Professional Documents

Culture Documents

QFD

Uploaded by

Bommireddy Koushik ReddyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QFD

Uploaded by

Bommireddy Koushik ReddyCopyright:

Available Formats

Description of the QFD Process

Quality Function Deployment (QFD) is a structured, multi-disciplinary technique for product definition that maximizes value to the customer. The application of the QFD process is an art that varies somewhat from practitioner to practitioner, but the graphic on the next page illustrates a typical application of the QFD process. The graphic shows a concept called the QFD House of Quality (HOQ), a device for organizing the flow of thinking and discussion that leads to finished product specifications. The House of Quality is built by a firm's own multi-disciplinary team under guidance from a trained QFD facilitator (preferably a facilitator with both marketing and technical experience). Given one or more specific objectives (e.g., a narrow focus such as "optimize engine performance" or a more global focus such as "optimize overall passenger comfort"), the QFD process starts with obtaining customer requirements through market research. These research results are inputs into the House of Quality. Below is a discussion of each of the rooms of the House of Quality and how they are built. The "Whats" Room: Typically there are many customer requirements, but using a technique called affinity diagramming, the team distills these many requirements into the 20 or 30 most important needs. The affinity diagramming process is critical to the success of QFD in that there is vigorous discussion to reach consensus as to what the customers really meant by their comments. This is a powerful technique for reconciling the different interpretations held by marketing, design engineering or field service. The affinity diagramming process usually takes about one to two solid team days to complete, depending on how narrow or global the objective is. The results from the affinity diagramming are placed into the "Whats" room in the HOQ. The Importance Ratings and Customer Competitive Assessment Rooms: Marketing and /or the market researcher designs the market research so that the team can use the results as inputs to successfully complete the Importance Ratings and Customer Competitive Assessment rooms. These rooms are located on the matrix where benefit rankings and ratings are assembled for analysis. TheImportance Rankings provide the team with a prioritization of customer requirements while the Customer Competitive Assessment allows us to spot strengths and weaknesses in both our product and the competition's products. The "Hows" Room: The next step is the completion of the "Hows" room. In this activity the entire team asks for each "What", "How would we measure product performance which would provide us an indication of customer satisfaction for this specific 'What'?" The team needs to come up with at least one product performance measure, but sometimes the team recognizes that it takes several measures to adequately characterize product performance.

The Relationships Matrix Room: After the "Hows" room has been completed, the team begins to explore the relationships between all "Whats" and all "Hows"as they complete the Relationships Matrix room. During this task the team systematically asks, "What is the relationship between this specific 'how' and this specific 'what'?" "Is there cause and effect between the two?" This is a consensus decision within the group. Based on the group decision, the team assigns astrong, medium, weak or no relationship value to this specific "what/how" pairing. Then the team goes on to the next "what/how" pairing. This process continues until all "what/how" pairings have been reviewed. The technical community begins to assume team leadership in these areas. The Absolute Score and Relative Score Rooms: Once the Relationships Matrix room has been completed, the team can then move on to the Absolute Score and Relative Score rooms. This is where the team creates a model or hypothesis as to how product performance contributes to customer

satisfaction. Based on the Importance Ratings and the Relationship Matrix values, the team calculates the Absolute and Relative Scores. These calculations are the team's best estimate as to which product performance measures ("hows") exert the greatest impact on overall customer satisfaction. Engineering now begins to know where the product has got to measure up strongly in order to beat the competition. The last three rooms receive the most input from the technical side of the team, but total team involvement is still vital. The Correlation Matrix Room: There are times in many products where customer requirements translate into physical design elements which conflict with one another; these conflicts are usually reflected in the product "hows". TheCorrelation Matrix room is used to help resolve these conflicts by highlighting those "hows" which have are share the greatest conflict. For example, let's say that the "how" called "weight" should be minimized for greatest customer satisfaction. At the same time there might be two other "hows"titled "strength" and "power capacity". The customer has expressed preferences that these be maximized. Based on what we know about physics, there may be a conflict in minimizing "weight" and maximizing "strength" and "power capacity". The analysis that takes place in the Correlation Matrix room systematically forces a technical review for all likely conflicts and then alerts the team to either optimize or eliminate these conflicts or consider design alternatives. The mechanics of the analysis is to review each and every "how" for possible conflict (or symbiosis) against every other "how". As mentioned in the previous sentence sometimes symbiotic relationships between "hows" do surface in this analysis. This analysis also allows the team to capitalize on those symbiotic situations.

The Technical Competitive Assessment Room: This is the room where engineering applies the measurements identified during the construction of the "Hows" room. "Does our product perform better than the competitive product according to the specific measure that we have identified?" Here is where the team tests the hypothesis created in the Relative Score room. It helps the team to confirm that it has created "hows" that make sense, that really do accurately measure characteristics leading to customer satisfaction. Analysis in the Technical Competitive Assessment and Customer Competitive Assessment rooms can also help uncover problems in perception. For example, perhaps the customer wants a car that is fast, so your team comes up with the"how" of "elapsed time in the quarter mile". After comparing performance between your car and the competitor's vehicle, you realize that "you blew the doors off the competitor's old crate". However when you look in the Customer Competitive Assessment room, you see that most of the marketplace perceives the competitor's car as being faster. While you might have chosen one of the correct"hows" to measure performance, it is clear that your single "how" does not completely reflect performance needed to make your car appear faster. The Target Values Room: The last room of Target Values contains the recommended specifications for the product. These specifications will have been well thought out, reflecting customer needs, competitive offerings and any technical trade-off required because of either design or manufacturing constraints. The House of Quality matrix is often called the phase one matrix. In the QFD process there is also a phase two matrix to translate finished product specifications into attributes of design (architecture, features, materials, geometry, subassemblies and / or component parts) and their appropriate specifications. Sometimes a phase three matrix is used to attributes of design specifications into manufacturing process specifications (temperature, pressure, viscosity, rpm, etc.).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Features of Academic WritingDocument4 pagesFeatures of Academic WritingJudith Tero Muñez86% (43)

- Intermediate Unit TestsDocument37 pagesIntermediate Unit TestsZekiye Şen100% (5)

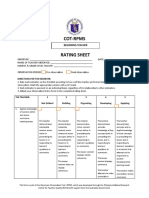

- COT-RPMS Beginning Teacher Rating SheetDocument4 pagesCOT-RPMS Beginning Teacher Rating SheetRudy ClariñoNo ratings yet

- CBT Delivery PrinciplesDocument11 pagesCBT Delivery PrinciplesFrances Mae CabanesNo ratings yet

- Enlivenment Andreas WeberDocument76 pagesEnlivenment Andreas Webersoto100% (2)

- It's Half Past ... WorksheetDocument1 pageIt's Half Past ... WorksheetKyawt Hnin Hayman SoeNo ratings yet

- Chapter One 1.1 Background To The StudyDocument18 pagesChapter One 1.1 Background To The StudyOkonkwo Anthony DozieNo ratings yet

- Lesson Plan in Music (Dynamics)Document5 pagesLesson Plan in Music (Dynamics)Sujim YMNo ratings yet

- Sreb College Ready Literacy Course OverviewDocument1 pageSreb College Ready Literacy Course Overviewapi-373506180No ratings yet

- MODULE 3 MTB MLE Teaching MethodologiesDocument20 pagesMODULE 3 MTB MLE Teaching MethodologiesJoyce FuertezNo ratings yet

- MQP For MBA I Semester Students of SPPUDocument2 pagesMQP For MBA I Semester Students of SPPUfxn fndNo ratings yet

- Edtpa Lesson PlanDocument3 pagesEdtpa Lesson Planapi-457201254No ratings yet

- 40 Great Education Research Paper TopicsDocument25 pages40 Great Education Research Paper TopicsMagelyn NBNo ratings yet

- Experimental Project On Action ResearchDocument3 pagesExperimental Project On Action Researchddum292No ratings yet

- SA2 Criterion B and C-taskid16036TSK1120230412085553611Document10 pagesSA2 Criterion B and C-taskid16036TSK1120230412085553611Ashneel ChakravortyNo ratings yet

- DLP WRB 10 2Document5 pagesDLP WRB 10 2ironickNo ratings yet

- Ahmed Ismail: Chinese-Arabic Interpretation TranslatorDocument2 pagesAhmed Ismail: Chinese-Arabic Interpretation TranslatorAbdulrahman TahaNo ratings yet

- Предметно-интегрированное обучение (Clil: Content And Language Integrated Learning) английскому языку на основе применения дистанционных образовательных технологийDocument45 pagesПредметно-интегрированное обучение (Clil: Content And Language Integrated Learning) английскому языку на основе применения дистанционных образовательных технологийНазерке ЧабденоваNo ratings yet

- Taylor Elton ResumeDocument2 pagesTaylor Elton Resumeapi-531485472No ratings yet

- Kubler-Ross-Change-Curve - Emotional Change PDFDocument1 pageKubler-Ross-Change-Curve - Emotional Change PDFbresmanNo ratings yet

- Assignment 1Document44 pagesAssignment 1api-368682595No ratings yet

- Lesson Planning 1 - 10 GradersDocument4 pagesLesson Planning 1 - 10 GradersViviana Salgado RuizNo ratings yet

- Almaz Mamaru Counseling Psychologist (BA, MA) Department of Psychiatry, Bahardar UniversityDocument39 pagesAlmaz Mamaru Counseling Psychologist (BA, MA) Department of Psychiatry, Bahardar UniversityAklile TsegaNo ratings yet

- The Difference Between Mentoring and Coaching: Valerie PelanDocument4 pagesThe Difference Between Mentoring and Coaching: Valerie PelandobiNo ratings yet

- Success For AllDocument79 pagesSuccess For AllKaraNo ratings yet

- Chronological CV ExampleDocument1 pageChronological CV ExampleFuiorNo ratings yet

- Module I Nature and Scope of Research MethodologyDocument6 pagesModule I Nature and Scope of Research MethodologyKhushbu Saxena100% (1)

- Being Manager Leader and CoachDocument78 pagesBeing Manager Leader and CoachBCENE UCSINo ratings yet

- Contribution - 2019 - She Ji The Journal of Design Economics and InnovationDocument1 pageContribution - 2019 - She Ji The Journal of Design Economics and InnovationnitakuriNo ratings yet

- Mhgap StressDocument18 pagesMhgap StressYash CabilesNo ratings yet