Professional Documents

Culture Documents

Works Instruction For Piping Welding Inspection

Uploaded by

Abg SepulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Works Instruction For Piping Welding Inspection

Uploaded by

Abg SepulCopyright:

Available Formats

PIPING INSPECTION PROCEDURE

Doc. No Rev. No Date Page

: : : :

K-KEM/QP/IT/PPg/23 0 01.03.2009 Page 1 of 5

b.

AMENDMENT AND REVISION RECORD.

The K-KEM Quality Assurance Engineer will be responsible for revising this document in accordance with the Document Control Procedure and for obtaining the approval of the Departmental Manager for all revisions. The revised section or paragraph will be indicated coloring (light green). An amendment to this Document will necessitate the issue of a revised copy of the complete document, all amendments will be recorded in the register below: Amendment Number Revision No./ Issued No. Amendment and Originator Details Name/Position/Department Ref. Section Receive Date

PIPING INSPECTION PROCEDURE

Doc. No Rev. No Date Page

: : : :

K-KEM/QP/IT/PPg/23 0 01.03.2009 Page 2 of 5

c. a. b. c.

CONTENTS. Piping Inspection Procedure Cover Page. Amendment and Revision Record. Contents.

1. 2. 3. 4. 5. 6.

Purpose. Scope. Abbreviation. Responsibility. Procedure. Appendices.

PIPING INSPECTION PROCEDURE

Doc. No Rev. No Date Page

: : : :

K-KEM/QP/IT/PPg/23 0 01.03.2009 Page 3 of 5

1.

PURPOSE. The purpose of this procedure is as a guidelines to all inspection personnels for carrying out an inspection for piping that joint by welding. This to ensure that the inspection are carry out in accordance to the specified codes and project specifications.

2.

SCOPE. These covers for the piping that were in process and newly constructed piping.

3.

ABBREVIATION. RT QA QAM QMS NDT Jt W1 Sch Acc/Abu Radiations Test. Quality Assurance. Quality Assurance Manual. Quality Management System. Non-Destructive Test. Joint. Welder Identification. Piping Schedule. The inspection accepted by the inspector namely Abu.

4.

RESPOSIBILITY. The inspector's shall be fully responsible in the total implementation of this procedure. The development of this work instruction shall be by the section head of the entire department and shall be review by the QA engineer and approve by the Technical Manager prior to the execution of the job.

5.

PROCEDURE. Before Welding. The inspector shall review the following; ISOMETRIC drawings. Understanding of the weld map is importance. The NDT requirements by the client specifications and the code requirements. The inspection interfaces, as to ensure that reworks is minimised. To ensure that the requirement of inspection tools are available, such as welding gage, temple stick, paint marker, steel ruler and torchlight. Welding procedures specification (WPS), Welder qualification test record (WQT), Materials mild certificates (piping & welding filler metals). The ITP for the particular project. All the above informations shall assist the inspector while carrying out the inspection.

PIPING INSPECTION PROCEDURE

Doc. No Rev. No Date Page

: : : :

K-KEM/QP/IT/PPg/23 0 01.03.2009 Page 4 of 5

During Welding. Fit-Up and Welding Visual Inspection. The inspector shall check the fit-up of the newly joint pipe prior to start welding by the welders. Ensure the welders are being qualified earlier. The inspector is to mark on the pipe that is been visually inspected and as a minimum, the informations written on the pipe's joint are as followings; Joint No Fit-up Root Fill/Cap Jt. 001 Sch 80-Sch 80 W1 W2 Inspector ID Acc/Abu Acc/Abu Acc/Abu

After Welding. Upon completion of the welding by the welders, then, the inspector is to carry out a visual inspection. Any finding found during the inspection shall be recorded into his note book and at the same time to marked the finding (e.g. pin hole) by using the paint marker onto the pipe's weldment that having the defect. The marking is for the purpose of an immediate action by the welder to repair or to remove the defect. After the repair works is completed, then again the same inspector has to come for visual inspection. It is importance that, the inspector to ensure the repair works is done in accordance to the approved repair procedure. Reporting. All of the inspection done is to be reported in a standard report format established in the Appendix 1. The numbering system for the inspection report shall as followings; Rpt. No. : aaa/bbb. Note : aaa bbb Client's name. Running number.

6.

APPENDICES. Appendix 1 Piping Welding Inspection Report.

PIPING INSPECTION PROCEDURE

Doc. No Rev. No Date Page

: : : :

K-KEM/QP/IT/PPg/23 0 01.03.2009 Page 5 of 5

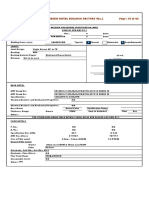

Appendix 1 Piping Welding Inspection Report

Rpt. No. :

NO

JT. NO.

JT. DESCRIPTIONS (Sch - Sch)

PIPE ISOMETRIC NO

REF. CODES

MAT'L SPEC.

WPS NO

WELDER NO. (Root/Fill/Cap)

VISUAL INSPECTION RESULT

Inspected by;

Approved by (Client Inspection Representative);

.................................................................................................. Name : Date :

.................................................................................................. Name : Date :

You might also like

- Inspection In Manufacturing A Complete Guide - 2020 EditionFrom EverandInspection In Manufacturing A Complete Guide - 2020 EditionNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- 03-01 Material TraceabilityDocument1 page03-01 Material TraceabilityAngel AngeleyeNo ratings yet

- File 9 - API 570 - Vol-1 - B 31.3 NotesDocument5 pagesFile 9 - API 570 - Vol-1 - B 31.3 NotesAnonymous 2zcLfLjWNo ratings yet

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- SOP - 06 - Visual and Dimensional ProcedureDocument22 pagesSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Painting Repair Procedure Rev01webDocument4 pagesPainting Repair Procedure Rev01webAneesh JoseNo ratings yet

- Material Inspection Report: Project Name Date InspDocument22 pagesMaterial Inspection Report: Project Name Date InspRafiqKuNo ratings yet

- Field Joint Coating Selection TableDocument3 pagesField Joint Coating Selection Tableicemage1991100% (1)

- Ferrite Content Measurement Guide for FERITSCOPE MP30Document5 pagesFerrite Content Measurement Guide for FERITSCOPE MP30Fasil Paruvanath100% (1)

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- GTAW Welding ParametersDocument1 pageGTAW Welding ParameterssahadNo ratings yet

- WI Dimensional Control Sign1Document6 pagesWI Dimensional Control Sign1gusyahri001No ratings yet

- Reduce Repair Rate of Welding ProcessesDocument3 pagesReduce Repair Rate of Welding ProcessesAnouar AbdelmoulaNo ratings yet

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- Flange Joint Box-UpDocument1 pageFlange Joint Box-UpJR MohanNo ratings yet

- Presentase JKT CS WUR MDDocument25 pagesPresentase JKT CS WUR MDErick Savrinaldo100% (1)

- Piping External Visual Inspection ProcedureDocument3 pagesPiping External Visual Inspection Procedurecamasa2011100% (1)

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselDocument6 pagesF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoNo ratings yet

- Pig Launcher Fabrication and Installation Activity PlanDocument1 pagePig Launcher Fabrication and Installation Activity PlanbeqsNo ratings yet

- Welding Procedure Specification and Procedure Qualification RecordDocument2 pagesWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanNo ratings yet

- Reconstruction of Pakistan Refinery Tank T-53Document16 pagesReconstruction of Pakistan Refinery Tank T-53javaidahmedshaikh100% (1)

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping EngineersVignesh MohanNo ratings yet

- Welding Procedures and Welding Qualiy Control For PipingDocument18 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- Doha West Power Station RAP Washing ScheduleDocument4 pagesDoha West Power Station RAP Washing ScheduleASHIL PRABHAKARNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Job Description NDTDocument4 pagesJob Description NDTNDTInstructorNo ratings yet

- Wash Tank Repair & Improvement Minas and Petapahan ProjectDocument9 pagesWash Tank Repair & Improvement Minas and Petapahan ProjectEndika Alfan100% (2)

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Tank Inspectiom ChecksheetDocument3 pagesTank Inspectiom Checksheetyskushwah16100% (1)

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocument1 pageInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiNo ratings yet

- Madina Group W.L.L. Procedure Qualification Record 152Document38 pagesMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNo ratings yet

- Welding Procedure SpecificationsDocument2 pagesWelding Procedure SpecificationsGerhard Kemp0% (1)

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocument26 pagesHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahNo ratings yet

- Minera Chinalco Peru Project InstructionsDocument2 pagesMinera Chinalco Peru Project InstructionsLuisNo ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Non-Conformity Report: Corrective Action RequestDocument2 pagesNon-Conformity Report: Corrective Action Request3582618No ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- Cutting Procedure GuideDocument3 pagesCutting Procedure Guiderial100% (1)

- Liquid Penetrant Testing Report SummaryDocument1 pageLiquid Penetrant Testing Report SummaryAbdul NaveedNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- As Run Sheet-Pqr-051Document14 pagesAs Run Sheet-Pqr-051Anonymous rYZyQQot550% (1)

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- ONGC Effluent Plant Pipe Installation GuideDocument14 pagesONGC Effluent Plant Pipe Installation GuideNithin Mathai100% (1)

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

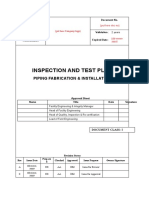

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- API 570 Piping InspectorDocument2 pagesAPI 570 Piping InspectorRinto AgustinoNo ratings yet

- Sample # 1Document3 pagesSample # 1Clarence Ferro100% (1)

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- Inspection & NDT ControlDocument2 pagesInspection & NDT ControlRyan Gillespie75% (4)

- 3.2 Develop The Material Control PlanDocument9 pages3.2 Develop The Material Control Planjesus_bs100% (1)

- Vijay CV Cswip NaceDocument3 pagesVijay CV Cswip NaceVijay RajputNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Tank Construction Quality ProceduresDocument36 pagesTank Construction Quality ProceduresJagdish Busa100% (2)

- HOPM03-2022-AAH - Tender NoticeDocument4 pagesHOPM03-2022-AAH - Tender NoticeAbg SepulNo ratings yet

- 20N SellsheetDocument2 pages20N SellsheetAbg SepulNo ratings yet

- Goodway Coil Cleaning Pro Guide 04-2014Document4 pagesGoodway Coil Cleaning Pro Guide 04-2014Abg SepulNo ratings yet

- Three-phase Asynchronous Motor Used Specially for Coal Grinding MachineDocument5 pagesThree-phase Asynchronous Motor Used Specially for Coal Grinding MachineAbg SepulNo ratings yet

- Pocket Lamp 2016 V2Document30 pagesPocket Lamp 2016 V2Abg SepulNo ratings yet

- PSMB PPT 1 13Document1 pagePSMB PPT 1 13Abg SepulNo ratings yet

- GreenergyLED - CompanyProfile 2017 - ReduceDocument16 pagesGreenergyLED - CompanyProfile 2017 - ReduceAbg SepulNo ratings yet

- XR30CX GBDocument4 pagesXR30CX GBAbg SepulNo ratings yet

- BASF Silo Strengthe Presentation - Rev.01 - FINAL SUBMISSIONDocument15 pagesBASF Silo Strengthe Presentation - Rev.01 - FINAL SUBMISSIONAbg SepulNo ratings yet

- Ex-Hgx34p-315-4 S R407CDocument9 pagesEx-Hgx34p-315-4 S R407CAbg SepulNo ratings yet

- Heat Load Estimation E20 Form-SIDocument1 pageHeat Load Estimation E20 Form-SIAbg Sepul70% (10)

- FullrmpDocument92 pagesFullrmpAbg SepulNo ratings yet

- DC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecDocument12 pagesDC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecarsolNo ratings yet

- Wireless Mouse m325 Quick Start GuideDocument2 pagesWireless Mouse m325 Quick Start GuideFabolos 9No ratings yet

- Applied Fluid Mechanics: Viscosity of FluidsDocument22 pagesApplied Fluid Mechanics: Viscosity of FluidsMaggie HepditchNo ratings yet

- Manual Servicio SubaruDocument5,963 pagesManual Servicio SubaruCristian Mauricio Alarcon RojasNo ratings yet

- Pipeline Tow MethodDocument25 pagesPipeline Tow MethodctrlaltdestroyNo ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- STN Cat Novelties Vol.i 2023Document89 pagesSTN Cat Novelties Vol.i 2023ruba herbawiNo ratings yet

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDocument25 pagesPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNo ratings yet

- Revision of Bs 8002, 8004, AND 8081Document34 pagesRevision of Bs 8002, 8004, AND 8081Rupesh Kaushik100% (1)

- Service Menu - SamyGODocument5 pagesService Menu - SamyGOVenkatesh SubramanyaNo ratings yet

- Establishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitectureDocument3 pagesEstablishing OPC UA Connectivity With Rockwell Automation® Integrated ArchitecturehuiyitNo ratings yet

- Determining The Redundancy FactorDocument6 pagesDetermining The Redundancy FactorEdris Salehi GolsefidiNo ratings yet

- Guess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerDocument31 pagesGuess Questions of Aramco Written Examination For Hse Supervisor / Engineer / OfficerAlam Shamsher0% (1)

- 03.job Specification Instrumentaton PDFDocument27 pages03.job Specification Instrumentaton PDFshareyhouNo ratings yet

- Hanson G209 (SW Valves)Document12 pagesHanson G209 (SW Valves)AKSHEYMEHTANo ratings yet

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Ps 1 SolDocument3 pagesPs 1 SolPang XsNo ratings yet

- Course OutlineDocument14 pagesCourse OutlineTony SparkNo ratings yet

- Unit Conversion Heat TransferDocument5 pagesUnit Conversion Heat TransferFamela GadNo ratings yet

- LMDQDocument601 pagesLMDQMohd Azamuddin Mohd SaifullizanNo ratings yet

- ESD Protection in CMOS: Characterization and Failure AnalysisDocument113 pagesESD Protection in CMOS: Characterization and Failure AnalysisElisavNirolfNo ratings yet

- Acsomega 9b01541Document9 pagesAcsomega 9b01541Benedictus EduardoNo ratings yet

- Supercharging: Superchargers & TurbochargersDocument11 pagesSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

- Parts List 8198417 RevCDocument12 pagesParts List 8198417 RevCSonaina KhanNo ratings yet

- Biogas Calculator TemplateDocument27 pagesBiogas Calculator TemplateAlex Julian-CooperNo ratings yet

- Bilge Alarm Monitor OMD 11Document22 pagesBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- Demographically Similar EntriesDocument1 pageDemographically Similar EntriesTahsildar MydukurNo ratings yet

- Cotta Transfer Case Lube PlanDocument3 pagesCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNo ratings yet

- ITU ISUP Release Cause CodesDocument5 pagesITU ISUP Release Cause Codesdelgado08No ratings yet

- For Steel Cage Lapping by Using U-ClipDocument4 pagesFor Steel Cage Lapping by Using U-Cliptin aungtunNo ratings yet