Professional Documents

Culture Documents

Machine Dynamics: Mass, Damping

Uploaded by

Vasile RaduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Dynamics: Mass, Damping

Uploaded by

Vasile RaduCopyright:

Available Formats

Chapter 6

MACHINE DYNAMICS

The primary reasons for vibration profile variations are the dynamics of the machine, which are affected by mass, stiffness, damping, and degrees of freedom. However, care must be taken because the vibration profile and energy levels generated by a machine also may vary depending on the location and orientation of the measurement.

MASS, STIFFNESS, AND DAMPING

The three primary factors that determine the normal vibration energy levels and the resulting vibration profiles are mass, stiffness, and damping. Every machine-train is designed with a dynamic support system that is based on the following: the mass of the dynamic component(s), a specific support system stiffness, and a specific amount of damping.

Mass

Mass is the property that describes how much material is present. Dynamically, it is the property that describes how an unrestricted body resists the application of an external force. Simply stated, the greater the mass the greater the force required to accelerate it. Mass is obtained by dividing the weight of a body (e.g., rotor assembly) by the local acceleration of gravity, g. The English system of units is complicated compared to the metric system. In the English system, the units of mass are pounds-mass (lbm) and the units of weight are pounds-force (lbf). By definition, a weight (Le., force) of 1 lbf equals the force produced by 1 lbm under the acceleration of gravity. Therefore, the constant, gc, which has the same numerical value as g (32.17) and units of lbm-ft/lbf-sec2,is used in the definition of weight:

26

Machine Dynamics

27

Mass*g Weight = g C

Therefore, Mass = Therefore, Mass = Weight*g, = -lbf

g

Weight*gc

g

lbm*ft lbf*sec2

= Ebm

ft 2

sec

Stiffness

Stiffness is a spring-like property that describes the level of resisting force that results when a body undergoes a change in length. Units of stiffness are often given as pounds per inch (Ibf/in.). Machine-trains have more than one stiffness property that must be considered in vibration analysis: shaft stiffness, vertical stiffness, and horizontal stiffness.

Shaft Stiffness

Most machine-trains used in industry have flexible shafts and relatively long spans between bearing-support points. As a result, these shafts tend to flex in normal operation. Three factors determine the amount of flex and mode shape that these shafts have in normal operation: shaft diameter, shaft material properties, and span length. A small-diameter shaft with a long span will obviously flex more than one with a larger diameter or shorter span.

Vertical Stiffness

The rotor-bearing support structure of a machine typically has more stiffness in the vertical plane than in the horizontal plane. Generally, the structural rigidity of a bearing-support structure is much greater in the vertical plane. The full weight of and the dynamic forces generated by the rotating element are fully supported by a pedestal cross-section that provides maximum stiffness. In typical rotating machinery, the vibration profile generated by a normal machine contains lower amplitudes in the vertical plane. In most cases, this lower profile can be directly attributed to the difference in stiffness of the vertical plane when compared to the horizontal plane.

Horizontal Stiffness

Most bearing pedestals have more freedom in the horizontal direction than in the vertical. In most applications, the vertical height of the pedestal is much greater than the horizontal cross-section. As a result, the entire pedestal can flex in the horizontal plane as the machine rotates.

28

Vibration Fundamentals

Mass

":"!

.5

Weight (W)

Figure 6.1 Undamped spring-mass system.

This lower stiffness generally results in higher vibration levels in the horizontal plane. This is especially true when the machine is subjected to abnormal modes of operation or when the machine is unbalanced or misaligned.

Damping

Damping is a means of reducing velocity through resistance to motion, in particular by forcing an object through a liquid or gas, or along another body. Units of damping are often given as pounds per inch per second (lbf/in./sec, which is also expressed as lbf-sec/in.). The boundary conditions established by the machine design determine the freedom of movement permitted within the machine-train. A basic understanding of this concept is essential for vibration analysis. Free vibration refers to the vibration of a damped (as well as undamped) system of masses with motion entirely influenced by their potential energy. Forced vibration occurs when motion is sustained or driven by an applied periodic force in either damped or undamped systems. The following sections discuss free and forced vibration for both damped and undamped systems.

Free Vibration-Undamped

To understand the interactions of mass and stiffness, consider the case of undamped free vibration of a single mass that only moves vertically, as illustrated in Figure 6.1. In this figure, the mass M is supported by a spring that has a stiffness K (also referred to as the spring constant), which is defined as the number of pounds of tension necessary to extend the spring 1 in.

Machine Dynamics

29

The force created by the static deflection, Xi, of the spring supports the weight, W, of the mass. Also included in Figure 6.1 is the free-body diagram that illustrates the two forces acting on the mass. These forces are the weight (also referred to as the inertia force) and an equal, yet opposite force that results from the spring (referred to as the spring force, F,). The relationship between the weight of mass M and the static deflection of the spring can be calculated using the following equation:

w=KXi

If the spring is displaced downward some distance, X,, from Xi and released, it will oscillate up and down. The force from the spring, F,, can be written as follows, where u is the acceleration of the mass:

It is common practice to replace acceleration a with

d2X

7the second derivative of the ,

dt displacement, X, of the mass with respect to time, t. Making this substitution, the equation that defines the motion of the mass can be expressed as:

M d2X

gc dt2

- - = -KX

M d2X or - - + K X =

gc

dt2

Motion of the mass is known to be periodic in time. Therefore, the displacement can be described by the expression:

x

where

= Xocos(ot)

X = Displacement at time t X, = Initial displacement of the mass o = Frequency of the oscillation (natural or resonant frequency) t = Time. If this equation is differentiated and the result inserted into the equation that defines motion, the natural frequency of the mass can be calculated. The first derivative of the equation for motion given previously yields the equation for velocity. The second derivative of the equation yields acceleration. dX Velocity = - = X = -wXosin(ot)

dt

30

Vibration Fundamentals

d2X 2 Acceleration = - = X = -W Xocos(ot) dt2 dLX Inserting the above expression for acceleration, or 2 , into the equation for F, yields the following: dt

M M ---w2 X + K X = --w 2 i K = 0

gc

gc

Solving this expression for w yields the equation:

o =

where

w = Natural frequency of mass K = Spring constant M = Mass.

Note that, theoretically, undamped free vibration persists forever. However, this never occurs in nature and all free vibrations die down after time due to damping, which is discussed in the next section.

Free Vibration-Damped

A slight increase in system complexity results when a damping element is added to the spring-mass system shown in Figure 6.2. This type of damping is referred to as viscous damping. Dynamically, this system is the same as the undamped system illustrated in Figure 6.1, except for the damper, which usually is an oil or air dashpot mechanism. A damper is used to continuously decrease the velocity and the resulting energy of a mass undergoing oscillatory motion.

The system is still comprised of the inertia force due to the mass and the spring force, but a new force is introduced. This force is referred to as the damping force and is proportional to the damping constant, or the coefficient of viscous damping, c. The damping force is also proportional to the velocity of the body and, as it is applied, it opposes the motion at each instant.

Machine Dynamics

31

x=0

Figure 6.2 Damped spring-mass system.

In Figure 6.2, the unelongated length of the spring is Lo and the elongation due to the weight of the mass is expressed by h. Therefore, the weight of the mass is Kh. Figure 6.2(a) shows the mass in its position of stable equilibrium. Figure 6.2(b) shows the mass displaced downward a distance X from the equilibrium position. Note that X is considered positive in the downward direction. Figure 6.2(c) is a free-body diagram of the mass, which has three forces acting on it. The weight (Mglg,), which is directed downward, is always positive. The damping force

(c-

,which is the damping constant times velocity, acts opposite to the direc-

tion of the velocity. The spring force, K(X

+ h), acts in the direction opposite to the

displacement. Using Newtons equation of motion, where

1F = M u , the sum of

32

Vibration Fundamentals

the forces acting on the mass can be represented by the following equation, remembering that X is positive in the downward direction:

Dividing by M . -.

gC

To look up the solution to the preceding equation in a differential equations table (such as in the CRC Handbook o Chemistry and Physics) it is necessary to change f the form of this equation. This can be accomplished by defining the relationships, cg, / M = 2p and K g , / M = 02, which converts the equation to the following fonn:

n

dX d'X - -2p--w -d? dt

Note that for undamped free vibration, the damping constant, c, is zero and, therefore, p is also zero. d2X 2 ---=--ox

dt2

The solution of this equation describes simple harmonic motion, which is given below:

X = Acos(wt) + Bsin(ot)

dX Substituting at t = 0, then X = X , and - = 0 , then dt

X0COS(Wt)

This shows that free vibration is periodic and is the solution for X . For damped free vibration, however, the damping constant, c, is not zero. dX d2X = - 2 p - - w dt dt2

2

Machine Dynamics

33

or

2

d2+2p-+w dt2 dt

dX

=0

or

D +2pD+w

which has a solution of

=o

d2t

X = Ae

where

d'r

+Be

d, = - p + J p 2 - w 2 d2 - - p - J m There are different conditions of damping: critical, overdamping, and underdamping. Critical damping occurs when p = w . Overdamping occurs when p > w . Underdamping occurs when p c w . The only condition that results in oscillatory motion and, therefore, represents a mechanical vibration is underdamping. The other two conditions result in aperiodic motions. When damping is less than critical ( p < w ), then the following equation applies:

X = xo -e

a1

-pr

(a,cosalt

+ psinalt)

where

Force1 ribration-Undamped

The simple systems described in the preceding two sections on free vibration are alike in that they are not forced to vibrate by any exciting force or motion. Their major contribution to the discussion of vibration fundamentals is that they illustrate how a system's natural or resonant frequency depends on the mass, stiffness, and damping characteristics. The mass-stiffness-damping system also can be disturbed by a periodic variation of external forces applied to the mass at any frequency. The system shown in Figure 6.1 is increased in complexity by the addition of an external force, F,, acting downward on the mass.

34

Vibration Fundamentals

In undamped forced vibration, the only difference in the equation for undamped free vibration is that instead of the equation being equal to zero, it is equal to Fo sin(ot):

Since the spring is not initially displaced and is driven by the function Fo sin(wt), a particular solution, X = X , sin(ot), is logical. Substituting this solution into the above equation and performing mathematical manipulations yields the following equation for X :

X = C , sin(o,t)

where

+ C2cos(wnt)+

xs t

1-(oh,)

sin(o t )

= Spring displacement at time, t X,, = Static spring deflection under constant load, F,

03

03,

= Forcedfrequency

= Natural frequency of the oscillation

= Time

C ,,C, = Integration constants determined from specific boundary conditions.

In the above equation, the first two terms are the undamped free vibration, and the third term is the undamped forced vibration. The solution, containing the sum of two sine waves of different frequencies, is itself not a harmonic motion.

Forced Vibration-Damped

In a damped forced vibration system such as the one shown in Figure 6.3, the motion of the mass M has two parts: (1) the damped free vibration at the damped natural frequency and (2) the steady-state harmonic motions at the forcing frequency. The damped natural frequency component decays quickly, but the steady-state harmonic associated with the external force remains as long as the energy force is present. With damped forced vibration, the only difference in its equation and the equation for damped free vibration is that it is equal to Fo sin(wt) as shown below instead of being equal to zero. dX + c-d t + Kx

= Fosin(ot)

gc dt2

With damped vibration, damping constant c is not equal to zero and the solution of the equation gets quite complex assuming the function, X = X, sin(wt - $). In this equation, $ is the phase angle, or the number of degrees that the external force, F, sin(ot), is ahead of the displacement, X , sin(ot - $). Using vector concepts, the following

Machine Dynamics

35

Mass

Mass

Figure 6.3 Damped forced vibration system.

equations apply, which can be solved because there are two equations and two unknowns:

M 2 Vertical vector component: K X , - -w X , - Focos$ = 0

gC

Horizontal vector component:

cox, - F,sin$ = 0

Solving these two equations for the unknowns X , and $:

where

c = c ,

Dampingconstant

M

gc

= Critical damping = 2-w,

36

Vibration Fundamentals

c/c, = F, = FdK = o = on = w,wn =

Damping ratio External force Deflection of the spring under load, Fo (also called static deflection,X,,) Forcedfrequency Natural frequency of the oscillation Frequency ratio.

For damped forced vibrations, three different frequencies have to be distinguished:

the undamped natural frequency, on= q =

d m

Jm damped natural frequency, the

;

; and the frequency of maximum forced amplitude, sometimes

referred to as the resonant frequency.

DEGREES FREEDOM OF

In a mechanical system, the degrees of freedom indicate how many numbers are required to express its geometrical position at any instant. In machine-trains, the relationship of mass, stiffness, and damping is not the same in all directions. As a result, the rotating or dynamic elements within the machine move more in one direction than in another. A clear understanding of the degrees of freedom is important in that it has a direct impact on the vibration amplitudes generated by a machine or process system.

One Degree of Freedom

If the geometrical position of a mechanical system can be defined or expressed as a single value, the machine is said to have one degree of freedom. For example, the position of a piston moving in a cylinder can be specified at any point in time by measuring the distance from the cylinder end.

A single degree of freedom is not limited to simple mechanical systems such as the cylinder. For example, a 12-cylinder gasoline engine with a rigid crankshaft and a rigidly mounted cylinder block has only one degree of freedom. The position of all of its moving parts (i.e., pistons, rods, valves, cam shafts, etc.) can be expressed by a single value. In this instance, the value would be the angle of the crankshaft.

However, when mounted on flexible springs, this engine has multiple degrees of freedom. In addition to the movement of its internal parts in relationship to the crank, the entire engine can now move in any direction. As a result, the position of the engine and any of its internal parts require more than one value to plot its actual position in space. The definitions and relationships of mass, stiffness, and damping in the preceding section assumed a single degree of freedom. In other words, movement was limited to a

Machine Dynamics

37

Figure 6.4 Torsional one-degree-of-freedomsystem.

single plane. Therefore, the formulas are applicable for all single-degree-of-freedom mechanical systems. The calculation for torque is a primary example of a single degree of freedom in a mechanical system. Figure 6.4 represents a disk with a moment of inertia, I, that is attached to a shaft of torsional stiffness, k. Torsional stiffness is defined as the externally applied torque, T, in inch-pounds needed to turn the disk one radian (57.3 degrees). Torque can be represented by the following equations:

2Torque = Moment of inertia

x angular acceleration

dL@ .. = I= I@ dt2

38

Vibration Fundamentals

In this example, three torques are acting on the disk: the spring torque, damping torque (due to the viscosity of the air), and external torque. The spring torque is minus (-)k@,where @ is measured in radians. The damping torque is minus (-)cd, , where c is the damping constant. In this example, c is the damping torque on the disk caused by an angular speed of rotation of one radian per second. The external torque is Tosin(ot).

or

Z$ + cd, + k$ = Tosin(ot)

Two Degrees o Freedom f

The theoly for a one-degree-of-freedomsystem is useful for determining resonant or natural frequencies that occur in all machine-trains and process systems. However, few machines have only one degree of freedom. Practically, most machines will have two or more degrees of freedom. This section provides a brief overview of the theories associated with two degrees of freedom. An undamped two-degree-of-freedom system is illustrated in Figure 6.5. The diagram of Figure 6.5 consists of two masses, M, and M2, which are suspended from springs, K , and K,. The two masses are tied together, or coupled, by spring K3, so that they are forced to act together. In this example, the movement of the two masses is limited to the vertical plane and, therefore, horizontal movement can be ignored. As in the single-degree-of-freedomexamples, the absolute position of each mass is defined by its vertical position above or below the neutral, or reference, point. Since there are two coupled masses, two locations @e., one for M,and one for M2) are required to locate the absolute position of the system.

To calculate the free or natural modes of vibration, note that two distinct forces are acting on mass, M,: force of the main spring, K , , and that of the coupling spring, the K3. The main force acts upward and is defined as -K,X,. The shortening of the coupling spring is equal to the difference in the vertical position of the two masses, X , - X,. Therefore, the compressive force of the coupling spring is K3(X, - X,). The compressed coupling spring pushes the top mass, M,, upward so that the force is negative.

Because these are the only tangible forces acting on M,, equation of motion for the the top mass can be written as:

or

Machine Dynamics

39

///// / / / / / /

Xl

M2

x2

I

\ \ \ \ \ \ \ \ \ \ \ \

Figure 6.5 Undamped two-degree-of-freedom system with a spring couple.

The equation of motion for the second mass, M2, is derived in the same manner. To make it easier to understand, turn the figure upside down and reverse the direction o f X I and X,. The equation then becomes:

M2x

g C

- -K,X,-K,(X,

4 2 )

or

M

Ax2 ( K 2 + K , ) X 2 +

gc

-K 3 X , = 0

40

Vibration Fundamentals

If we assume that the masses M , and M2 undergo harmonic motions with the same frequency, 0 , and with different amplitudes, A, and A,, their behavior can be represented as follows:

X, = Alsin(ot)

X, = A2sin(ot)

By substituting these into the differential equations, two equations for the amplitude

A, ratio, - , can be found:

A2

- -A2

-K3

Ml

--o

gc

2

-K,-K3

For a solution of the form we assumed to exist, these two equations must be equal:

or

This equation, known as the frequency equation, has two solutions for 02. When substituted in either of the preceding equations, each one of these gives a definite value

A, for - . This means that there are two solutions for this example, which are of the

A2

form A , sin(0t) and A2sin(wt). As with many such problems, the final answer is

Machine Dynamics

41

the superposition of the two solutions with the final amplitudes and frequencies determined by the boundary conditions.

Many Degrees of Freedom

When the number of degrees of freedom becomes greater than two, no critical new parameters enter into the problem. The dynamics of all machines can be understood by following the rules and guidelines established in the one- and two-degree-of-freedom equations. There are as many natural frequencies and modes of motion as there are degrees of freedom.

You might also like

- Ess Model Mechs YsDocument7 pagesEss Model Mechs YsJeyaram kumar0% (1)

- Mixed multiple DOF systemsDocument13 pagesMixed multiple DOF systemspanos2244662864100% (1)

- Vibration Analysis of Ship Structural MembersDocument8 pagesVibration Analysis of Ship Structural MembersTommyVercettiNo ratings yet

- Dynamic Analysis of StructuresDocument57 pagesDynamic Analysis of StructuresYollanda LorenzaNo ratings yet

- Theory of Vibration: Natural Frequencies and Damped SystemsDocument30 pagesTheory of Vibration: Natural Frequencies and Damped SystemsCharles OndiekiNo ratings yet

- Equations of MotionDocument6 pagesEquations of MotionDharshan KofiNo ratings yet

- Mechanical Vibrations SolutionDocument96 pagesMechanical Vibrations Solutionchetan100% (4)

- PDF Dynamic Analysis of StructuresDocument43 pagesPDF Dynamic Analysis of StructuresChegue BureNo ratings yet

- Formal Report Lab 1Document11 pagesFormal Report Lab 1Mohan RyanNo ratings yet

- 7 Momentum and ImpulseDocument17 pages7 Momentum and ImpulseAjay VasanthNo ratings yet

- Week 1 Vibration IntroductionDocument22 pagesWeek 1 Vibration IntroductionSaya SantornoNo ratings yet

- Motion and Dynamics: 3.1 Making Sense of Dynamic EquilibriumDocument6 pagesMotion and Dynamics: 3.1 Making Sense of Dynamic EquilibriumnasirfahimNo ratings yet

- Elastisitas Hukum Hooke: Free Vibration Without DampingDocument13 pagesElastisitas Hukum Hooke: Free Vibration Without DampingIntanSarahitaNNo ratings yet

- DampingDocument7 pagesDampingManP13No ratings yet

- 5.6 Unforced Mechanical Vibrations: Simple Harmonic MotionDocument8 pages5.6 Unforced Mechanical Vibrations: Simple Harmonic MotionHaridev MoorthyNo ratings yet

- CH 2Document95 pagesCH 2유지상No ratings yet

- Types of Damping 1. Viscous DampingDocument6 pagesTypes of Damping 1. Viscous DampingZandro GagoteNo ratings yet

- Oscillations: 15.1. Simple Harmonic MotionDocument13 pagesOscillations: 15.1. Simple Harmonic Motioneka123No ratings yet

- Phys 1401 Experiment 10 Simple Harmonic Motion COmpletedDocument15 pagesPhys 1401 Experiment 10 Simple Harmonic Motion COmpletedAsaad iqbalNo ratings yet

- LECTURE Statics of Rigid BodiesDocument22 pagesLECTURE Statics of Rigid BodiesRey Ar OrionNo ratings yet

- Free Vibration of ParticlesDocument19 pagesFree Vibration of ParticlesDavid AmachreeNo ratings yet

- CH 03c, Coulomb Damping in Free Vibration of SDOFDocument10 pagesCH 03c, Coulomb Damping in Free Vibration of SDOFAtalelew ZeruNo ratings yet

- Basic Principles of VibrationsDocument6 pagesBasic Principles of Vibrationsdskumar49No ratings yet

- AE2610 Lab HelicopterDocument12 pagesAE2610 Lab HelicopterRandom PersonNo ratings yet

- Paper36 ViscousVersusStructuralDampingDocument7 pagesPaper36 ViscousVersusStructuralDampingCindy WangNo ratings yet

- Spring Constant Measurement - Static Dynamic MethodDocument7 pagesSpring Constant Measurement - Static Dynamic MethodPrasetyaJayaputra50% (2)

- Lecture 02 IntroductionDocument17 pagesLecture 02 IntroductionCaleb100% (1)

- SD GRDocument17 pagesSD GRApril IngramNo ratings yet

- Reporting Forced VibrationDocument21 pagesReporting Forced VibrationCliffjoen “cjac15” CarurucanNo ratings yet

- Chapter 5Document9 pagesChapter 5Umbina GesceryNo ratings yet

- Chapter TwoDocument49 pagesChapter TwoAbenezer MarkNo ratings yet

- Single Degree of Freedom Systems Free Vibration GuideDocument76 pagesSingle Degree of Freedom Systems Free Vibration GuideDame AyaneNo ratings yet

- Dynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural DynamicsDocument11 pagesDynamics of Structures and Soils: Deterministic Structural Dynamics. Random Stochastic or Random Structural Dynamicspanos2244662864No ratings yet

- DampingDocument20 pagesDampingjudeekene_403330720100% (1)

- Static Mechanical System Section1: Stress, Shear Force and Bending MomentDocument17 pagesStatic Mechanical System Section1: Stress, Shear Force and Bending MomentHadhi Hassan KhanNo ratings yet

- ME 354A Vibration Problems and SolutionsDocument4 pagesME 354A Vibration Problems and SolutionsAkhilNo ratings yet

- Build Dynamic Models and Solve Equations of MotionDocument7 pagesBuild Dynamic Models and Solve Equations of Motionamanda siraitNo ratings yet

- Physics Lab Report 5Document3 pagesPhysics Lab Report 5Catherine Linsley0% (1)

- NPTEL - Mechanical Engineering - Vibration ControlDocument10 pagesNPTEL - Mechanical Engineering - Vibration Control8104772799No ratings yet

- Ch2 1Document7 pagesCh2 1xmtqnkn8vjNo ratings yet

- Mechanical Accelerometer System AnalysisDocument4 pagesMechanical Accelerometer System AnalysisAlejandro López SaldañaNo ratings yet

- Spring Oscillator Lab ReportDocument10 pagesSpring Oscillator Lab ReportVincent Vuong100% (2)

- Mechanical VibrationsDocument57 pagesMechanical VibrationsHari Tej AvvaruNo ratings yet

- Impact MechanicsDocument8 pagesImpact MechanicsMarvin BaquialNo ratings yet

- Strength of Material Interview Question and AnswersDocument27 pagesStrength of Material Interview Question and AnswersArjun M Betageri66% (29)

- End Term Lab Reports TOMDocument26 pagesEnd Term Lab Reports TOMSabtain AbbasNo ratings yet

- Lesson 2. Free Vibrations With Viscous DampingDocument8 pagesLesson 2. Free Vibrations With Viscous Dampingzyx xyzNo ratings yet

- Limitation Imposed On Structural DesignerDocument2 pagesLimitation Imposed On Structural DesignerdvarsastryNo ratings yet

- Free and Undamped Oscillation ProcedureDocument4 pagesFree and Undamped Oscillation ProcedureVinot EsanNo ratings yet

- Dynamics (Egr2301) - Spring 2015 Project Video Analysis and Modeling of Dynamic SystemsDocument19 pagesDynamics (Egr2301) - Spring 2015 Project Video Analysis and Modeling of Dynamic SystemsIlias LaroussiNo ratings yet

- Theories of Elastic FailureDocument15 pagesTheories of Elastic FailurejaishowNo ratings yet

- Measuring Spring Stiffness and Natural FrequencyDocument60 pagesMeasuring Spring Stiffness and Natural FrequencyRobert Lau Yik SiangNo ratings yet

- Department of Aerospace Engineering, IIT Madras AS 5970 Structural Dynamics and AeroelasticityDocument1 pageDepartment of Aerospace Engineering, IIT Madras AS 5970 Structural Dynamics and AeroelasticitylalbaghNo ratings yet

- Chapter-Ii Introduction To ModellingDocument50 pagesChapter-Ii Introduction To ModellingAHMEDNo ratings yet

- Man GN PDF 1Document20 pagesMan GN PDF 1Adrian A UPD100% (1)

- Theory of Elastisity, Stability and Dynamics of Structures Common ProblemsFrom EverandTheory of Elastisity, Stability and Dynamics of Structures Common ProblemsNo ratings yet

- IndexDocument3 pagesIndexVasile RaduNo ratings yet

- List of AbrevDocument2 pagesList of AbrevVasile RaduNo ratings yet

- Newnes Boston Oxford Auckland Johannesburg Melbourne New DelhiDocument3 pagesNewnes Boston Oxford Auckland Johannesburg Melbourne New DelhiVasile RaduNo ratings yet

- CH 30Document19 pagesCH 30Vasile RaduNo ratings yet

- CH 22Document2 pagesCH 22Vasile RaduNo ratings yet

- CH 27Document4 pagesCH 27Vasile RaduNo ratings yet

- CH 26Document9 pagesCH 26Vasile RaduNo ratings yet

- GlossaryDocument5 pagesGlossaryVasile RaduNo ratings yet

- ContentsDocument2 pagesContentsVasile RaduNo ratings yet

- CH 29Document2 pagesCH 29Vasile RaduNo ratings yet

- CH 21Document9 pagesCH 21Vasile RaduNo ratings yet

- CH 20Document5 pagesCH 20Vasile RaduNo ratings yet

- CH 28Document6 pagesCH 28Vasile RaduNo ratings yet

- CH 23Document5 pagesCH 23Vasile RaduNo ratings yet

- CH 24Document5 pagesCH 24Vasile RaduNo ratings yet

- CH 18Document1 pageCH 18Vasile RaduNo ratings yet

- CH 16Document8 pagesCH 16Vasile RaduNo ratings yet

- 19Document6 pages19Ajay RanganathanNo ratings yet

- CH 17Document11 pagesCH 17Vasile RaduNo ratings yet

- Analysis Techniques: TrendingDocument5 pagesAnalysis Techniques: TrendingVasile RaduNo ratings yet

- CH 10Document6 pagesCH 10Vasile RaduNo ratings yet

- CH 12Document15 pagesCH 12Vasile RaduNo ratings yet

- Vibration Data and Formats: TypesDocument7 pagesVibration Data and Formats: TypesVasile RaduNo ratings yet

- Data Acquisition: Detectors: TransducersDocument11 pagesData Acquisition: Detectors: TransducersVasile RaduNo ratings yet

- Vibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisDocument3 pagesVibration Analysis Applications: 2.1 Equipment and Processes Typical0 Monitored by Viiration AnalysisVasile RaduNo ratings yet

- Vibration Analysis OverviewDocument7 pagesVibration Analysis OverviewVasile RaduNo ratings yet

- Vibration Theory: Periodic MotionDocument9 pagesVibration Theory: Periodic MotionVasile RaduNo ratings yet

- CH 4Document4 pagesCH 4Vasile RaduNo ratings yet

- CH 1Document2 pagesCH 1Vasile RaduNo ratings yet

- High Power Factor Soft SwitchedDocument7 pagesHigh Power Factor Soft SwitchedMohan KrishnaNo ratings yet

- Electrical Supply SystemDocument52 pagesElectrical Supply SystemfarahNo ratings yet

- Force and Motion Goals and ObjectivesDocument3 pagesForce and Motion Goals and Objectivesapi-431079208No ratings yet

- Calculation of Electro Dynamic Forces On Busbars in LV SystemsDocument4 pagesCalculation of Electro Dynamic Forces On Busbars in LV Systemsgormankung100% (1)

- Solutions of Ac - DC Power Flow.-1Document15 pagesSolutions of Ac - DC Power Flow.-1Krishna Reddy100% (1)

- Class: XII Subject: PHYSICSDocument22 pagesClass: XII Subject: PHYSICSSenthil KumarNo ratings yet

- Pe Question Paper PDFDocument2 pagesPe Question Paper PDFyr48No ratings yet

- EDC Manual PDFDocument83 pagesEDC Manual PDFMrinal MitraNo ratings yet

- Voltage and current on lossless transmission linesDocument21 pagesVoltage and current on lossless transmission linesrushitaaNo ratings yet

- AC Generator Project ReportDocument14 pagesAC Generator Project ReportRahul Patel78% (18)

- The Threshold Welding Current Model for Large Area ContactsDocument7 pagesThe Threshold Welding Current Model for Large Area Contactssrinivas rao rayuduNo ratings yet

- Inclined Slotted Waveguide Antenna Design: AbstractDocument5 pagesInclined Slotted Waveguide Antenna Design: AbstractriyazNo ratings yet

- Physics NotesDocument2 pagesPhysics NotesRexell CusipagNo ratings yet

- ECEN 615 Methods of Electric Power Systems Analysis: Lecture 14: PSERC Webinar On Synthetic GridsDocument44 pagesECEN 615 Methods of Electric Power Systems Analysis: Lecture 14: PSERC Webinar On Synthetic GridsManuelNo ratings yet

- RL RLC Load 222Document3 pagesRL RLC Load 222hamza mandlwiNo ratings yet

- ArticleDocument22 pagesArticlefNo ratings yet

- Xii Physics Electrostatics SolutionDocument31 pagesXii Physics Electrostatics SolutionKushal DubeyNo ratings yet

- 059 DonDocument6 pages059 DonEgwu Francis obinnaNo ratings yet

- GeneralPhysics1 12 Q2 Mod2 GravityDocument20 pagesGeneralPhysics1 12 Q2 Mod2 GravityAllysa Nicole AldaNo ratings yet

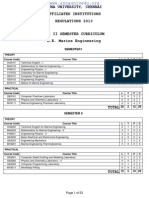

- Anna Univeristy 1st Sem Syllabus For Marine EngineeringDocument23 pagesAnna Univeristy 1st Sem Syllabus For Marine EngineeringmadhusivaNo ratings yet

- Trans Basic ConceptsDocument13 pagesTrans Basic ConceptsSakshi AgrawalNo ratings yet

- Electrical Design Training Class: Line LossDocument54 pagesElectrical Design Training Class: Line Losssri_electricalNo ratings yet

- Tom-Ii Lab ManualDocument26 pagesTom-Ii Lab ManualTochi Krishna AbhishekNo ratings yet

- TX RX Elementary Introduction To Ferrite Isolators Circulators and RF LoadsDocument14 pagesTX RX Elementary Introduction To Ferrite Isolators Circulators and RF LoadshectorieNo ratings yet

- Basic Vibration Training For Engro EnergyDocument70 pagesBasic Vibration Training For Engro EnergyHesham IbrahemNo ratings yet

- John Becker PIC Magnetometry Logger Part 2Document5 pagesJohn Becker PIC Magnetometry Logger Part 2sorinn1987No ratings yet

- FEM With Analytical Approach Based Wind and Seismic Design Recommendations For Vertical Tall Process ColumnDocument9 pagesFEM With Analytical Approach Based Wind and Seismic Design Recommendations For Vertical Tall Process ColumnSASWAT MISHRANo ratings yet

- Scripta Materialia: R. Skomski, J.M.D. CoeyDocument6 pagesScripta Materialia: R. Skomski, J.M.D. CoeyJaime FalaganNo ratings yet

- Static Force AnalysisDocument16 pagesStatic Force AnalysisMohamed Ashraf HindyNo ratings yet

- Measure Earth Resistance Using Digital Earth TesterDocument5 pagesMeasure Earth Resistance Using Digital Earth Testerrishika chhibberNo ratings yet