Professional Documents

Culture Documents

Niko Steel Industries

Uploaded by

ajaykrishnaaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Niko Steel Industries

Uploaded by

ajaykrishnaaCopyright:

Available Formats

NIKO STEEL INDUSTRIES Home About Us Technical Info Quality Policy Enquiry Form Contact Us

TECHNICAL INFO :

Pipes & Tubes Sheets, Coils & Plates Structural Steel Round Bar & Wire Pipe Fittings Flanges Valves Gaskets Non Ferrous Metal OUR CLIENTS We are supplying Sheets, Plates and Coils made from Carbon Steel, Stainless Steel & Special Alloys for different industries.Our products are made from Steel Alloys, Stainless Steel, Nickel and Titanium Special Alloys well known factories according to standards ASTM, DIN, BS or any other required. Stainless Steel Plates Austentic, Marstentic & Duplex stainless steel plates Some of the popular Specn. are ASTM A 240 Tp 202 / 304 / 304L / 316 / 316L / 321 /309 / 310 / 317L / 409 / 410 / 410S / 430 / UNS NO. S31803 / UNS NO. S32205 / SAF 2205 ( Pressure Vessel Chrome Molybdenum Alloy Steel ) A quality normalised and tempered material for steam turbine diaphragms and associated uses within the power generation industry.We Stock Low Alloy Steel Plate in Following Grades.The Following Grades Are Available: ASTM A 387 GR. 11 CL. 1 / 2,ASTM A 387 GR. 12 CL. 1 / 2 ASTM A 387 GR. 22 CL. 1 / 2,ASTM A 387 GR. 5 CL. 1 / 2 DIN 17175 15Mo3 / 16Mo3, ASTM SPECIFICATION A 387 GR. 2 CL. 2 / 204 GR. A / 204. B This Material is manufactured to specific ASTM standards in order to produce a superior quality carbon steel plate of consistent ant controlled properties designed to withstand the internal pressure of pressure vessels,boilers, and valves.We Stock Boiler Quality Steel Plate in Following Grades The Following Grades Are Available: ASTM A 516 GR. 60,ASTM A 516 GR. 70 ASTM A 515 GR. 70 ,IS 2002 GR. 1 / GR. 2 Steel plates are used mainly for the manufacture of bridges, steel structures, ships, large diameter pipes, storage tanks, boilers, railway wagons and pressure vessels. The company also produces weatherproof steel plates for the construction of railcars.We Stock Mild Steel Plate in Following Grades The Following Grades Are Available: ASTM A36 S275JR ,IS-2062 GR. A / B, Fe 410WA, Fe 410WB ASTMA 36 GOST 08KP / 3 PS SP SAE 1006 / 1010 /1020

SHEETS, PLATES & COILS

Alloy Steel Plates SA 387

Boiler Quality Plates

Mild Steel / Carbon Steel Plates /HR Coils

Abrasion Resistant Steel ABRASION RESISTAN 200/400/450/500 wear-resistant steel. has a hardness of approximately Plates 200/400/450/500 HB. It combines high wear resistance with toughness and good weldability. Brand name supplied by us are of TISCRAL / SAILHARD/ JISCRAL/ LAS07 / HARDOX / DILLIDUR / DUROSTAT / ABRASO / XAR AND Other well know brands. Quenched & Tempered Steel Plates We also supply Quenched & Tempered steel plates, of Specn. ASTM A 514 GR. B,ASTM A 517 GR. F, ASTM A 537 CL.1 & CL. 2 Quenched & Tempered Steel Plates We also supply Quenched & Tempered steel plates, of Specn. ASTM A 514 GR. B,ASTM A 517 GR. F, ASTM A 537 CL.1 & CL. 2

High Tensile Steel Plates High Tensile Steel Plate of Following Grades are available with us IS 8500 Fe 440, Fe 440B, Fe 490, Fe 490B, Fe 540, Fe 540B, Fe 570, Fe 570B, Fe 590, Fe 590B SAILMA 300, 300HI, 350, 350HI, 410, 410HI, 450, 450HI S275J2G3, S355J2G3, S355J2GIW, S355JR DILLIMAX 690, NAXTRA 70 Nickel Based Alloy Plates The Following Grades Are Available: Nickel 200,Nickel 201,Monel 400

http://www.nikosteel.com/sheets-tech.htm#carbon[04-Jun-12 7:57:03 PM]

NIKO STEEL INDUSTRIES Inconel 600,Inconel 625 Incoloy 800 / UNS NO. 8800 / UNS NO. 8810 ,Incoloy 825 S.S. 904L / UNS NO. 8904 Hastalloy C / SAE-276 Producing Methods : Dimensions : Sheet & Coil -Hot Rolled ,Cold Rolled ,Special Finishes ,Strip -Hot Rolled ,Cold Rolled Plate -Hot Rolled Cold Rolled: Sheet and Plate, Thickness 0.15 to 8 mm , Width up to 2500 mm Length up to 8200 mm Hot Rolled: Sheet and Plate ,Thickness 1 to 100 mm Width up to 3000 mm Length up to 8200/10000/12000 mm Cold Rolled: Coil , Thickness 1 to 10 mm , Width 1000/1200/1250/1500 mm

FINISHES:

Standard mill finishes can be applied to flat rolled stainless steel directly by the rollers and by mechanical abrasives. Steel is first rolled to size and thickness and then annealed to change the properties of the final material. Any oxidation that forms on the surface (scale) is removed by pickling, and the passivation layer is created on the surface. A final finish can then be applied to achieve the desired aesthetic appearance. No. 0 - Hot Rolled Annealed, thicker plates No. 1 - Hot rolled, annealed and passivated No. 2D - cold rolled, annealed, pickled and passivated No. 2B - as above with additional pass through polished rollers No. 2BA - Bright Annealed (BA) as above with highly polished rollers No. 3 - coarse abrasive finish applied mechanically No. 4 - fine abrasive finish No. 6 - matte finish No. 7 - reflective finish No. 8 - mirror finish Annealing, Shot Blasting and Leveling , Pickling, Bright Annealing Polishing , Marking, Plastic Coating *Rapid transit cars,*buses, aircraft,* cargo containers Retractor springs ,*Hose clamps ,*Conveyors Bottling machinery ,*Jewelry ,*Cryogenic vessels and components ,*Still tubes ,*Expand metal parts Mixing bowls ,*Dryers ,*Furnace parts ,*Heat exchangers Paper mill equipment ,*Oil refining equipment *Textile industry ,*Dyeing equipment ,*Jet engine partsWelded storage tanks for *organic chemicals Combustion chambers ,*Furnace arch supports Kiln linings ,*Smoke control ductwork ,*Coal chutes Gauge parts ,*Cutlery ,*Fish hooks ,*Glass molds Bank vaults ,*Fasteners ,*Skewers,,*Dairy industry *Burner and emission control components ,*Recuperators Pipes,* tubes

APPLICATIONS FOR

ASTM STANDARDS USED FOR SHEETS / PLATES

ASTM Grade C max A 240 Mn max Chemical requirements percent(%) P max S max Si max Ni Cr. Mo Cu Others Tensile Strength mini-Mpa 515-75 485-70 515-75 515-75 485-70 515-75 515-75 Mechanical requirements Yield Strength Elong Hardness brinell mini-Mpa mini Rockwell % 205-30 170-25 205-30 205-30 170-25 205-30 205-30 40 40 40 40 40 40 40 202 00092 18300088 21700095 21700095 21700095 21700095 20200092

0.08 2.00 0.045 0.030 0.75 304 304L 0.030 2.00 0.045 0.030 0.75 310 S 0.08 2.00 0.045 0.030 1.50 0.08 2.00 0.045 0.030 0.75 316 316L 0.030 2.00 0.045 0.030 0.75 317L 0.030 2.00 0.045 0.030 0.75 0.08 2.00 0.045 0.030 0.75 321 0.08 2.00 0.045 0.030 0.75 347

8.0010.5 8.0012.0 19.022.0 10.014.0 10.014.0 11.015.0 9.0012.0 9.0013.0 -

18.020.0 18.020.0 24.026.0 16.018.0 16.018.0 18.020.0 17.019.0 17.019.0 0.500.80 4.00-

2.003.00 2.003.00 3.004.00

5(C+N) <Ti< 0.70% 10C < Cb + Ta <1.10%

A 387 class 1

2 5 7

0.05- 0.55- 0.035 0.040 0.150.21 0.80 0.04 0.030 0.40 0.15 0.30- 0.030 0.030 0.050

0.450.60 0.45-

Class Class2 Class1 Class2 310 230 4861 310 205 620 380-

22 18 18

max201HB max92HRB max202HB

http://www.nikosteel.com/sheets-tech.htm#carbon[04-Jun-12 7:57:03 PM]

NIKO STEEL INDUSTRIES class2 9 11 12 21 22 0.15 0.15 0.040.17 0.040.17 0.040.17 0.040.17 0.60 0.300.60 0.300.60 0.400.65 0.400.65 0.300.60 0.300.60 0.030 0.035 0.035 0.035 0.035 0.030 0.04 0.04 0.035 0.035 0.035 0.035 1.00 1.00 0.500.80 0.150.40 0.50 0.50 6.00 6.008.00 8.0010.0 1.001.50 0.801.15 2.753.25 2.002.50 0.65 0.450.65 0.901.10 0.450.65 0.450.60 0.901.10 0.901.10 550 415585 415585 415585 415585 380550 415585 415585 A 515 55 60 65 70 0.20 0.27 0.31 0.33 0.90 0.90 0.90 1.20 0.035 0.035 0.035 0.035 0.04 0.04 0.04 0.04 0.150.40 0.150.40 0.150.40 0.150.40 0.150.40 0.150.40 0.150.40 0.150.40 380-515/5575 415-550/6080 450-585/6585 485-620/7090 380-515/5575 415-550/6080 450-585/6585 485-620/7090 205-30 220-32 240-35 260-38 27 25 23 21 515690 515690 515690 515690 45585 205 205 240 230 205 205 310 310 310 275 310 310 18 22 22 18 18 max92HRB max217HB max95HRB max217HB max95HRB max217HB max95HRB max217HB max95HRB max201HB max92HRB max201HB max92HRB

515690

A 516

55 60 65 70

0.20 0.23 0.26 0.28

0.601.20 0.851.20 0.851.20 0.851.20 0.851.20

0.035 0.035 0.035 0.035

0.04 0.04 0.04 0.04

205-30 220-32 240-35 260-38

27 25 23 21

A537 Class1 0.24 class2 0.24

0.70- 0.035 0.040 0.151.35 0.035 0.040 0.40 0.150.700.40 1.35

0.25 0.80max 0.35 max 0.80 max 0.35 max 0.25 max max

485-620/7090 550-69080100

345-50 415-60

22 22

IS-2062-92 STEEL FOR GENERAL STRUCTURAL PURPOSES

Grade Designation % Chemical Composition C Mn S max max max A b FE410 WA FE410 WB 0.23 0.22 1.5 1.5 Yield Strength(Min) %EI.in Tensile Mpa s gauge Strength length (Min) P Si C.E. <20mm 20>40min 5.56OSo Kg/mm2 max max max 40min 0.42 41.8 41.8 250 250 240 240 230 230 23 23 Bend Test Std. Lest Piece charpy V Notch Impact Energy Joule min 2t for 27 3t for t>25mm 27

0.050 0.050

31 <25 min

0.045 0.045 0.40 0.41

FE410 WC

0.20

1.5

0.040 0.040 0.40 0.36

41.8

250

240

230

23

2t

IS-2002-62 STEEL PLATES FOR BOILERS

CHEMICAL COMPOSITION Designation IS 2002-1 IS 2002-2A IS 2002-2B C Max 0.18 0.20 0.22 Si Max 0.10-0.35 0.10-0.35 0.10-0.35 P Max 0.040 0.050 0.050 TENSILE TEST S Max 0.040 0.050 0.050 Tensile Strength Mpa 362-442 412-491 510-608 ELONGATION Yield Strength Mpa 540 491 491 Test Piece 5.65So 4So 5.65So 4So 5.65So 4So % min. 26 30 25 29 20 24

http://www.nikosteel.com/sheets-tech.htm#carbon[04-Jun-12 7:57:03 PM]

NIKO STEEL INDUSTRIES

Home | About Us | Technical Info | Quality Policy | Enquiry Form | Contact Us

Copyright NIKO STEEL INDUSTRIES. All Rights Reserved Site Developed by www.mesotek.com

http://www.nikosteel.com/sheets-tech.htm#carbon[04-Jun-12 7:57:03 PM]

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Catia Interview Question and AnwersDocument64 pagesCatia Interview Question and AnwersajaykrishnaaNo ratings yet

- Astm A700Document40 pagesAstm A700hegiro2011No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Standard Holes and Tapping ChartDocument1 pageStandard Holes and Tapping ChartajaykrishnaaNo ratings yet

- Cold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsDocument4 pagesCold-Drawn, Stress-Relieved Carbon Steel Bars Subject To Mechanical Property RequirementsSofiaJabadanEspulgarNo ratings yet

- FESTO Basic PLCDocument180 pagesFESTO Basic PLCapi-3769014100% (25)

- Durehete 950Document5 pagesDurehete 950ellisforheroes100% (1)

- BS en 14475 - 2006 - Reinforced FillDocument60 pagesBS en 14475 - 2006 - Reinforced Fillselcukx75% (4)

- AWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 106Document1 pageAWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 106JuniorNo ratings yet

- FESTO Basic PnuematicsDocument115 pagesFESTO Basic Pnuematicsapi-3769014100% (10)

- SAES-M-001 PDF Download - Structural Design Criteria For Non-Building Structures - PDFYAR - Engineering Notes, Documents & LecturesDocument10 pagesSAES-M-001 PDF Download - Structural Design Criteria For Non-Building Structures - PDFYAR - Engineering Notes, Documents & LecturesZahidRafiqueNo ratings yet

- Silver Bridge Collapse 1967Document11 pagesSilver Bridge Collapse 1967Jatin ChaudharyNo ratings yet

- Delcam Power Mill Roughing and Finishing ProgrammeDocument27 pagesDelcam Power Mill Roughing and Finishing Programmeajaykrishnaa68% (19)

- 99 Pneumatic ApplicationsDocument121 pages99 Pneumatic Applicationsapi-3731420100% (7)

- Conveyor DesignsDocument34 pagesConveyor Designsajaykrishnaa100% (2)

- Rail Technical Guide FinalDocument13 pagesRail Technical Guide FinalMarin Laurentiu100% (1)

- Unigraphics NX4 ManualDocument700 pagesUnigraphics NX4 Manualajaykrishnaa100% (7)

- Arcelormittal Crane Rails enDocument6 pagesArcelormittal Crane Rails enjulius_xNo ratings yet

- Guide To Selection: Call Toll Free 800-562-0357Document7 pagesGuide To Selection: Call Toll Free 800-562-0357ajaykrishnaaNo ratings yet

- Mild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankDocument2 pagesMild Steel Sheets:-: Range of Sheet, Plate, Strip, Flat & BlankajaykrishnaaNo ratings yet

- Tool Steel CompositionDocument5 pagesTool Steel CompositionajaykrishnaaNo ratings yet

- Ajay Covering LetterDocument1 pageAjay Covering LetterajaykrishnaaNo ratings yet

- Technical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact UsDocument3 pagesTechnical Info:-: Home About Us Technical Info Quality Policy Enquiry Form Contact UsajaykrishnaaNo ratings yet

- THK LM Guide en - A01 - 102Document2 pagesTHK LM Guide en - A01 - 102ajaykrishnaaNo ratings yet

- Conveyor Chain GuideDocument59 pagesConveyor Chain GuideajaykrishnaaNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- Over Cap FeederDocument1 pageOver Cap FeederajaykrishnaaNo ratings yet

- Speed and Accuracy Applications: Linear Drive UnitsDocument31 pagesSpeed and Accuracy Applications: Linear Drive UnitsajaykrishnaaNo ratings yet

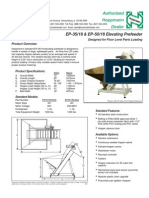

- Ep 35 50Document1 pageEp 35 50ajaykrishnaaNo ratings yet

- DSC Modular Conveyor Systems BrochureDocument32 pagesDSC Modular Conveyor Systems BrochureJuan Manuel LaraNo ratings yet

- Innovative Designs For Positive Parts TransferDocument21 pagesInnovative Designs For Positive Parts TransferajaykrishnaaNo ratings yet

- Afttp 1Document2 pagesAfttp 1ajaykrishnaaNo ratings yet

- UG Interview QuestionsDocument16 pagesUG Interview Questionsharsharg6_8No ratings yet

- Basic Mathematics by Thomas WardDocument23 pagesBasic Mathematics by Thomas WardazuzardNo ratings yet

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1No ratings yet

- Stainless Steel - Wikipedia, The Free EncyclopediaDocument7 pagesStainless Steel - Wikipedia, The Free EncyclopediaTuan DoNo ratings yet

- Syllabus WELDING TECHNOLOGY R2017Document2 pagesSyllabus WELDING TECHNOLOGY R2017CHANDRAPRAKASHNo ratings yet

- As 2003-1991 Carbon and Low Alloy Steel - Measurement of DecarburizationDocument6 pagesAs 2003-1991 Carbon and Low Alloy Steel - Measurement of DecarburizationSAI Global - APACNo ratings yet

- Av Me CategoriesDocument20 pagesAv Me Categoriesrajkiran_bNo ratings yet

- General Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingDocument62 pagesGeneral Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingclaudiaNo ratings yet

- AWS Certified-Welder-Application (01-2023)Document2 pagesAWS Certified-Welder-Application (01-2023)hanz bermejoNo ratings yet

- Welding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationDocument30 pagesWelding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationMario TanNo ratings yet

- Orm AssignmentDocument2 pagesOrm AssignmentDeepNo ratings yet

- Heat Treatment of Carbon SteelDocument23 pagesHeat Treatment of Carbon SteelArielle Joyce de JesusNo ratings yet

- Accessories For Pipes: FlangesDocument7 pagesAccessories For Pipes: FlangesJbr IrvingNo ratings yet

- An Overview of Carbon Steel - Chemical Composition & Application SummaryDocument11 pagesAn Overview of Carbon Steel - Chemical Composition & Application SummaryLutfi ArdiansyahNo ratings yet

- Arc Welding ReportDocument14 pagesArc Welding ReportAkmal HazimNo ratings yet

- AMACS Corrugated Grid Packing Web2Document1 pageAMACS Corrugated Grid Packing Web2ValiNo ratings yet

- Science - 101020 - Physical and Chemical Changes Class 7 AssignmentDocument4 pagesScience - 101020 - Physical and Chemical Changes Class 7 AssignmentDeepak KansalNo ratings yet

- ME6008Document3 pagesME6008anon_782224603No ratings yet

- Astm A193-A193m-03 Alloy & Stainless Steel BoltDocument14 pagesAstm A193-A193m-03 Alloy & Stainless Steel BoltCharwin PicaoNo ratings yet

- Archana Tata SteelDocument58 pagesArchana Tata SteelSanjay Veerabhadrakumar0% (1)

- Asme Section Ii A-2 Sa-736 Sa-736mDocument6 pagesAsme Section Ii A-2 Sa-736 Sa-736mdavid perezNo ratings yet

- Welding of Steel PipingDocument8 pagesWelding of Steel PipingElias EliasNo ratings yet