Professional Documents

Culture Documents

BPP Risk Register-For UNIBA

Uploaded by

Desy NataliaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BPP Risk Register-For UNIBA

Uploaded by

Desy NataliaCopyright:

Available Formats

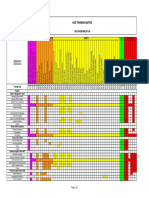

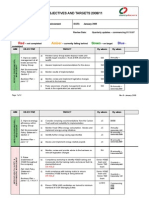

Risk Assessment Record

Existing Risk Remaining Risk Risk Medium Rank 17

Suggested Improvements

What the dept. needs to do! Electrical Tagging and Installation Verification Develop Energy Saving Program Existing Controls (incl History) none Stricker Promotion Energy Saving

Minor Unlikely Low 21 Minor Minor Cons Like Unlikely Possible Medium 18 Risk Low Rank 21

ID

Process/Area

Activity

S or E Risk

S

Aspect / Hazard Type

electrical

Impact / Unwanted event / Consequence Electrical shock Computer on at all times increases the electricity consumption Spending too many papers may affect the use of natural resource and also produce more wastes to environment Electricity used may increase CO emmission Machine's cartridge can be pollutant for environment Electrical shock Electricity used may increase CO emmission Electricity used may increase CO emmission Traffic Incidents Vehicle use may increase CO emission. Injury caused by struck by crane movement Injury caused by struck down material injury and property damage caused by struck down and caught in H/E Water contamination from result of washing H/E eye iritation caused by spark of oil / chemical Explosive caused by gas leakage

Cons Moderate

Like Unlikely

Any suggested improvements should be considered as part of your yearly HSE Goals & Objectives

Typing

E Air Emissions

Insignificant

Almost Certain

High

15

Waste Stream

Insignificant

Possible

Low

22

Develop Energy Saving Program

Stricker Promotion Energy Saving

Insignificant Insignificant Minor Unlikely Rare Unlikely

Office

E E Air Emissions Ground Contamination

Insignificant Minor

Possible Possible

Low Medium

22 18

Develop Energy Saving Program Sosialization on HSE talks Electrical Tagging and Installation Verification Develop Energy Saving Program Develop Energy Saving Program Provide Defensive Driving Training for personnel in charge Develop Energy Saving Program

Stricker Promotion Energy Saving Provide hazard and pollutan garbage bin none Stricker Promotion Energy Saving Stricker Promotion Energy Saving Daily checklist Stricker Promotion Energy Saving PPE

Low Low

24 25

electrical

Minor

Possible

Medium

18

Low Insignificant Insignificant Minor Possible Unlikely Unlikely Low Insignificant Minor Rare Unlikely Low Low

21

Air Emissions Air Emissions Movement Air Emissions

Insignificant Insignificant Moderate Insignificant

Possible Possible Possible Unlikely

Low Low High Low

22 22 13 24

Low Low

22 24 21 25

Pantry Travelling Outside

E S E

Receiving H/E (unloading from truck) Dismantle

Movement

Major

Possible

Extreme

21

Gravitation

Major

Possible

Extreme

Qualified personnel on lifting and rigging, certification of OHC & lifting device

Unlikely Unlikely

Cleaning oil cooler with steam clean

Movement

Major

Unlikely

High

12

Effluent and Wash Water

Insignificant

Unlikely

Low

24

Sosialization on HSE Talks Provide SOP and JSA, PPE mandatory Provide SOP/JSA repair air cooler leakage and increase knowledge personnel on used equipment Provide SOP/JSA repair air cooler leakage and increase knowledge personnel on used equipment

PPE & SOP PPE & SOP

Insignificant Minor

Unlikely Unlikely

Low

24

Cleaning oil cooler with reverse pump Repair Oil Cooler leakage with solder pb:sn 60:40 Repair Oil Cooler leakage with silver solder

Chemicals

Minor

Possible

Medium

18

Low

21

APAR standby

Minor

Unlikely Low 21

H/E Workshop

Pressure

Moderate

Possible

High

13

PPE, APAR standby

Insignificant

Possible Low 22 21 22 21 21 22

S S S S

Pressure Chemicals Chemicals Movement Air Emissions Movement

Explosive caused by gas leakage

Moderate

Possible

High

13

Minor Insignificant

Unlikely Possible Unlikely Unlikely Possible

Low Low Low Low Low

Painting Storage

E S

Respiratory dissorder caused by cat spray inhalation for long period Injury caused struck by H/E movement Injury caused struck by H/E movement Injury caused struck by engine movement Engine testing may increase CO emmission Warming up engine may increase CO emmission Hearing deficiencies caused by noise from warming up engine chemical spill

Minor

Almost Certain

Provide SOP and JSA, PPE mandatory

High 12

Minor Minor Insignificant

Major

Unlikely

Qualified personnel on lifting and rigging, certification of OHC & lifting device Qualified personnel on lifting and rigging, certification of OHC & lifting device Qualified personnel on lifting and rigging, certification of OHC & lifting device Develop Energy Saving Program Develop Energy Saving Program Provide SOP and JSA, PPE mandatory Sosialization on HSE Talks Stricker Promotion Energy Saving

Moderate

Unlikely Medium 17

Delivery H/E (loading to truck) Receiving Genset (unloading from the truck) Testing Engine Workshop Warming Up Genset (RM)

Movement

Major

Unlikely

High

12

Moderate

Unlikely Medium 17

Movement

Major

Unlikely

High

12

E E S

Air Emissions Air Emissions Noise

Insignificant Insignificant Moderate

Almost Certain Almost Certain Likely

High High High

15 15 9

Moderate Major Moderate Minor

Rare Rare Unlikely Unlikely

Medium Medium Medium

20 16 17

Rechange lubricant (Routine Maintenance) Delivery Genset(loading to the truck) Receive Material

Ground Contamination

Insignificant

Unlikely

Low

24

Low Minor Unlikely Low Insignificant Unlikely Low Moderate Unlikely Medium

21

Movement

Injury caused struck by engine movement Injury and property damage caused by struck down material Explosive caused by gas leakage

Moderate

Unlikely

Medium

17

21

S S

Gravitation Temprature

Moderate Catastrophic

Rare Unlikely

Medium Extreme

20 7

Provide SOP/JSA receiving material and increase knowledge personnel on used equipment

PPE, Flow order sheet

24 17

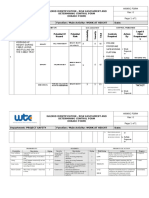

Risk Assessment Record

Existing Risk Remaining Risk Risk High Medium Medium High High Medium Medium Extreme High Medium Medium High High Medium Medium Medium High Medium Medium Rank 12 18 18 13 15 18 20 7 12 18 18 13 15 18 20 18 12 18 18

Suggested Improvements

What the dept. needs to do! Existing Controls (incl History)

Cons Moderate Like Unlikely Rare Risk Medium Low Rank 17 23

ID

Process/Area

Activity

S or E Risk

S

Aspect / Hazard Type

electrical Radiation Sharp Object Chemicals Air Emissions Movement Gravitation Temprature electrical Radiation Sharp Object Chemicals Air Emissions Movement Gravitation Sharp Object electrical Temprature Sharp Object

Repair Radiator Tank

Fire Cutting Torch

S S E

Impact / Unwanted event / Consequence Electrical shock caused by cutting torch machine Eye iritation caused by light cutting torch hand injury caused by caught in gram material Respiratory dissorders caused by gas inhalation for long period air pollution caused by combustion products injury caused by struck against tank Injury and property damage caused by struck down material Explosive caused by gas leakage Electrical shock caused by cutting torch machine Eye iritation caused by light cutting torch hand injury caused by caught in gram material Respiratory dissorders caused by gas inhalation for long period air pollution caused by combustion products injury caused by struck against tank Injury and property damage caused by struck down material Eye and skin exposure to splashes gram material Electrical shock caused by welding machines Burn injury caused contact with hot surface Eye and skin exposure to splashes gram material Air pollution caused by combustion products Explosive caused by gas leakage Electrical shock caused by machines Eye iritation caused by cutting torch Eye and skin exposure to splashes gram material Respiratory dissorders caused by gas inhalation for long period Air pollution caused by combustion products Hearing deficiencies caused by noise from grinding process fire case caused by spark form grinding process Hand injury caused by exposed grinders Hand Injury caused by struck by material injury caused by struck against material Skin iritation caused by NDT Chemical injury caused by struck againts material Injury & property damage caused by material falls from height Injury caused by struck down material Injury caused by struck down material Injury and property damage caused by struck down material

Cons Major Minor Minor Moderate Insignificant Minor Moderate Catastrophic Major Minor Minor Moderate Insignificant Minor Moderate Minor Major Minor Minor

Like Unlikely Possible Possible Possible Almost Certain Possible Rare Unlikely Unlikely Possible Possible Possible Almost Certain Possible Rare Possible Unlikely Possible Possible

Any suggested improvements should be considered as part of your yearly HSE Goals & Objectives

Provide SOP/JSA Fire Cutting Torch,and Display that SOP in Welding area, Inspected Cutting Torch Equipment Periodically, give Refresh Training to personnel on Fire Handling

Minor

PPE, Flow order sheet,APAR Standby

Moderate Moderate Minor Insignificant Moderate Moderate Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Rare Rare Possible Unlikely Rare Possible Rare Low Moderate Moderate Unlikely Unlikely Rare Unlikely Unlikely Rare Possible Rare Unlikely Unlikely Unlikely Rare Unlikely Low Minor Insignificant Insignificant Minor Unlikely Possible Possible Unlikely Low Low Low Low 21 21 22 22 21 23 Medium Medium Low Low Medium Medium Low Low Medium Medium Low Low Low Medium Low Low 17 17 21 24 17 17 21 21 17 17 25 23 22 17 23 22

Mobilization tank to H/E Workshop Receive Material

S S S S S

Sosialization on HSE Talks Provide SOP/JSA receiving material and increase knowledge personnel on

PPE, Flow order sheet PPE, Flow order sheet

Remove Broken Fire Cutting Torch Bolt

S S E

Provide SOP/JSA Fire Cutting Torch,and Display that SOP in Welding area, Inspected Cutting Torch Equipment Regularly, give Refresh Training to personnel on Fire Handling, increase knowledge personnel about potential hazard

Minor

PPE, Flow order sheet,APAR Standby

Minor Moderate Moderate Insignificant Minor

Mobilization tank to H/E Workshop Receive Material Drilling machine

S S S S S

Sosialization on HSE Talks Provide SOP/JSA receiving material and increase knowledge personnel on increase knowledge personnel about used equipment Display SOP in Welding area, Inspected welding Equipment Regularly, give Refresh Training to personnel on Fire Handling, increase knowledge personnel about potential hazard

PPE, Flow order sheet PPE, Flow order sheet

S.O.P, PPE, Flow Order Sheet, Maintenace Insignificant inspection

Moderate Minor

Welding

S.O.P, PPE, Flow order sheet,APAR Standby Insignificant

Minor

Air Emissions

Insignificant

Almost Certain

High

15

S S S S S E

Pressure electrical Radiation Sharp Object Chemicals Air Emissions Noise Temprature Sharp Object Movement Movement Chemicals Movement Gravitation Gravitation Movement Gravitation

Catastrophic Major Minor Minor Moderate Insignificant Moderate Major Major Minor Minor Moderate Minor Minor Minor Minor Minor

Unlikely Unlikely Possible Possible Possible Almost Certain Possible Possible Possible Possible Possible Likely Possible Possible Possible Possible Possible

Extreme High Medium Medium High High High Extreme Extreme Medium Medium High Medium Medium Medium Medium Medium

7 12 18 18 13 15 13 8 8 18 18 9 18 18 18 18 18

Medium Medium Low Low Medium Medium Low Low Low Low Low Medium

17 17 23 21 17 20 22 25 24 21 21 20

Fabrication of Frame

Fire Cutting Torch/plasma cutting

Provide SOP/JSA Fire Cutting Torch,and Display that SOP in Welding area, Inspected Cutting Torch Equipment Regularly, give Refresh Training to personnel on Fire Handling, increase knowledge personnel about potential hazard

Minor

PPE, Flow order sheet,APAR Standby

Minor Moderate Moderate Insignificant Insignificant Insignificant

Grinding

S S S

Provide SOP,

Install as per drawing Load test NDT Mobilization to Engine Workshop Receive Tank Radiator Install Sleeve To Tank with air shop Mobilization to H/E Workshop Receive Pump

S S S S S S S S

Resleeve Radiator tank

Provide SOP, Sozialitation about potensial hazard on HSE Talks Provide Safety Induction for third parthy Provide Safety Induction for third parthy, check SOP NDT third party Sosialization Potential Hazard on HSE Talks increase knowledge personnel on used equipment Display SOP in work area, increase knowledge personnel about potensial Sosialization on HSE Talks increase knowledge personnel on used equipment

PPE, Flow Order Sheet SOP, PPE,FOS PPE,FOS PPE, Flow order sheet PPE, Flow order sheet SOP, PPE,FOS PPE, Flow order sheet PPE, Flow order sheet

Minor Minor Moderate Minor

Risk Assessment Record

Existing Risk Remaining Risk Risk Medium Extreme Medium High High Medium Medium High Medium Medium Medium High Medium Medium Low High Low High Medium High High High Medium High High Low High Extreme High Medium High Medium Medium High Rank 18 7 17 13 12 18 18 15 17 18 17 13 17 17 22 13 24 13 18 13 13 13 18 13 13 21 13 4 13 18 13 18 19 13

Suggested Improvements

What the dept. needs to do! Provide SOP, increase personnel knowledge about pump and potensial increase knowledge personnel about used equipment, potensial hazard Display SOP in work area, increase knowledge personnel about potensial Display SOP in Welding area, Inspected welding Equipment Regularly, give Refresh Training to personnel on Fire Handling, increase knowledge personnel about potential hazard increase knowledge personnel about used equipment Provide SOP, increase personnel knowledge about pump and potensial Display SOP in work area, increase knowledge personnel about potensial hazard on HSE Talks Sosialization Potential Hazard on HSE Talks Sosialization Potential Sosialization Potential Sosialization Potential Sosialization Potential Talks Sosialization Potential Talks Hazard on HSE Hazard on HSE Hazard on HSE Hazard on HSE Hazard on HSE Existing Controls (incl History) PPE, Flow Order Sheet

Minor Moderate Cons Like Unlikely Unlikely Possible Rare Rare Unlikely Unlikely Rare Unlikely Possible Possible Low Moderate Unlikely Rare Rare Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Unlikely Possible Unlikely Unlikely Possible Unlikely Medium Minor Possible 17 Medium Low Low Low Medium Medium 22 17 25 25 21 17 17 Risk Low Medium Low Medium Medium Low Low Medium Low Low Rank 21 17 22 20 20 21 21 20 21 22

ID

Process/Area

Activity Dismantling Pump Fabricate Wearing, pump shaft use Pump Lathe Machine Presss Fit wearing use gun heater

S or E Risk

S S S S S

Aspect / Hazard Type

Gravitation Mechanics electrical Gravitation electrical Temprature Sharp Object Air Emissions electrical Gravitation Pressure Movement Mechanics electrical Ground Contamination electrical Ground Contamination electrical Movement electrical Biological Chemicals Sharp Object Biological Chemicals Spill and Pollution electrical Gravitation Sharp Object Movement Movement Sharp Object Ground Contamination Movement

Repair Pump Build up use welding machine

S S E

milling use lathe machine assembly pump hydro test Maintenance OHC Maintenance Housekeeping Refueling to genset Building maintenance Maintain WTP

S S S S S S E S E S S S S

Impact / Unwanted event / Consequence Injury and property damage caused by struck down material Dissability caused by caught between machine Electrical shock caused by machines Injury and property damage caused by struck down material Electrical shock caused by welding machines Burn injury caused contact with hot surface Eye and skin exposure to splashes gram material Air pollution caused by combustion products Electrical shock caused by machine failure Injury caused by struck down material Injury caused by fraction material injury caused by struck by OHC injury caused by caught in OHC Electrical shock Waste oil spill Electric shock Oil spill Electrical shock injury caused struck by tools Electrical shock Illness caused by bacterial contamination Illness caused by chemical contamination Hand injury caused by sharp garbage Illness caused by bacterial contamination Illness caused by chemical contamination Oil spill caused by waste handling Electrical shock Fatality caused by falls from height injury caused by caught in cutting machine injury caused struck by tools Back pain and musle strain/sprain caused by non-ergonomic position Injury caused by caught in sharp object Garbage from packing material Back pain and musle strain/sprain caused by non-ergonomic position Fire case caused by chemical material exposed by hot temprature Injury & property damage caused by traffic incidents

Cons Minor Catastrophic Moderate Moderate Major Minor Minor Insignificant Moderate Minor Moderate Moderate Moderate Moderate Insignificant Moderate Insignificant Moderate Minor Moderate Moderate Moderate Minor Moderate Moderate Minor Moderate Catastrophic Moderate Minor Moderate Minor Insignificant Moderate

Like Possible Unlikely Unlikely Possible Unlikely Possible Possible Almost Certain Unlikely Possible Unlikely Possible Unlikely Unlikely Possible Possible Unlikely Possible Possible Possible Possible Possible Possible Possible Possible Unlikely Possible Possible Possible Possible Possible Possible Likely Possible

Any suggested improvements should be considered as part of your yearly HSE Goals & Objectives

S.O.P, PPE, Flow Order Sheet, Maintenace Insignificant inspection SOP, PPE,FOS

Moderate Moderate Minor

S.O.P, PPE, Flow order sheet,APAR Standby

Minor Moderate

S.O.P, PPE, Flow Order Sheet, Maintenace Minor inspection PPE, Flow Order Sheet SOP, PPE,FOS SOP, PPE, Maintenace Periodic SOP, PPE, Maintenace Periodic SOP, PPE, Housekeeping checklist SOP, PPE SOP, PPE, Maintenace Periodic SOP, PPE, Maintenace Periodic

Insignificant Insignificant

Insignificant Insignificant Minor Moderate Moderate Moderate Moderate

Medium Medium Medium Low Medium Medium Low Medium Medium Medium Low Medium Low Low Medium

17 17 17 21 17 17 21 17 17 17 21 18 21 21 18

Waste Handling Facility

S S S

Sosialization Potential Hazard on HSE Talks

SOP, PPE

Moderate Minor Moderate

Cleaning WWTP

S E S

Sosialization Potential Hazard on HSE Talks

SOP, PPE

Moderate Minor

ME building Landscape Property maintenance Receiving Material Dismantling Material Logistic Storage Material

S S S S S E S

Sosialization Potential Hazard on HSE Talks Sosialization Potential Hazard on HSE Talks Sosialization Potential Hazard on HSE Talks Sosialization Potential Hazard on HSE Talks Sosialization Potential Hazard on HSE Talks Reuse,Recyle,Reduce Sosialization Potential Hazard on HSE Talks humidity and temprature on logistic must be setting in a standard condition Provide Defensive Driving Training for personnel in charge

Moderate

SOP, PPE SOP, PPE SOP, PPE SOP SOP Garbage Classification SOP Air condition & classification of material motor vehicle inspection and maintenance

Moderate Moderate Minor Minor Minor Minor Minor Moderate

Temprature

Major

Possible

Extreme

Delivery Material

Movement

Moderate

Possible

High

13

Medium

18

You might also like

- Brief Description of Incident:: Job Safety ObservationDocument1 pageBrief Description of Incident:: Job Safety ObservationFrancis Enriquez TanNo ratings yet

- 2949 HSE Risk Register - 2013-06-16 RevD1-VB FreeDocument3 pages2949 HSE Risk Register - 2013-06-16 RevD1-VB Freesalic201388% (8)

- Safety Induction Attendance Form SampleDocument1 pageSafety Induction Attendance Form SampleChyeAmshariYumanNo ratings yet

- BSM - Company ProfileDocument15 pagesBSM - Company ProfileLarasanto Cipta AgungNo ratings yet

- Hse Training MatrixDocument2 pagesHse Training MatrixYose Rizal100% (1)

- List of Record - HseDocument2 pagesList of Record - HseMohd FadlyNo ratings yet

- Brief HSE Procedures ContentsDocument2 pagesBrief HSE Procedures Contentsarifayee-1No ratings yet

- Riskman Template-FinalDocument3 pagesRiskman Template-Finalapi-238786020No ratings yet

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- Rev. Issued For General Use Reference No. HSE-PRO-04-F06 0.0 Serial No. 1 of 1Document1 pageRev. Issued For General Use Reference No. HSE-PRO-04-F06 0.0 Serial No. 1 of 1subhanmusadiqNo ratings yet

- Sample Hse Targets 2011Document1 pageSample Hse Targets 2011Ridho Sugiharto100% (1)

- Updated Workplace Coronavirus Prevention PlanDocument6 pagesUpdated Workplace Coronavirus Prevention Planvictor100% (4)

- Hazard RegisterDocument1 pageHazard RegisterSamuel Maclean ArthurNo ratings yet

- CV Rio Paksi SadewoDocument2 pagesCV Rio Paksi SadewominhaNo ratings yet

- HSEDocument10 pagesHSEMohamad ZackuanNo ratings yet

- Hse Training Matrix AKP AMLBDocument10 pagesHse Training Matrix AKP AMLBadrian lazuardiNo ratings yet

- ANNEX 15 - HSE Requirements Menara Batch 2Document26 pagesANNEX 15 - HSE Requirements Menara Batch 2AmaliahAisyahRakhmiNo ratings yet

- Corrective Actions Tracking RegisterDocument1 pageCorrective Actions Tracking RegisterYasir MushtaqNo ratings yet

- 3S HSE Training MatrixDocument2 pages3S HSE Training Matrixmashangh100% (3)

- Code of Practice: Ref Cop Gra Issue 1, Dec 2003 Always Refer To Intranet For Latest Version 1Document15 pagesCode of Practice: Ref Cop Gra Issue 1, Dec 2003 Always Refer To Intranet For Latest Version 1etaNo ratings yet

- GNPOC List ofDocument3 pagesGNPOC List ofHSE S4No ratings yet

- Env Audit - TimetableDocument1 pageEnv Audit - Timetablerobby damanikNo ratings yet

- HIRARC Work at HeightDocument2 pagesHIRARC Work at HeightPanchdev KumarNo ratings yet

- Dashboard Data: Safety Inspections Safety Walkthroughs Hazard HuntsDocument4 pagesDashboard Data: Safety Inspections Safety Walkthroughs Hazard HuntsWilson Lozano SilvaNo ratings yet

- HSE Training MatrixDocument10 pagesHSE Training Matrixsubhanmusadiq100% (4)

- S018 HSE Training Program Rev1 Oct 2017Document4 pagesS018 HSE Training Program Rev1 Oct 2017LydaRozoRNo ratings yet

- Accident&Incident Reporting FlowchartDocument1 pageAccident&Incident Reporting FlowchartAtika MaulannaNo ratings yet

- New Safety Plan 2010Document192 pagesNew Safety Plan 2010prosperity_174No ratings yet

- 05 04 AMM Daily HSE Statistics Report AprDocument1 page05 04 AMM Daily HSE Statistics Report AprPT. ANUGRAH MIRAN MANDIRINo ratings yet

- HSE Statistics Presentation ExampleDocument23 pagesHSE Statistics Presentation Examplesamirhsqe100% (1)

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- 2 HirarcDocument10 pages2 HirarcHaji Mohd DimyatiNo ratings yet

- Induction ChecklistDocument2 pagesInduction ChecklisthasanNo ratings yet

- Traffic MG T Plan TempDocument4 pagesTraffic MG T Plan TempLeoven Jef Suzara LorinNo ratings yet

- Health and Safety - Risk AssessmentDocument3 pagesHealth and Safety - Risk AssessmentjaimieNo ratings yet

- Monthly Fire Audit ReportDocument2 pagesMonthly Fire Audit ReportmahendkakdeNo ratings yet

- Departmetit: Malrtehance Cost t5% Expenditurc BudsetDocument1 pageDepartmetit: Malrtehance Cost t5% Expenditurc Budsetrobby damanikNo ratings yet

- Toolbox Talk Risk Identification CardDocument21 pagesToolbox Talk Risk Identification CardDheeraj Menon0% (1)

- Risk Register 001Document4 pagesRisk Register 001SreekumarNo ratings yet

- Lock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorDocument1 pageLock Out Tag Out-Permit To Work Process Flow Chart: EPC Sub-ContractorShailendraNo ratings yet

- JHA 004 - Machine Excavaton, Backfill and Compaction Work - REV000 (For Sir)Document7 pagesJHA 004 - Machine Excavaton, Backfill and Compaction Work - REV000 (For Sir)Venkadesh Periathambi100% (1)

- Form Subcontractor Daily HSE Statistics ReportDocument2 pagesForm Subcontractor Daily HSE Statistics ReportadityaNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Risks Assessment - Al Khor ProjectDocument4 pagesRisks Assessment - Al Khor Projectloveson709No ratings yet

- Risk Assessment For 9th of May Drone ShootDocument2 pagesRisk Assessment For 9th of May Drone Shootapi-285527005No ratings yet

- HSI-Safety Plan-2019Document8 pagesHSI-Safety Plan-2019Arvin Omboy100% (1)

- Health and Safety Objectives 2009Document4 pagesHealth and Safety Objectives 2009mujahid1137100% (1)

- 2013 Mom Hse 036 PDFDocument22 pages2013 Mom Hse 036 PDFebsmsartNo ratings yet

- IRP 22 Risk Register 2015Document30 pagesIRP 22 Risk Register 2015Jeya Kumar100% (1)

- Drilling & Blasting: Format No.: F 01 15 01, Rev. 05, Rev. Date:-10. 02. 2009 4Document4 pagesDrilling & Blasting: Format No.: F 01 15 01, Rev. 05, Rev. Date:-10. 02. 2009 4Bhagat DeepakNo ratings yet

- QHSE Roadmap 2023Document1 pageQHSE Roadmap 2023Syed Ahmed manzoorNo ratings yet

- Occupational Health, Safety & Environment Management System: Hse Biweekly ReportDocument3 pagesOccupational Health, Safety & Environment Management System: Hse Biweekly ReportAhmed Hassan SabryNo ratings yet

- 2013 Mom Hse 035 PDFDocument15 pages2013 Mom Hse 035 PDFebsmsart100% (1)

- Safety Joint Inspection Report 9-ReplyDocument12 pagesSafety Joint Inspection Report 9-Replyloveson709100% (1)

- HSE Risk Assessment (UTM)Document1 pageHSE Risk Assessment (UTM)kamalNo ratings yet

- STFC Objectives and Targets SHE PlanDocument2 pagesSTFC Objectives and Targets SHE PlanThato KebuangNo ratings yet

- HSEMSDocument37 pagesHSEMSHafiz SabriNo ratings yet

- Matrix TrainingDocument5 pagesMatrix TrainingRengga PramadyaksaNo ratings yet

- Risk RegisterDocument24 pagesRisk Registervikrant911100% (2)

- Def - Pemf Chronic Low Back PainDocument17 pagesDef - Pemf Chronic Low Back PainFisaudeNo ratings yet

- Solutions - HW 3, 4Document5 pagesSolutions - HW 3, 4batuhany90No ratings yet

- 184 Учебная программа Английский язык 10-11 кл ОГНDocument44 pages184 Учебная программа Английский язык 10-11 кл ОГНзульфираNo ratings yet

- 1941 Iraq and The IlluminatiDocument4 pages1941 Iraq and The IlluminatiZaneWeltonNo ratings yet

- COE301 Lab 2 Introduction MIPS AssemblyDocument7 pagesCOE301 Lab 2 Introduction MIPS AssemblyItz Sami UddinNo ratings yet

- Classroom Activty Rubrics Classroom Activty Rubrics: Total TotalDocument1 pageClassroom Activty Rubrics Classroom Activty Rubrics: Total TotalMay Almerez- WongNo ratings yet

- Btech CertificatesDocument6 pagesBtech CertificatesSuresh VadlamudiNo ratings yet

- An Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud ComputingDocument18 pagesAn Enhanced RFID-Based Authentication Protocol Using PUF For Vehicular Cloud Computing0dayNo ratings yet

- Subtotal Gastrectomy For Gastric CancerDocument15 pagesSubtotal Gastrectomy For Gastric CancerRUBEN DARIO AGRESOTTNo ratings yet

- PCZ 1503020 CeDocument73 pagesPCZ 1503020 Cedanielradu27No ratings yet

- Mat101 w12 Hw6 SolutionsDocument8 pagesMat101 w12 Hw6 SolutionsKonark PatelNo ratings yet

- Jmac TempDocument5 pagesJmac TempDan GerNo ratings yet

- Baumer Tdp02 Tdpz02 Ds enDocument4 pagesBaumer Tdp02 Tdpz02 Ds enQamar ZiaNo ratings yet

- 11 - Chapter 3Document27 pages11 - Chapter 3sam000678No ratings yet

- You'Re My Everything - Glenn FredlyDocument2 pagesYou'Re My Everything - Glenn FredlyTommy Juliansyah MarsenoNo ratings yet

- Fisker Karma - Battery 12V Jump StartDocument2 pagesFisker Karma - Battery 12V Jump StartRedacTHORNo ratings yet

- Statistics and Probability Course Syllabus (2023) - SignedDocument3 pagesStatistics and Probability Course Syllabus (2023) - SignedDarence Fujihoshi De AngelNo ratings yet

- Job Stress InterventionsDocument5 pagesJob Stress InterventionscocaralucamihaelaNo ratings yet

- Assignment On Porters Generic StrategiesDocument12 pagesAssignment On Porters Generic StrategiesGeetinder Singh78% (9)

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDocument8 pagesProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay Dumol80% (5)

- Paper 11-ICOSubmittedDocument10 pagesPaper 11-ICOSubmittedNhat Tan MaiNo ratings yet

- ENGL102 Othello Act 3 Discussion QuestionsDocument2 pagesENGL102 Othello Act 3 Discussion QuestionsDaniel DenningNo ratings yet

- ARMY - Chapter Eight Explosive BreachingDocument25 pagesARMY - Chapter Eight Explosive Breachingrsreeth100% (1)

- Interventional Studies 2Document28 pagesInterventional Studies 2Abdul RazzakNo ratings yet

- Practical Research 2 Group 11 RRL, Proposed Title and Answers To The QuestionsDocument14 pagesPractical Research 2 Group 11 RRL, Proposed Title and Answers To The QuestionsFeby Margaret AngNo ratings yet

- Exchange 2010 UnderstandDocument493 pagesExchange 2010 UnderstandSeKoFieNo ratings yet

- Reaffirmed 1998Document13 pagesReaffirmed 1998builconsNo ratings yet

- On The Margins - A Study of The Experiences of Transgender College StudentsDocument14 pagesOn The Margins - A Study of The Experiences of Transgender College StudentsRory J. BlankNo ratings yet

- Tugas Bahasa Inggris: ButterflyDocument4 pagesTugas Bahasa Inggris: ButterflyRiyadi TeguhNo ratings yet

- Laminar Premixed Flames 6Document78 pagesLaminar Premixed Flames 6rcarpiooNo ratings yet