 > 10 5 > 10 5 > 10 5 > 10 5 > 10 5 ca. 160 ca. 80 ca. 20 ca. 10

TO 4070 ca. 1400 ca. 2300 ca. 1800 ca. 1500 ca. 800 ca. 400 ca. 150 ca. 50 ca. 20 < 10

TO 5070 ca. 2100 ca. 4200 ca. 2000 ca. 2800 ca. 1000 ca. 400 ca. 200 ca. 70 ca. 20 ca. 10

ca. 13000 ca. 30 > 10 5 ca. 400 ca. 500 ca. 900 > 10 5 > 10 5

ca. 15000 > 10 5 ca. 13000 > 10 5 ca. 2000 ca. 250 ca. 50 ca. 35 ca. 10 > 10 5 > 10 5

ca. 75000 ca. 100 ca. 500 < 10 < 10 < 10

ca. 3000 ca. 80 ca. 60 ca. 25

Storage

a) The Emulan types should be stored in their original packaging, which should be kept tightly sealed, in a dry place. Storerooms must not be overheated. b) The Emulan types are hygroscopic and soluble in water, with the result that they absorb moisture very quickly. Drums should be tightly resealed each time material is taken from them. c) The setting points of the Emulan types must be taken into consideration when determining the storage temperature. d) The Emulan types can become cloudy if they are stored at low temperatures, but this has no effect on their performance. The cloudiness can be dissipated by heating them to 50 60 C. e) Liquid that has solidified or that shows signs of precipitation should be heated to 50 70 C* and homogenized before use. f) Drums that have solidified or that have begun to precipitate should be reconstituted by gentle heating, preferably in a heating cabinet. The temperature must not be allowed to exceed 50 70 C*. This also applies if drums are heated by external electrical elements. Internal electrical elements should not be used because of the localized anomalies in temperature that they cause. g) The Emulan types must be blanketed with nitrogen if they are stored in heated tanks (at 50 70 C*) to prevent them from coming into contact with air. Gentle, constant stirring helps to prevent them being discoloured as a result of prolonged contact with electrical elements or external heating coils. h) Emulan OG should be stored in a dry place at a temperature not exceeding 25 30 C.

Materials Shelf life

The Emulan types should be stored in tanks made from AISI 316 Ti or AISI 321 stainless steel. The Emulan types have a shelf life of two years, provided they are stored in their original packaging and kept tightly sealed.

Applications

The Emulan types can be used to prepare oil-in-water and water-in-oil emulsions. Individual products can usually be classified as being oil-inwater or water-in-oil emulsifiers, but it is often difficult to allocate combinations of different emulsifiers to either of these categories. It is also difficult to categorize emulsions that deviate from the norm in that, for instance, they consist of more than two phases. Some of the products in the Emulan range can also be used to disperse solids such as waxes, polymers or rubber latex in water, and to stabilize aqueous dispersions. Dispersions of this type are employed as impregnating resins, lubricants, polishes and protective coatings, and they can be used to dedust powders. The choice of emulsifier plays a large part in determining the stability of emulsions. The nature of the hydrophilic and lipophilic components of the emulsifier molecule and the proportions of hydrophilic and lipophilic groups determine their performance and the applications open to them. Oil-in-water emulsions are usually obtained if the emulsifier molecule is predominantly hydrophilic, and water-in-oil emulsions are obtained if the emulsifier molecule is predominantly hydrophobic.

* The temperature depends on the melting point or setting point. 9

The ratio between the two parts of the molecule is expressed by the hydrophilic lipophilic balance (HLB), as defined by W.C. Griffin (Journ Soc. Cosm. Chemists, 1 [1949], 311; 5 [1954], 249). The hydrophilic lipophilic balance is a useful practical guide to the applications open to different emulsifiers, but the final choice of emulsifier always depends on the results of practical tests in the laboratory. The usual method is to use a combination of two or more emulsifiers, because this approach offers greater scope. The Emulan types have the advantage that they are compatible with each other, with cationic and anionic emulsifiers, and with many other substances. Emulsions prepared with emulsifiers from the Emulan range are largely insensitive to variations in temperature. They are largely unaffected by the presence of soil and, to a lesser extent, electrolytes. As with all other nonionic emulsifiers, the performance of the Emulan types can be affected by tannins, other substances of a phenolic nature, and complex acids such as phosphotungstic acid and its salts. Emulan A Oil phase (o/w) Mainly used to emulsify petroleum oils, fatty oils and mixtures thereof. Can also be used in combination with other emulsifiers to emulsify solid fats, aromatic compounds, chlorinated hydrocarbons, silicone oils and similar substances of a polar nature. Main applications Level of addition Emulan AF Oil phase (o/w) Paraffin wax, paraffin oils and petroleum oils. Can also be used in combination with other emulsifiers to emulsify vegetable oils, solid fats, ester waxes, beeswax, chlorinated hydrocarbons, silicone oils and aromatic compounds. Petroleum oil emulsions and paraffin wax emulsions. 5 20 %, expressed as a proportion of the substance to be emulsified. Drilling oils, rolling oils, drawing oils, release agents for concrete formwork, spinning oils, cleaners, metal polishes and buffing compounds. 5 15 %, expressed as a proportion of the substance to be emulsified.

Main applications Level of addition Emulan AT 9 Oil phase (o/w) Main applications Level of addition Emulan EL Oil phase (o/w)

Paraffin wax. Highly concentrated paraffin wax emulsions. 5 20 %, expressed as a proportion of the paraffin wax.

Mainly used to emulsify fatty acids, fatty oils, solid fats, ester waxes, many different organic solvents and solutions of polymers, etc., in organic solvents. Solubilizer for cyclic compounds and dyes. All types of emulsions prepared from fatty acids, fatty oils, organic solvents and substances dissolved in them, such as polymers, resins, dyes, etc. Can be used in combination with calcium dodecylbenzenesulfonate in emulsifiable pesticide concentrates. 5 15 %, expressed as a proportion of the substance to be emulsified.

Main applications

Level of addition Emulan ELP Oil phase (o/w) Main applications Level of addition

Mainly used to emulsify vegetable oils. All types of emulsions prepared from vegetable oils and substances dissolved in them, e. g. in emulsifiable pesticide concentrates. 5 15 %, expressed as a proportion of the substance to be emulsified.

10

Emulan NP 2080, Emulan OP 25 Oil phase (o/w) Main applications Mainly used to emulsify acrylic esters, styrene and vinyl monomers. Also used to emulsify ester waxes and fatty acids. Polymer dispersions. Can be used alone or in combination with anionic emulsifiers such as Emulphor OPS 25 or cationic emulsifiers in emulsion polymerization processes for many different types of monomer, such as acrylic esters, styrene and vinyl compounds. Also used to emulsify ester waxes and fatty acids. Can be used to stabilize emulsions, suspensions and latices. Level of addition Emulan OC Oil phase (o/w) Mainly used to emulsify waxes, especially montanic ester waxes and carnauba wax, fatty acids, many different organic solvents and substances dissolved in organic solvents. Dry-bright wax polishes. Emulan OC can be used to emulsify montanic ester wax and blends of montanic ester wax with paraffin wax, microcrystalline wax, oxidized microcrystalline wax, emulsifiable polyethylene wax (Luwax OA Pastilles), and Fischer-Tropsch wax. 5 15 %, expressed as a proportion of the wax to be emulsified, depending on the type of wax. For waxes, especially montanic ester waxes and carnauba wax, fatty acids, and many organic solvents and dissolved organic substances such as polymers, etc. Dispersing solids formed by chemical reaction, precipitation or coagulation. Dispersing pigments and dyes during grinding, either dry, in water or in aqueous mixtures of organic solvents. Can be used in combination with protective colloids. Can also be used to stabilize emulsions and suspensions. Examples include stabilizing concentrated hydraulic fluids and corrosion inhibitors before they are diluted with very hard water. They prevent polymer dispersions from precipitating when pigments, fillers or other additives are added, and they can be used to stabilize dispersions that are exposed to heat or contaminated with soil. Level of addition As an emulsifier 5 15 %, expressed as a proportion of the substance to be emulsified. As a stabilizer 1 10 %, expressed as a proportion of the substance to be dispersed. Emulan OK 5 Oil phase (o/w) Mainly used to emulsify petroleum oils and organic solvents. Compatible with other emulsifiers such as Emulan A, Emulan P, Emulan PO, Korantin SH, Lutensol AP 7, sulfonated oils and soaps. Solvent-based cleaners, drilling oils and release agents for concrete formwork. 5 15 %, expressed as a proportion of the substance to be emulsified. 5 15 %, expressed as a proportion of the substance to be emulsified.

Main applications

Level of addition Emulan OG, Emulan OU Oil phase (o/w)

Main applications

Main applications Level of addition Emulan P Oil phase (o/w)

Mainly used to emulsify paraffin oils and other petroleum oils such as kerosene, spindle oil and mineral spirits. Can also be used to emulsify fatty oils and aromatic solvents in combination with other emulsifiers.

11

Main applications

All types of emulsions prepared from light petroleum fractions such as paraffin oils and spin finishes for textiles, and for spinning oils and cleaners that contain solvents. 5 10 %, expressed as a proportion of the substance to be emulsified.

Level of addition Emulan PO Oil phase (o/w)

Mainly used in combination with other emulsifiers to emulsify petroleum oils and organic solvents. Compatible with emulsifiers such as Emulan A, Emulan P, Korantin SH, Lutensol AP 7, sulfonated oils and soaps. Solvent-based cleaners, drilling oils and release agents for concrete formwork. 5 15 %, expressed as a proportion of the substance to be emulsified.

Main applications Level of addition Emulan TO types Oil phase (o/w) Main applications

Mainly used to emulsify acrylic esters, styrene and vinyl monomers. Polymer dispersions. Can be used alone or in combination with anionic surfactants in emulsion polymerization processes for many different types of monomer, such as acrylic esters, styrene and vinyl compounds. Substitutes for highly ethoxylated alkylphenol ethoxylates.

Level of addition

In polymerization processes 1 5 %, expressed as a proportion of the monomers to be emulsified.

Safety

We know of no ill effects that could have resulted from using the Emulan types for the purpose for which they are intended and from processing them in accordance with current practice. According to the experience we have gained over many years and other information at our disposal, the Emulan types do not exert any harmful effects on health, provided that they are used properly, due attention is given to the precautions necessary for handling chemicals, and the information and advice given in our safety data sheets are observed. Ecology Most of the Emulan types are at least 90 % biodegradable and satisfy the requirements of German surfactants legislation. The only exception is Emulan OP 25.

Note

The information submitted in this publication is based on our current knowledge and experience. In view of the many factors that may affect processing and application, these data do not relieve processors of the responsibility of carrying out their own tests and experiments; neither do they imply any legally binding assurance of certain properties or of suitability for a specific purpose. It is the responsibility of those to whom we supply our products to ensure that any proprietary rights and existing laws and legislation are observed.

12

Printed in Germany

BASF Aktiengesellschaft Marketing Spezialchemikalien I 67056 Ludwigshafen/Germany

You might also like

- TI Lutensol AO ES1070e May2004Document12 pagesTI Lutensol AO ES1070e May2004Argentus Asesorías QuímicasNo ratings yet

- Metalworking Additives IndustryDocument5 pagesMetalworking Additives IndustryMayank GuptaNo ratings yet

- Plurafac LF TypesDocument19 pagesPlurafac LF TypesJavier Miranda RodríguezNo ratings yet

- Viscosity Chart MediaDocument1 pageViscosity Chart MediaEmad MhdzdhNo ratings yet

- Soap CalculatorDocument23 pagesSoap CalculatorJoao Henrique Vieira PradoNo ratings yet

- Specific Gravity Chart PDFDocument5 pagesSpecific Gravity Chart PDFChristian D. Orbe0% (1)

- Lutensol atDocument10 pagesLutensol atVilas DhakappaNo ratings yet

- Plasguard 7122 PDFDocument18 pagesPlasguard 7122 PDFNageswara Rao BavisettyNo ratings yet

- Wine List Cape North Distribution 2012Document12 pagesWine List Cape North Distribution 2012boonsomNo ratings yet

- Diccionario V1Document1,308 pagesDiccionario V1Ed VanegasNo ratings yet

- Book 1Document6 pagesBook 1AmerBurekovicNo ratings yet

- General Characteristic of Crude OilDocument20 pagesGeneral Characteristic of Crude Oildassi99No ratings yet

- Fundamentals of Distillation PDFDocument89 pagesFundamentals of Distillation PDFjamjam1062No ratings yet

- U-250 (EOA 2150) Unit Specification Fluid: Feed Ethylene OxideDocument23 pagesU-250 (EOA 2150) Unit Specification Fluid: Feed Ethylene Oxideemoreno6581No ratings yet

- Corrosion Resistance of Thermoplastics &thermosetsDocument11 pagesCorrosion Resistance of Thermoplastics &thermosetsprateek_bhoirNo ratings yet

- ASTM TablesDocument29 pagesASTM TablesStemo100% (1)

- Capacitor Code GuideDocument2 pagesCapacitor Code GuideMalik SameeullahNo ratings yet

- Plasguard 3070 Chemical Exposure GuideDocument11 pagesPlasguard 3070 Chemical Exposure GuideNageswara Rao BavisettyNo ratings yet

- Princípios Elementares Dos Processos Químicos (Felder) - GráficosDocument10 pagesPrincípios Elementares Dos Processos Químicos (Felder) - GráficosRobson AlmeidaNo ratings yet

- Allowable Ampacities of Insulated Conductors RatedDocument1 pageAllowable Ampacities of Insulated Conductors RatedDan C. LabagnoyNo ratings yet

- Mid Sem PresentationDocument15 pagesMid Sem PresentationdivyaNo ratings yet

- Specific GravityDocument15 pagesSpecific GravityZoran Danilov100% (1)

- 08 130204e Emulan TypesDocument9 pages08 130204e Emulan TypesM. Ismail Fakhar HussainNo ratings yet

- Bintulu Condensate RegularDocument12 pagesBintulu Condensate Regulardassi99No ratings yet

- Nido RetailDocument10 pagesNido RetailMily CamachoNo ratings yet

- Crude Oil Assay Report: OriginalDocument14 pagesCrude Oil Assay Report: Originaldassi99No ratings yet

- PictureDocument12 pagesPictureSougata KunduNo ratings yet

- PPPPPPDocument10 pagesPPPPPPSougata KunduNo ratings yet

- CCCCDocument8 pagesCCCCRaju SamuelNo ratings yet

- Katalog 1 NoviDocument12 pagesKatalog 1 NoviAmerBurekovicNo ratings yet

- Chillere Cu Adsorbtie: Recuperare de Caldura Racire SolaraDocument18 pagesChillere Cu Adsorbtie: Recuperare de Caldura Racire Solaraxenia_1970No ratings yet

- Talas: AYAA, AYAC, AYAF, & AYAT Polyvinyl Resins Information SheetDocument1 pageTalas: AYAA, AYAC, AYAF, & AYAT Polyvinyl Resins Information SheetDgek LondonNo ratings yet

- Beban Terhadap SFC: Laporan Pengujian Mesin Deutz Bf10LDocument2 pagesBeban Terhadap SFC: Laporan Pengujian Mesin Deutz Bf10LRaditya ObitzNo ratings yet

- ADocument2 pagesAmaraki998No ratings yet

- Surf Act Ants For Industrial ApplicationsDocument24 pagesSurf Act Ants For Industrial ApplicationsLuis Antonio Encarnación Castro100% (4)

- Lubricants HANDBOOK PDFDocument214 pagesLubricants HANDBOOK PDFeng13100% (16)

- KondenzatoriDocument30 pagesKondenzatoriMirjana Stranatic-RisticNo ratings yet

- Miri Crude Assay RPTDocument14 pagesMiri Crude Assay RPTapiskai100% (1)

- Chemical Corrosion Chart 2Document40 pagesChemical Corrosion Chart 2teddydeNo ratings yet

- PNEUMATEX TervezesiSegedlet PlanningDocument24 pagesPNEUMATEX TervezesiSegedlet Planningatisz333No ratings yet

- Lutensol A 1Document10 pagesLutensol A 1Vilas DhakappaNo ratings yet

- 123dok Pengaruh+Total+Solid+Dan+Total+Alkali+Aktif+Pada+Black+Liqour+ (Lindi+Hitam) +Terhadap+Kualitas+Pulp+YDocument51 pages123dok Pengaruh+Total+Solid+Dan+Total+Alkali+Aktif+Pada+Black+Liqour+ (Lindi+Hitam) +Terhadap+Kualitas+Pulp+Ypathun tambaNo ratings yet

- Viscosity-Graded Asphalt Cement: Standard Specification ForDocument4 pagesViscosity-Graded Asphalt Cement: Standard Specification Formohammed karasnehNo ratings yet

- Sokalan PA TypesDocument7 pagesSokalan PA TypesQuoc ThanhNo ratings yet

- Chemical Resistance GuideDocument16 pagesChemical Resistance GuidePette MingNo ratings yet

- OPTIMIZING ROASTING TEMPERATUREDocument7 pagesOPTIMIZING ROASTING TEMPERATUREDannyNo ratings yet

- Final Sizing Cost Count Wise 18.03.14Document3 pagesFinal Sizing Cost Count Wise 18.03.14soyeb60No ratings yet

- Tabela Referentnih Vrednosti 5 Part DiffDocument1 pageTabela Referentnih Vrednosti 5 Part DiffAmela MangicNo ratings yet

- Macrogol Cetostearyl EtherDocument2 pagesMacrogol Cetostearyl EtherjaimurugeshNo ratings yet

- Etoolbox ViscosityDocument4 pagesEtoolbox ViscositySamber MataNo ratings yet

- Acid Properties and Fluid Flow CharacteristicsDocument20 pagesAcid Properties and Fluid Flow CharacteristicsPablo SotoNo ratings yet

- The Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterFrom EverandThe Chemistry of Dairy Products - A Chemical Analysis of Milk, Cream and ButterNo ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- Architecture of the Shot: Constructing the Perfect Shots and Shooters from the Bottom UpFrom EverandArchitecture of the Shot: Constructing the Perfect Shots and Shooters from the Bottom UpNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Flow CupsDocument3 pagesFlow Cupsrazamehdi3No ratings yet

- Gardner Delta Color Comparator ModelsDocument1 pageGardner Delta Color Comparator Modelsrazamehdi3No ratings yet

- Flow CupsDocument3 pagesFlow Cupsrazamehdi3No ratings yet

- Astm D7029-2004 - GT +petDocument5 pagesAstm D7029-2004 - GT +petrazamehdi3No ratings yet

- ASTM - D1259 - Non Volatile Content PDFDocument3 pagesASTM - D1259 - Non Volatile Content PDFrazamehdi3100% (1)

- Gardner Delta Color Comparator ModelsDocument1 pageGardner Delta Color Comparator Modelsrazamehdi3No ratings yet

- ASTM Test Methods Guide For Epoxy Resins D4142Document2 pagesASTM Test Methods Guide For Epoxy Resins D4142razamehdi3No ratings yet

- TDS TW5001Document2 pagesTDS TW5001razamehdi3No ratings yet

- Steam Presuure - TemperatureDocument1 pageSteam Presuure - Temperaturerazamehdi3No ratings yet

- Steam Presuure - TemperatureDocument1 pageSteam Presuure - Temperaturerazamehdi3No ratings yet

- ASTM - D445 - Viscosity of Epoxy Resin PDFDocument3 pagesASTM - D445 - Viscosity of Epoxy Resin PDFrazamehdi3No ratings yet

- ASTM - D1259 - Non Volatile Content PDFDocument3 pagesASTM - D1259 - Non Volatile Content PDFrazamehdi3100% (1)

- BPA Market ReportsDocument16 pagesBPA Market Reportsrazamehdi3No ratings yet

- Epoxy HardenerUS20100012888Document5 pagesEpoxy HardenerUS20100012888razamehdi3No ratings yet

- ASTM - D445 - Viscosity of Epoxy ResinDocument3 pagesASTM - D445 - Viscosity of Epoxy Resinrazamehdi3No ratings yet

- Cal FormulaesDocument3 pagesCal Formulaesrazamehdi3No ratings yet

- ASTM D2071 Amine Value Fatty AminesDocument4 pagesASTM D2071 Amine Value Fatty Aminesrazamehdi3No ratings yet

- Clinical PsychologyDocument1 pageClinical Psychologyrazamehdi3No ratings yet

- Essay PURDocument8 pagesEssay PURrazamehdi3No ratings yet

- TDS Byk-065 enDocument2 pagesTDS Byk-065 enrazamehdi3No ratings yet

- Clinical PsychologyDocument1 pageClinical Psychologyrazamehdi3No ratings yet

- Us5786522 Ge-1998Document5 pagesUs5786522 Ge-1998razamehdi3No ratings yet

- Anti Tack Additives 2007-New Names (NXPowerLite)Document16 pagesAnti Tack Additives 2007-New Names (NXPowerLite)razamehdi3No ratings yet

- Brochure Raw Materials For Textile AuxiliariesDocument14 pagesBrochure Raw Materials For Textile Auxiliariesrazamehdi3100% (1)

- Immigration Law BrochureDocument26 pagesImmigration Law BrochureSyed Muhammad AhsanNo ratings yet

- Skin Whitening PreparationDocument14 pagesSkin Whitening PreparationMárcio AlvesNo ratings yet

- NSF - 305-2016 - Norma Productos OrganicosDocument66 pagesNSF - 305-2016 - Norma Productos OrganicosAle-Gina G VidalNo ratings yet

- Abg Orlando Report (2016) 19.04 .2017Document59 pagesAbg Orlando Report (2016) 19.04 .2017缪忠琴100% (1)

- AMINADocument15 pagesAMINARODHIANSYAH DJAYASINGANo ratings yet

- 11.alcohol, Phenol & Ethers Colour Booklet PDFDocument59 pages11.alcohol, Phenol & Ethers Colour Booklet PDFMridu BhandariNo ratings yet

- Sintesis Metil Nitro AcetatoDocument3 pagesSintesis Metil Nitro AcetatoImanol ZapicoNo ratings yet

- Tween 80 PDFDocument2 pagesTween 80 PDFKamila AqilaNo ratings yet

- Experiment No. 4 Carboxylic Acids and Esters (Initial)Document2 pagesExperiment No. 4 Carboxylic Acids and Esters (Initial)Christine MarcellanaNo ratings yet

- Tylose PSO 810001Document4 pagesTylose PSO 810001pkh29No ratings yet

- Amort Hydril KDocument21 pagesAmort Hydril KFernando Aybar100% (1)

- Curs 3 EnglezaDocument25 pagesCurs 3 EnglezaFlaviu TomuțaNo ratings yet

- Waterman & Mole. Analysis of Phenolic Plant Metabolites. Blackwell 1994Document246 pagesWaterman & Mole. Analysis of Phenolic Plant Metabolites. Blackwell 1994Lía FC100% (1)

- AbzymesDocument17 pagesAbzymesRitvik Chaturvedi100% (1)

- Esterification Experiment Produces Fruit-Smelling EsterDocument5 pagesEsterification Experiment Produces Fruit-Smelling EsterKuguneshwryNo ratings yet

- MitDocument13 pagesMitKasi RuddrarajuNo ratings yet

- CALIFORNIA STATE SCIENCE FAIR 2009 PROJECT SUMMARYDocument1 pageCALIFORNIA STATE SCIENCE FAIR 2009 PROJECT SUMMARYRattanDeep SinghNo ratings yet

- Inci Names 3colDocument103 pagesInci Names 3colVinay RaghavendranNo ratings yet

- Preparation of Benzy L Acetate Post LabDocument3 pagesPreparation of Benzy L Acetate Post LabNina PobleteNo ratings yet

- Yearly Lesson Plan 2016-2017 Term 3Document9 pagesYearly Lesson Plan 2016-2017 Term 3Fazliawati Mahayuddin50% (2)

- IR Spectroscopy TutorialDocument36 pagesIR Spectroscopy TutorialreddygrNo ratings yet

- Chapter Four PowerpointDocument109 pagesChapter Four PowerpointthanaNo ratings yet

- Speciality Chemicals Product ListDocument201 pagesSpeciality Chemicals Product ListJakin RookNo ratings yet

- Acrylic Acid ProductionDocument82 pagesAcrylic Acid ProductionDarrold Lim73% (11)

- Novel SurfactantDocument659 pagesNovel Surfactantnarendragcp100% (1)

- Reactive and Hybrid Separations: Incentives, Applications, BarriersDocument48 pagesReactive and Hybrid Separations: Incentives, Applications, BarriersKarime KantunNo ratings yet

- D 268 - 96 - Rdi2oc05ngDocument6 pagesD 268 - 96 - Rdi2oc05ngrestor3dNo ratings yet

- Phytochemical Screening and Biological ActivitiesDocument6 pagesPhytochemical Screening and Biological Activitiesalanbecker_alNo ratings yet

- Kulinkovich Cyclopropanation: A. General Description of The ReactionDocument4 pagesKulinkovich Cyclopropanation: A. General Description of The ReactionSangvenkatNo ratings yet

- Carboxylic Acids, Esters, and Other Acid Derivatives: Test BankDocument14 pagesCarboxylic Acids, Esters, and Other Acid Derivatives: Test BankAda VessaliusNo ratings yet

- Volatile Oil فاينلDocument81 pagesVolatile Oil فاينلZain BaderNo ratings yet