Professional Documents

Culture Documents

Installation Manual - Dodge Caliber SRT-4

Uploaded by

Srt RomeroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual - Dodge Caliber SRT-4

Uploaded by

Srt RomeroCopyright:

Available Formats

TCS: Driver Mod Installation Manual

Contents

Introduction ................................................................................................................................................. 2 TCS Packing List ........................................................................................................................................ 3 Tools Needed for Installation...................................................................................................................... 4 Wire Identification ...................................................................................................................................... 4 Soldering Standard Butt Connection ...................................................................................................... 5 Soldering T Connection....................................................................................................................... 6 Quick Reference TCS Wiring Diagram ...................................................................................................... 7 TCS:DriverMod Wire Chart ....................................................................................................................... 8 Detailed Installation .................................................................................................................................... 9

1|Page

TCS: Driver Mod Installation Manual

Introduction

The purpose of this document is to provide very detailed information regarding the installation of the ND Performance - Traction Control System. The installation of the system is very straight forward and typically not very difficult, but care must be taken. This document includes detailed step-by-step instructions and includes many pictures to help clarify. Average installation time is around 4.5 hours at a normal pace. This system should be installed by professional. In our experience, the vast majority of problems associated with aftermarket automotive electronics systems are due to improper installation. Improper installation can lead to a system that is unsafe, unusable, intermittent, and improper installation can even damage the Traction Control System or the vehicle electronics. ND Performance will not warranty this product or any damage that is caused to your vehicle due to improper installation (See warranty and disclaimer documentation). If you do not feel comfortable installing this system on your vehicle we strongly urge that you take your vehicle to a certified professional for installation. Due to the nature of the electrical systems in the Dodge Caliber SRT-4, there is only one reliable way to install TCS:DriverMod into your vehicle. That method is to solder and shrink wrap / tape all wiring into the vehicle's wiring. Soldering provides the most solid wire to wire connection. During the course of this installation, you will be wiring TCS:DriverMod into several key systems of your vehicle. Among those systems are the Powertrain Control Module (PCM) and the Anti-lock Brake Module (ABM). These two systems directly affect the driveability and safety of your vehicle. Great care must be taken to follow the instructions and to take your time to install the wiring carefully. All information needed for the installation should be contained within this detailed document, however if you have any questions please feel free to contact us at neil@ndperformance.com

2|Page

TCS: Driver Mod Installation Manual

TCS Packing List

Traction Control Unit Wiring Harness TCS Tuner CD (For Microsoft Windows 2000/XP/Vista) Map Switcher Map Switcher Cable (10) 4 zipties Rubber feet for TCS Unit Promotional sticker

If you are missing any of the components, please email us at neil@ndperformance.com

3|Page

TCS: Driver Mod Installation Manual

Tools Needed for Installation

Soldering Iron (and solder) Wire strippers Pliers (Regular or slip-joint) Electrical Tape and/or heat shrink tubing Serrated knife/blade Wire coat hanger or heavy wire (at least 12GA) to route wires through vehicle Small flathead screwdriver Vehicle jack and jack stands Socket set and ratchet.

Wire Identification

Looking at the wiring harness, you will notice that some of the wires are solid in their coloring, and others have stripes. In these instructions, if you see a wire color called out by a single name, RED for instance, is the solid red colored wire. If you see a wire color called out RED/BLACK that is the red wire with a black stripe (or tracer, as it is called).

4|Page

TCS: Driver Mod Installation Manual

How to Properly Solder

This section of the document simply describes how to properly solder and protect wire to wire connections. It includes how to properly solder a T connection, as well as how to solder a standard wire to wire connection (i.e. butt connect).

Soldering Standard Butt Connection

1. Strip approximately 1/2 of insulation from each wire to be connected. Cut approximately 1 of heat shrink tubing as well. 2. Place one wire through the heat shrink tubing and twist the stranded copper wire together so that joint is linear. 3. Use a soldering iron (with a small amount of solder on it) to heat the wire for a few seconds, and then simultaneously apply solder to the twisted copper and soldering iron, coating the entire junction with solder. Do not add an excessive amount of solder. 4. Finally move the heat shrink tubing over the soldered junction and heat the tubing with a heat gun or lighter.

5|Page

TCS: Driver Mod Installation Manual

Soldering T Connection

1. With the new wire that is to be Td in (i.e. the wire coming from the TCS harness) strip approximately 1/2 to 1 of insulation from the wire. With the existing wire that is going to be tapped (i.e. the wire in the vehicle) remove the insulation from a 1/4 to 1/2 section so that only the copper is exposed but the wire is still intact. 2. Wrap the new wire around the existing wire, so that the new wire is parallel to the existing wire. 3. Use a soldering iron (with a small amount of solder on it) to heat the wire for a few seconds, and then simultaneously apply solder to the twisted copper and soldering iron, coating the entire junction with solder. Do not add an excessive amount of solder. 4. Finally using electrical tape cleanly wrap up the soldered junction.

6|Page

TCS: Driver Mod Installation Manual

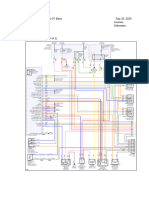

Quick Reference TCS Wiring Diagram

Diagram will be added soon. 18May09

7|Page

TCS: Driver Mod Installation Manual

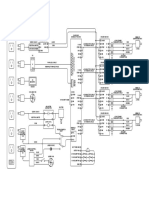

TCS:DriverMod Wire Chart

The following chart details what each wire in the TCS:DriverMod wiring harness is, and what its function is. Wire Color RED BLACK LIGHT GREEN GRAY BLUE/WHITE RED/BLACK GREEN/DARK BLUE WHITE/GREEN YELLOW/WHITE BLACK/ORANGE (Coaxial Cable) BLACK (Coaxial Cable) YELLOW YELLOW/BLUE GREEN GREEN/BLACK WHITE WHITE/BLACK LIGHT BLUE LIGHT BLUE/RED Function +12V Power Input Ground (2 BLACK wires) Retard/Digital Input (Future Use) PWM/N2O/WI Control (Future Use) Electronic Boost Control Output (Future Use) MAP Sensor Signal Input TPS Sensor Signal Input (Future Use) ESP/Digital Output Control (Future Use) Clutch Up-Stop Switch Input Front ABS Sensor Signal Rear ABS Sensor Signal Ignition Coil #1 Input Ignition Coil #1 Output Ignition Coil #2 Input Ignition Coil #2 Output Ignition Coil #3 Input Ignition Coil #3 Output Ignition Coil #4 Input Ignition Coil #4 Output

8|Page

TCS: Driver Mod Installation Manual

Detailed Installation

1. Remove aftermarket strut tower brace if installed. Remove negative battery terminal. 2. Remove the front drivers kick panel and pry up the sill panel (not necessary to completely remove sill panel). The kick panel will pop off after the sill panel has been pried up.

3. Lay harness down and place the harness plugs side under drivers seat. Route the wires towards the firewall under the drivers sill. (Dodge Neon SRT-4 shown, but installation is typical)

9|Page

TCS: Driver Mod Installation Manual

4. Remove the 13mm bolt just above the hood release latch, and place the bolt through the eye terminal of the two BLACK wires (found in the smaller of the two wire bundles coming from the TCS connectors). Reinstall the bolt, ensuring that the terminal/wires do not get damaged.

5. The other wires left in this part of this smaller wire bundle, WHITE/GREEN, LIGHT GREEN, and GREEN/DARK BLUE (some installations) are not used at this time, and can be coiled up, and stored beneath the kick panel upon reassembly. 6. At this point, you will need to jack up the front left corner of the vehicle, and remove the front left wheel. Be sure to use quality jack stands, and be sure that the rear wheels are chocked to prevent it from rolling You have heard it before, but it is true; SAFETY FIRST! 7. After you have removed the wheel, you will need to remove the back half of the inner fender splash shield. You will not need to take it completely out of the vehicle, although doing so will make it easier to work on. The inner fender splash shield is held in place with plastic fasteners. These fasteners are easily removed with a little finesse. First, use a small flat blade screwdriver to pry the center of the fastener outward. When it is sticking out far enough, grasp the center with pliers, and the whole fastener should come out. If the center pulls out of the fastener, dont panic! Just pull the rest of it out, and reassemble the fastener. 10 | P a g e

TCS: Driver Mod Installation Manual

8. There is a large rubber grommet that runs through the frame, and is located inside the rear of the drivers side inner fender area. If you stick your head up to where you can see into the area behind the fender, just forward of the front door, you will see a large, oblong rubber grommet with a wiring harness coming through it. Locate this grommet.

11 | P a g e

TCS: Driver Mod Installation Manual

9. Cut/Poke a small hole through the grommet to allow the TCS harness to fit through. This can be done with a small serrated knife/blade (we use a small X-Acto knife). When placing the hole in the harness be sure not to place the hole too close to the center of the grommet where the existing vehicle wiring harness is located. We have found that toward the rear of the car, there is an area of the grommet that is the easiest, and best place to make the incision. Make the hole about 1 long. This should be enough to fit the TCS harness through.

10. At this point, you will want to route a stiff wire or coat hanger (wire is preferred) through this hole from the outside of the car to the inside. Push about 2 feet of wire into the car. Using a brightly colored wire will make finding it inside the car easier. Once the wire is found inside the car, route it through the wires under the dash until it comes out in the kick panel area.

12 | P a g e

TCS: Driver Mod Installation Manual

11. At this point you are going to pull the main harness through the grommet. You will notice that the harness is split into two sections. One section has only a few wires in it, while the other has several. You want the section with several wires. Take the end of this bundle of wires, and fold back the two single BLACK wires (one is BLACK the other is BLACK/ORANGE). Tape the wires together in a bundle, and then tape this bundle to the stiff wire you pushed through the grommet. Once that is done, have an assistant help you to pull the wire bundle through the grommet. GO SLOWLY!!! Once you have the bundle through, pull the two black wires through VERY gently. The part at the end of these wires wrapped in colored tape can easily be pulled off the wires. Guide the colored tape parts through the hole in the grommet as carefully as possible. Once you are done, it will look like this:

13 | P a g e

TCS: Driver Mod Installation Manual

12. Now, the wiring harness needs to be routed through the inner fender, through the very narrow gap between the inner fender sheet metal and the fender itself. Looking in through the wheel well, look up, and forward, towards the front of the Power Distribution Module (PDM, aka the fuse box). You will see that gap go from about and make a dip, or notch about 1 in diameter. That is the target. Route your guide wire through that notch. The picture below shows the wires coming through that gap, but are actually coming through behind that notch. You want them in the notch that is forward of where this picture is showing them. (Picture is from a prototype install, and is now outdated, but illustrates the gap between the inner fender and the fender that we are working with). NOTE: Route the TCS wiring above the vehicles main wiring harness, in an effort to make the run between the grommet and the notch in the fender as short as is possible, without pulling it tight.

13. Pull the wiring harness all the way through the notch, including the two BLACK wires with the colored tap at the end. Again, be careful with this item at the end of the wires, as it is very fragile. At this point, unwrap the tape you put on the bundle of wires, and discard the guide wire.

14 | P a g e

TCS: Driver Mod Installation Manual

14. Now, take the cover off the top of the PDM, and set it aside. There are three tabs securing the PDM in place. Push them with your thumb or a small flat blade screwdriver, and lift the PDM out of place. It will swivel forward towards the front of the car. Lay it on its back. Route the TCS wiring harness down from the fender notch, through the base of the PDM, as shown in the picture below. Route the main harness and the two black wires through the PCM bracket, which you can see in the upper right of the picture. The two loose wires (RED and YELLOW/WHITE) will stay in the PDM area.

15 | P a g e

TCS: Driver Mod Installation Manual

15. The RED (Ignition power, +12v) wire will be the first one we solder in. There is a connector in the middle of the underside of the PDM. There are only three wires in it. This is where we are going to draw power for the TCS from. Locate the connector (it is the only one with only 3 wires in it), and disconnect it from the PDM. This will give us slack in the wiring to work with. You are going to splice into the LIGHT BLUE/GREY wire in the PDM wiring harness. Solder this connection, and then seal it with black electrical tape.

16 | P a g e

TCS: Driver Mod Installation Manual

16. Next, take the YELLOW/WHITE wire (TCS harness, clutch up-stop switch). Route this wire off towards the front connector of the PCM. At this point, you need to remove the PCM connector and the cover from that connector. Push the tab on top of the front PCM connector (PCM C1), and then gently pry the grey lever up, while wiggling the PCM connector up. After it is off, use a small flat blade screwdriver to pry the connector cover off by pushing the tab in at the front of the connector (towards the rear of the car for the front connector). The cover will swivel up, and then off, as shown below (rear PCM C2 connector shown, but same for both connectors).

17 | P a g e

TCS: Driver Mod Installation Manual

17. Locate the clutch up-stop switch signal, Cavity 43, DARK GREEN/ORANGE wire in the PCM C1 connector. Splice the TCS YELLOW/WHITE wire to this one, solder, and tape it up. You can route the TCS YELLOW/WHITE wire inside the PCM C1 connector wire loom to hide it, and make it come out of the loom inside the PDM. Wrap the whole PCM wire bundle up in some tape to make it all neat, and then put the connector cover back on (make sure the grey lever is up when you put the cover on), and put the PCM C1 connector back on the PCM.

18 | P a g e

TCS: Driver Mod Installation Manual

18. At this point, it is time to put the PDM back in place. You can put the cover back on, or leave that until later. If the TCS wiring harness is routed properly, the PDM will go back in place as if the TCS harness was not even there.

19. Now it is time to work with the rear PCM C2 connector. Unhook the C2 connector the same way as the C1 connector in the above steps. Take the cover off of it. There are several wires to hook up in this section. Pull the wire bundle up, around the PCM to meet the PCM C2 connector. We are concerned with several of the remaining wires, but not all of them. The two black wires will need to continue on to the right side of the car, so lay them aside for now. There are a few other wires we do not need right now. The GREY (PWM/N2O/WI output) wire, the BLUE/WHITE (EBC) wire, and the GREEN/DARK BLUE (TPS, some installations) wire are all unused as of this writing. They can be simply taped up and out of the way for now, and may be used in future updates to TCS, as features are added. 20. The remaining wires will all be hooked up in the PCM C2 connector. Lets start with the RED/BLACK (MAP signal) wire. Locate the VIOLET/LIGHT BLUE wire in cavity 85. Splice into this wire, solder and tape it up.

19 | P a g e

TCS: Driver Mod Installation Manual

21. Now we will turn our attention to the wiring going to all four ignition coils. This wiring consists of 4 wires, all gathered in the lower right corner of the connector when viewed from the left side of the vehicle. Lets start with cylinder #1. This wire is in Cavity 76 DARK GREEN/LIGHT BLUE, which is the 4th from the end, in the lower right corner of C2. Cut this wire about 1 from the connector. Strip off both ends of the wire. On the PCM side of that wire, you are going to solder in the YELLOW wire. After soldering, tape or heat shrink this connection. Now take the other part of the DARK GREEN/LIGHT BLUE wire (the part going into the main vehicle harness). To this wire, solder the YELLOW/BLUE TCS wire. Now move to the next wire in Cavity 75, DARK BLUE/TAN, cylinder #2. Cut this wire like the last one, 1 from the C2 connector. On the PCM side, solder the GREEN TCS wire, and on the harness side, solder the GREEN/BLACK wire. Once you have taped up those connections, move onto cylinder #3, located in C2 Cavity 74, DARK BLUE/ORANGE. Cut this wire the same 1 from the C2 connector. On the PCM side, solder the WHITE TCS wire, and on the harness side, solder the WHITE/BLACK TCS wire. Lastly, cylinder #4 is located in the last cavity, 73, GREY/DARK BLUE. This wire has a little less length to it, and you may have to cut it 1 from the C2 connector. On the PCM side, solder in the LIGHT BLUE TCS wire. On the harness side, solder in the LIGHT BLUE/RED TCS wire. When you are finished, the harness will look a little like this:

20 | P a g e

TCS: Driver Mod Installation Manual

22. Bundle all of these wires up, and put a layer of black electrical tape on the whole thing. Do this neatly, as you need to be able to get the PCM C2 connector cover back on. Put the cover back on (with the grey lever up) and then reinstall the connector back onto the PCM. Congrats! You have finished all of the PCM wiring. It should look like the picture below (your vehicle may not have a strut tower brace installed).

21 | P a g e

TCS: Driver Mod Installation Manual

23. Now its time to work with the two remaining BLACK wires. These wires contain the sensors that must hook into the vehicles ABS system. First, lets route them the rest of the way through the engine bay. First, remove the firewall to hood rubber seal. This simply pulls off. Lay it aside for now. Next, loosen the fasteners holding the fiber insulation blanket to the firewall. There is an 11mm sheet metal nut in the middle, plus a 10mm nut holding the firewall to hood ground strap at the right side. There is also a plastic nut towards the right side that can be removed with your fingers. Once the nuts are all off, pry down the insulation blanket to gain access behind it.

24. Next, route the two black wires behind this blanket. Be sure that the wires are below the insulation blanket mounting studs. Route the wires as shown in the following picture (disregard the color of these wires in the picture, yours are BLACK and BLACK/ORANGE.)

25. Next, put all of the nuts and the ground strap back on over the insulation blanket, and secure into place.

22 | P a g e

TCS: Driver Mod Installation Manual

26. Now we need to work with the ABM connector. This is a little tight to work with, but work your hand down past the A/C lines to the ABM connector. This connector is removed by squeezing the two tabs near the bottom of the connector together, and then lifting up in a swiveling manner.

23 | P a g e

TCS: Driver Mod Installation Manual

27. Once the connector is off, you will need to pull it up to where you can work on it. You may have to cut one or two tie straps that are holding it down to the frame rail. Once you have cut them, you will be able to bring the connector up above the A/C lines, to where you can access all of the wiring. With the connector in the open position, you can access the wires you need.

28. Now route the two BLACK wires around to the connector. Check to be sure that when connector is put back in place that the two BLACK wires will go down to the ABM unit without wrapping around a brake line or A/C line. Take time to figure this out. It is simple, and will save headaches later on.

24 | P a g e

TCS: Driver Mod Installation Manual

29. Once you have routed the wires, remove the colored protective tape from the sensors at the end of the BLACK wires.

30. Notice that there are two colored bands on the tiny metal wire leads. One is WHITE the other is BLUE. These bands signify the polarity of the sensors, and are crucial to getting them installed properly.

25 | P a g e

TCS: Driver Mod Installation Manual

31. CAUTION: You are about to begin the most delicate part of the TCS installation. Great care must be taken to limit how much you bend the leads on the sensors. They will break easily! Breaking them will mean a substantial delay in getting your TCS working!!!! You are also about to work on the wiring for the ABS and ESP systems in your vehicle. Go slowly, and be careful. Failure to follow the instructions here can lead to a non-functional ABS system, which will reduce the safety of your vehicle! 32. Remove about 1 1/2 2 of the tape/insulation from the wiring harness at the ABM connector. 33. There are two wires we are concerned with in the ABM connector. The first wire is in Cavity 46, DARK GREEN/TAN(Left Front Wheel Speed Sensor Signal). About 1 from the ABM connector, cut this wire. On the harness side, cut 1 of this wire out (shorten the wire). 34. Locate the BLACK/ORANGE TCS wire, and orient the sensor so that the BLUE band faces the ABM connector and the WHITE band faces the harness.

26 | P a g e

TCS: Driver Mod Installation Manual

27 | P a g e

TCS: Driver Mod Installation Manual

35. Solder the BLUE band side lead to the DARK GREEN/TAN wire coming from the ABM. To do this, strip about of insulation off the wire. Carefully twist the DARK GREEN/TAN wire around the sensor lead. Trim off any excess of the sensor lead. Solder this connection. 36. On the WHITE band side of the sensor, connect the harness side of the DARK GREEN/TAN wire in the same way as the above step. When completed, your connections should look like the picture below. Tape these connections up.

37. Now we are going to do the same thing with the other sensor. The other sensor is for the rear wheel ABS sensor. This wire is in Cavity 37, LIGHT GREEN /DARK BLUE (Left Rear Wheel Speed Signal). About 1 from the ABM connector, cut this wire. On the harness side, cut 1 of this wire out (shorten the wire). 38. Locate the BLACK TCS wire, and orient the sensor so that the BLUE band faces the ABM connector and the WHITE band faces the harness. Solder the BLUE band side lead to the LIGHT GREEN /DARK BLUE wire coming from the ABM. To do this, strip about of insulation off the wire. Carefully twist the LIGHT GREEN /DARK BLUE wire around the sensor lead. Trim off any excess of the sensor lead. Solder this connection. 28 | P a g e

TCS: Driver Mod Installation Manual

39. On the WHITE band side of the sensor, connect the harness side of the LIGHT GREEN/DARK BLUE wire in the same way as the above step. 40. You now need to secure the two black wires, and keep them from being pulled on, and in turn pulling on the sensors. To do this, make the two wires loop into the connector as shown below. At the end of the connector, you will find a pair of holes meant to be used for a zip tie. Use one of the supplied zip ties to fasten the wiring harness to the connector, and provide strain relief to the wires.

41. Now, route the ABM connector back down to the ABM itself. It may be helpful to close the connector, and reopen it once in position. Align the ABM connector with the ABM, and push it into place. While maintaining a little pressure on the connector, close the cover on it, locking it into place. Put the C shaped clip back on the hose it was clamped to. Use some of the zip ties to replace the ties that were cut earlier. 42. Neaten up any of the remaining wiring items under the hood, and reassemble anything you still have apart. 43. Back inside the car, put the TCS wiring harness underneath the kick panel and sill plate, and 29 | P a g e

TCS: Driver Mod Installation Manual

reinstall both the panel (do this first), and then the sill plate. You will see that there is a perfect spot for the TCS wiring to come out of the sill plate and under the drivers seat. 44. Push the drivers seat all the way forward. Its time to hook up the TCS box. Looking at the TCS on end, you will see two white connectors directly next to each other. Push the TCS main harness connectors into these connectors until you see/hear them click into place. 45. Next, place the Map Switcher somewhere in the vehicle that works best for you. We have found that the small area just behind and below the shifter is a good spot for the Map Switcher, but you can put it anywhere you would like. Plug the Map Switcher cable into the Map Switcher, and route the other end of the cable to the TCS box, making sure that wherever you route it, it will not be pinched or pulled on. 46. Plug the Map Switcher cable into the small jack at the other end of the TCS box. At this time, you should also plug in a RS232 serial cable, or a USB to Serial adapter cable. Route that cable out to wherever you will tune TCS. 47. Back outside the vehicle, reinstall the inner fender splash shield, and reinstall the wheel. Lower the vehicle to the ground, and torque the wheel lug nuts to 95 ft*lbs. 48. Hook up the negative battery cable. 49. If all has been installed properly, you should now be able to start the car. The very first start may take a few extra turns of the engine, but it should then start up without any warning lights or CELs. 50. Congratulations! You have made it! TCS:DriverMod is now yours, and ready to be tuned! All units have been burned-in, bench tested, and are ready for immediate use. TCS is automatically operational with a launch limiter set at 3500, and a generic (medium aggressiveness) TCS map. For more information on TCS operation please see the operation manual/notes on the CD provided or check the website for the most recent information. If the vehicle does not start or operate properly we suggest double checking all of your connections (and this install document in its entirety), and if the problem persists contact ND Performance immediately.

30 | P a g e

You might also like

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Chrysler Neon 99 - Instrument Panel and SystemsDocument4 pagesChrysler Neon 99 - Instrument Panel and SystemseephantomNo ratings yet

- Codigo DTC para Jeep JKDocument11 pagesCodigo DTC para Jeep JKEmiliano Esquinca Ávila100% (1)

- Nissan Murano Engine Air Intake DuctDocument8 pagesNissan Murano Engine Air Intake DuctenkcyongNo ratings yet

- 1985 Honda Accord SE-i - Diagramas ElectricosDocument15 pages1985 Honda Accord SE-i - Diagramas ElectricosRodrigo López100% (1)

- 2010 - Caliber JEEP BOITE T355Document484 pages2010 - Caliber JEEP BOITE T355thierry.fifieldoutlook.comNo ratings yet

- Cirrus System Sec.Document26 pagesCirrus System Sec.Carlos Calderon Moctezuma100% (1)

- Automatic Transmission: DaihatsuDocument95 pagesAutomatic Transmission: Daihatsugroomblack5No ratings yet

- 2019 Toyota Corolla 2.0L Eng VIN 4 SEDocument220 pages2019 Toyota Corolla 2.0L Eng VIN 4 SEalex acuña cordovaNo ratings yet

- MTX-L PlusDocument14 pagesMTX-L Plusjuanlasserre9444No ratings yet

- Multipoint Fuel Injection SystemDocument6 pagesMultipoint Fuel Injection Systemalan kurniawanNo ratings yet

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDocument3 pagesEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNo ratings yet

- 6 67 (0:,5,1 ',$ 5$06 $Uwlfoh7H (W: 9Ronvzdjhq4Xdqwxp) RukwwsyronvzdjhqpvnuxDocument10 pages6 67 (0:,5,1 ',$ 5$06 $Uwlfoh7H (W: 9Ronvzdjhq4Xdqwxp) RukwwsyronvzdjhqpvnuxCristiano GregorioNo ratings yet

- PG Murano 2006Document72 pagesPG Murano 2006Alexander GutierrezNo ratings yet

- 2015 Hyundai Elantra GT Base 2.0LDocument116 pages2015 Hyundai Elantra GT Base 2.0LData TécnicaNo ratings yet

- NacelleDocument7 pagesNacellecarlitos232067% (3)

- OTC Family of Battery Testers: Sabre HPDocument4 pagesOTC Family of Battery Testers: Sabre HPJhon Jairo Mazuera GuzmanNo ratings yet

- Hydrocarbon Crack SystemDocument2 pagesHydrocarbon Crack SystemLucian Si Silvia PoneaNo ratings yet

- 95 DDocument563 pages95 DGutium AlexeyNo ratings yet

- System Wiring Diagrams: Air ConditioningDocument67 pagesSystem Wiring Diagrams: Air ConditioningJose Luis Orozco RobledoNo ratings yet

- 4HP14 Manual 98-152Document17 pages4HP14 Manual 98-152Azmi Mushoffa100% (1)

- Town & Country: 2009 Owner'S ManualDocument543 pagesTown & Country: 2009 Owner'S ManualLarry LawrenceNo ratings yet

- 94camry-Engine Removal & InstallationDocument12 pages94camry-Engine Removal & InstallationTrey OwenNo ratings yet

- Civic Direccion AsistidaDocument83 pagesCivic Direccion AsistidaCarlos Mendoza CambrónNo ratings yet

- Neon 2002Document4 pagesNeon 2002Rogelio ArenasNo ratings yet

- Familia 33 BQ 50Document76 pagesFamilia 33 BQ 50FlakoO0No ratings yet

- Driveline: SectionDocument229 pagesDriveline: Sectionjair HernandezNo ratings yet

- Jatco 506 EDocument1 pageJatco 506 EmasephxNo ratings yet

- Ford Escort Rear Disc Brake Conversion - 001Document8 pagesFord Escort Rear Disc Brake Conversion - 001910pcsupport100% (1)

- Delphi EGR Opel Newsletter - 3 - 4Document4 pagesDelphi EGR Opel Newsletter - 3 - 4mnbvqwertNo ratings yet

- Sweeper ManualDocument10 pagesSweeper ManualGoran RajkovNo ratings yet

- 2007 Dodge Caliber ManualDocument360 pages2007 Dodge Caliber ManualJinyuan FangNo ratings yet

- Sony+XM 504Z+Car+Power+AmplifDocument18 pagesSony+XM 504Z+Car+Power+AmplifB.r. ArturoNo ratings yet

- Installation Instructions 30-5130Document8 pagesInstallation Instructions 30-5130alexcus1539No ratings yet

- SB 10059671 2273 PDFDocument10 pagesSB 10059671 2273 PDFZool Car زول كار100% (1)

- Converter Lining CatalogDocument76 pagesConverter Lining CatalogMarianoNo ratings yet

- CVT / TCM Calibration Data "Write" Procedure: Applied VehiclesDocument20 pagesCVT / TCM Calibration Data "Write" Procedure: Applied VehiclesАндрей ЛозовойNo ratings yet

- Automatic Level Control PDFDocument82 pagesAutomatic Level Control PDFRicardo Cornejo Lafuente100% (1)

- Suzuki Annual Report 2012Document103 pagesSuzuki Annual Report 2012Ahmed SiddiquiNo ratings yet

- Maruti SwiftDocument25 pagesMaruti SwiftAnkur BhatNo ratings yet

- 1996 Dodge Grand Caravan Localizacion de ComponentesDocument28 pages1996 Dodge Grand Caravan Localizacion de ComponentesLuis Angel BarajasNo ratings yet

- Diagrama de Coneccion de Motores para CNCDocument1 pageDiagrama de Coneccion de Motores para CNCFreddy CajasNo ratings yet

- Super Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelDocument64 pagesSuper Airflow Converter: Super Air Flow Converter Wiring Diagram by ModelOdien SalehNo ratings yet

- AE86 Levin-TruenoDocument1 pageAE86 Levin-TruenoToshiba PortegeNo ratings yet

- GM Parts Manual - Firebird 1993-2000 AllDocument2,385 pagesGM Parts Manual - Firebird 1993-2000 AllRashid JuarezNo ratings yet

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- Mitsubishi 4 g63 Turbo PDFDocument48 pagesMitsubishi 4 g63 Turbo PDFAlexandru UngureanuNo ratings yet

- SensorDocument25 pagesSensorlyndorNo ratings yet

- Diagramas Prelude H22A1Document53 pagesDiagramas Prelude H22A1Rodríguez AndrésNo ratings yet

- 2011 Chevrolet Traverse Owners PDFDocument452 pages2011 Chevrolet Traverse Owners PDFGabe HollowsNo ratings yet

- Atra Atb418 A604 41teDocument1 pageAtra Atb418 A604 41teossoskiNo ratings yet

- 2013 MEGA CV - Axles CatalogDocument57 pages2013 MEGA CV - Axles Cataloglv621048No ratings yet

- Titan y Aarmada CKPDocument3 pagesTitan y Aarmada CKPLeandro FerreiraNo ratings yet

- Installation Manual - Dodge Spirit RTDocument20 pagesInstallation Manual - Dodge Spirit RTalfredoNo ratings yet

- Installing DCC DecodersDocument20 pagesInstalling DCC Decodersauberry53500% (1)

- E-Type EDIS Ignition Kit v3Document26 pagesE-Type EDIS Ignition Kit v3k74785723No ratings yet

- 3D Printed Hovercraft ManualDocument30 pages3D Printed Hovercraft Manualdfdf dgfdNo ratings yet

- Craven Speed Gauge Install For Obsessive-Compulsives: Getting The Wires From The Engine Compartment Through The FirewallDocument9 pagesCraven Speed Gauge Install For Obsessive-Compulsives: Getting The Wires From The Engine Compartment Through The FirewallBolinha's Wash ClubNo ratings yet

- MYLAPS RC Manual Vjan2010Document18 pagesMYLAPS RC Manual Vjan2010pabg76No ratings yet

- TTSH Version 4 Build Guide v1 - 2Document41 pagesTTSH Version 4 Build Guide v1 - 2Loli BreederNo ratings yet

- GarageBand Shortcuts From Midnight MusicDocument6 pagesGarageBand Shortcuts From Midnight MusicScampNo ratings yet

- EyeprocuctsDocument264 pagesEyeprocuctsapi-3703018No ratings yet

- Fine Jewelry - Skinner Auction 2711BDocument196 pagesFine Jewelry - Skinner Auction 2711BSkinnerAuctions100% (4)

- CAPE Biology Plan and DesignDocument2 pagesCAPE Biology Plan and DesignDaniel McDougall100% (3)

- The Ashryn Spire: A Forbidden Lands One-Shot by Andrew NicholsDocument6 pagesThe Ashryn Spire: A Forbidden Lands One-Shot by Andrew NicholsTywyll100% (1)

- Something RandomDocument3 pagesSomething RandomJames100% (1)

- Exegesis On Matt 7v1-12Document11 pagesExegesis On Matt 7v1-12sadeyedgirl100% (2)

- PDF Download Before You Say I Do A Marriage Preparation Manual For CouplesDocument2 pagesPDF Download Before You Say I Do A Marriage Preparation Manual For CouplesKevin EdroNo ratings yet

- BSTA Spring 2009Document33 pagesBSTA Spring 2009RKgowthu RamuNo ratings yet

- UnderDocument293 pagesUnderXam Xann100% (12)

- Casual QuestionsDocument3 pagesCasual QuestionsPeter Paul Enero PerezNo ratings yet

- Lights and Sounds PlaylistDocument2 pagesLights and Sounds PlaylistMalakai3000No ratings yet

- 3D Subtitles TutorialDocument15 pages3D Subtitles Tutorialekc_1971No ratings yet

- The Ecology of Authorial Ascension PDFDocument1 pageThe Ecology of Authorial Ascension PDFMihai IacobNo ratings yet

- Cronology Gaudiya Sampradaya IDocument27 pagesCronology Gaudiya Sampradaya IMaximiliano Baratelli100% (2)

- The Last Ride Together: Robert BrowningDocument11 pagesThe Last Ride Together: Robert BrowningUma DebbarmaNo ratings yet

- Buckely - The Forms of Autobiography, SpengemannDocument6 pagesBuckely - The Forms of Autobiography, SpengemannMario P CNo ratings yet

- 778007-Knit Today 12 2013Document100 pages778007-Knit Today 12 2013Mares Florentina100% (7)

- Lit1 Task 01-22-2020Document2 pagesLit1 Task 01-22-2020Niela LazaroNo ratings yet

- Astrotheology of The AncientsDocument6 pagesAstrotheology of The AncientsDonnaveo Sherman100% (2)

- ICFES TrainingDocument2 pagesICFES TrainingJairo Eduardo Cajigas RamirezNo ratings yet

- Descriptive EssayDocument3 pagesDescriptive EssayjamielhallNo ratings yet

- 018: Uklas Ultura: Terms and ConditionsDocument4 pages018: Uklas Ultura: Terms and ConditionsRevo NatzNo ratings yet

- Louis Dumont Homo Hierarchicus The Caste System and Its Implications 1988 PDFDocument271 pagesLouis Dumont Homo Hierarchicus The Caste System and Its Implications 1988 PDFJuan Ossio100% (2)

- Moby Dick Chapters 102-114 PDFDocument5 pagesMoby Dick Chapters 102-114 PDFRomesor ApolNo ratings yet

- A History of Science and Technology in The Philippines During Pre-Colonial PeriodDocument2 pagesA History of Science and Technology in The Philippines During Pre-Colonial PeriodLady of the LightNo ratings yet

- Steve Jobs: "The Entrepreneur That I Most Admire"Document4 pagesSteve Jobs: "The Entrepreneur That I Most Admire"Joose Raymundo RamirezNo ratings yet

- Impressionism: An Interactive Powerpoint Lesson Created by Megan SierzDocument16 pagesImpressionism: An Interactive Powerpoint Lesson Created by Megan SierzPetre LeescuNo ratings yet

- Bajorek - Photography and National Memory - Senegal 1960Document13 pagesBajorek - Photography and National Memory - Senegal 1960Bruna TrianaNo ratings yet

- Poetry Response SheetDocument1 pagePoetry Response SheetamberrobinsNo ratings yet

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 4.5 out of 5 stars4.5/5 (9)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosFrom EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosRating: 5 out of 5 stars5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Heat Transfer Engineering: Fundamentals and TechniquesFrom EverandHeat Transfer Engineering: Fundamentals and TechniquesRating: 4 out of 5 stars4/5 (1)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsFrom EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovNo ratings yet