Professional Documents

Culture Documents

Summer Training Project Report

Uploaded by

Piyush Pankaj Mishra0 ratings0% found this document useful (0 votes)

170 views71 pagesBHEL is the largest engineering and manufacturing enterprise in India in the energy related infrastructure sector today. BHEL caters to core sectors of the Indian Economy viz., Power Generation's and Transmission, Industry, Transportation, Telecommunications and telecommunications.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBHEL is the largest engineering and manufacturing enterprise in India in the energy related infrastructure sector today. BHEL caters to core sectors of the Indian Economy viz., Power Generation's and Transmission, Industry, Transportation, Telecommunications and telecommunications.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

170 views71 pagesSummer Training Project Report

Uploaded by

Piyush Pankaj MishraBHEL is the largest engineering and manufacturing enterprise in India in the energy related infrastructure sector today. BHEL caters to core sectors of the Indian Economy viz., Power Generation's and Transmission, Industry, Transportation, Telecommunications and telecommunications.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 71

1

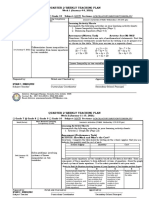

Bharat Heavy Electricals Limited, Ranipur, Haridwar

Summer Training Project Report

for

Block III Turbine and Auxillary Block

(under the supervision of Mr. S. Haldhar)

Submitted by -

Daoud Zaman Khan

B.Sc. (Engg.) IIIrd Year

Faculty of Engineering

Dayalbagh Educational Institute, Agra

2

Contents

S. No.

Topic Page No.

1. Acknowledgements 3

2. BHEL An Overview 4

3. HEEP An Overview 11

4. Brief Description of all the Blocks 16

5. Bay-wise Description of Block III 19

6. Study of Block III 26

7. Study of Blade Shop 30

8. Study of Important/Major Machine Tools and

Machines

36

9. Study of Material Specifications 58

10. Classification of Blades 68

11. Hydro Turbine Laboratory 69

12. Manufacturing Divisions of BHEL 71

3

Acknowledgements

Working at BHEL was indeed a great experience and for the successful commencement of my

training I need to thank a lot many of the people in the organisation.

First of all I am to Mr. B. B. Roy (retd. AGM) who gave me the initial guidance for getting myself

selected in the training at the Organisation.

I am very grateful to Mr. S. Haldhar (DGM, Block III) for taking me under his guidance and also

providing me the relevant information so that I could get started with the training in the area

allotted to me.

For my period of training at the BHEL I am also very grateful to the Engineers and Machine

operators of BHEL working at Block III for providing me adequate information so that I could get

proper information and also get myself acquainted with the work environment.

4

BHEL An Overview

BHEL is the largest engineering and manufacturing enterprise in India in the energy related infrastructure

sector today. BHEL was established more than 40 years ago when its first plant was setup in Bhopal ushering

in the indigenous Heavy Electrical Equipment Industry in India a dream which has been more than realized

with a well-recognized track record of performance it has been earning profits continuously since 1971-72.

BHEL caters to core sectors of the Indian Economy viz., Power Generation's & Transmission, Industry,

Transportation, Telecommunication, Renewable Energy, Defence, etc. The wide network of BHEL's 14

manufacturing division, four power Sector regional centres, over 150 project sites, eight service centres and

18 regional offices, enables the Company to promptly serve its customers and provide them with suitable

products, systems and services efficiently and at competitive prices. BHEL has already attained ISO 9000

certification for quality management, and ISO 14001 certification for environment management.

POWER GENERATION

Power generation sector comprises thermal, gas, hydro and nuclear power plant business as of 31.03.2001,

BHEL supplied sets account for nearly 64737 MW or 65% of the total installed capacity of 99,146 MW in the

country, as against nil till 1969-70.

BHEL has proven turnkey capabilities for executing power projects from concept to commissioning; it

possesses the technology and capability to produce thermal sets with super critical parameters up to 1000

MW unit rating and gas turbine generator sets of up to 240 MW units rating. Co-generation and combined-

cycle plants have been introduced to achieve higher plant efficiencies. To make efficient use of the high-ash-

content coal available in India, BHEL supplies circulating fluidized bed combustion boilers to both thermal

and combined cycle power plants.

The company manufactures 235 MW nuclear turbine generator sets and has commenced production of 500

MW nuclear turbine generator sets.

Custom made hydro sets of Francis; Pelton and Kaplan types for different head discharge combination are

also engineering and manufactured by BHEL.

In all, orders for more than 700 utility sets of thermal, hydro, gas and nuclear have been placed on the

5

Company as on date. The power plant equipment manufactured by BHEL is based on contemporary

technology comparable to the best in the world and is also internationally competitive.

The Company has proven expertise in Plant Performance Improvement through renovation modernisation

and uprating of a variety of power plant equipment besides specialised know how of residual life assessment,

health diagnostics and life extension of plants.

POWER TRANSMISSION & DISTRIBUTION (T & D)

BHEL offer wide ranging products and systems for T & D applications. Products manufactured include power

transformers, instrument transformers, dry type transformers, series and stunt reactor, capacitor tanks,

vacuum and SF circuit breakers gas insulated switch gears and insulators.

A strong engineering base enables the Company to undertake turnkey delivery of electric substances up to

400 kV level series compensation systems (for increasing power transfer capacity of transmission lines and

improving system stability and voltage regulation), shunt compensation systems (for power factor and

voltage improvement) and HVDC systems (for economic transfer of bulk power). BHEL has indigenously

developed the state-of-the-art controlled shunt reactor (for reactive power management on long

transmission lines). Presently a 400 kV Facts (Flexible AC Transmission System) project under execution.

INDUSTRIES

BHEL is a major contributor of equipment and systems to industries. Cement, sugar, fertilizer, refineries,

petro-chemicals, paper, oil and gas, metallurgical and other process industries lines and improving system

stability and voltage regulation, shunt compensation systems (for power factor and voltage improvement)

and HVDC systems (for economic transfer of bulk power) BHEL has indigenously developed the state-of-the-

art controlled shunt reactor (for reactive power management on long transmission lines). Presently a 400 kV

FACTS (Flexible AC Transmission System) projects is under execution.

The range of system & equipment supplied includes: captive power plants, co-generation plants DG power

plants, industrial steam turbines, industrial boilers and auxiliaries. Water heat recovery boilers, gas turbines,

heat exchangers and pressure vessels, centrifugal compressors, electrical machines, pumps, valves, seamless

steel tubes, electrostatic precipitators, fabric filters, reactors, fluidized bed combustion boilers, chemical

recovery boilers and process controls.

6

The Company is a major producer of large-size thruster devices. It also supplies digital distributed control

systems for process industries, and control & instrumentation systems for power plant and industrial

applications. BHEL is the only company in India with the capability to make simulators for power plants,

defence and other applications.

The Company has commenced manufacture of large desalination plants to help augment the supply of

drinking water to people.

TRANSPORTATION

BHEL is involved in the development design, engineering, marketing, production, installation and

maintenance and after-sales service of Rolling Stock and traction propulsion systems. In the area of rolling

stock, BHEL manufactures electric locomotives up to 5000 HP, diesel-electric locomotives from 350 HP to

3100 HP, both for mainline and shunting duly applications. BHEL is also producing rolling stock for special

applications viz., overhead equipment cars, Special well wagons, Rail-cum-road vehicle etc., Besides traction

propulsion systems for in-house use, BHEL manufactures traction propulsion systems for other rolling stock

producers of electric locomotives, diesel-electric locomotives, electrical multiple units and metro cars. The

electric and diesel traction equipment on India Railways are largely powered by electrical propulsion systems

produced by BHEL. The company also undertakes retooling and overhauling of rolling stock in the area of

urban transportation systems. BHEL is geared up to turnkey execution of electric trolley bus systems, light

rail systems etc. BHEL is also diversifying in the area of port handing equipment and pipelines transportation

system.

TELECOMMUNICATION

BHEL also caters to Telecommunication sector by way of small, medium and large switching systems.

RENEWABLE ENERGY

Technologies that can be offered by BHEL for exploiting non-conventional and renewable sources of energy

include: wind electric generators, solar photovoltaic systems, solar lanterns and battery-powered road

vehicles. The Company has taken up R&D efforts for development of multi-junction amorphous silicon solar

cells and fuel based systems.

7

INTERNATIONAL OPERATIONS

BHEL has, over the years, established its references in around 60 countries of the world, ranging for the

United States in the West to New Zealand in the Far East. These references encompass almost the entire

product range of BHEL, covering turnkey power projects of thermal, hydro and gas-based types, substation

projects, rehabilitation projects, besides a wide variety of products, like transformers, insulators,

switchgears, heat exchangers, castings and forgings, valves, well-head equipment, centrifugal compressors,

photo-voltaic equipment etc. Apart from over 1110MW of boiler capacity contributed in Malaysia, and

execution of four prestigious power projects in Oman, Some of the other major successes achieved by the

Company have been in Australia, Saudi Arabia, Libya, Greece, Cyprus, Malta, Egypt, Bangladesh, Azerbaijan,

Sri Lanka, Iraq etc.

The Company has been successful in meeting demanding customer's requirements in terms of complexity of

the works as well as technological, quality and other requirements viz extended warrantees, associated

O&M, financing packages etc. BHEL has proved its capability to undertake projects on fast-track basis. The

company has been successful in meeting varying needs of the industry, be it captive power plants, utility

power generation or for the oil sector requirements. Executing of Overseas projects has also provided BHEL

the experience of working with world renowned Consulting Organisations and inspection Agencies.

In addition to demonstrated capability to undertake turnkey projects on its own, BHEL possesses the

requisite flexibility to interface and complement with International companies for large projects by supplying

complementary equipment and meeting their production needs for intermediate as well as finished

products.

The success in the area of rehabilitation and life extension of power projects has established BHEL as a

comparable alternative to the original equipment manufacturers (OEMs) for such plants.

TECHNOLOGY UPGRADATION AND RESEARCH & DEVELOPMENT

To remain competitive and meet customers' expectations, BHEL lays great emphasis on the continuous

upgradation of products and related technologies, and development of new products. The Company has

upgraded its products to contemporary levels through continuous in house efforts as well as through

acquisition of new technologies from leading engineering organizations of the world.

8

The Corporate R&D Division at Hyderabad, spread over a 140 acre complex, leads BHEL's research efforts in a

number of areas of importance to BHEL's product range. Research and product development centres at each

of the manufacturing divisions play a complementary role.

BHEL's Investment in R&D is amongst the largest in the corporate sector in India. Products developed in-

house during the last five years contributed about 8.6% to the revenues in 2000-2001.

BHEL has introduced, in the recent past, several state-of-the-art products developed in-house: low-NQx oil /

gas burners, circulating fluidized bed combustion boilers, high-efficiency Pelton hydro turbines, petroleum

depot automation systems, 36 kV gas-insulated sub-stations, etc. The Company has also transferred a few

technologies developed in-house to other Indian companies for commercialisation.

Some of the on-going development & demonstration projects include: Small wall blowing system for cleaning

boiler soot deposits, and micro-controller based governor for diesel-electric locomotives. The company is

also engaged in research in futuristic areas, such as application of super conducting materials in power

generations and industry, and fuel cells for distributed, environment-friendly power generation.

HUMAN RESOURCE DEVELOPMENT INSTITUTE

The most prized asset of BHEL is its employees. The Human Resource Development Institute and other HRD

centres of the Company help in not only keeping their skills updated and finely honed but also in adding new

skills, whenever required. Continuous training and retraining, positive, a positive work culture and

participative style of management have engendered development of a committed and motivated work force

leading to enhanced productivity and higher levels of quality.

HEALTH, SAFETY AND ENVIRONMENT MANAGEMENT

BHEL, as an integral part of business performance and in its endeavour of becoming a world-class

organization and sharing the growing global concern on issues related to Environment. Occupational Health

and Safety, is committed to protecting Environment in and around its own establishment, and to providing

safe and healthy working environment to all its employees.

For fulfilling these obligations, Corporate Policies have been formulated as:

9

ENVIRONMENTAL POLICY

- Compliance with applicable Environmental Legislation/Regulation;

- Continual Improvement in Environment Management Systems to protect our natural environment

and Control Pollution;

- Promotion of activities for conservation of resources by Environmental Management;

- Enhancement of Environmental awareness amongst employees, customers and suppliers. BHEL will

also assist and co-operate with the concerned Government Agencies and Regulatory Bodies engaged

in environmental activities, offering the Company's capabilities is this field.

OCCUPATIONAL HEALTH AND SAFETY POLICY

- Compliance with applicable Legislation and Regulations;

- Setting objectives and targets to eliminate/control/minimize risks due to Occupational and Safety

Hazards;

- Appropriate structured training of employees on Occupational Health and Safety (OH&S) aspects;

- Formulation and maintenance of OH&S Management programmes for continual improvement;

- Periodic review of OH&S Management System to ensure its continuing suitability, adequacy and

effectiveness;

- Communication of OH&S Policy to all employees and interested parties.

The major units of BHEL have already acquired ISO 14001 Environmental Management System Certification,

and other units are in advanced stages of acquiring the same. Action plan has been prepared to acquire

OHSAS 18001 Occupational Health and Safety Management System certification for all BHEL units.

In pursuit of these Policy requirements, BHEL will continuously strive to improve work particles in the light of

advances made in technology and new understandings in Occupational Health, Safety and Environmental

Science.

10

PARTICIPATION IN THE "GLOBAL COMPACT" OF THE UNITED NATIONS

The "Global Compact" is a partnership between the United Nations, the business community, international

labour and NGOs. It provides a forum for them to work together and improve corporate practices through

co-operation rather than confrontation.

BHEL has joined the "Global Compact" of United Nations and has committed to support it and the set of core

values enshrined in its nine principles:

PRINCIPLES OF THE "GLOBAL COMPACT"

HUMAN RIGHTS

1. Business should support and respect the protection of internationally proclaimed human rights; and

2. Make sure they are not complicit in human rights abuses.

Labor Standards

3. Business should uphold the freedom of association and the effective recognition of the right to

collective bargaining;

4. The elimination of all form of forces and compulsory labour.

5. The effective abolition of child labour, and

6. Eliminate discrimination.

Environment

7. Businesses should support a precautionary approach to environmental challenges;

8. Undertake initiatives to promote greater environmental responsibility and

9. Encourage the development and diffusion of environmentally friendly technologies.

By joining the "Global Compact", BHEL would get a unique opportunity of networking with corporate and

sharing experience relating to social responsibility on global basis.

11

HEEP An Overview

Over the years, Bharat Heavy Electricals Limited has emerged as world class Engineering and Industrial giant,

the best of its kind in entire South East Asia. Its business profile cuts across various sectors of

Engineering/Power utilities and Industry. The Company today enjoys national and international presence

featuring in the "Fortune International-500" and is ranked among the top 12 companies in the world,

manufacturing power generation equipment. BHEL has now 14 Manufacturing Divisions, 8 Service Centres

and 4 Power Sectors Regional Centres besides a large number of project sites spread over India and abroad.

The Company is embarking upon an ambitious growth path through clear vision, mission and committed

values to sustain and augment its image as a world class enterprise.

VISION

World-class, innovative, competitive and profitable engineering enterprise provides total business solutions.

MISSION

The leading Indian engineering enterprise providing quality products systems and services in the fields of

energy, transportation, infrastructure and other potential areas.

VALUES

- Meeting commitments made to external and internal customers.

- Foster learning creativity and speed of response.

- Respect for dignity and potential of individuals.

- Loyalty and pride in the company.

- Team playing.

- Zeal to excel.

- Integrity and fairness in all matters.

HEAVY ELECTRICAL EQUIPMENT PLANT (HEEP)

At Hardwar, against the picturesque background of Shivalik Hills, 2 important manufacturing units of BHEL

are located viz. Heavy Electrical Equipment Plant (HEEP) & Central Foundry Forge Plant (CFFP). The hum of

12

the construction machinery woke up Shivalik Hills during early 60s and sowed the seeds of one of the

greatest symbol of Indo Soviet Collaboration Heavy Electrical Equipment Plant of BHEL. Following is the

brief profile of Heavy Electrical Equipment Plant:-

1. ESTABLISHMENT AND DEVELOPMENT STAGES:

* Established in 1960s under the Indo-Soviet Agreements of 1959 and 1960 in the area of Scientific,

Technical and Industrial Cooperation.

* DPR prepared in 1963-64, construction started from October '63.

* Initial production of Electric started from January, 1967.

* Major construction / erection / commissioning completed by 1971-72 as per original DPR scope.

* Stamping Unit added later during 1968 to 1972.

* Annual Manufacturing capacity for Thermal sets was expanded from 1500 MW to 3500 MW under

LSTG. Project during 1979-85 (Sets upto 500 MW, extensible to 1000/1300 MW unit sizes) with

marginal addition in facilities with the collaboration of M/s KWU-Siemens, Germany.

* Motor manufacturing technology updated with Siemens collaboration during 1984-87.

* Facilities being modernized continually through Replacements / Reconditioning-Retrofitting,

Technological / operational balancing.

2. INVESTMENTS:

* Gross Block as on 31.3.95 is Rs. 355.63 Crores (Plant and Machinery Rs. 285.32 Crores).

* Net Block as on 31.3.95 is Rs. 113.81 Crores (Plant & Machinery Rs. 76.21 Crores).

3. CLIMATIC AND GEOGRAPHICAL:

* Hardwar is in extreme weather zone of the Western Uttar Pradesh of India and temperature varies

from 2

o

C in Winter (December to January) to 45

o

C in Summer (April-June); Relative humidity 20%

during dry season to 95-96% during rainy season.

* Longitude 78

o

3' East, Latitude 29

o

55'5" North.

13

* Height above Mean Sea Level = 275 metres.

* Situated within 60 to 100 KMs of Foot-hills of the Central Himalayan Ranges; Ganges flows down

within 7 KMs from the Factory area.

* HEEP is located around 7 KMs on the Western side of Hardwar city.

4. COMMUNICATION & TRANSPORTATION:

* Telegraphic Code "BHARAT TELEC, HARDWAR"

* TLX Lines: 05909-206 / 207

* Telephones: P&T / STD (01334) 427350-59, 423050-423954

FAX: (0091) (1334) 426462 / 425069 / 426082 / 426254

* Direct Board gauge train lines to Calcutta (Howrah), Delhi, Bombay, Lucknow, Dehradun and other

major cities; Railway Siding for goods traffic connected to Hardwar Railway Station.

5. POWER & WATER SUPPLY SYSTEM:

- 40 MVA sanctioned Electric Power connection from UP Grid (132 KV / 11KV / 6.6 KV) (Connected

load around 185 MVA)

- 26 deep submersible Tube Wells with O.H. Tanks for water supply.

- A 12 MW captive thermal power station is located in the factory premises.

6. FIRE PROTECTION:

- Managed by CISF with around 40 personnel and a host of latest fire fighting equipment and fire

tenders.

7. MANPOWER:

Total strength is 9904 as on 31.3.96 which includes around 3000 qualified Engineers and Technicians

(including substantial number of Post graduates), 5200 skilled artisans and the rest in other

categories.

14

8. TOWNSHIP AND PERIPHERAL INFRASTRUCTURES:

* A large modern township for employees and allied personnel with social and welfare amenities.

* Medical: - Main Hospital (200 beds) 1

- Dispensaries in various 9

Townships sectors

- Occupational health centre 1

* Educational: No. of Schools (including 19

Intermediate levels)

Science Degree College 1

* Residential: Around 6780 quarters.

* Other amenities:

- Good Road network, Shopping Centres, Central Stadium, Community Centres, A Club, Police

Stations, CISF Complex for over 500 CISF personnel, Convention Hall (a most modern Air

Conditioned Auditorium with 1500 seating capacity) and Parks.

9. HEEP PRODUCT PROFILE:

* THERMAL AND NUCLEAR SETS

(Turbines, Generators, Condensers and Auxiliaries of unit capacity upto 1000 MW)

* HYDRO SETS INCLUDING SPHERICAL AND DISC VALVES

(Kaplan, Francis, Pelton and reversible Turbines of all sizes and matching generators and auxiliaries

maximum runner dia 6600 mm)

* ELECTRICAL MACHINES:

(For various industrial applications, pump drives & power station auxiliaries, Unit capacity upto

20000 KW AC / DC)

15

* CONTROL PANELS

(For Thermal / Hydro sets and Industrial Drives)

* LARGE SIZE GAS TURBINES

(Unit Rating: 60-200 MW)

* LIGHT AIRCRAFT

* DEFENSE PRODUCTS

10. HEEP: FACILITIES AND INFRASTRUCTURE

Modernisation and regular upgradation / up gradation of facilities and other infrastructure is a

continuous endeavour at HEEP, BHEL. After initial setting up of the plant during the year 1964-72, in

collaboration with the Soviet Union, the plant facilities and infrastructures have since been continuously

upgraded under various investment projects viz, Stamping Unit Project, LSTG Project, Motor Project,

Governing Components Project, TG Facilities Modernisation, TG Facilities Augmentation, Quality Facilities

Augmentation, EDP projects, Gas Turbine Project, Facilities have also been added and establishments have

been created for new projects in Defence and Aviation Project. Additionally, R &D facilities have also been

created under Generators Research Institute, Pollution Control Research Institute, HTL modernization and

other such schemes.

Today the Plant has unique manufacturing and testing facilities, computerized numerically controlled

machine-tools, Blade shop, heavy duty lathes, milling machines, boring machines, machining centres and

many more. The Over Speed Vacuum Balancing Tunnel created for rotors upto 1300 MW (32T, 6.9 M dia

bladed rotor, 6 rpm upto 4500 rpm) is one of the 8 of its kind in the entire world.

The total spectrum of sophisticated, unique and other facilities at HEEP, Hardwar are the state-of-

the-art in manufacturing processes and can be utilized for a variety of products' manufacture.

16

Brief Description of all the Blocks

Block I-

Block-I, also known as Electrical Machines Block, is designed to manufacture Hydro generators, Turbo

generators and large & medium size AC and DC machines. Testing facilities for Turbo generators, Heavy

motors and medium-size electrical motors are available in the Block itself. There is also a special Test Bed for

testing of turbo generators of capacity of 500 MW and above. Apart from facilities and equipment for

manufacture of turbo generators and electrical machines, the Block also has a Babitting Section. Babitting

of bearing liners for Turbo generators, Turbines, Hydro generators, AC Motors and DC Motors is carried out

in this section. The Block has its own over speed balancing installation; where the dynamic balancing of

Turbo generator-rotors of less than 500 MW rating is done. Rotors having higher rating are balanced in OSBT

of Block-III.

Fabricated components are received from fabrication blocks (Block-II, IV, VI, VIII), while other castings,

forgings are received from CFFP and other sources for Turbo generators, Hydro generators and Electrical

motors. Stampings are received from Stampings manufacture section; Block-VI and coils, bars, insulating

details and sheet metal components are received from Block-IV. These are then machined, assembled, tested

and dispatched.

Block II-

Block-II, also known as Fabrication Block, is a feeder block for various products- Steam Turbines, Hydro

Turbines, Turbo generators, Hydrogenerators, Electrical Machines, Apparatus and Control Gear, Aircraft and

SRGM (Smooth Recoil Gun Mounting). The main processes in this Block are cutting, bending and welding of

metal sheets etc. to form fabricated structures. The Block also has useful equipments like Hydraulic Bending

Presses and Straightening Rollers. Other notable facilities include a CNC six-spindle drilling machine, a

plasma-flame cutting machine, shot-blasting apparatus and various furnaces. The Block also has facilities for

NDT (Non Destructive Testing) of various components. The following Non-Destructive tests can be conducted

17

DP Test (Die Penetration Test), MPI (Magnetic Particle Inspection), UT (Ultrasonic Testing) and Radiography

which includes X-ray and -ray testing.

Block IV-

Block-IV, also called as CIM&ACM (Coil and Insulation Manufacturing & Apparatus and Control Gear

Manufacturing), is a feeder block to Block-I. It is a feeder block for Class F windings for Turbogenerators,

Hydrogenerators and Class F and H insulation for AC and DC motors. It also supplies all insulation

components for Turbogenerators, Hydrogenerators, and motors. Control panels for Turbogenerators,

Hydrogenerators, Industrial drives for motors, and Turbogenerators auxiliaries, contactor relays and master

controllers are also manufactured in this Block.

Block V-

Block-V, also called as Fabrication and Forge Block is again a feeder block. Fabrication work being done in

this block is of Steam Turbine parts like Condenser, Water Box (Front and Rear), assemblies of LP cylinder,

Storage Tanks etc.; Hydro Turbine parts, Hydrogenerator and motor assemblies and components. Forging of

carbon, alloy and stainless steels are manufactured in this block. It is equipped with pneumatic hammers,

gas-fired furnaces and hydraulic manipulators.

Block VI-

Block-VI, also called as Fabrication Block, is also a feeder block. Manufacturing of all types of dies, including

stamping dies and press forms is carried out in one bay, while stamping for Turbogenerators,

Hydrogenerators and motors are manufactured in other bay. The Block is equipped with Welding, Drilling,

Shot Blasting and CNC Flame cutting facilities. The items manufactured in this block are Condensers, Steam

Turbine components (Oil Tanks and Hollow Guide Blades), Hydro Turbine components (Stay Rings),

Hydrogenerator and motors (Stator Frames) etc.

18

Block VII-

Block-VII, also called as Woodworking section, is also a feeder block. Bay-I, known as Packaging section

manufactures packages for packaging and dispatch of various products. Bay-II manufactures wings (made of

Spruce wood) for Light Trainer Aircraft, Swati, manufactured by Aviation Group.

Block VIII-

Block-VIII, also called as Heat Exchanger Block, is designed to manufacture Heat Exchanger Units for Steam

Turbines, Hydro Turbines, Turbogenerators, Hydrogenerators etc. Blanks cut to size and shapes are received

from Block-II and Block-VI. These are assembled, welded and machined. The items manufactured here are

LP Heater, Ejectors, Gland Steam Coolers, Oil Coolers, Oil Tanks, Bearing Covers, Turbine shaft Covers, Oil

Bath, Thrust Bearings and stator frames of motors.

All blocks have a most modern and streamlined layout with mechanized material handling facilities like

inter-bay and inter-block transfer bogies, rail tracks connecting the main blocks with railway system, Electric

Overhead Travelling (EOT) cranes etc. An open gantry connecting all major manufacturing blocks for ease of

inter-block material movement is also provided.

19

Bay wise description of Block III

Block III manufactures Steam Turbines, Hydro Turbines, Gas Turbines and Turbine Blades. Special

tooling is also manufactured in the Tool Room located in the same block. Block III consists of four

bays viz. Bay-I, II, III and IV. It is therefore equipped with a large number of general purpose and

special purpose machine tools to do the machining jobs.

The following is the baywise description of the various machine tools in each of the bays:-

BAY-I:

Bay-I, earlier known as the Hydro turbine shop, is now known as HMS-I (Heavy Machine ShopI).

The various machines in this bay are as follows:

1. Horizontal Boring Machines (Layout No. 1-1, 1-2, 1-11, 1-14, 1-15, 1-28)

These are general purpose horizontal borers, mostly of Russian origin and have now been

retrofitted with DROs (Digital Read Out panels). Their capacity ranges from medium to heavy. A

large variety of operations e.g. boring, tapping, thread whirling on casings viz. HP, IP, ESV & CV etc.

is carried out on these machines. Also, many operations of Hydro turbine runner are carried out on

these machines.

2. CNC Horizontal Boring Machine (Layout No. 1-118)

This horizontal borer supplied by M/s. Skoda, Czech Republic is equipped with Sinumerik 850M

CNC system (Computer Numeric Control System). It has a travel of 12500 mm., has a table size of

4000*3500 mm. and can take a job weighing upto 60 tonnes. Heavier jobs like casings of HP, IP

modules are machined on this setup.

3. Vertical Boring Machines (Layout No. 1-10, 1-18)

These are also general purpose vertical borers, mostly of Russian origin and have now been

retrofitted with DROs. Their variety ranges from medium to heavy duty. Operations like contour

machining scrape milling of joint plane and machining of servomotor housings are carried out on

these machines.

4. Marking Table and Apparatus (Layout No. 1-5, 1-6)

Marking table is one of the most important apparatus, because the accuracy of marking and

subsequent machining depends on the marking table. The marking tables surface is flat upto 0.02

mm/metre and its flatness is to be certified from competent authority every two years. All the jobs

before being sent for machining are brought to this table for marking first.

5. Planer (Layout No. 1-20)

The planer is capable of providing a maximum cutting force of 10,000 kg. and is equipped with 4

tool heads, 2 each in vertical and horizontal directions. The machine is again of Russian origin, being

supplied by M/s. Yefremov Plant, Tiazhstankogidro, USSR.

6. DC Vertical Borer (Layout No. 1-4)

Also called as Universal Turning and Boring Mill, the machine has been supplied by M/s. Kolomna

Machine Tool Works, USSR and has now been retrofitted with DRO panel. It can accommodate a

workpiece of diameter upto 12500 mm. and weighing upto 200 tonnes. The maximum travel of

vertical tool heads from the center of table is 5200 mm.Large jobs like IP outer casing, water box,

condenser plates, runner of hydro turbines etc. are machined on this machine.

20

7. Ram-Borers (Layout No. 1-112, 1-119)

These are horizontal boring machines, supplied by M/s. Skoda, Czech Republic. These are called

as Ram borers due to the fact that they have a high amount of rigidity built in the spindle. Due to

this construction, these machines can sustain huge amount of cuts. The spindle can traverse a

distance of 16000 mm. without being subject to cantilever effects. These machines can handle jobs

of weight up to 160 tonnes. Jobs like boring holes in Control Valves casing, Gas turbine combustion

chamber are done on these machines.

8. OT Platform (Layout No. 1-9)

It is a wooden platform used for overturning of heavy components.

9. Radial Boring machines (Layout No. 1-16, 1-7)

These machines have the added advantage over vertical boring machines that their arm can

swing, in a radius of upto 1500 mm. The spindle of these machines can move axially a distance of

500mm. These machines are portable in nature, and with the help of EOTs (Electrical Overhead

Travelling Cranes) maybe taken to the place desired.

10. Cylindrical Grinder (Layout No. 1-184)

This is a cylindrical grinder, supplied by M/s. National Economic Administrative District Machine

Tool Works, Kharkov, USSR. It has a swing of 800 mm. and can accommodate a job weighing upto 5

tonnes in weight. It is used for grinding stay vanes (of Hydro turbines) and also casings of

servomotors (of Steam turbines).

11. Deep Drilling Machine (Layout No. 1-105)

This again is a special purpose machine, of Russian origin and used for drilling holes in stay vanes

(of Hydro turbines).

12. CNC Horizontal Boring Machine (Layout No. 1-114)

This horizontal borer, supplied by M/s. Wotan, Germany is equipped with Fanuc 12M CNC

system. It has a special tool magazine, which can accommodate upto 40 tools. This machine is being

used for machining of control valves casings. The machine also boasts of an automated chip

removal system (conveyor belt type).

13. Centre Lathes (Layout No. 1-21, 1-22, 1-23)

These are general purpose center lathes, of Russian origin, used for machining of journals and

rotors of spherical and disc valves (of Hydro turbines), Guide vanes etc. These have now been fitted

with DRO control panels.

14. CNC Lathe (Layout No. 1-120)

This CNC lathe has been supplied by M/s. Ravensburg, Germany and is equipped with Sinumerik

820T CNC system. The lathe can accommodate a job of size upto 12000 mm. and 20 tonnes in

weight. It has 3 tool carriers. It is used to turn Tie Rods of Gas Turbine, which have very high

length/diameter ratio. Tie-Rod is a very long bolt (length approx. 10 meter & diameter 350 mm.)

which is used to assemble and hold the gas turbine rotor discs to form a composite turbine rotor.

The machine had been installed especially for machining of Gas turbine Tie-rods, but now is also

being used for machining of short rotors of Steam turbines (e.g. HP rotor). The machine also boasts

of an automated chip removal system (conveyor belt type).

21

15. Heavy Duty Lathe (Layout No. 1-29)

This Russian lathe has been manufactured by M/s. Karamatorsk Heavy Machine Tool Works,

USSR and is under NC control. While the maximum swing is 3200 mm., the distance between

centers is 16000 mm. This lathe is used for a variety of purposes ranging from machining of Hydro

turbine shafts to measurement of runouts of 210 MW Russian design LP rotors.

16. Assembly Beds (Layout No. 1-31, 1-41, 1-35)

These assembly beds are used for the assembly of Guide apparatus, stay ring, etc. of Hydro

turbines.

17. Pit for vertical assembly of Gas turbine rotors

The pit has a hydraulically lifted platform which can travel upto 10 metre in height to facilitate

access to different stages of the rotor. During assembly of Gas turbine rotors, utmost care is needed

to correctly match the Hirth Serrations on the discs face. The platform allows this to be achieved

with ease.

18. Combustion Chamber Assembly Platform

The combustion chamber of a Gas turbine has a metallic shell, lined on the inside by refractory

tiles. These tiles are fitted in the metallic shell in this 3-tier platform.

BAY-II:

Bay-II, earlier known as the Steam turbine shop, is now known as HMS-II (Heavy Machine Shop

II). The various machines in this bay are as follows:

1. Marking Table (Layout No. 2-187)

Marking table is one of the most important apparatus, because the accuracy of marking and

subsequent machining depends on the marking table. The marking tables surface is flat upto 0.02

mm/meter and its flatness is to be certified from competent authority every two years. All the jobs

before being sent for machining, are brought to this table for marking first.

2. Planer (Layout No. 2-189)

The planer, supplied by The Yefremov Plant, Tiazhstankogidro-Press, USSR, is the largest in India

of its type. It can traverse a distance of 12 metres and can accommodate jobs weighing upto 100

tonnes. It has 4 toolheads, 2 each in vertical and horizontal direction, which can provide a maximum

cutting force of 40 tonnes. The machine is powered by 2 motors, each of rating 130 kW and is used

for machining of HP and IP casings.

3. Precision Heavy Duty Lathe (Layout No. 2-181, 2-182, 2-186)

These lathes have been supplied by M/s. Karamatorsk Heavy Machine Tool Works, USSR and

have a swing of 2000 mm. The maximum distance between centers is 8000 mm. and these can

accommodate a job weighing upto 20 tonnes. These lathes are fitted with DRO control panels and

are being used for machining of HP and IP rotors (of 200, 210 MW Steam turbines).

4. CNC Lathe (Layout No. 2-360)

This is the biggest lathe in entire BHEL Hardwar, and has been supplied by M/s. Hoesch-MFD,

Germany. Its distance between centers is 18000 mm. and it can accommodate a job weighing upto

320 tonnes. It is being used for machining for LP rotors (KWU Design) of 500, 200, 210 MW Steam

turbines. It is equipped with Sinumerik 7T CNC system and has three tool carriers. The machine also

boasts of an automated chip removal system (conveyor belt type).

22

5. CNC Lathe (Layout No. 2-394)

This lathe has also been supplied by M/s. Hoesch-MFD, Germany and is equipped with Sinumerik

3T CNC system. Its distance between centers is 8000 mm. and it can accommodate a job weighing a

maximum of 110 tonnes. It is being used for machining of HP, IP rotors of 500, 200, 210 MW Steam

turbines (KWU Design).

6. Ram Borers (Layout No. 2-387, 2-317)

These are horizontal borers manufactured by M/s. Skoda, Czech Republic and have now been

retrofitted with NC Control system. These have the property of extremely rigid spindle arm, which

enables these machines to take a very heavy amount of cut, while at the same time maintaining

extremely high accuracy levels. The spindle arm has been so designed, so as to be unaffected by

cantilever effects, even over a traversing distance of 8000 mm. These machines are being used for

boring, tapping, thread whirling etc. operations on casings HP and IP.

7. CNC Stub Borer (Layout No. 2-420)

This horizontal borer supplied by M/s. Heyligenstaedt, Germany is equipped with Sinumerik 7T

CNC system. Its boring diameter ranges from 625 to 2500 mm. and it can take a job weighing upto

100 tonnes. To accommodate jobs of various sizes, its table rests on CI (Cast Iron) blocks, which

enable the table to be moved up and down. The machine has a very high degree of rigidity built in it

and cuts down the machining time to 25% of the time taken on conventional horizontal or vertical

borers. To control the surface properties of the job, and also to control the temperature rise (which

occurs due to heat build up caused by a large amount of cut), the entire setup is housed in an air-

conditioned chamber. It is being used for roughing of HP and IP inner casings. The machine is one of

the eight of its kind in the entire world.

8. Horizontal Boring Machines (Layout No. 2-185, 2-197, 2-198)

These are general purpose horizontal borers, mostly of Russian origin, and have now been

retrofitted with DRO control panels. Their capacity ranges from medium to heavy. Boring of holes in

HP and IP casings is done on these machines. Also the machining of Guide Blade carriers of Gas

turbines is being undertaken on these machines.

9. OT Platform

It is a wooden platform used for overturning of heavy components.

10. CNC Vertical Borer (Layout No. 2-328)

This vertical boring machine has been supplied by M/s. Homma, Japan and is equipped with

Fanuc 7T CNC system. It has a turning diameter of 4000 mm. and a maximum ram travel of 2200

mm. Machining of holes in HP and IP casings is done on these machines. Also the machining of

Guide Blade carriers of Gas turbines is being undertaken on these machines.

11. Kopp Milling machine (Layout No. 2-389, 2-390)

This milling machine has been supplied by M/s. Kopp, Germany and is being used exclusively for

machining of fir-tree roots in Steam turbine rotors. Fir-tree roots are being currently employed in LP

rotors of 500 MW and 200 MW rating. The machine is equipped with two milling heads that can be

used simultaneously without sacrificing accuracy. This is especially important because of the fact

that LP rotor, being double flow, is symmetrical about the central plane and thus machining of both

sides can be done simultaneously. The machine is fitted with a NC control system and is very

accurate. Fir-tree roots are being machined with the help of form cutters.

23

12. CNC Vertical Borer (Layout No. 2-422)

This vertical boring machine is of Japanese origin and has been supplied by M/s. Osaka Machines,

Japan. It is equipped with Fanuc 6TB, 3TC CNC system. The machine is capable of taking on jobs of

upto 70 tonnes in weight and has 2 boring heads, each of which has a travel of 2200 mm. in vertical

direction. The machine is being used for machining of inner casings of Steam turbines and guide

blade carriers of Gas turbines.

13. Band-Saw Machine

The machine has been recently acquired and has been supplied by M/s. Pehaka, Germany. The

machine is NC controlled and has a laser marking system built in. The machine is being currently

used for making slits in inner casings (to allow for stress-relieving).

14. CNC Vertical Boring machine (Layout No. 2-472)

The machine has been supplied by M/s. Schiess, Germany and is equipped with Sinumerik 850T

CNC system. It has a table diameter of 4000 mm. and max. turning height of 4200 mm. The ram

measures 300*250 mm. and it can take a load of upto 80 tonnes. The machine is being used for

machining of inner casings of Steam turbines and guide blade carriers of Gas turbines.

15. Rotor Assembly (Layout No. D-2)

The rotor assembly area is where the rotors are finally assembled. Here, the manufactured

blades from Bay-IV and the machined rotor are brought in. The fitting of blades and sealing strips

then takes place here.

16. Radial Drilling Machine (Layout No. 2-208)

This machine is portable in nature, and with the help of EOTs maybe taken to the place desired. It

is used for drilling holes in workpieces, as and when required.

17. Rotor Turning Device (Layout No. 2-211)

This machine has an electric motor installed in it and also a platform that can rotate by 90

0

. This is

being used for turning over blade discs of Gas turbine rotors. The rotor disc is picked up by an EOT

and placed on the platform which is in horizontal position. The platform is then rotated by 90

0

and

the disc taken out from the platform. It is now turned over and then placed back on the platform.

The platform is then returned back to its horizontal position. The disc can now by picked up by EOT

again, having been turned over.

18. Indicating Stand (Layout No. 2-412)

The fully bladed LP rotor of 500 MW turbine measures 3853.2 mm. at the point of maximum

diameter. This large a rotor cant even be accommodated on machine no. 2-360 (Sl. No. 4, Bay-II).

Therefore, for machining of shroud and measurements of runouts, this ingenious arrangement has

been made. In this arrangement, a headstock and tailstock have been paired with a flat surface. The

rotor is fixed in these and the tool-post is then calibrated. This arrangement is not very rigid and

thus, can be used only for taking very light cuts.

19. CNC Horizontal Boring Machine (Layout No. 2-473)

This horizontal borer has been supplied by M/s. Skoda, Czech Republic and it is equipped with

Sinumerik 850M CNC system. Its spindle diameter measures 200 mm. and it can take a maximum

load of 60 tonnes. This machine is being used exclusively for machining Gas turbine components

e.g. Casing, Bearing housing etc.

24

20. Gas turbine blading area

The Gas turbine blading area is being used exclusively for assembly of Gas turbine rotor discs and

Guide blade carriers. One of the machines, which has been recently acquired is used for caulking of

blades in discs. This machine is fully automated and the ram is hydraulically energized. Another

noteworthy machine here is Wax Melting Equipment. It is a low temperature electric furnace which

is used to mix and melt Wax and Colaphonium, which is required to arrest the blade movement

during the blade tip machining of stator blade rings.

21. CNC Facing Lathe (Layout No. 2-474)

This lathe which has been supplied by M/s. Ravensburg, Germany is equipped with Sinumerik

820T CNC system. It has a maximum turning length of 2000 mm. It is used basically for facing rotor

discs but can turn other components also. The machine also boasts of an automated chip removal

system (conveyor belt type).

22. Creep-feed Grinding machine (Layout No. 2-491)

This machine has been supplied by M/s. ElbSchliff, Germany and has been equipped with

Sinumerik 3GG CNC system. . This machine grinds the Hirth serration on rotor disc surfaces. Hirth

serrations are radial grooves teeth on both the faces of the rotor discs. Torque is transmitted

through these serrations, which are very accurately ground. The machines accuracy is of the order

of +/- 1 Arc/sec. and it can take a maximum load of 20 ton.

23. CNC Surface Broaching machine (Layout No. 2-485)

The machine has been supplied by M/s. MarbaixLapoint, UK and is equipped with Sinumerik

850M CNC system. It has a broaching capacity of 320 kN, and a broaching stroke of 10.3 meter with

a cutting stroke speed of 25 m/min. The machine has a very high accuracy of +/- 3 Arc/sec. It is used

to make groove on the outer diameter of rotor discs for the fitting of moving blades on the discs.

The machine is only one of the two of its kind in the world; with the other one being possessed

by M/s. Creusot-Loire, France.

24. Broach Sharpening machine (Layout No. 2-487)

This machine has been bought from M/s. Landriani, Italy and is equipped with Selca CNC system.

It can accommodate a workpiece of maximum diameter upto 250 mm. and length upto 200 mm.

BAY-III:

Bay-III is known as Governing and Light Machine Shop. The shop organization is described

below:

1. Bearings and Miscellaneous Parts Machining Section-

This section is equipped with small and medium size basic machine tools e.g. lathes, Milling

machines, Horizontal Borer, Vertical Borer, Drilling machine etc. for manufacture of bearings and

other miscellaneous parts of turbine. Here, machining of Torus/Spherical piece and spherical

support takes place, along with manufacturing of bearings from forging blanks.

2. Sealing and Diaphragm Machining Section-

It is equipped with medium size Vertical Boring, Horizontal Boring, Plaining, Drilling machines etc.

wherein castings of Sealing housings, Liner housings, Forgings of Rotor Discs, castings and fabricated

25

Diaphragms and components of camframes are machined. It is also equipped with CNC machining

center. Precision Horizontal Boring, Plano-Milling machines etc. are for manufacture of Governing

Casings, Servo Casings and other medium parts of governing and main Turbine assemblies.

One of the most important machining operations taking place in this section is the machining of

U and I sealing rings (used in Steam turbines). This is a technically demanding process because of

the fact that these rings are made of Mnemonic metals, which have Nickel content higher than

50%. Presence of such high amounts of nickel greatly reduces the machinability of these metals.

This problem is addressed by using extremely slow feed rates.

3. Governing Machining Section-

This section is equipped with medium size and small size lathes, CNC lathes, Milling, Grinding

(Internal, External and Surface), Drilling, Slotting and Honing machines. Governing assembly parts

are machines here. Honing of valve spindles as well as their superfinishing also takes place in this

section.

4. Diaphragm and Governing Assembly Section-

It is equipped with deflection testing equipment for Diaphragms, Dynamic Balancing machine for

balancing impeller of centrifugal oil pumps and small fittings and assembly equipment. Governing

test stand is equipped with facilities like Oil pumping unit, Pressure receiver, Servomotor,

Overspeed testing of Emergency governor.

5. Light Machine Shop-

In addition to normal conventional machine tools, it is equipped with CNC lathes, CNC milling,

CNC Vertical Boring, precision milling, planetary grinding machines etc. for the manufacture of small

and medium precision of governing and other turbine parts.

Inconel (alloy having Nickel content higher than 65%) components machining also takes place

in this section. These Inconel components are used in Gas Turbines.

26

Block III Turbine and Auxiliary Block

Block III manufactures Steam Turbines, Hydro Turbines, Gas Turbines and Turbine Blades. Special tooling

are also manufactured in the Tool Room located in the same block.

The Block consists of 4 Bays, viz. Bay-I and II of size 36X378 metres and 36X400 metres respectively and

Bay-III and IV of size 24X402 metres and 24X381 metres respectively. The Block is equipped with the facilities

of Electric Overhead Travelling (EOT) Cranes, compressed air, Steam, Over speed Balancing Tunnel (OSBT),

indicating stand for Steam turbine rotors, one Test stand for testing 210 MW steam turbines Russian design,

one Test stand for Hydro Turbine Guide Apparatus and two separate Test Stands for the testing of Governing

Assemblies of Steam and Hydro Turbines.

MANUFACTURING FACILITIES

1. HYDRO TURBINES

For manufacturing of Hydro Turbines, Bay-I has the following sections:

(a) Circular Components machining Section-

This section is equipped with a number of large/heavy size Horizontal and Vertical Boring Machines,

Drilling Machines, Centre Lathes, Marking Table and Assembly Bed. The major components machined in this

section are Spiral Casing with Stay Ring, Spherical and Disc Valve bodies and Rotors.

(b) Runner and Servo Motor Housing Machining Section-

This section is equipped with NC/CNC and conventional machines comprising Heavy and Medium size

Vertical and Horizontal Boring Machines, Centre Lathes, Grinding machines and Drilling machines, Marking

Table, Assembly Bed, Assembly Stands for Steam Turbine and Gas Turbine assemblies and wooden platform

for overturning heavy components.

Hydro Turbine Runners, Servomotors, cylinders, Labyrinth Ring, Regulating Ring, Stay Ring, Turbine Cover,

Lower Ring, Kaplan Turbine Runner Body and Blades are machined here.

Steam Turbine components like cylinders and rotors along with Gas Turbine components like

Combustion chamber outer casing, Flame Tube, Dome, Tie-rod, Guide Blade carriers and Bearing

Pedestals are also machined in this section.

(c) Guide Vanes and Shaft Machining Section-

This section is equipped with Heavy Duty Lathes up to 16 metres bed, CNC turning machines, Horizontal

Boring Machine, Heavy Planer, Deep Drilling Machine, Boring Machines and Assembly Beds. Turbine shafts,

Guide Vanes, Journals and Rotors of Spherical and Disc valves are machined here. Rotors of Steam Turbines

are also machined in this section.

(d) Assembly Section-

In this section, assembly and testing of Guide Apparatus, Disc Valves, Spherical Valves, Servomotor shaft

and combined boring of Coupling Holes are done.

(e) Preservation and Packing Section-

Final preservation and packing of all the Hydro Turbine components/assemblies is done here.

27

(f) Small components machining Section-

This section is equipped with Planetary Grinding machine, Cylindrical Grinding machine, Small size

lathes, Planers and Vertical and Horizontal Boring machines. Small components like Bushes, Levers,

Flanges etc. and Governing Assemblies are machined here.

(g) Governing Elements Assembly and Test Stand Section-

This section is equipped with facilities like oil Pumping Unit, Pressure Receiver, Servomotors etc. for

assembly and testing of Governing Elements.

2. STEAM TURBINES

The facilities and parts manufactured in the various sections of Steam Turbine manufacture are as follows:

Turbine casing machining Section-

It is equipped with large size Planer, Drilling, Horizontal Boring, Vertical Boring, CNC Horizontal and

Vertical Boring machines etc. Fabrication work like casings, pedestals etc. are received from Fabrication Block

II.

Rotor Machining Section-

It is equipped with large size machine tools like Turning Lathe, CNC Lathes, Horizontal Boring machines,

special purpose Fir-Tree Groove Milling machine etc. Some rotor forgings are imported from Russia,

Germany, and Italy etc. And some are indigenously manufactured at CFFP, BHEL, and Hardwar.

(a) Rotor Assembly Section-

This is equipped with Indicating Stand; small size Grinding, Milling, Drilling machines, Press and

other devices for fitting Rotors and Discs. Machined Rotor, discs and Blades are assembled here.

Balancing and Over speeding of Rotor is done on the dynamic balancing machine.

(b) Turbine Casing Assembly Section-

Machined casings are assembled and hydraulically tested by reciprocating pumps at two times

the operating pressure.

(c) Test Station-

Test Station for testing of 210 MW USSR design Steam Turbine at no load is equipped with

condensers, Ejector, Oil Pumps, Oil Containers, Steam Connections etc. required for testing. Over

speed testing is done for emergency Governor. Assembly Test Stands for different modules of

Siemens design are equipped with accessory devices.

(d) Painting, Preservation and Packing Section-

All the parts are painted, preserved and packed here for final dispatch.

(e) Bearings and Miscellaneous Parts Machining Section-

This section is equipped with small and medium size basic machine tools e.g. lathes, Milling

machines, Horizontal Borer, Vertical Borer, Drilling machine etc. for manufacture of bearings and

other miscellaneous parts of turbine.

28

(f) Sealing and Diaphragm Machining Section-

It is equipped with medium size Vertical Boring, Horizontal Boring, Planing, Drilling machines etc.

wherein castings of Sealing housings, Liner housings, Forgings of Rotor Discs, castings and fabricated

Diaphragms and components of cam frames are machined. It is also equipped with CNC machining

centre.

Precision Horizontal Boring, Plano-Milling machines etc. are for manufacture of Governing

Casings, Servo Casings and other medium parts of governing and main Turbine assemblies.

(g) Governing Machining Section-

This section is equipped with medium size and small size lathes, CNC lathes, Milling, Grinding,

Drilling, Slotting and Honing machines. Governing assembly parts are machines here.

(h) Diaphragm and Governing Assembly Section-

It is equipped with deflection testing equipment for Diaphragms, Dynamic Balancing machine for

balancing impeller of centrifugal oil pumps and small fittings and assembly equipment. Governing

test stand is equipped with facilities like Oil pumping unit, Pressure receiver, Servomotor, Over

speed testing of Emergency governor.

(i) Light Machine Shop-

In addition to normal conventional machine tools, it is equipped with CNC lathes, CNC milling,

CNC Vertical Boring, precision milling, planetary grinding machines etc. for the manufacture of small

and medium precision of governing and other turbine parts.

3. GAS TURBINES

All the components of Gas Turbine are machined and assembled using the facilities available for

manufacturing of Steam and Hydro turbines except the following facilities which are procured

exclusively for the manufacturing of Gas Turbine and are installed in the areas specified for Gas

Turbine manufacturing:

(a) Hydraulic lifting Platform-

This facility is used for assembly and disassembly of G.T. rotor. This is a hydraulically operated

platform which travels upto 10 meter height to facilitate access to different stages of rotor. This is

installed in Bay-I assembly area.

(b) CNC Creep Feed Grinding Machine-

This is installed in Gas Turbine machining area Bay-II extension. This machine grinds the hirth

serration on rotor disc surfaces. Hirth serrations are radial grooves teeth on both the faces of the

rotor discs. Torque is transmitted through these serrations, which are very accurately ground.

(c) External Broaching Machine-

This machine is installed in G.T. machining area and is used to make groove on the outer diameter

of rotor discs for the fitting of moving blades on the discs.

(d) CNC Facing Lathe-

This machine is installed in G.T. machining area and is used basically for facing rotor disc but can

turn other components also.

(e) CNC Turning Lathe-

This machine is installed in Bay-I Heavy Machine Shop and is used to turn Tie Rods of Gas

Turbine, which have very high length/diameter ratio. Tie-Rod is a very long bolt (length approx. 10

29

meter & dia. 350 mm.) which is used to assemble and hold the gas turbine rotor discs to form a

composite turbine rotor.

(f) Wax Melting Equipment-

This is a low temperature electric furnace installed in Gas Turbine blading area in Bay-II. It is used

to mix and melt Wax and Colaphonium, which is required to arrest the blade movement during the

blade tip machining of stator blade rings.

(g) Gas Turbine Test Bed-

This test bed is installed near the Gas Turbine machining area in Bay-II. This facility is used to

finally assemble the gas turbine. Combustion Chambers are not assembled here, which are

assembled with main assembly at the site.

(h) Combustion Chamber Assembly Platform-

This facility is a 3-tier platform installed in Bay-I assembly area and is used for assembly of

Combustion Chambers of Gas Turbine.

30

Blade Shop

Introduction:

Major part of Turbine Blade Machining Shop is located in Bay-IV of Block-III. In this shop various

types of Steam Turbine and Gas Turbine Compressor blades are machined from bar stock, drawn

profile, precision and envelope forgings. It is a batch production shop comprising of various kinds of

CNC Machines and Machining Centres, besides various special purpose and general purpose

machines. The layout of equipments is as per technological sequence of the manufacturing process.

Blade shop implements various On Line Quality Control Techniques through Run Charts and Control

charts. This shop is divided into four distinct areas. Details of facilities are given in various schedules

of Section-II.

2. Manufacturing Facilities:

i) Plain Milling Section

It prepares accurate reference surfaces on the blade blanks by milling and grinding

operation. It also manufactures the brazed type blades by induction brazing of drawn profile

and suitably machined spacers. This section carries out banking by Band Saws, rhomboid

grinding on Duplex grinding machines and thickness grinding on Surface grinders.

ii) Copy Milling Section

The Semi blanks prepared from plain milling section are further machined by copy Milling

Machines / CNC machines (CNC Heller and BSK Bed type Klopp, BFH / BEK Knee type

Machines) for concave and convex aero-dynamic profile forms, (HTC-600, BFK Machines) for

expansion angles, Compound taper grinding of radial plane is carried out by Surface grinders.

It comprises of T-root machining centres for machining of T-root.

iii) LP Section

This area deals with all types of free standing and forged blades for steam Turbine

Compressor. The free standing blades are cerrobend casted in boxes to hold the blade with

respect to the profile. These blades roots are subsequently machined on NTH, MPA-80A and

31

T30 Machining Centres. There is a five station 360

o

circular copy milling machine for

machining the profile of envelope forged blades / stocks for Steam Turbine and Gas Turbine

Blades. It also has 3D copy Milling and CNC Machines with digitizing features for Tip-thinning,

Fitted milling. The inlet edge of the last stage of Low pressure Turbine Moving blades are

hardened on Special Purpose Flame Hardening equipment.

iv) Polishing Section

Blade Contours are ground and polished to achieve the desired surface finish and other

aerofoil requirements.

There are also other small sections e.g. Fitting Section, Tool and Cutter Grinding, Tooling

Repair Section in Blade Shop.

v) Inspection Device

- 3 D Coordinate Measuring Machines for taper and rhomboid checking.

- Moment weighing Equipment

- Real time Frequency analyzer for checking frequency of free standing blades.

- Contour plotter for plotting of blade profile with various magnifications.

- Fir tree root inspection device.

- Magna spray crack detection equipment.

vi) Miscellaneous

There are other important facilities e.g. High rack storage system for fixtures. Compactor

system storage for finished blades. Jib cranes and EOT cranes for material handling. The semi

finished batches of blades are kept in special boxes for inter-operation movements. An AGV

(Automated Guided Vehicle) is also located in LP Section of Blade Shop for better material

movement.

32

3.0 MANUFACTURING PROCESS

The manufacturing process of turbine blades primarily depends on the type of blade e.g. Bar type,

Brazed type, free standing (Forged type), Gas Turbine Compressor blades. The bar type and brazed

type blades are also known as drum stage glades. The manufacturing technology of each of these

blades along with recommended machine tools / equipment is furnished below.

3.1 BAR TYPE BLADES

PROCESS / OPERATION MACHINE TOOL/EQUIPMENT USED

i. Blanking of area material Circular saw/band saw

ii. Sizing to rectangular shape Hor. Milling Machine

iii. Thickness grinding Surface grinder

iv. Rhomboid milling Duplex milling machine

v. Rhomboid grinding Duplex grinding machine

vi. Milling perpendicularity on both ends Hor. Milling machine

vii. Milling radius on surround Hor. Copy milling m/c

viii. Finish milling of convex and

concave profile

Hor. Copy milling / CNC

Hor. Milling machine

ix. Milling expansion faces of convex

And concave sides at root and shroud

Hor. Copy milling m/c/

CNC milling m/c

x. Root slot/root chamfer and

Radit at root and shround

Milling

2 spindle T-root roughing, m/c and

root radius copy milling m/c, T-root

machining centre

xi. Taper grinding Surface grinder

33

xii. Grinding and polishing of profile

And expansion faces

Abrasive belt polishing m/c

xiii. Final Rounding, chamfering etc. Manual fitting.

3.2 BRAZED TYPE BLADES

PROCESS / OPERATION MACHINE TOOL/EQUIPMENT USED

i. Cutting of drawn profile & spacer blank Hor. Milling machine

ii. Sizing to rectangular shape Hor. Milling machine

iii. Thickness grinding Surface grinder

iv. Rough and finish milling of internal profile

of spacer

Hor. Milling machine

v. Cutting-off spacer Abrasive cutting

vi. Brazing of drawn profile and spacer Right frequency inducting brazing installation

vii. Milling of width Duplex milling machine

viii. Pin rough and Root slot Vert. Milling m/c

ix. External profile rough and finish machining Hor. Milling machine

x. Pin turning Pin turning lathe

xi. Grinding and polishing Abrasive belt polishing m/c

xii. Debarring and rounding Manual fitting

34

3.3 FREE STANDING BLADES

PROCESS / OPERATION MACHINE TOOL/EQUIPMENT USED

i. Grinding of ref. Belts Abrasive belt polishing

ii. Milling of inlet & outlet edge 3D Vert. Copy milling m/c

iii. Center hole drilling CNC machining Centre

iv. Encapsulating with cerrobend alloy Cerrobend casting equip.

v. Re-melting of cerrobend alloy Fir-tree root machining center

vi. Re-melting of cerrobend alloy Cerrobend casting equip.

vii. Machining of fillets Vertical 3D copy milling machine

viii. Grinding and polishing Abrasive belt polishing

ix. Cutting-off blade tip Abrasive cutting machine

x. Inlet edge hardening Frame hardening equip. (if required)

xi. Blade tip rounding Vert. 3-D copy milling m/c

xii. Tip thinning (if reqd.) -do-

35

3.3 GAS TURBINE BLADES

PROCESS / OPERATION MACHINE TOOL/EQUIPMENT USED

i. Cerrobend casting Cerrobend casting equip.

ii. Root machining Hor. Machining center

iii. Re-melting of cerrobend alloy Cerrobend casting equip.

iv. Profile checking Vert. Stand

v. Length cutting Circular saw/hor. Milling m/c

vi. Tenon Hor. Milling m/c

vii. Grinding and polishing of fillet Abrasive belt polishing m/c

36

Broad Specification of Major/Important Machine Tools

and Machines

A: CNC MACHINE TOOLS

CNC HORIZONTAL BORERS:

1. Item Description : CNC Horz. Borer

Model : RAPID 6C

Supplier : WOTN, GERMANY

CNC Control System : FANUC 12M

Spindle Dia. : 200mm

Table : 4000 x 4000 mm

Max. Load on Table : 100 T

Travers : X=20000, Y=5000, X=1400mm

Ram traverse : W = 1000 mm

Ram size : 400 x 400 mm

Power Rating : 90 KW

Weight of the m/c : 111 T

ATC Capacity : 60 Nos.

Plan No. : 1-227 (Block-I)

2. Item Description : CNC Stub Borer

Model : DW 1800

Supplier : HEYLIGENSTAEDT, GERMANY

CNC Control System : SINUMERIK 7T

Boring Dai : 625 2500 mm

Table : 4000 x 4000 mm

Headstock Travel : 4000 mm

Spindle Speed : 0.5 90 RPM (in 4 Steps)

Power Rating : 63 KW

37

Max. Load Capacity : 100 T

Weight of the m/c : 72 T

Plan No. : 27-420 (Block-III)

3. Item Description : CNC Horz. Borer (2 Nos.)

Model : W200 HB NC

Supplier : SKODA, CZECH

CNC Control System : SINUMERIK 850 M

Spindle Dia. : 200 mm

Traverse : X=12500,

Y=5000,

Z=2000mm

CNC LATHES

4. Items Description : CNC Centre Lathe

Model : D-1800 NYF

Supplier : HOESCH MFD, GERMANY

CNC Control System : SINUMERIK 3T

Centre Distance : 8000 mm

Swing Over Carriage : 1800 mm

Swing Over Bed : 2400 mm

Spindle Speed : 0 125 RPM

Power Rating : 92 KW

Weight of the Job : 110 TON

Weight of the m/c : 124 TON

Plan No. : 2-394 (Block-III)

5. Item Description : CNC Centre Lathe

Mode : D-2300 NYFS-1

Supplier : HOESCH MFC, GERMANY

CNC Control System : SINUMERIK 7T

38

Centre Distance : 18000 mm

Swing Over Carriage : 2300 mm

Swing Over Bed : 2900 mm

Spindle Speed : 5 125 RPM

Power Rating : 110 KW

Weight of the job : 320 TON

Weight of the m/c : 216 TON

Plan No. : 2-360 (Block-III)

6. Item Description : CNC Centre Lathe

Model : KV2-1100 CNC

Supplier : RANVENSBURG, GERMANY

CNC Control System : SINUMERIK 820 T

Centre Distance : 12000 mm

Centre Height : 900 mm

Swing Over Carriage : 1100 mm

Swing Over Bed : 1400 mm

Max. Turning Length : 12000 mm

Spindle Speed : 2-600 RPM

Longitudinal Cutting Feed (Z-Axis) : 1-5000 mm / min.

Transfer Cutting Feed (X-Axis) : 1-5000 mm/min.

Main Spindle Drive Motor : 95.5 KW DC

Max. Feed Force Z/X Axis : 45000 N

No. of Tool carriers : 3

Plan No. : 1-120 (Block-III)

CNC MILLING MACHINES

7. Item Description : CNC Horz. Milling M/c (6 Nos.)

Model : BFH-15

Supplier : BATLIBOI, INDIA

39

CNC Control System : SINUMERIK 810 M

Table : 1500 x 400 mm

Traverse : X=1170 mm

Y=420 mm

Z=420 mm

Spindle Speed : 45 to 2000 RPM

Power Rating : 11 KW

Max. Load Capacity : 630 Kg

Weight of the m/c : 4200 Kg

Plan No. : 2-449, 2-453, 2-454, 2-459, 2-460 (Block-

III:TBM)

8. Item Description : Universal Milling M/cs (2Nos.)

Model : BFK-15

Supplier : BATLIBOI, INDIA

CNC Control System : SINUMERIK 810 M

Table : 1500 x 400 mm

Traverse : X=1170 mm

Y=420 mm

Z=420 mm

Spindle Speed : 45-2000 RPM

Power Rating : 11 KW

Max. Load Capacity : 630 Kg

Weight of the m/c : 4200 Kg

Plan No. : 2-463, 2-466 (Block-III: TBM)

9. Item Description : CNC Bed Type Milling M/c

Model : FSQ 80 CNC

40

Supplier : TOSKURIM, CZECH

CNC Control System : SINUMERIK 810 M

Table : 3000 x 800 mm

TEE SLOT 28H7

Traverse : X= 3000 mm

Y= 870 mm

Z= 850 mm

Spindle Speed Range : H 2500 RPM

Spindle Drive Power : 18 KW continuous

22 KW intermittent

Spindle Head Size : 620 x 500 incldg ram

543 x 420 encldg ram

ATC Capacity : 24 Nos.

Table Load : 2500 Kg

Plan No. : 2-484 (Block-III)

CNC MACHINING CENTRES

10. Item Description : SPL. Purpose 6 Station T-Root Machining Centre (2nos.)

Supplier : MIH, JAPAN

CNC Control System : FANUC 7M

Indexing Table : 1900 mm dia

Indexing Position : 6 Nos.

Plan No. : 2-356, 2-41 (Block-III: TBM)

11. Item Description : SPL Purpose FIR Tree Root M/cing Cenre

Model : NTH 200

Supplier : RIGID, SWITZERLAND

CNC Control System : SINUMERIK 7M

41

Table : 1400 x 1400 mm

Traverse : X= 1950 mm

Y= 900 mm

Z= 600 mm

Spindle Speed : 30600 RPM

No of Spindle : 4

Power Rating : 22 KW

Plan No. 2-354 (Block-III TBM)

CNC VERTICAL BORERS

12. Item Description : CNC Vertical Borer

Model : TMD 40 / 50

Supplier : OSAKA MACHINES, JAPAN

CNC Control System : FANUC 6TB, 3TC

Table dia : 4000 mm

Turning dia : 5000 mm

Turning Height : 4200 mm

Spindle Speed : 0.23-30 RPM

No. of Ram : 2

Power Rating : 75 KW

Max. Load Capacity : 70T

Machine Weight : 100 T

Max. Ram Travel (Vertical) : 2200 mm

Plan No. : 2-422 (Block-III)

13. Item Description : CNC Vertical Borer (2 Nos.)

Model : 40 DZ

Supplier : SCHIESS, GERMANY

42

CNC Control System : SINUMERIK 850 T

Table : 4000 mm

Max. Turning dia : 5000 mm

Max. Turning Height : 4200 mm

Ram size : 300 x 250 mm

Table Speed : 0.63 63 RPM

Max. Vertical Travel of Ram : 2200 mm

Power Rating : 71 KW

Table Load Carrying Capacity : 80 T

ATC Capacity : 12 Nos.

Plan No. : 1-235 (Block-I), 2-472 (Block-III)

14. Item Description : CNC Vertical Borer

Model : 32 DS 250

Supplier : SCHIESS, GERMANY

CNC Control System : SINUMERIK 850T

Table : 2500 mm

Table Load Carrying Capacity: 25T

Max. Turning Dia : 3200 mm

Max. Turning Height : 2200 mm

Ram Size : 210 x 250 mm

Max. Travel of Ram : 1400 mm

Table Speed : 0.8 160 RPM

Power Rating : 56 KW

ATC Capacity : 12 Nos.

Plan No. : 2-483 (Block-III)

OTHER SPECIAL PURPOSE CNC MACHINES

15. CNC SURFACE BROACHING M/C

Make : Marbaix Lapointe, UK

43

Model : Champion 32 /10, 300

CNC System : SINUMERIC 850 M

Broaching capacity (pulling force) : 320 KN

Broaching slide stroke : 10.3 mm

Broaching slide width : 1500 mm

Max tool length (continuous /row) : 9650 mm

Broaching Speed (cutting stroke) : 1-25 M/min

Broaching Speed (return stroke) : 60 M/min

Drive power rating : 135 KW

Broaching slide movement : Electro-mechanical

Maximum noise level : < 80 Dbs

Max. dia of the disc (mountable) : 2300 mm

Max. weight of the job : 3000 Kgs

Indexing & rotating tables | : 1500 mm, 1000 mm

Indexing accuracy : +/- 3 Arc sec.

Plan No. : 2-485

16. CREEP FEED GRINDING M/C

Make : ELB CHLIFE, GERMANY

Model : ELTAC SFR 200 CNC

CNC System : SINUMERIC 3 GG

Work-piece diameter : 200 2000 mm

Work height : 2400 mm

Rotary & indexing table dia. : 2050 mm

Indexing accuracy : +/- 1 ARC SEC

Max. load capacity : 20000 KG

Y-axis (grinding head movement)

Vert. Traverse : 750 mm

44

Z- axis (grinding head support)

Movement on cross rail)

Horizontal traverse : 2400 mm

Traverse feed rate : 02 1200 mm /min

Grinding head main support

Drive motor : 34 KW

Grinding wheel max. dia. : 500 mm

Max. width : 100 mm

Bore : 203.2 mm

Surface speed : 16-35 M/Sec.

Plan No. : 2-491

17. BROACH SHARPENING M/C

Make : LANDRIANI, ITALY

CNC System : SELCA

Work-piece diameter : Upto 250 mm

Work Length : 200 mm

Plan No. : 2-487

B: NON-CNC MACHINE TOOLS

(1) PRECISION HEAVY DUTY LATHE