Professional Documents

Culture Documents

Hawkeye Micro Split Current Switch

Uploaded by

qambar786Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hawkeye Micro Split Current Switch

Uploaded by

qambar786Copyright:

Available Formats

VERIS INDUSTRIES

CURRENT MONITORING

INSTALLATION GUIDE

H300

Micro Split-Core Go/No Go Current Switch

Installers Specifications

Amperage Range Sensor Supply Voltage Isolation Temperature Range Humidity Range Frequency Status Output Ratings Off State Leakage Terminal Block AWG Range Terminal Block Torque Range

Compliant

300

US Patent 7,193,428 (other patents pending)

0.15 - 60A Continuous Induced from monitored conductor 600VAC rms (UL), 300VAC rms (CE), insulated conductors only -15 to +60C 10-90% RH non-condensing 50/60Hz N.O. 1.0A@30VAC/DC non-polarity sensitive Open switch represents 1+ MEG ohms of resistance 16-22 AWG 7 in-lb

RoHS

Specification Note: For CE compliance, conductor shall be insulated according to IEC 610101:2001, Installation Category III or equivalent. The product design provides for functional insulation only.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes. This equipment must only be installed and serviced by qualied electrical personnel. Read, understand and follow the instructions before installing this product. Turn o all power supplying equipment before working on or inside the equipment. Use a properly rated voltage sensing device to conrm power is o. DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION Only install this product on insulated conductors.

quick install

1. Plan the installation: Locate a mounting surface for the removable mounting bracket that will allow the monitored conductor to pass through the iris, or window when it is installed and keep the product at least 1/2 from any uninsulated conductors (CE). Determine cable routing for the controller connection, allowing wiring to reach the mounting location. 2. Drill holes to mount the bracket to the chosen surface using the included screws. 3. Wire the output connections between the sensor and the controller (solid-state contact). 4. Snap the sensor over the wire to be monitored and push the latch until it is securely closed. Clip the assembly to the mounting bracket. 5. Close up and power up.

Failure to follow these instructions will result in death or serious injury.

NOTICE

This product is not intended for life or safety applications. Do not install this product in hazardous or classied locations. The installer is responsible for conformance to all applicable codes. Mount this product inside a suitable re and electrical enclosure.

DimEnsions

0.18 (x2) (5 mm)

1.5 (38 mm)

Wiring ExamplE

Insulated Conductor ONLY BUILDING AUTOMATION CONTROLLER POWER SOURCE

0.6 (15 mm)

DI DI

Push to "lock" in place

0.3 (8 mm) 6 AWG max.

1.6 (40 mm)

1.8 (45 mm)

POWER SOURCE

1.2 (30 mm)

UNIT VENT HEATER

Z205622-0A

PAGE 1

2009 Veris Industries USA 800.354.8556 or +1(0)503.598.4564 / support@veris.com

08091

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris V logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

VERIS INDUSTRIES

H300

INSTALLATION GUIDE

opEration

The H300 is a current-sensitive switching device which monitors current (amperage) in the conductor passing through it. A change in amperage in the monitored conductor which crosses the switch threshold will cause the resistance of the FET status output to change state, similar to the action of a mechanical switch. In this model, the threshold is fixed at 150mA AC max. The status output is suitable for connection to building controllers, or other appropriate data acquisition equipment operating at up to 30 volts. The H300 requires no external power supply to generate its output.

troublEshooting

Problem

No Reading at Controller

Solution

Check for control voltage at sensor (<30V) Check for amperage in monitored conductor (> 0.15A) Assure that sensor core mating surfaces are clean and that the core clamp is completely closed

notEs

For load currents greater than sensor maximum rating: Use a 5 Amp (H68xx series) Current Transformer (CT) as shown.

240A

> 60A (Sensor max.)

300A:5A

H68xx5A

DANGER: 5A CTs can present hazardous voltages. Install CTs in accordance with manufacturer's instructions. Terminate the CT secondary before applying current.

CAUTION

Derate the products maximum current for the number of turns through the sensing window using the following formula.

RISK OF EQUIPMENT DAMAGE

Rated Max. Amps Number of Turns = Max. monitored Amps e.g. : 100A 4 Turns = 25 Amps max. in monitored conductor

Failure to follow these instructions can result in overheating and permanent equipment damage.

For load currents less than sensor minimum rating: Wrap the monitored conductor through the center hole and around the sensor body to produce multiple turns through the "window." This increases the current measured by the transducer.

<0.15 A (Sensor min.)

0.1A

Controller must be programmed to account for the extra turns. e.g., if four turns pass through the sensor (as shown) the normal threshold current must be divided by 4.

4x

Z205622-0A

PAGE 2

2009 Veris Industries USA 800.354.8556 or +1(0)503.598.4564 / support@veris.com

08091

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris V logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

You might also like

- 30V - 2A Power Supply ST4073 OperatingDocument11 pages30V - 2A Power Supply ST4073 Operatingilesh22No ratings yet

- ManualOmronE5CWL, ControladorDocument1 pageManualOmronE5CWL, ControladorJose CruzNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Hawkeye 221transductor de Alta Corriente InstalacionDocument1 pageHawkeye 221transductor de Alta Corriente InstalacionJossi Perez ANo ratings yet

- TPR-Pro (ENG)Document2 pagesTPR-Pro (ENG)alokedas11No ratings yet

- ZEN-PA03024: Model Number StructureDocument8 pagesZEN-PA03024: Model Number Structuregustaf parlindunganNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Smag 62Document24 pagesSmag 62sadrianocNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- AC Current Probe Model MN05: User ManualDocument4 pagesAC Current Probe Model MN05: User ManualPaulo DiasNo ratings yet

- Em266 enDocument17 pagesEm266 enगणेश पराजुलीNo ratings yet

- Manual Analizador Extech 382090Document27 pagesManual Analizador Extech 382090EFRAIN HERRERA RODRIGUEZNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- Spec 49Document2 pagesSpec 49വടിവാൾ പ്രാഞ്ചിNo ratings yet

- Phase-Sequence Phase-Loss Relay: K8AB-PH1-LDocument8 pagesPhase-Sequence Phase-Loss Relay: K8AB-PH1-LNguyễn Thanh QuangNo ratings yet

- Manual MT-SX48 - EN - 170216Document65 pagesManual MT-SX48 - EN - 170216MiguedxtrNo ratings yet

- PX Series DatasheetDocument3 pagesPX Series DatasheetSamantha GraciNo ratings yet

- Service Manual: Model: - SZ2 MONO SeriesDocument20 pagesService Manual: Model: - SZ2 MONO SeriesHamza AbbasiNo ratings yet

- Phase Sequence Relays)Document8 pagesPhase Sequence Relays)sabrahimaNo ratings yet

- Digital Multimeter DT830 Series ManualDocument12 pagesDigital Multimeter DT830 Series ManualJohn G.75% (4)

- BM235 Manual EEVblog PDFDocument30 pagesBM235 Manual EEVblog PDFRavenSpyNo ratings yet

- Hanyoung Ax Serie Instruction Manual Eng PDFDocument4 pagesHanyoung Ax Serie Instruction Manual Eng PDFMorita HdzNo ratings yet

- Is 3 eDocument2 pagesIs 3 emohamedwalyNo ratings yet

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

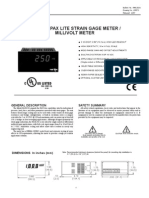

- Model Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedDocument8 pagesModel Paxlsg - Pax Lite Strain Gage Meter / Millivolt Meter: C Us Listed Us ListedJosé Tomas CisnerosNo ratings yet

- Clamp Sensor - Model 8113Document16 pagesClamp Sensor - Model 8113chockanan suwanprasertNo ratings yet

- LG Flatron t530s Chassis CA-138Document42 pagesLG Flatron t530s Chassis CA-138victorino2009No ratings yet

- Color Monitor: Service ManualDocument43 pagesColor Monitor: Service ManualzeugenioNo ratings yet

- Moosh I Meter Manual Rev 1Document23 pagesMoosh I Meter Manual Rev 1Mauricio Cesar Molina ArtetaNo ratings yet

- 32 Ls 400Document44 pages32 Ls 400drone001No ratings yet

- +manual HANYOUNG AXseries PDFDocument2 pages+manual HANYOUNG AXseries PDFWilliams MedinaNo ratings yet

- Instruction Manual: Kyoritsu Electrical Instruments Works, Ltd. Tokyo, JapanDocument1 pageInstruction Manual: Kyoritsu Electrical Instruments Works, Ltd. Tokyo, JapanEz FerdinandoNo ratings yet

- Sharp 20f540 Chassis Ga2 SMDocument36 pagesSharp 20f540 Chassis Ga2 SMWilmer MendozaNo ratings yet

- 300 Series Photoelectric Smoke Detector SystemDocument4 pages300 Series Photoelectric Smoke Detector SystemgeoffffNo ratings yet

- Instruction Manual: Model 7SL High/Low LimitrolDocument48 pagesInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNo ratings yet

- AC Current Clamp: Instruction SheetDocument6 pagesAC Current Clamp: Instruction SheetKhaled Aboul-ELaNo ratings yet

- DTV2760CDocument57 pagesDTV2760Cplasmapete100% (1)

- TSG131A Instructions Service ManualDocument286 pagesTSG131A Instructions Service ManualbzrmiltosNo ratings yet

- Bose 1600VI 1800VI Profesional Service ManualDocument60 pagesBose 1600VI 1800VI Profesional Service ManualSteven100% (2)

- LA 76931S 7N DatasheetDocument20 pagesLA 76931S 7N DatasheetjulioescandonNo ratings yet

- Liteon c1770nslDocument36 pagesLiteon c1770nslGabriel CristeaNo ratings yet

- ETM45ENDocument3 pagesETM45ENDiego CordovaNo ratings yet

- LG R60V26 Manual de ServicioDocument70 pagesLG R60V26 Manual de ServicioElectropartes NicaraguaNo ratings yet

- Compaq Monitor CPQ Fs7550-V7550Document32 pagesCompaq Monitor CPQ Fs7550-V7550KathafiNo ratings yet

- Tenma Multimeter 72-7735Document45 pagesTenma Multimeter 72-7735tititwister100% (1)

- CT720g S774AAR5S2NCDocument45 pagesCT720g S774AAR5S2NCAnonymous CJnGHNNo ratings yet

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- Instalation ManualDocument9 pagesInstalation Manualjoseluisrosglz1678No ratings yet

- Aoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Document44 pagesAoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Luis Gamalier Zurita0% (1)

- Op MFM384 MFM384-C Op347-V05Document4 pagesOp MFM384 MFM384-C Op347-V05Lyle ThompsonNo ratings yet

- Service Manual: Xga Color Monitor Model: 710BDocument59 pagesService Manual: Xga Color Monitor Model: 710Bmasava03No ratings yet

- True-Rms Remote Display Digital Multimeter: Getting Started ManualDocument16 pagesTrue-Rms Remote Display Digital Multimeter: Getting Started Manualhuunghi130882No ratings yet

- Eurotherm 3216 PDFDocument6 pagesEurotherm 3216 PDFRoyalty GouldNo ratings yet

- Zenith H20H52DT - Service ManualDocument48 pagesZenith H20H52DT - Service ManualrolaperezNo ratings yet

- Voyager & Discovery Quick StartDocument12 pagesVoyager & Discovery Quick StartDiego Alejandro Gallardo IbarraNo ratings yet

- Kew Snap: Instruction ManualDocument24 pagesKew Snap: Instruction ManualClaudio CostaNo ratings yet

- 20-21 Ipads Shopping GuideDocument1 page20-21 Ipads Shopping Guideapi-348013334No ratings yet

- ZIOIEXCELDocument4 pagesZIOIEXCELSunil GNo ratings yet

- Summer 2019 - OSD Exam Paper MS - FINALDocument13 pagesSummer 2019 - OSD Exam Paper MS - FINALAsifHossainNo ratings yet

- 2008 Almocera vs. OngDocument11 pages2008 Almocera vs. OngErika C. DizonNo ratings yet

- File 1379580604 PDFDocument9 pagesFile 1379580604 PDFMuhammad Salik TaimuriNo ratings yet

- Best Evidence Rule CasesDocument5 pagesBest Evidence Rule CasesRemy Rose AlegreNo ratings yet

- BA Trolley AMC PO Vijay Sabre Cont - PrintDocument7 pagesBA Trolley AMC PO Vijay Sabre Cont - PrintParag ChandankhedeNo ratings yet

- k90mcc6 PDFDocument381 pagesk90mcc6 PDFTammy JohnsonNo ratings yet

- Cbi LNG Storage US Rev8 LoresDocument4 pagesCbi LNG Storage US Rev8 LoresVilas AndhaleNo ratings yet

- Key GroupsDocument11 pagesKey GroupsJose RodríguezNo ratings yet

- Belimo Fire and Smoke Brochure en UsDocument8 pagesBelimo Fire and Smoke Brochure en UsAmr AbdelsayedNo ratings yet

- Activity 2.1 Test Your Food Safety IQDocument3 pagesActivity 2.1 Test Your Food Safety IQAustin PriceNo ratings yet

- DS Introduction To TreeDocument23 pagesDS Introduction To TreePrashant JainNo ratings yet

- Corporation Law Syllabus With Assignment of CasesDocument4 pagesCorporation Law Syllabus With Assignment of CasesMarilou AgustinNo ratings yet

- Orig Chap 1Document11 pagesOrig Chap 1hazel alvarezNo ratings yet

- MyLabX8 160000166 V02 LowRes PDFDocument8 pagesMyLabX8 160000166 V02 LowRes PDFhery_targerNo ratings yet

- Lapid V CADocument11 pagesLapid V CAChami YashaNo ratings yet

- SD HospitalDocument2 pagesSD HospitalSam PowelNo ratings yet

- TSD OSD Portal Quick Start Guide V1.0Document5 pagesTSD OSD Portal Quick Start Guide V1.0sijovow282No ratings yet

- Java 9 Real - TimeDocument57 pagesJava 9 Real - TimeDiego AmayaNo ratings yet

- Job Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouDocument97 pagesJob Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouShah NawazNo ratings yet

- MT7605B DSDocument7 pagesMT7605B DSVishal dtuNo ratings yet

- Communication To Offer-ContractsDocument20 pagesCommunication To Offer-ContractsAarif Mohammad BilgramiNo ratings yet

- HD785-7 Fault Codes SEN05900-01-3Document16 pagesHD785-7 Fault Codes SEN05900-01-3ISRAEL GONZALESNo ratings yet

- Subject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDDocument4 pagesSubject: Industrial Marketing Topic/Case Name: Electrical Equipment LTDRucha ShirudkarNo ratings yet

- Assy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NODocument11 pagesAssy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NOFaiz Qilafa ZimamNo ratings yet

- PneumaxDocument2 pagesPneumaxandresNo ratings yet

- Shortcrete PDFDocument4 pagesShortcrete PDFhelloNo ratings yet

- Optimizing The Office.: Transforming Business ProcessesDocument10 pagesOptimizing The Office.: Transforming Business ProcessesNOSHEEN MEHFOOZNo ratings yet

- Hr-Analytics (Case Study)Document3 pagesHr-Analytics (Case Study)Jeeshan IdrisiNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)