Professional Documents

Culture Documents

LCQ and Deca Series Ion Gauge Troubleshooting

Uploaded by

GopiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LCQ and Deca Series Ion Gauge Troubleshooting

Uploaded by

GopiCopyright:

Available Formats

Ion Gauge Troubleshooting for LCQ and Deca Series

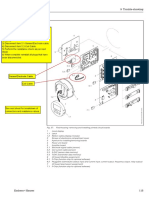

Introduction: This document is designed to be used by the instrument user to determine whether the Ion Gauge has failed and user correctable or instead will a service call be needed. Electronic Technician steps are included in case such personnel are available locally. Observations: A. The Ion Gauge pressure reads 0. B. The Ion Gauge is not lit. (Will not turn on or stay on.) C. The Convectron Gauge reads a normal; pressure D. The Turbo is at full speed. User level troubleshooting: 1. Outgas. If this is a new Ion Gauge or one that has been vented for a long time then outgas it. A new or gassy Ion Gauge may need to be outgassed. Try turning on the Ion Gauge several times. If it stays on a little longer with each iteration then gassiness is indicated. Keep trying. Each time the Ion Gauge is turned on you will see the pressure begin to rise until it hits the cutoff at 10e-5. This is the Ion Gauge heating up from the filament heat and driving gas off of the glass walls. Eventually the pressure will rise but level off below 10e-5 and start back down without knocking out the gauge. Don't give up until you have tried 15 times. 2. Replace. Replace the Ion Gauge out of hand if you have one. See our KnowledgeBase record Mahn-56F72 for the details. Electronic Technician level troubleshooting: 3. Turn off the LCQ Electronics at the Service Mode switch. 4. Remove the top cover to expose the Ion Gauge and cable. 5. Ring out the ion gauge. a. Remove the blue connector from the top of the ion gauge b. Probe pairs of conductors on the ion gauge itself so that you have measured and noted the resistance between each pair. See figure 1.

4 3 2 9

2 + 4: Filament 3: Grid 9: Collector

Figure 1. Ion Gauge pins and functions. The pair 2 to 4 should read a short (<10ohms). If that pair reads open then the filament has broken, the ion gauge will need to be replaced, and that might be all that is wrong. All other pairs should read open (>1Mohm). Any shorts to the filament indicate the filament is warped, the ion gauge will need to be replaced, and that might be all that is wrong. For those two conditions replace the ion gauge. c. Restore the blue connector to the ion gauge. 6. Remove the right side cover to uncover the System Control pcb. Confirm the electronics are turned off at the Service Mode switch. 7. Check the F1 and F2 fuses on the system PCB. a. Remove the fuses from the System Control pcb. b. Measure and note their resistance.

Thermo Fisher Technical Support KnowledgeBase record Walton-3F13B Printed to PDF 10/30/2009 Page 1 of 2

8. Ring out the Ion Gauge cable connected to the Ion Gauge. Ref: figure 2 a. Disconnect the cable from P9 on the system control pcb. b. Probe pairs of pins in the removed cable end (not P9) to confirm the filament is integral and all the other pins that go to the ion gauge are open circuit. See figure 2 and Table 1

Figure 2. Plug P9 on the system Control pcb IG Element: Collector Filament Filament Grid Table 1. Signal paths IG Pin: 9 2 4 3 Signal Name: COLL FIL1 FIL2 +180 P9 Pin 1 3 4 5

Your work can be restricted to the signals in table 1 even though the cable also carries other signals. If your observations in step 5b above were the expected ones but the same signals measured here are different then this indicates a short or open in the cable. 9. Manipulation of the interlock bypass jumpers. Discussion: Jumpers on the system board can be used to get the system running despite an ion gauge failure. E3 Convectron Gauge Interlock. Located in the High Voltage area on the left side of the system PCB. Normally jumpered "ON". With this setting, the vacuum interlock logic is activated if the convectron pressure is low enough. Also the ion gauge is inhibited from operating. For test purposes, you can set E3 to the "OFF" position to disable this interlock. E5 External Interlock. Located above the LEDs on the bottom right area of the system PCB. Normally jumpered "ON". With this setting, the vacuum interlock logic is activated if the probe head (ESI or APCI) is pulled back from the spray shield. For test purposes, you can set E5 to the "OFF" position to disable this interlock. E6 Vacuum Interlock. Located above the LEDs on the bottom right area of the system PCB. Normally jumpered "ON". With this setting, the vacuum interlock logic is activated if any of the interlocks are tripped. For test purposes, you can set E6 to the "OFF" position to disable this interlock. E7 Ion Gauge Interlock. Located above the LEDs on the bottom right area of the system PCB. Normally jumpered "ON". With this setting, the vacuum interlock logic is activated if the ion gauge pressure is not low enough. For test purposes, you can set E7 to the "OFF" position to disable this interlock. 10. Move all 3 bypass jumpers on the system PCB. Then move them back one at a time. See which one disables the ion gauge. Endofdoc

Thermo Fisher Technical Support KnowledgeBase record Walton-3F13B Printed to PDF 10/30/2009 Page 2 of 2

You might also like

- Secrets in NumbersDocument26 pagesSecrets in Numbersmdkafzal100% (5)

- Oxygen Sensor Simulator - JumperDocument7 pagesOxygen Sensor Simulator - JumperBrianssrt4100% (2)

- The Ultimate 30 Day Guide To Going Full Carnivore PDFDocument76 pagesThe Ultimate 30 Day Guide To Going Full Carnivore PDFJanZen100% (1)

- Bonus Report: Brought To You by Jestine YongDocument22 pagesBonus Report: Brought To You by Jestine YongmaxxNo ratings yet

- 13976233-NDP711SRM-Nissan Datsun Pl-720 1983-1986 Service Repair Manual PDFDocument641 pages13976233-NDP711SRM-Nissan Datsun Pl-720 1983-1986 Service Repair Manual PDFHector Gp100% (3)

- Charging System - Test: Previous ScreenDocument15 pagesCharging System - Test: Previous ScreenWalterNo ratings yet

- Sims 4 CheatsDocument29 pagesSims 4 CheatsAnca PoștariucNo ratings yet

- 320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 Engine (SEBP5228 - 25) - Basic Search PDFDocument11 pages320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 Engine (SEBP5228 - 25) - Basic Search PDFedykuswari50% (4)

- Introduction To Pharmacy ManagementDocument28 pagesIntroduction To Pharmacy ManagementSirry HidayaniNo ratings yet

- Akai LCT37Z6TA CMO (11-27-06) LCDDocument135 pagesAkai LCT37Z6TA CMO (11-27-06) LCDRicardo PicassoNo ratings yet

- Cat 740B-2011Document17 pagesCat 740B-2011Tom Souza100% (2)

- Ablutophobia Fear of Bathing and HomoeopathyDocument8 pagesAblutophobia Fear of Bathing and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (1)

- Exp 1 Multimeter, Breadboard and Power Supply (2012)Document14 pagesExp 1 Multimeter, Breadboard and Power Supply (2012)usmpowerlab50% (2)

- Refining Topsoe Reactor InternalsDocument8 pagesRefining Topsoe Reactor InternalsGopiNo ratings yet

- 08 Coramex Corix 70 Plus Service Manual PDFDocument17 pages08 Coramex Corix 70 Plus Service Manual PDFkizen_5No ratings yet

- MID 039 - CID 1847 - FMI 09: Pantalla AnteriorDocument6 pagesMID 039 - CID 1847 - FMI 09: Pantalla AnteriorWalterNo ratings yet

- Frigidaire Washer FAFW3801LW3 Tech Data Sheet (Wiring Diagrams)Document6 pagesFrigidaire Washer FAFW3801LW3 Tech Data Sheet (Wiring Diagrams)kstindcNo ratings yet

- Uhde Nitric Acid Process BrochureDocument0 pagesUhde Nitric Acid Process BrochureGopiNo ratings yet

- Uhde Nitric Acid Process BrochureDocument0 pagesUhde Nitric Acid Process BrochureGopiNo ratings yet

- COVID 19 ReportDocument21 pagesCOVID 19 ReportDatu Nor Balindong82% (11)

- 140M D4N BD LiftDocument6 pages140M D4N BD LiftsuelifashNo ratings yet

- EB 57 EWLC TroubleshootingDocument7 pagesEB 57 EWLC TroubleshootingFrenkyFaking FourFingersNo ratings yet

- Gallien-Krueger ML Series AmplifierDocument23 pagesGallien-Krueger ML Series Amplifierkilol0100% (1)

- T H e R M oDocument2 pagesT H e R M oLinaNo ratings yet

- LESSON NOTES HeszronDocument7 pagesLESSON NOTES HeszronHezron gibronNo ratings yet

- Promag 50 53 Resistance CheckDocument4 pagesPromag 50 53 Resistance CheckMikeNo ratings yet

- ZR22 Detector TroubleshootingDocument3 pagesZR22 Detector TroubleshootingControl InstrumentationNo ratings yet

- Exp. 8 Capacitpr and Inductor TestingDocument9 pagesExp. 8 Capacitpr and Inductor Testingمحمد ابو خضيرNo ratings yet

- "Annie" Analyzer/Tester ManualDocument5 pages"Annie" Analyzer/Tester ManualDarrin Bacon100% (1)

- Troubleshooting: D3G, D4G and D5G Track-Type Tractors ElectrohydraulicDocument5 pagesTroubleshooting: D3G, D4G and D5G Track-Type Tractors ElectrohydraulicX'mix ĐreamerNo ratings yet

- MAG500-6000 Installation & Fault FindingDocument21 pagesMAG500-6000 Installation & Fault FindinglquickfallNo ratings yet

- Como Probar Sistema Electrico AlternadorDocument18 pagesComo Probar Sistema Electrico AlternadorEckard GuendelNo ratings yet

- How To Troubleshoot Air Flow Failure' of Agilent 700 Series ICP-OESDocument8 pagesHow To Troubleshoot Air Flow Failure' of Agilent 700 Series ICP-OESarshavskaya.95No ratings yet

- Duo Therm TroubleshooterDocument9 pagesDuo Therm TroubleshooterDale LewisNo ratings yet

- EPRC10-EC 12/24 Volt Solar Charge ControllerDocument5 pagesEPRC10-EC 12/24 Volt Solar Charge ControllerONETRUEGEMLLCNo ratings yet

- 08 Coramex Corix 70 Plus Service Manual PDFDocument17 pages08 Coramex Corix 70 Plus Service Manual PDFkizen_5100% (1)

- MID 039 - CID 1846 - FMI 09: Pantalla AnteriorDocument6 pagesMID 039 - CID 1846 - FMI 09: Pantalla AnteriorWalterNo ratings yet

- Opto Isolators Lesson 07-17-2012Document35 pagesOpto Isolators Lesson 07-17-2012whynot05No ratings yet

- 5.7 Troublesh Ootin G GU IDEDocument3 pages5.7 Troublesh Ootin G GU IDEav_emyNo ratings yet

- Emergency Stop Switch Circuit - Test (RENR5096)Document3 pagesEmergency Stop Switch Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- Pan DLP 61lcx65Document81 pagesPan DLP 61lcx65Terry SeymourNo ratings yet

- Pt61lcx65 SM Panasonic enDocument81 pagesPt61lcx65 SM Panasonic enJim SteeleNo ratings yet

- Controlling High Voltage Devices with RelaysDocument7 pagesControlling High Voltage Devices with RelaysSharfuddin ZishanNo ratings yet

- Geiger M Uller Counter (GM Counter)Document26 pagesGeiger M Uller Counter (GM Counter)AviteshNo ratings yet

- Toyota PradoDocument5 pagesToyota Pradorahul_nissanNo ratings yet

- Ut33a Palm Size Multimeter ManualDocument13 pagesUt33a Palm Size Multimeter ManualTheo SopranoNo ratings yet

- 3.1 Product Brochure With Technical Specifications ES Ever Shield RevisedDocument12 pages3.1 Product Brochure With Technical Specifications ES Ever Shield RevisedVivek RajanNo ratings yet

- Illustration 1 g01375618 Connections of The Forward/reverse Position SensorDocument3 pagesIllustration 1 g01375618 Connections of The Forward/reverse Position SensorNofy SNo ratings yet

- Aea 1305 WC El MS 0030Document10 pagesAea 1305 WC El MS 0030Adil HasanovNo ratings yet

- Operating Instructions For Models With PSU-III-LED: 1. Product FeaturesDocument5 pagesOperating Instructions For Models With PSU-III-LED: 1. Product FeaturesNicole CollazosNo ratings yet

- Codigos Aire Acondicionado PDFDocument4 pagesCodigos Aire Acondicionado PDFJhonatan rincon martinezNo ratings yet

- PL Electrically Heated Systems 8N - 1Document4 pagesPL Electrically Heated Systems 8N - 1Pelis CloneNo ratings yet

- ICA Lab Manual PDFDocument193 pagesICA Lab Manual PDFVijay MNo ratings yet

- Revision Harness y ConectoresDocument9 pagesRevision Harness y ConectoresVladimir Illich Pinzon BallenNo ratings yet

- Panasonic PT 52lcx66Document83 pagesPanasonic PT 52lcx66ferdialvascribdNo ratings yet

- Hfe Classe Audio Cap-80 101 ServiceDocument19 pagesHfe Classe Audio Cap-80 101 Servicehesso1No ratings yet

- Caza Falla Low VoltageDocument10 pagesCaza Falla Low Voltagevictor laraNo ratings yet

- Promag 50 53 Resistance Check PDFDocument4 pagesPromag 50 53 Resistance Check PDFAllisson MacedoNo ratings yet

- Power System - Ii Lab Manual (EE-328) Vi Semester Electrical EngineeringDocument22 pagesPower System - Ii Lab Manual (EE-328) Vi Semester Electrical EngineeringRahul DuttaNo ratings yet

- Electrolux 2Document12 pagesElectrolux 2Juan Garcia HernandezNo ratings yet

- CAT Relay TestDocument4 pagesCAT Relay TestmkNo ratings yet

- Lesson - Check and Test Starting SystemDocument138 pagesLesson - Check and Test Starting SystemMarcel Baring ImperialNo ratings yet

- 1.2 Section Ii-GeneralDocument24 pages1.2 Section Ii-Generaljames kuriaNo ratings yet

- EFI Troubleshooting ManualDocument30 pagesEFI Troubleshooting ManualJuan Carlos Abreu Palomera100% (1)

- Codigos Lavadora FrigidaireDocument16 pagesCodigos Lavadora FrigidaireLeonardoNo ratings yet

- Mitsubishi 89 Wiring-DiagDocument91 pagesMitsubishi 89 Wiring-DiagDinesh JayasekaraNo ratings yet

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsDocument7 pagesTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoNo ratings yet

- Panasonic PT-50LC14Document105 pagesPanasonic PT-50LC14Imthiyas AhmedNo ratings yet

- Ozone Epa MethodDocument47 pagesOzone Epa MethodAslam BashaNo ratings yet

- MSME Associations Data SheetDocument1 pageMSME Associations Data SheetGopiNo ratings yet

- CSIR-UGC NET Exam Guide for Chemical SciencesDocument3 pagesCSIR-UGC NET Exam Guide for Chemical SciencespikumarNo ratings yet

- RSC Preparation of Ammonium Sulfate Student PDFDocument1 pageRSC Preparation of Ammonium Sulfate Student PDFextraNo ratings yet

- Gasification Based Topsoe WSA Process PrinciplesDocument4 pagesGasification Based Topsoe WSA Process PrinciplesGopiNo ratings yet

- Identification Tests-General Inorganic IonsDocument5 pagesIdentification Tests-General Inorganic IonsGopiNo ratings yet

- Identification Tests-General Inorganic IonsDocument5 pagesIdentification Tests-General Inorganic IonsGopiNo ratings yet

- Synthesis, Properties of H2SO4Document2 pagesSynthesis, Properties of H2SO4GopiNo ratings yet

- SO2 Standards in Asia Factsheet 26 Aug 2010Document5 pagesSO2 Standards in Asia Factsheet 26 Aug 2010GopiNo ratings yet

- 091001F5WH Lib R090001HeldrichCDocument46 pages091001F5WH Lib R090001HeldrichCGopiNo ratings yet

- Spartan 10 ManualDocument619 pagesSpartan 10 ManualGopiNo ratings yet

- MSDS of REN 60Document7 pagesMSDS of REN 60GopiNo ratings yet

- 11-SuperCritical Fluid ChromatographyDocument6 pages11-SuperCritical Fluid ChromatographyGopiNo ratings yet

- Autonomy Vs IntegrationDocument31 pagesAutonomy Vs IntegrationWahid KhanNo ratings yet

- Report Anomalies and Normalization SummaryDocument5 pagesReport Anomalies and Normalization SummaryThomas_GodricNo ratings yet

- 1st Part PALIAL CasesDocument255 pages1st Part PALIAL CasesAnonymous 4WA9UcnU2XNo ratings yet

- Corporate Insolvency NotesDocument15 pagesCorporate Insolvency NotesAnirudh SoodNo ratings yet

- Syllabus 30A Fall 2014Document4 pagesSyllabus 30A Fall 2014Gabby TanakaNo ratings yet

- LIC Jeevan Labh Plan (836) DetailsDocument12 pagesLIC Jeevan Labh Plan (836) DetailsMuthukrishnan SankaranNo ratings yet

- GEY 102-Introduction To Geology 1-Lecture Slides - Prof. M.E. NtonDocument44 pagesGEY 102-Introduction To Geology 1-Lecture Slides - Prof. M.E. Ntonabuabdmuqseet2001No ratings yet

- 01 Petrolo 224252Document7 pages01 Petrolo 224252ffontanesiNo ratings yet

- Solución: R T β T R (T) = 1000 Ω ΩDocument6 pagesSolución: R T β T R (T) = 1000 Ω ΩDuvan BayonaNo ratings yet

- My Reading Experience of 'Hello Bastar' Highlighting Development, Decentralization and DefenseDocument3 pagesMy Reading Experience of 'Hello Bastar' Highlighting Development, Decentralization and DefenseSri Tejaswini Mantena0% (1)

- PGW Spring SuitDocument14 pagesPGW Spring Suitapi-3700386No ratings yet

- SAP FICO Asset Accounting 1Document3 pagesSAP FICO Asset Accounting 1Ananthakumar ANo ratings yet

- Mythical Origins of The Hungarian Medieval LegislationDocument8 pagesMythical Origins of The Hungarian Medieval LegislationLucas LixaNo ratings yet

- GelSight - Measurement of Surface RoughnessDocument5 pagesGelSight - Measurement of Surface RoughnessXto PeregrinNo ratings yet

- Fiber006 SorDocument1 pageFiber006 SormbuitragoNo ratings yet

- MC Data Dig Graphic Organizer 1Document5 pagesMC Data Dig Graphic Organizer 1api-461486414No ratings yet

- Crafting Your Keto Diet MindsetDocument3 pagesCrafting Your Keto Diet MindsetoculosoakleyNo ratings yet

- Coursework of Signals and Systems: Moh. Kamalul Wafi December 6, 2018Document2 pagesCoursework of Signals and Systems: Moh. Kamalul Wafi December 6, 2018kartiniNo ratings yet

- Employee Retention Plan QuestionnaireDocument5 pagesEmployee Retention Plan QuestionnaireThayyib MuhammedNo ratings yet

- The Bare Foot Boy 3 Ab 2 ManadoDocument100 pagesThe Bare Foot Boy 3 Ab 2 ManadoKotakuNo ratings yet

- LP Direct & Indirect SpeechDocument7 pagesLP Direct & Indirect SpeechJoana JoaquinNo ratings yet

- Dialnet AnalysingCommonMistakesInTranslationsOfTouristText 4419765 PDFDocument16 pagesDialnet AnalysingCommonMistakesInTranslationsOfTouristText 4419765 PDFEquipo CuatroNo ratings yet

- Present Tense Review for Motorcycle RepairDocument2 pagesPresent Tense Review for Motorcycle RepairFaheemuddin Veterans50% (2)

- Analyze Financial Performance with Ratio AnalysisDocument4 pagesAnalyze Financial Performance with Ratio AnalysisKartikeyaDwivediNo ratings yet