Professional Documents

Culture Documents

Spread Borough

Uploaded by

Matthew ButlerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spread Borough

Uploaded by

Matthew ButlerCopyright:

Available Formats

HOME

Inclined Troughed Belt Conveyor Systems for Underground Mass Mining Operations

J C Spreadborough1 and A G L Pratt2

ABSTRACT

Inclined troughed belt conveyors are more frequently being selected from a range of alternatives, which include shafts and trucks for ore haulage in underground mass mining projects. Belt conveyor haulage systems are being operated with lifts exceeding those normally associated with truck haulage systems and approaching the limits of shaft haulage systems. A belt conveyor haulage system, in this context, incorporates subsystems for: crushing, tramp detection and removal, and haulage. This paper presents details of recent inclined troughed belt conveyor systems for underground mining operations, and explores the application of inclined troughed belt conveyors for the increasing demands of future underground mass mining projects.

the application of cable belt conveyors, though similar principals can be applied to define their limits of application.

TROUGHED BELT CONVEYOR SYSTEMS

An underground conveyor haulage system will, in general, incorporate subsystems for:

crushing, tramp detection and removal, and haulage.

Each of these subsystems will incorporate resources and facilities for:

monitoring and control, and maintenance.

The satisfactory performance of the haulage system is dependent on the performance of each subsystem and on the performance of the resources and facilities provided for monitoring and control and maintenance. The crushing subsystem is required to reduce run-of-mine (ROM) material to a size suitable for loading to haulage conveyors. A typical crushing station is depicted in Figure 2. The tramp detection and removal subsystem is required to remove tramp materials from the material stream and hence prevent tramp damage to haulage conveyors. The tramp detection and removal subsystem will incorporate conveyors, tramp magnets, metal detectors and in some cases, facilities for manual tramp removal in a configuration appropriate for the size, shape, magnetic properties and quantity of tramp anticipated. The demands on the tramp detection and removal equipment vary with the ground conditions and mining method. Poor ground conditions necessitate a greater utilisation

INTRODUCTION

The selection of haulage systems for underground mines has focused on shaft haulage, trucks and belt conveyors. The application of these alternatives in the Australian mining industry is summarised in Figure 1 as a graph showing lift (m) versus annual production (kt/a) (Pratt, 2005). Troughed belt conveyors are shown to be applied in the range to 8 Mt/a and 1200 m lift. This paper further defines the current range of application of troughed belt conveyor systems, defines limits on their application and the scope for increasing these limits to the demands of future underground mass mining projects. This paper does not address

1. 2. Associate Director, Maunsell Australia, 10 Finchley Street, Milton Qld 4064. Email: John.Spreadborough@Maunsell.com MAusIMM, Group Manager Mine Engineering, Newcrest Mining Limited, Level 8, 600 St Kilda Road, Melbourne Vic 3004. Email: Adrian.Pratt@Newcrest.com.au

FIG 1 - Operating ranges for underground haulage systems.

Tenth Underground Operators Conference

Launceston, TAS, 14 - 16 April 2008

71

J C SPREADBOROUGH and A G L PRATT

of rock bolts, straps and mesh for ground support. The block cave method generally requires ground support only at the undercut and extraction levels. Ground support generally contributes the majority of the tramp in the ore stream. Other contributors include drill consumables, Load-haul-dump (LHD) bucket hardware and chute liners. The haulage subsystem (Figure 3) includes the chutes, skirts, belt, idlers, pulleys, drives and structures that support and transport the material from the feed point to the discharge point. The haulage subsystem may incorporate more than one conveyor flight and more than one transfer point. Critical elements in the haulage subsystem include:

Belt to support the material and to transfer tractive forces to

the material. The belt carcass and the associated splices provide tensile strength. The belt covers provide protection for the carcass and splices from impact, abrasion and corrosion.

Idlers to support the belt. Pulleys to resist belt tensions at changes of direction and to

transfer tractive forces from the drives to the belt.

Drives to provide driving and braking tractive force and inertia

Feed chute of dimensions appropriate for the material

the driving and braking controls provide for minimum dynamic effects when starting and stopping, and for no material retained in the transfer chutes for all stopping scenarios, including emergency and power failure stops. for belt sag control.

received to direct the material on centre and in line with the receiving belt.

Take-up to provide belt tension for no slip at the drives and

FIG 2 - Typical crushing station.

FIG 3 - Typical haulage conveyor head end.

72

Launceston, TAS, 14 - 16 April 2008

Tenth Underground Operators Conference

INCLINED TROUGHED BELT CONVEYOR SYSTEMS FOR UNDERGROUND MASS MINING OPERATIONS

Holdbacks to prevent reverse movement, each capable of

holding 150 per cent of the load applied by the conveyor (AS1755) also able to withstand extreme events (drives stalled in reverse, or belt locked, drives stalled, resultant belt tension resisted by the holdback). The monitoring and control functions are required to confirm correct operation and to initiate warnings or shut down in the event of malfunction to prevent injury and equipment damage. Devices are typically provided at the haulage subsystem for detection of:

Maintenance equipment at the haulage subsystem will typically include:

monorails and/or cranes at drives and pulleys for change-out

or repair;

belt clamps to resist belt tensions when installing or

maintaining the belt (spring applied, hydraulic release, tested for holding capacity);

belt reel handling facilities; and belt splicing/repair facilities. CURRENT APPLICATIONS

Troughed belt conveyors are applied over a wide range of length/lift combinations, but at the limits are grouped as long (overland) or high lift conveyors (Figure 4). Troughed belt conveyors for mass mining operations frequently fall into the second (high lift) group. Troughed belt conveyors are also applied over a wide range of material flow rates, belt widths and belt speeds (Figure 5 and Table 1).

belt drift, drive slip, belt rip, belt carcass and belt splice deterioration, take-up over-travel, equipment over-temperature, and emergency.

1000

800

Prosper Haniel

600 Lift (m) Chuquicamata Ridgeway Portal Nifty CV3 Kapok Mc Arthur River Ridgeway Trunk Gordonstone Drift Cadjebut Revenge Crinum 0 Channar KPC High Lift

400

Long (Overland)

200

Curragh North Dawson CV-193 Lafarge Surma

-200 0 5 10 Length (km) 15 20 25

FIG 4 - Length/lift for typical long (overland) and high lift troughed belt conveyors.

1000

800

Prosper Haniel

600 Lift (m) Ridgeway Portal 400 Nifty CV3 Kapok Mc Arthur River 200 Cadjebut Ridgeway Trunk Revenge Crinum KPC Lafarge Surma -200 0 1000 2000 3000 Feed Rate (t/h) 4000 Curragh North Dawson CV-193 Channar

Chuquicamata

Gordonstone Drift

5000

6000

FIG 5 - Productivity ranges for typical long (overland) and high lift troughed belt conveyors.

Tenth Underground Operators Conference

Launceston, TAS, 14 - 16 April 2008

73

J C SPREADBOROUGH and A G L PRATT

TABLE 1

Details for typical long (overland) and high lift troughed belt conveyors (Baigent, 2005; Kusel, 1999; McLennan, 2001).

Conveyor High lift Prosper Haniel Chuquicamata CB002 Ridgeway Portal Nifty CV3 Kapok McArthur River Ridgeway Trunk Gordonstone Drift Cadjebut Revenge Long (overland) Curragh North Crinum Dawson CV-193 Channar KPC Lafarge Surma Coal Coal Hard rock Hard rock Coal Hard rock 20 035 9955 16 300 10 400 13 100 17 000 68 52 4 0 0 -120 2500 1100 2400 2200 1350 800 7.5 4.9 5.1 4.1 5.3 3.0 1200 ST1500 900 ST1600 2 35 cable belt 1050 ST3150 1000 ST2250 750 ST1800 Coal Hard rock Hard rock Hard rock Hard rock Hard rock Hard rock Coal Hard rock Hard rock 3745 4578 2863 2324 2400 2680 1213 1555 2500 1500 783 540 503 408 400 305 226 215 200 185 2000 5500 840 500 200 470 1100 5000 300 450 5.5 6.0 3.0 3.9 2.8 1.6 3.4 5.0 2.5 1.6 1400 ST7500 1830 ST10 000 1050 ST5500 900 ST3150 630 900 1050 ST2240 1800 ST4500 850 1200 Material Length (m) Lift (m) Rate (t/h) Speed (m/s) Belt spec

1000

800

Ridgeway Portal

Lift (m)

600 ST5500 400

Increase Length, Reduce Lift Increase Carcass Strength (reduce troughability)

200

0 0 2 4 6 8 10 12 14 Length (km)

FIG 6 - Limits of length and lift based on the Ridgeway Portal configuration with 840 t/h, 3 m/s, splice FoS = 6.7 for ST500 to ST7100.

LIMITS OF APPLICATION

The slope of the high lift group is limited by the slope of the drift or decline/incline in which the conveyor is mounted. This is normally in the range 1:5.3 to 1:5.4 (10.5 to 10.7) where the development is carried out using rubber-tyred equipment. Length and lift are limited by the belt carcass construction and the strength of the belt splice. These limits of length are presented in Figure 6 for the Ridgeway Portal configuration operating at 840 t/h, 3 m/s and with a splice factor of safety (FoS) of 6.7 for belt constructions in the range ST500 to ST7100. The choice of belt construction is also limited by the troughability of the belt. Troughability is the ratio of the cross belt sag to belt width and generally reduces with increases in carcass strength. Reduced troughability results in poor belt tracking and hence edge damage and/or tripping on belt drift.

FUTURE APPLICATIONS

Advances in future designs will be fundamentally linked to the load-carrying capacity of the available belt constructions and splice designs. It is useful to recognise a parameter that is used to compare wire rope constructions. This parameter is called the free length and is defined as the length at which a rope will break under its own weight. It is calculated by dividing the rope strength by its weight per unit length. The free length of a range of steel cord belt constructions is presented in Figure 7. The free length calculation recognises:

loss of strength at the splice, free length of bare cords (reduces with increases in carcass

strength), and

self weight of rubber in the carcass and in the covers.

74

Launceston, TAS, 14 - 16 April 2008

Tenth Underground Operators Conference

INCLINED TROUGHED BELT CONVEYOR SYSTEMS FOR UNDERGROUND MASS MINING OPERATIONS

Loss of strength at the splice is presented here based on:

no carcass splice (hence no loss of strength) for the upper

data points, and

spliced carcass with loss of strength increasing by five per

cent with number of splice steps above two (DIN 22101 1982:02) for the lower data points. Advances in splice design have reduced the magnitude of the loss of strength at the splice for the higher strength multi-step splices. The weight of covers is based here on the standard minimum thickness (increases with increases in carcass strength, DIN 22101 1982:02) with an additional carry cover thickness of 6 mm. The knee in the free length curves tends to favour designs based on carcass constructions with strengths less than around ST3000. Designers of long (overland) conveyors have exploited this characteristic. Table 1 shows that long (overland) conveyors generally utilise lighter belt constructions. In the case of the Curragh North and Dawson conveyors, intermediate drives have been incorporated to reduce tensions, and hence to facilitate

10 9 8 Free Length (km) 7 6 5 4 3 2 1 0 0 1000 2000 3000 ST1000 ST2000 ST2800

lighter constructions. Splice factors of safety are reduced to around 5.5 (Baigent, 2005). Designers of high lift conveyors can exploit this characteristic in a similar manner. The potential range of application of a new generation of high lift troughed belt conveyors is illustrated for the Ridgeway Portal application operating at 840 t/h, with belt speed increased from 3 to 5 m/s and splice safety factor reduced from 6.7 to 5.5 (Figure 8). This shows when comparing Figure 8 with Figure 6 that the carcass could be reduced from ST5500 to ST2800, or that the lift could be increased from 503 m to around 750 m using the existing ST5500 belt. This illustrates the potential for utilising lighter belts for a given application and hence reducing the capital and operating costs of the haulage system. Alternatively, this illustrates the potential for applying a single flight conveyor to a greater lift and again reducing the capital and operating costs of the haulage system by reducing the number of transfer/drive stations. The key issues in achieving these increases in length and lift include:

ST4000

ST5000ST5500

ST6300

ST7100

Reducing Troughability ST500

4000

5000

6000

7000

8000

Carcass Strength (kN)

FIG 7 - Free length for 1 m width of conveyor belt for no carcass splice (upper data points) and for spliced carcass (lower data points).

1000

800

Ridgeway Portal

ST5500

Lift (m)

600 ST2800 400

200

0 0 2 4 6 8 10 12 14 Length (km)

FIG 8 - Limits of length and lift based on the Ridgeway Portal conveyor (840 t/h, with belt speed increased to 5 m/s and belt splice FoS reduced to 5.5).

Tenth Underground Operators Conference

Launceston, TAS, 14 - 16 April 2008

75

J C SPREADBOROUGH and A G L PRATT

Limit the additional strains applied to the belt by: designing chutes to minimise material impact at the

loading point;

improved splice designs for higher strength and longer life,

and

improved chute designs.

Current designs are limited by a number of paradigms relating to belt speed, splice factors of safety and the application of intermediate drives. The further exploitation of these technologies, focusing on a number of key issues, will contribute to breaking down these paradigms and facilitating the implementation of a new generation of high lift troughed belt conveyors.

selecting conservative pulley diameters, transition

lengths and vertical curves; and

selecting drive and drive control equipment to limit

dynamic effects when starting and stopping.

Increase belt speeds/reduce belt tensions/reduce burden load

and address the resulting dust, life, noise, belt resonance and wear issues by:

providing facilities to limit dust generation; selecting idlers, pulleys and drives for life and noise

limitation;

REFERENCES

AS1755 2000 conveyors. Safety requirements. Baigent, D, 2005. Curragh North materials handling project, in Proceedings Bulk Materials Handling Conference, Mackay. DIN 22101 1982:02. Continuous mechanical handling equipment Belt conveyors for bulk materials Bases for calculation and design. DIN 22101 2000:08. Continuous conveyors Belt conveyors for loose bulk materials Basis for calculation and dimensioning. Kusel, B, 1999. The success story of self-extinguishing steel cord conveyor belts in underground coal mining, International Mining Quarterly Review, 44. McLennan, G, 2001. Energy efficient belt conveyor at BHP Gregory/ Crinum, in Bulk Solids Handling, 21(1):73. Nordell, L K, 1991. The Channar 20 km Overland A flagship of modern belt conveyor technology, Bulk Solids Handling, (11)4:781. Pratt, A G L, 2005. Application of conveyors for underground haulage, in Proceedings Ninth Underground Operators Conference, pp 273-283 (The Australasian Institute of Mining and Metallurgy: Melbourne). Pratt, A G L, 2008. Mine haulage Options and the process of choice, in Proceedings Tenth Underground Operators Conference, pp 179-188 (The Australasian Institute of Mining and Metallurgy: Melbourne). Troncoso, J, Francis, R and Pedersen, L, 1993. Design and construction of coal handling facilities at Gordonstone Colliery, Bulk Solids Handling, 13(4):823.

installing idlers to avoid belt resonance; and designing chutes and/or accelerating belts to minimise

abrasion at the load point.

Increase the fatigue life/load carrying capacity of belt splices

by addressing:

splice design; temperature control, cleanliness and UV exposure when

forming the splice;

splicing procedures and personnel training; quality of splice materials; quality of splicing equipment; and splice monitoring.

CONCLUSIONS

A number of technologies have contributed to the successful application of troughed belts in underground mass mining operations. These include:

improved drive control equipment, belt condition monitoring,

76

Launceston, TAS, 14 - 16 April 2008

Tenth Underground Operators Conference

You might also like

- Pigging GE - Ge - Pii - Metalloss - JV - Bim-112514 - 0 PDFDocument7 pagesPigging GE - Ge - Pii - Metalloss - JV - Bim-112514 - 0 PDFMatthew ButlerNo ratings yet

- Pigging - Quest Integrity - pipeline-integrity-solutions-brochure-LTR-Rev.05-15-web PDFDocument6 pagesPigging - Quest Integrity - pipeline-integrity-solutions-brochure-LTR-Rev.05-15-web PDFMatthew ButlerNo ratings yet

- Eziline Mortar Mix - Linings PDFDocument1 pageEziline Mortar Mix - Linings PDFMatthew ButlerNo ratings yet

- SKFDocument48 pagesSKFemreali1No ratings yet

- I Rod Clip Techdata A4 PDFDocument2 pagesI Rod Clip Techdata A4 PDFMatthew ButlerNo ratings yet

- SKF Heavy BearingsDocument56 pagesSKF Heavy Bearingssrtsrt1616No ratings yet

- IPS Polyflo Double Wall Containment Pipe PDFDocument6 pagesIPS Polyflo Double Wall Containment Pipe PDFMatthew ButlerNo ratings yet

- OneSteel Piping Systems Data ChartDocument18 pagesOneSteel Piping Systems Data Chartpete0980100% (1)

- Nu Bolt Techdata A4 PDFDocument2 pagesNu Bolt Techdata A4 PDFMatthew ButlerNo ratings yet

- IPS - Argusafe Double Wall Containment Pipe Datasheet PDFDocument12 pagesIPS - Argusafe Double Wall Containment Pipe Datasheet PDFMatthew ButlerNo ratings yet

- EURAPIPE ABS Design Manual PDFDocument60 pagesEURAPIPE ABS Design Manual PDFMatthew ButlerNo ratings yet

- EURAPIPE ABS Product Catalogue PDFDocument20 pagesEURAPIPE ABS Product Catalogue PDFMatthew ButlerNo ratings yet

- Fag Housings PDFDocument84 pagesFag Housings PDFNebojša JovanovićNo ratings yet

- 6116 1-EnDocument218 pages6116 1-EnLuong Tam ThinhNo ratings yet

- CGA Best Practices 2013Document121 pagesCGA Best Practices 2013Erik HobbsNo ratings yet

- Plain Bearing Plummer BlockDocument54 pagesPlain Bearing Plummer BlockMatthew ButlerNo ratings yet

- AERZEN Turbo Blowers PDFDocument16 pagesAERZEN Turbo Blowers PDFMatthew ButlerNo ratings yet

- INA BuchesDocument68 pagesINA BuchesTravis DavisNo ratings yet

- WS Spec PDFDocument350 pagesWS Spec PDFMatthew Butler100% (1)

- RNZCH PDFDocument685 pagesRNZCH PDFMatthew ButlerNo ratings yet

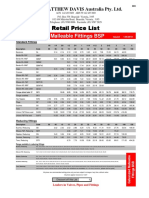

- Retail Price List Retail Price List Retail Price List Retail Price ListDocument1 pageRetail Price List Retail Price List Retail Price List Retail Price ListMatthew ButlerNo ratings yet

- Coalminshr 01Document290 pagesCoalminshr 01Matthew ButlerNo ratings yet

- Special Fasteners For EngineersDocument4 pagesSpecial Fasteners For EngineersMatthew ButlerNo ratings yet

- Cooling Towers ChecklistDocument6 pagesCooling Towers ChecklistMatthew ButlerNo ratings yet

- 01 - Gal Mal 1-12-08 PDFDocument1 page01 - Gal Mal 1-12-08 PDFMatthew ButlerNo ratings yet

- HumeCeptor Tech Manual 01Document39 pagesHumeCeptor Tech Manual 01Matthew ButlerNo ratings yet

- Stabilization of Supersonic Vent Gas FromDocument14 pagesStabilization of Supersonic Vent Gas FromMatthew ButlerNo ratings yet

- Legend ValvesDocument58 pagesLegend ValvesdokundotNo ratings yet

- Spirac Grit Classifier SANDSEP - A4 - v1Document4 pagesSpirac Grit Classifier SANDSEP - A4 - v1Matthew ButlerNo ratings yet

- HUMES - Stormwater - CatalogueDocument16 pagesHUMES - Stormwater - CatalogueMatthew ButlerNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- #2802 - ENGLISH Men's Figure Skating BodyshirtsDocument7 pages#2802 - ENGLISH Men's Figure Skating BodyshirtsSamuel David ZambranoNo ratings yet

- Astm A 564-A 564M-2004 R2009Document7 pagesAstm A 564-A 564M-2004 R2009yzmouseNo ratings yet

- Mec ShotDocument25 pagesMec ShotnoobNo ratings yet

- ASMe Sec2 PartcDocument53 pagesASMe Sec2 PartcSARSAN NDTNo ratings yet

- Manual de Diseno Drywall RONDO PDFDocument258 pagesManual de Diseno Drywall RONDO PDFYorbiCastilloNo ratings yet

- MD - Sharif CVDocument3 pagesMD - Sharif CVsharifmunna20022469No ratings yet

- Effective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuDocument4 pagesEffective Control of Warping During Injection Molding: Ming-Shyan Huang, Shih-Chih Nian, and Chih-Yang WuPrabhath SanjayaNo ratings yet

- Halene P Technical Data Sheet for Polypropylene Homopolymer F110Document1 pageHalene P Technical Data Sheet for Polypropylene Homopolymer F110Dharmendrasinh ZalaNo ratings yet

- Concrete Urban MiningDocument4 pagesConcrete Urban MiningAlba MaquedaNo ratings yet

- Hardening and TemperingDocument3 pagesHardening and TemperingwtfnoneoNo ratings yet

- ISO 9001 Quality Management System DocumentsDocument33 pagesISO 9001 Quality Management System DocumentsSanjay Rajpal100% (1)

- Director Facilities Management in Boston MA Resume Jana DenglerDocument2 pagesDirector Facilities Management in Boston MA Resume Jana DenglerJanaDengler100% (1)

- 2005 PSS Road MeshDocument4 pages2005 PSS Road MeshJim Arturo Rivera VidalNo ratings yet

- AAL-Meritor Operations Case Study For Naissance 2012Document11 pagesAAL-Meritor Operations Case Study For Naissance 2012Gaurav GuptaNo ratings yet

- Toops Policy Procedure Check For Incoming GoodsDocument3 pagesToops Policy Procedure Check For Incoming GoodsMarc-Oliver ThielNo ratings yet

- Ateneo de Davao University Jacinto ST., Davao CityDocument10 pagesAteneo de Davao University Jacinto ST., Davao CityChoco MallowNo ratings yet

- Inventory Management Report On BMTF FinalDocument16 pagesInventory Management Report On BMTF FinalKhabirIslamNo ratings yet

- Energy Analysis of The Steel Making IndustryDocument7 pagesEnergy Analysis of The Steel Making Industrymrshami7754No ratings yet

- Demo Asme PWHT PreheatDocument54 pagesDemo Asme PWHT PreheatWalter TrajadaNo ratings yet

- NESMAN Manpower Utilization and Costs ReportDocument55 pagesNESMAN Manpower Utilization and Costs ReportFaiq RehmanNo ratings yet

- Al-Cu Phase DiagramDocument4 pagesAl-Cu Phase DiagramSandeep YadavNo ratings yet

- OM Inventory Systems & Simulation GameDocument39 pagesOM Inventory Systems & Simulation GamesilentrockerNo ratings yet

- Rail Integrity Manual 82011Document71 pagesRail Integrity Manual 82011Ovidiu PruteanuNo ratings yet

- Production Theory & EstimationDocument26 pagesProduction Theory & EstimationMelyan LhyandNo ratings yet

- R Steel Catalog 2017Document69 pagesR Steel Catalog 2017R-SteelNo ratings yet

- CSU Non Sparking Safety Tools CatalogDocument88 pagesCSU Non Sparking Safety Tools CatalogJhon SanfraNo ratings yet

- Welcome: K.S.K College of Engineering and Technology Department of Mechanical EngineeringDocument26 pagesWelcome: K.S.K College of Engineering and Technology Department of Mechanical EngineeringRisath AhamedNo ratings yet

- Caution: Hemically Lackening RassDocument21 pagesCaution: Hemically Lackening RassHarry Herdiana AgustianNo ratings yet

- Overview of Construction IndustryDocument39 pagesOverview of Construction IndustryHariz AkhmalNo ratings yet

- CH 5 Test BankDocument10 pagesCH 5 Test BankSehrish Atta100% (3)