Professional Documents

Culture Documents

Diesel Injection Pump

Uploaded by

Ubay DillahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diesel Injection Pump

Uploaded by

Ubay DillahCopyright:

Available Formats

Diagnosis Technician Course Guide

Diesel Engine>>Diesel Injection Pump

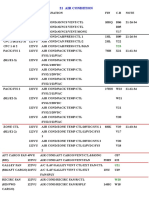

Group [Injection Pump] Description Unit Instruction Points PPT No. 1 Ref. (page) 1/1 Time (min.) 180

SUGGESTION - Check the installation location of the injection pump on an actual vehicle. - Use the VE pump type cut model or disassembly parts and check each parts.

Summary of Operation

- The highly pressurized fuel is generated by the plunger and pumped into the injection nozzle. - The governor controls the injection volume and the timer controls the injection timing. - The feed pump pumps the fuel into the injection pump from the fuel tank and the regulating valve controls the discharge pressure. - The plunger is driven by the drive shaft. It reciprocates by the roller and cam plate to pumps the fuel. - The fuel is distributed to each cylinder through the distribution passages.

1/1

Feed Pump and Regulating Valve Fuel Delivery and Injection

3 4

1/1 1/3

Fuel Cut-off Solenoid Anti-reverse Rotation Automatic Timer (Injection Timing Control) [VE Pump Mechanical Governor] Description Construction & Function

- The fuel cut-off solenoid cuts off the fuel passage leading to the suction port, causing the engine to stop. - If the pump rotates in reverse, the fuel is not pumped. - The fuel pressure inside the pump pushes the timer piston to control the fuel injection timing. - The governor controls the fuel injection volume in accordance with the accelerator pedal opening angle and the engine speed. - There are two types of the governor; one is all-speed governor, which controls at all speed range, the other is the minimum-maximum speed governor, which controls only at minimum and maximum engine speeds. - The engine speed is determined according to the accelerator pedal opening angle. - Unless the accelerator pedal is fully depressed, the speed cannot reach the maximum speed.

10 13 14 15 16

1/1 1/1 1/1 1/1 1/1

All-speed Governor

17

1/1

M-M (Minimum-Maximum) Speed Governor Adjusting Screws

- The injection volume is determined according to the accelerator opening angle. - The engine speed is determined according to the engine load. - Idle speed adjusting screw : It can adjust the idle speed. - Maximum speed adjusting screw : It can adjust the maximum engine speed. (sealed) - Full-load setting screw : It can adjust the maximum injection volume at full-load. (sealed)

23 24

1/1 1/1

SUGGESTION - Perform the following operation, using an training vehicle. - Adjust the idle speed adjusting screw to check the change in idle speed. - Adjust the maximum speed adjusting screw to check the change in the maximum engine speed. - Adjust the full-load setting screw to check the change in the condition of the exhaust gas. - Replace the union bolt installed at the return pipe with one which diameter of the hole is larger, and check the exhaust gas condition when the engine speed increases. (If there is no union bolt which diameter of the hole is larger, make it.)

[VE Pump Options]

ACSD (Automatically-controlled Cold Starting Device) HAC (High-Altitude Compensator)

- The ACSD uses the contraction and expansion of the thermo wax and the spring force to make the fuel injection timing advanced or activate the fast idle. - The HAC decreases the maximum fuel injection volume in accordance with the high altitude to prevent the over-rich of the air-fuel mixture by drop of air density.

27 30

1/2 1/1

Turbocharger Boost Compensator

- The turbocharger boost compensator increases the maximum fuel injection volume in accordance with the intake air pressure when the pressure increases by the turbocharger. - The BACS is a device that has functions of both the high-altitude compensator and the turbocharger boost compensator. - The PCS is a device to reduce the maximum fuel injection volume to protect the transmission or the differential.

33

1/2

BACS (Boost and Altitude Compensator System) PCS (Power Control System)

38 39

1/1 1/1

1/1

You might also like

- Isuzu 6hk1 6sd1 Type EngineDocument23 pagesIsuzu 6hk1 6sd1 Type Engineابن حمزة الخدري الخدريNo ratings yet

- Section 4 Brake SystemDocument23 pagesSection 4 Brake SystemPriscila RodriguesNo ratings yet

- Bosch CP3 OperationDocument6 pagesBosch CP3 OperationGianfranco Danna Gálvez100% (2)

- 3Gr-Fse Fuel: GeneralDocument14 pages3Gr-Fse Fuel: Generalservice_007100% (1)

- SSP 190 Variable - Turb oDocument32 pagesSSP 190 Variable - Turb oactuator79No ratings yet

- Injectors and Fuel Lines - OverviewDocument17 pagesInjectors and Fuel Lines - Overviewjose_saugo2601100% (1)

- TF Bosch VP44 Fuel Pump (Ver1)Document43 pagesTF Bosch VP44 Fuel Pump (Ver1)Carlos A Romero92% (37)

- Description: Necessity of Turbocharger and SuperchargerDocument16 pagesDescription: Necessity of Turbocharger and SuperchargerNazrul Aizat ZunaidiNo ratings yet

- VVT Sensor PDFDocument4 pagesVVT Sensor PDFDoDuyBac100% (1)

- Bosch Fuel System Common RailDocument4 pagesBosch Fuel System Common RailAlaa saidNo ratings yet

- VP44 Service ManualDocument39 pagesVP44 Service Manualhelder100% (5)

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocument5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GeneralsadiksnmNo ratings yet

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- 1.1-Factore I Common Rail FuleDocument9 pages1.1-Factore I Common Rail FuleMANOJNo ratings yet

- Engine Management: Fuel ControlDocument102 pagesEngine Management: Fuel ControlTrần Phương HùngNo ratings yet

- Fuel InjectionDocument93 pagesFuel InjectionCh'ng Jie HanNo ratings yet

- Sleeve Metering Fuel SystemDocument6 pagesSleeve Metering Fuel SystemJosephNo ratings yet

- Variable Valve TimingDocument3 pagesVariable Valve Timingsandesh ganigaNo ratings yet

- HINO J08C J05C Type Engine PDFDocument29 pagesHINO J08C J05C Type Engine PDFDiego Cadena100% (3)

- Hino j08c j05c Type EngineDocument29 pagesHino j08c j05c Type EngineNaseer Ahmed Awan88% (8)

- VVT-i (Variable Valve Timing-Intelligent) SystemDocument4 pagesVVT-i (Variable Valve Timing-Intelligent) SystemJorge Armando VelázquezNo ratings yet

- What-When-How: Governor (Automobile)Document5 pagesWhat-When-How: Governor (Automobile)Er Rajesh BuraNo ratings yet

- Control Sysems in Automobiles1 TTLM1Document18 pagesControl Sysems in Automobiles1 TTLM1tselothaiilemariamNo ratings yet

- Supercharging and Turbocharging: High Performance Aircraft EnginesDocument42 pagesSupercharging and Turbocharging: High Performance Aircraft EnginesBalachander RkNo ratings yet

- Operation Stages HDI SIEMENSDocument9 pagesOperation Stages HDI SIEMENSSergio SambuelliNo ratings yet

- VVT (Variable Valve Timing)Document26 pagesVVT (Variable Valve Timing)PramodPradhan100% (1)

- 1gr Fe VvtisystemDocument4 pages1gr Fe VvtisystemGepenx AriesNo ratings yet

- Transmission Oil PumpDocument7 pagesTransmission Oil PumpPushkar Nath100% (1)

- SsangYong Korando / New Actyon - Engine Control SystemDocument172 pagesSsangYong Korando / New Actyon - Engine Control Systemtroublezaur80% (5)

- Ec55b TM - Public382425684Document237 pagesEc55b TM - Public382425684AimHigh100% (4)

- 06 NFC Pump Control SystemDocument31 pages06 NFC Pump Control Systempiteng1945100% (36)

- Auto Transsmission ShelhadaryDocument62 pagesAuto Transsmission ShelhadaryHRNo ratings yet

- 2 Variable Valve TimingDocument30 pages2 Variable Valve Timingadibazmi93100% (1)

- Weber Injection-Ignition SystemDocument27 pagesWeber Injection-Ignition SystemjohnvandurenNo ratings yet

- Repair Denso PumpsDocument77 pagesRepair Denso PumpsAka Diesel93% (14)

- PM Tune Up PC 1250SP - 7Document23 pagesPM Tune Up PC 1250SP - 7Abc KeuanganNo ratings yet

- 2 Variable Valve TimingDocument30 pages2 Variable Valve TimingAlex Mariei100% (1)

- Embraer145 EngineDocument61 pagesEmbraer145 EngineTaksi100% (2)

- Chapter-6 Carburation and InjectionDocument10 pagesChapter-6 Carburation and InjectionjeetNo ratings yet

- Komat'Su - HPI Fuel SystemDocument76 pagesKomat'Su - HPI Fuel SystemKarthik Rao100% (2)

- Hino Common Rail j05d J08eDocument50 pagesHino Common Rail j05d J08eAnonymous yjK3peI793% (15)

- Piston Displacement and Diesel EngineDocument11 pagesPiston Displacement and Diesel Enginetoto elopreNo ratings yet

- Fuel SystemDocument99 pagesFuel SystemPaulus Saing100% (5)

- Unit Ii - Si Engines: Fig. 2.1. Main Areas of Automotive Engine OperationDocument14 pagesUnit Ii - Si Engines: Fig. 2.1. Main Areas of Automotive Engine OperationSiva GaneshNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Learn to Drive: Everything New Drivers Need to KnowFrom EverandLearn to Drive: Everything New Drivers Need to KnowRating: 4 out of 5 stars4/5 (1)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Diesel Common Rail Injection Electronic Components ExplainedFrom EverandDiesel Common Rail Injection Electronic Components ExplainedRating: 3.5 out of 5 stars3.5/5 (7)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Dpc7301 Makita PBDocument9 pagesDpc7301 Makita PBAnte LetilovićNo ratings yet

- Audi A4 (1.8 L Fuel Injection Engine, 110 KW, Motronic (5-Valve/turbo), 4 Cylinder), Engine Codes AEBDocument7 pagesAudi A4 (1.8 L Fuel Injection Engine, 110 KW, Motronic (5-Valve/turbo), 4 Cylinder), Engine Codes AEBApopii Catalin100% (1)

- 16V71 Detroit DieselDocument1 page16V71 Detroit Dieseledgar ricoNo ratings yet

- MAN-Trouble Codes - EDC7 - 81 A 3736Document19 pagesMAN-Trouble Codes - EDC7 - 81 A 3736GastaoNo ratings yet

- Series 60 Engine Sensor Harness: Available in Some ApplicationsDocument1 pageSeries 60 Engine Sensor Harness: Available in Some ApplicationsDuy KhaNo ratings yet

- M Di 0038Document7 pagesM Di 0038Dayro Jose Geney OrtizNo ratings yet

- Possible Wear Element SourcesDocument1 pagePossible Wear Element SourcesJuan Jose Bermudez SilvaNo ratings yet

- MercruiserfuelsystemDocument16 pagesMercruiserfuelsystemwguenonNo ratings yet

- 03 - 01 - Major Alarm& Safety of 50DF With UNIC 3Document4 pages03 - 01 - Major Alarm& Safety of 50DF With UNIC 3Ashish KumarNo ratings yet

- Scion XB 2005 Overall Wiring DiagramDocument28 pagesScion XB 2005 Overall Wiring Diagramsixdust100% (10)

- FiatECUScan - Fiat, Alfa, Lancia ECU Reader - ScannerDocument127 pagesFiatECUScan - Fiat, Alfa, Lancia ECU Reader - ScannerAlessandro De TommasiNo ratings yet

- Gsr600k7e19 PDFDocument96 pagesGsr600k7e19 PDFAdolfoNo ratings yet

- Mercruiser Service Manual - 17Document967 pagesMercruiser Service Manual - 17pcbennison85% (13)

- 10436-PWT6.8 L - 6068afm75Document328 pages10436-PWT6.8 L - 6068afm75adrienspinozzi100% (1)

- Shop Manual Terracan 2005Document426 pagesShop Manual Terracan 2005Daniel MartinezNo ratings yet

- List of Diagnostic Trouble Codes J1939 Code J1939 Code Description Troubleshooting Procedure ATA CodeDocument15 pagesList of Diagnostic Trouble Codes J1939 Code J1939 Code Description Troubleshooting Procedure ATA CodeTrener Penza83% (66)

- Ecam ResetDocument36 pagesEcam ResetLeonard Komon100% (1)

- Bridgestone Motorcycle Factory Service Sheets PDFDocument50 pagesBridgestone Motorcycle Factory Service Sheets PDFMoppie Hofstede0% (1)

- 4tnv88-Dsa - Catalina 0cr10-m56600 - enDocument26 pages4tnv88-Dsa - Catalina 0cr10-m56600 - enjavier muñozNo ratings yet

- MS 200-200T Service ManualDocument118 pagesMS 200-200T Service ManualLance Ledgerwood100% (1)

- Petrol Engine Fuel Supply SystemDocument10 pagesPetrol Engine Fuel Supply SystemDank Memes KazhgamNo ratings yet

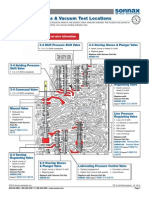

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- Service 1 Update Teleconference 0808Document6 pagesService 1 Update Teleconference 0808Garcia CruzNo ratings yet

- Toyota 5.7L-346ci-V8 Torque Specifications - TorkSpec - Knowledge For The MotorheadDocument16 pagesToyota 5.7L-346ci-V8 Torque Specifications - TorkSpec - Knowledge For The MotorheadBilly PageNo ratings yet

- Screw Compressor Screw CompressorDocument2 pagesScrew Compressor Screw CompressorRanda Septian Putra50% (2)

- Perkins 750KVA-825KVADocument4 pagesPerkins 750KVA-825KVAHải Nguyễn HồngNo ratings yet

- Ford Vehicle Report Card HRDocument4 pagesFord Vehicle Report Card HRFranco EsnaolaNo ratings yet

- Bomag BW 151 Ad 4 ElectricalDocument5 pagesBomag BW 151 Ad 4 ElectricalJennifer100% (49)

- To Study Different CarburetorsDocument4 pagesTo Study Different CarburetorsSamadhan Ware PatilNo ratings yet

- Dokumen - Tips - Hyster r005 h90ft Forklift Service Repair Manual 1624974803Document28 pagesDokumen - Tips - Hyster r005 h90ft Forklift Service Repair Manual 1624974803Denis Freire75% (4)