Professional Documents

Culture Documents

Creep Results

Uploaded by

walyatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Creep Results

Uploaded by

walyatCopyright:

Available Formats

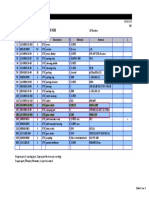

Conclusions: Thermal creep analysis was performed to match the

creep experimental data. Discrepancy among hand calculation, ANSYS, and experimental results were observed. It will be continued to look for the reason of the mentioned discrepancy.

Observation 1: The discrepancy is observed between Experimental and ANSYS results: ANSYS average creep deformation=~1.25% Experimental creep deformation=~1.7% Observation 2: The discrepancy is observed between Experimental and hand results: Experimental creep deformation=~1.7% Hand calculated creep deformation= ~5.1% The Significance of Creep Analysis In the second stage, the slope is ascending so it may lead to the third stage and cause failure and rupture. Creep is highly time dependent, thus it can show its effects in a longer time. All our present analyses on the divertor are rate-independent.

Creep is temperature dependent and it has more effects in higher temperatures. DEFINITON OF Creep Creep is a rate dependent material nonlinearity in which the material continues to deform under a constant load (ANSYS). Creep is highly time dependent and it displays its effects over a long time. Creep has 3 stages:

Stages Of Creep Creep has three stages:

1. First Stage: It is considered by the work-hardening behavior of the material. It makes the material more difficult to deform under strain. 2. Second Stage: Creep in this stage is steady state. In this stage, there is a balance work-hardening and thermal-softening which causes a constant and steady creep. (minimum creep rate) 3. Third Stage: In this stage, creep accelerates due to the accumulating damage which will cause rupture at the end of the stage.

Creep Analysis in ANSYS ANSYS is able to analyze first and second stages of creep. ANSYS uses Implicit and Explicit methods for creep. 1. Implicit is fast and accurate and works with temperature dependent creep constant. 2. In Divertor analysis, all the material properties are temperature dependent. 3. Explicit method is used for the analyses if it would not allow use to temp. dependent materials. It does not perform elastic-plastic analysis. But in our this analysis ,we have chosen implicit method , because this method is accurate and works with temperature dependent creep constant . Significance of Creep Analysis In the second stage, the slope is ascending so it may lead to the third stage and cause failure and rupture. Creep is highly time dependent, thus it can show its effects in a longer time. All our present analyses on the divertor are rate-independent. Creep is temperature dependent and it has more effects in higher temperatures.

Configuration of the sample

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Air Force To 32-1-101 Army TM 9 243 Navy m6290 Aj Man 1010 Marine Corp TM 10209 101 Technical Manual Use and Care of Hand Tools and Measuring Tools 14Document310 pagesAir Force To 32-1-101 Army TM 9 243 Navy m6290 Aj Man 1010 Marine Corp TM 10209 101 Technical Manual Use and Care of Hand Tools and Measuring Tools 14Michael SmallNo ratings yet

- Psalm151 160Document3 pagesPsalm151 160Gina KristenNo ratings yet

- Water Sensitive Urban Design GuidelineDocument42 pagesWater Sensitive Urban Design GuidelineTri Wahyuningsih100% (1)

- Vessel Fabrication Manual PDFDocument49 pagesVessel Fabrication Manual PDFwalyat100% (2)

- The Physics of GolfDocument15 pagesThe Physics of GolfwalyatNo ratings yet

- 65 ActsDocument178 pages65 ActsComprachosNo ratings yet

- Sperm Count EvaluationDocument3 pagesSperm Count EvaluationGarry Kin CamarilloNo ratings yet

- Daygame by Todd Valentine NotesDocument8 pagesDaygame by Todd Valentine NotesAdnanHassan100% (7)

- Pediatric Gynecology BaruDocument79 pagesPediatric Gynecology BaruJosephine Irena100% (2)

- TorqueDocument26 pagesTorquewalyat100% (2)

- Frequency Converter English ManualDocument33 pagesFrequency Converter English Manualproduccion multipack100% (2)

- Foundation Design LectureDocument59 pagesFoundation Design LectureJamaica MarambaNo ratings yet

- Faithgirlz Handbook, Updated and ExpandedDocument15 pagesFaithgirlz Handbook, Updated and ExpandedFaithgirlz75% (4)

- South Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliDocument29 pagesSouth Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliHari Dante Cry100% (1)

- Marxism and The Oppression of Women Lise VogelDocument259 pagesMarxism and The Oppression of Women Lise VogelMoises SaavedraNo ratings yet

- 4PH0 1P Rms 20120823 PDFDocument24 pages4PH0 1P Rms 20120823 PDFwalyatNo ratings yet

- PH PR AlllistedphysexprDocument68 pagesPH PR AlllistedphysexprwalyatNo ratings yet

- Tracker Video DesignDocument9 pagesTracker Video DesignwalyatNo ratings yet

- Aqa Gcse Physics 1 (Science) 2007+ Heat Energy Transfer - Revision Sheet 1 CrosswordDocument1 pageAqa Gcse Physics 1 (Science) 2007+ Heat Energy Transfer - Revision Sheet 1 CrosswordwalyatNo ratings yet

- Mid Term Examination2013Document15 pagesMid Term Examination2013walyatNo ratings yet

- Broken Arrow Public Schools AP Physics C Objectives: # Objective 1Document7 pagesBroken Arrow Public Schools AP Physics C Objectives: # Objective 1walyatNo ratings yet

- Mock Exam 11Document19 pagesMock Exam 11walyatNo ratings yet

- Edexcel IGCSE May 2012 Physics Paper-1Document36 pagesEdexcel IGCSE May 2012 Physics Paper-1John Hopkins0% (1)

- Picket Fence and Photo GateDocument2 pagesPicket Fence and Photo GatewalyatNo ratings yet

- Answers of Igcse Past Paper (2H) Nov 2009Document1 pageAnswers of Igcse Past Paper (2H) Nov 2009walyatNo ratings yet

- Taiwan Golf CoursesDocument6 pagesTaiwan Golf CourseswalyatNo ratings yet

- Triangle Square: Example: What Is The Area of This Rectangle?Document3 pagesTriangle Square: Example: What Is The Area of This Rectangle?walyatNo ratings yet

- Igcse (Edexcel International Gcse in Science - Code 4Sc0) - Double Science OptionDocument2 pagesIgcse (Edexcel International Gcse in Science - Code 4Sc0) - Double Science OptionwalyatNo ratings yet

- Thermal Energy QuestionsDocument7 pagesThermal Energy QuestionswalyatNo ratings yet

- Acid Rain: Russell R. DickersonDocument23 pagesAcid Rain: Russell R. DickersonwalyatNo ratings yet

- Halliday/Resnick/Walker Fundamentals of Physics 8 Edition: Classroom Response System QuestionsDocument47 pagesHalliday/Resnick/Walker Fundamentals of Physics 8 Edition: Classroom Response System QuestionswalyatNo ratings yet

- Troubleshooting Electrical CircuitsDocument32 pagesTroubleshooting Electrical Circuitswalyat100% (1)

- Lecture 1Document22 pagesLecture 1walyatNo ratings yet

- Good Electricity and Water AnalogyDocument63 pagesGood Electricity and Water AnalogywalyatNo ratings yet

- Commodity Pricing MantissaDocument12 pagesCommodity Pricing MantissawalyatNo ratings yet

- 0708 ElectricityDocument33 pages0708 ElectricitywalyatNo ratings yet

- Academic EnglishDocument61 pagesAcademic EnglishwalyatNo ratings yet

- Just Now As My Friend Dave Said There Are Two Possible Ends of Universe, Ice and FireDocument6 pagesJust Now As My Friend Dave Said There Are Two Possible Ends of Universe, Ice and FirewalyatNo ratings yet

- Syllabus (402050B) Finite Element Analysis (Elective IV)Document3 pagesSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavNo ratings yet

- Etl 213-1208.10 enDocument1 pageEtl 213-1208.10 enhossamNo ratings yet

- T 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationDocument3 pagesT 1246784488 17108574 Street Lighting Control Based On LonWorks Power Line CommunicationsryogaaNo ratings yet

- 11 - Morphology AlgorithmsDocument60 pages11 - Morphology AlgorithmsFahad MattooNo ratings yet

- BCSL 058 Previous Year Question Papers by IgnouassignmentguruDocument45 pagesBCSL 058 Previous Year Question Papers by IgnouassignmentguruSHIKHA JAINNo ratings yet

- Introduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Document161 pagesIntroduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Andres Bruno SaraviaNo ratings yet

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocument60 pagesPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65No ratings yet

- Annie Ovenden Exibition 2017Document19 pagesAnnie Ovenden Exibition 2017Vitaliy ChuenkoNo ratings yet

- SweetenersDocument23 pagesSweetenersNur AfifahNo ratings yet

- NDT Matrix 12-99-90-1710 - Rev.2 PDFDocument2 pagesNDT Matrix 12-99-90-1710 - Rev.2 PDFEPC NCCNo ratings yet

- Tyba S4 Syntax PDFDocument107 pagesTyba S4 Syntax PDFIndahNo ratings yet

- Practical 3.1 Determining The Specific Heat CapacityDocument3 pagesPractical 3.1 Determining The Specific Heat CapacityiAlex11No ratings yet

- BMS of Dubai International AirportDocument4 pagesBMS of Dubai International AirportJomari Carl Rafal MansuetoNo ratings yet

- Farmhouse Style Plans - Farm & CountryDocument6 pagesFarmhouse Style Plans - Farm & Countryhanif azriNo ratings yet

- Ield Methods: A Typical Field Mapping Camp in The 1950sDocument4 pagesIeld Methods: A Typical Field Mapping Camp in The 1950sshivam soniNo ratings yet

- The Gingerbread Man-1 EnglishareDocument40 pagesThe Gingerbread Man-1 EnglishareamayalibelulaNo ratings yet

- ESM-4810A1 Energy Storage Module User ManualDocument31 pagesESM-4810A1 Energy Storage Module User ManualOscar SosaNo ratings yet

- Greek ArchitectureDocument16 pagesGreek ArchitectureXlyth RodriguezNo ratings yet