Professional Documents

Culture Documents

Pre-Qualification Evaluation Criteria and Weighting April 2009 - Example

Uploaded by

Almas IqbalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre-Qualification Evaluation Criteria and Weighting April 2009 - Example

Uploaded by

Almas IqbalCopyright:

Available Formats

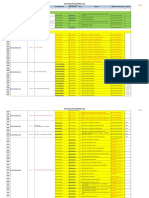

Scoring Sheet - Overview

Item Description Overall Score 2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 Organisation Company structure, ownership etc National / international enterprise Operating independently, subsid, branch, etc Regional offices Main fields of activities (oil, gas, chemicals) and the scope/extent of services provided; Major bank relations (confirm with PRL) JVs for execution of projects Employee turnover rates (last 3 years) Litigation history, if applicable Current Workload Current and expected workload (12-24 months) in job-hours/month and relating to the total jobhours/month Recently executed projects, espec FEED/EPCm & CPIF, scope, mahours & value Declaration of Compliance Parental Company Guarantee Professional Indemnity Insurance Secrecy agreement Financial Status Annual turnover (last 3 financial years & 2008 YTD) Tabulations financial status (confirm with PRL) Experience Process experience and Shell licences DEPs' experience Brownfield and Revamp experience EPC & EPCm Brownfield and Revamp experience Project sizes and original estimate vs. final cost comparisons Knowledge transfer and lessons learned Local Conditions Experience in Pakistani contracting market place Level of familiarity of ocal content requirements (confirm with PRL) Refining projects in Pakistan in: FEED or BDEP EPC and EPCm Experience in permitting systems in general & Pakistan (confirm with PRL) National and international Subcons in Pakistan; Brownfield project experience in Pakistan; Logistics experience in Pakistan; Environmental impact studies experience EPCm Project Execution and Management

2.10 2.11 2.12 2.13 2.14 2.15 2.16 3 3.1 3.2 3.3 3.4 3.5 3.6 4 4.1 4.2 4.3 4.3.a 4.3.b 4.4 4.5 4.6 4.7 4.8 5

5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 5.11 5.12 5.13 5.14 5.15 5.16 5.17 5.18 5.19 6 6.1 6.1.a 6.1.a.i 6.1.a.ii 6.1.a.iii 6.2 6.2.a 6.2.a.i 6.2.a.ii 6.2.b 6.2.b.i 6.3 6.3.a 6.3.a.i 6.3.a.ii

Structure of project organisation inc. organogram & steering committees Number, education, experience of PMs and PEs CV, track record of indicative PM and PEs Experience with EPCm reimbursable contracts Experience with incentive contracts (in partic CPIF) Comments on the use of incentives Organisation (office) for project delivery Organogram and composition of brownfield project team Communication lines and responsibilities Selection of project team members Involvement of process in equipment selection Number, education, experience of Discipline Engineers, inc CV & track record Number, education, experience of Construction Mgrs/Supervisors; inc CV & track record Indicative configuration and size of project team(s) during various phases Location of project team(s) during various project phases Main operating (management) centre Reporting structure, interfaces and relationships between the teams / work centre / sites & responsibility per process unit Use of VIPs Experience / relationship IPA

Management of HSE Risks and Sustainable Development Leadership and commitment Commitment to HSE through leadership How senior managers involved in HSE management Evidence of commitment at all org levels How positive culture towards HSE promoted, inc examples Policy and Strategic Objectives HSE policy documents HSE company policy document Overall responsible person for HSE in the organisation Availability of policy statements to employees Drawing policy statement to the attention of employees & advising of changes Organisation, Responsibilities, Resources, Standards and Documentation Organisation - commitment and communication How mgmt involved in HSE activities, objective-setting and monitoring Most senior person accountable for implementing HSE policy on-site How company structured to manage & communicate HSE effectively inc organogram to 6.3.a.iii illustrate 6.3.a.iv Provisions for HSE communication meetings Frequency, participation & agenda of HSE meetings, inc MoM 6.3.a.v How HSE competencies & responsibilities in job descriptions of: PM, Construction Mgr, HSE 6.3.a.vi Manager, Disciplines, safety officer 6.3.a.vii Ratio safety officers / workforce in Construction & Commissioning 6.3.a.viii Ratio safety officers & supervisors / workforce of (sub)contractors. 6.3.b 6.3.b.i 6.3.c 6.3.c.i Competence and Training of managers/ supervisors/senior site staff/ HSE advisers HSE training of Mgrs & Supervisors at all levels inc. details and competence/training matrix Competence and General HSE training Ensuring new & existing employees know basic & company HSE & how knowledge kept up to date

6.3.c.ii 6.3.c.iii 6.3.c.iv 6.3.d 6.3.d.i 6.3.d.ii 6.3.d.iii 6.3.d.iv 6.3.e 6.3.e.i 6.3.e.ii 6.3.e.iii 6.3.f 6.3.f.i 6.3.f.i.1 6.3.f.i.2 6.3.f.i.3 6.3.f.ii 6.3.f.iii 6.3.f.iv 6.3.f.v 6.3.f.vi 6.g 6.g.i 6.g.ii 6.g.iii 6.g.iv 6.4 6.4.a 6.4.a.i 6.4.a.ii 6.4.b 6.4.b.i 6.4.b.ii 6.4.b.iii 6.4.c 6.4.c.i 6.4.c.ii 6.4.d 6.4.d.i 6.4.e

Ensuring new & existing employees trained on job-related hazards & company requirements Ensuring job competency in managing HSE hazards and risks. How training implemented on a project (ensuring timeliness, quality, effectiveness) Specialised training How company identifies areas where specialised training required, which areas & training details How hazards (radioactive, asbestos, chemical, etc) identified, assessed and controlled, incl. training details Training details for personnel in live areas / systems Ensuring only properly qualified & certified personnel perform specific activities e.g. welding HSE qualified staff - additional training Any HSE qualifications over those provided in house and local legislation, incl details Additional training (incl refreshers) for supervisors & HSE officers HSE qualifications, knowledge, skills, experience specified when employing HSE Manager, incl CV Project HSE Manager Assessment of suitability of (sub)contractors/ other companies Describe how you assess: HSE competence HSE record of the (sub)Cons Capability of (sub)Cons to meet your/Clients HSE standards & requirements Standards (sub)Cons must meet, incl example How to ensure standards are met & verified Engaging (sub)Cons on HSE incl communication forums & agenda Experience with (sub)Cons that do not meet HSE requirements Promoting positive HSE-culture during a project, e.g. incentives Standards Company HSE performance standards in a project; Experience complying with Client's HSE performance standards How new industry / regulatory standards identified and implemented Overall structure for producing, updating & disseminating standards & details Hazards and Effects Management Hazards and effects assessment Techniques for identification, assessment, control & mitigation of hazards and effects What activities needs specific work method statement & job hazard analysis. Incl example Exposure of the workforce Experience & methods of monitoring workforce exposure to chemical, biological or physical agents Experience performing Health Risk Assessments & implementing remedial actions Experience of pre-employment medical checks, fitness & occupational illnesses reporting and monitoring Handling of chemicals Experience in storing, handling & working with chemicals & related HSE hazards mgmt Minimising exposure and reminding workforce on actual & potential hazards (chemicals, noise, radiation, etc.) Personal protective equipment Provision & upkeep of protective equipment and clothing (standard issue & specialised activities) Waste management

6.4.e.i 6.4.f 6.4.f.i 6.4.g 6.4.g.i 6.4.g.ii 6.4.h 6.4.h.i 6.4.h.ii 6.5 6.5.a 6.5.a.i 6.5.a.ii 6.5.a.iii 6.5.a.iv 6.5.b 6.5.b.i 6.5.b.ii 6.5.c 6.5.c.i 6.5.c.ii 6.5.d 6.5.d.i 6.5.d.ii 6.5.d.iii 6.5.d.iv 6.5.e 6.5.e.i 6.5.e.ii 6.5.e.iii 6.6 6.6.a 6.6.a.i 6.6.a.ii 6.6.a.iii 6.6.b 6.6.b.i 6.6.b.ii 6.6.c 6.6.c.i 6.6.d 6.6.d.i 6.6.e

Experience setting up waste management system, incl ident., class., min., disp., monitoring, reporting & liaison with local authorities Drugs and alcohol Drugs and alcohol policy? If so pre-employment and random testing in-place? Camp management Experience & approach labour force living arrangements (housing, camp, catering management, etc.); Welfare programmes in previous projects. Security Experience in security management on previous projects Typical organisation of activities related to security management, incl organogram Planning and Procedures HSE or operations manuals Company HSE manual (/Ops Manual incl HSE) in-place? If so incl copy Ensuring working practices on-site consistent with HSE Manual Consequence management, disciplinary procedure, non-compliance in HSE Promoting positive HSE-culture during a project, e.g. incentives Permit To Work (PTW) PTW experience specifically in brownfield projects, in / near live plants Engaging supervisors & safety officers in PTW compliance & workplace job hazard analysis Equipment control and maintenance Ensuring plant & equipment correctly registered, controlled & maintained Preventative maintenance system (incl if HSE critical equipment incl. in preventative maintenance system) Road Safety Management Managing road transport activities, incl. Document Previous project experience managing road transport activities Organogram of personnel involved in vehicle/drivers/journey mgmt incl. fit in the organisation Addressing drivers training & behaviour Emergency Response Experience in emergency response planning and preparedness Organogram of the personnel in emergency response incl. fit in the organisation Training & refresher programmes on emergency response preparedness Implementation and Performance Monitoring Management and performance monitoring of work activities Supervising & monitoring performance Performance criteria in company incl. examples Arrangements for passing on results & findings to (1) Base management and, (2) Site employees HSE performance achievement awards Awards for HSE? If so, list HSE performance achievements in previous projects Statutory notifiable incidents /dangerous occurrences Statutory notifiable incidents in last 5 yrs (safety, occupational health & environ.). If so, provide details Improvement requirement and prohibition notices Improvement requirements or prohibition notices by national body/regulator or prosecution under HSE legislation in last 5 yrs. If so, provide details. HSE performance records

6.6.e.i 6.6.e.ii 6.6.e.iii 6.6.e.iv 6.6.f 6.6.f.i 6.6.f.ii 6.6.f.iii 6.6.f.iv 6.7 6.7.a 6.7.a.i 6.7.a.ii 6.7.a.iii 6.7.a.iv 6.8 6.8.a 6.8.a.i 6.8.b 6.8.b.i 7 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 7.10 8 8.1 8.2 8.3 8.4 8.4.a 8.4.b 8.4.c 8.5

Records of incidents & HSE performance last 5 yrs? If so, provide: No. Fatalities, LTIs, Lost Workday Cases. Medical Treatment Cases and Restricted Work Day Cases. Fatal Accident Rate, LTIF & TRCF for each year. Include your company definitions How health performance recorded incl. examples How environmental performance recorded How often HSE performance reviewed & by whom Incident investigation and reporting Who conducts incident investigations How findings & learnings following investigation / incident communicated and implemented Example of incident investigation System for near miss, unsafe acts & conditions reporting Auditing and Review Auditing Policy on HSE auditing in-place? How policy specifies standards for auditing & auditor qualifications Companys HSE Plans include schedules for auditing? If so, range of auditing covered How effectiveness of auditing verified & how management reports & follows up audits. Attach project audit HSE Management - Additional Features Memberships of Associations Participation in relevant industry, trade & governmental organisations Additional features of your HSE management Details of other HSE features or arrangements not described elsewhere Quality Quality Management Quality policy & management commitment to quality Competence mapping, verification and auditing description Standard of QA system (e.g. ISO) & how long in-place Index of QA-manual Org. that carried out last quality appraisal (& if national or international org) & copy of appraisal report List of internal quality audits over last 2 yrs inc. disciplines audited & copy of last audit report Systems & resources to ensure quality of procured equipment & services Quality Assurance / Control QA / QC processes for the E,P & implementation phases Experience &/or knowledge of Pakistans local standards & requirements Practices for computer based engineering calculations Planning, Scheduling and Progress Control Number, education & experience of Project Scheduler inc. CV & track record of indicative Scheduler Structure of the planning organisation. Dedicated planning dept in-place? Level of involvement of engineering departments in planning Extent of management involvement in project controls Planning & scheduling methods in use: Simple bar charting Network scheduling Other Use of probabilistic planning (e.g. Monte Carlo analysis)

8.6 8.6.a 8.6.b 8.6.c 8.6.d 8.7 8.8 8.9 8.9.a 8.9.b 8.9.c 8.9.d 8.9.e 8.10 8.10.a 8.10.b 8.11 8.12 8.13 9 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 9.10 9.11 9.12 10 10.1 10.2 10.3 10.4 10.5 11 11.1 11.2 11.3

Programs/procedures applied (& if integrated project control system used) in: Planning & Scheduling Cost Control Time keeping & cost allocation system for job-hours, reproduction, computer use Project progress and recovery methodology. Computer system(s) used for planning & scheduling Network set-up based on WBS of scope & CTR method? Describing technique used for progress measurement: Deliverables Percent completion based on weighting factors and milestones achieved Earned man-hours Duration spent Frequency of progress reporting Track record of previous projects incl.: Relation between forecasted time schedules & actual schedules achieved Relation between forecasted costs & actual costs View on 30 month schedule Critical path & project key milestones practices Practices to optimise FEED/Design/Implementation schedule regarding CAPEX reduction Estimating and Cost Control Number, education & experience of Project Estimator / Controls, incl. CV & track record of indicative Estimator / Controls Methodology for producing cost estimates Methodology for cost control & reporting during devt & impl of a project Programs/procedures applied (& if integrated project control system used, & if so, descriptions given) for Cost Estimating & Cost Control Feedback if actual costs reflected in estimating system (e.g. historical data base) Use of probabilistic cost estimating methodologies (e.g. Monte Carlo analysis) Methodology for establishing contingencies Standard procedures/information flow/approval process applicable for change orders Experience & opinion on working life cycle cost estimates for specific items of equipment Business processes in Capex & Opex Value Analysis in strategic cost reduction (e.g. value engineering) Practices for handling insurance The organisation with respect to handling taxation & other duties Information management Programs / procedures for communication & document transfer to/from client & vendors Description of electronic document management system & project filing system Programs / procedures for Document Control (e.g. Electronic Data Management). Integrated project control system used? If so, incl description Document expediting & commenting practice & document revision control Methodologies for ensuring complete handover of documentation at end of project Process Design, Process Engineering and Systems Design Structure of the process engineering organisation Number, education & yrs of experience of process design engineers CV & track record of full time lead process engineer(s) incl. Those with Amine Scrubbing, Sulphur Production, HDS & TGU experience

11.4 11.5 11.6 11.7 11.8 11.9 11.10 11.11 11.12 11.13 11.14 11.15 12 12.1 12.2 12.3

Expertise on types of processes handled in HDS, TGU, Amine Scrubbing & SPUs Reference list of processes recently designed & completed Computer programmes used for process calculation, process simulation, heat integration, tray design, heat exchangers, etc. Interface relationship between process design, control, instruments, etc. Expertise on emergency de-pressurising systems, flare systems, gas dispersion modelling experts, etc. Experience with dynamic simulation: compressors, columns etc Experience with Operator Training Simulators system (OTS) Experience in the devt of PEFSs & statistics on the no. PEFSs in other contracts Experience in devt of intelligent P&Ids Can coloured drawings be generated (e.g. coloured P&IDs) for revisions, etc? Does company have separate systems department? Approach on system integration Mechanical Engineering Structure of mechanical engineering organisation Number, education & yes of experience of mechanical engineers CV & track record of chief/lead mechanical engineer(s) Pressure vessels Specialists available for mechanical design and engineering of vessels, columns, reactors, heat exchangers, (incl. equipment design devt, devt of equip spec sheets, requisitions, strength calculations, review/evaluation of vessel vendors works & design documents, etc.) Familiarity with industrial codes & standards, e.g. ASME, API, ISO, British Standards, etc. Expertise in welding & fabrication techniques & capability of welding engineers Software & computer programmes used for mechanical design of columns, vessel, heat exchangers & other static equipment Familiarity with DEPs in static equipment design, construction, installation Plot Plan, Piping and Flare/Relief Systems Capacity, experience & organisation of piping engineers & piping designers Availability of expertise in plot plan development, process systems/units layout with emphasis to plant operational safety & plant maintainability, piping drawing development, isometric drawings, & other piping detail drawings Expertise on pipe stress analysis incl software generally used for pipe stress analysis Experience & software for 3D CAD plant/piping modelling, cable trays and concrete and steel structures & companys capability to use programs to produce intelligent detailed drawings, Material Take Offs etc. Availability of expertise in flare/relief systems & capability of piping surge calculations Familiarity with DEPs with respect to piping design, construction, installation Heat transfer (Fired and unfired heat transfer units) Capacity, experience & organisation of heat transfer engineers, for fired heat transfer items (furnaces, fired heaters, etc.) & unfired heat transfer units (shell-and-tubes, airfin coolers, etc.) Computer programmes used for thermal rating Familiarity with DEPs with respect to furnace and heat exchanger design, construction, installation Familiarity with codes and standards, ASME, API, ISO, British Standards for furnaces & heat exchangers Rotating equipment Experience in pumps, and compressors of sizes & types normally found in a refinery

12.4 12.5 12.6 12.7 12.8 12.9

12.10 12.11

12.12 12.13 12.14

12.15 12.16 12.17 12.18 12.19

12.20 12.21 12.22 12.23 12.24 12.25 12.26

12.27

12.28 13 13.1 13.2 13.3

Experience in performance testing, erection, commissioning, start-up, operations Knowledge of double mech. seals, couplings, lube systems, etc. Responsibility of control systems for rotating equipment Experience with International Standards. i.e. review request for changes to or deviations from specifications, review and sign off equipment data sheet etc. Familiarity with DEPs for rotating equipment specifications Can company can carry out (pipe) vibration calculations/pulsation studies? If not subcontract to who? Noise control expertise Does company have full capability for coordination, design and engineering, integration, supply, installation, commissioning, QA/QC, maintenance, etc. of complete compressor package, i.e. including building(s) or shelters and auxiliaries? Materials specialists Available specialists for selection of construction materials (incl. non-metallic materials, Nickel steel), applicable codes, welding, & destructive & non-destructive testing Civil Engineering Description of structure of civil engineering organisation Number, education & yrs of experience of civil engineers CV & track record of chief/lead civil engineer(s) Experience in: concrete structures, steel structures, Control Room building architectural design, plant and non-plant building design, blast resistance design, HVAC, civil, geotechnical, seismic and foundation engineering, insulation and surface protection, storage tank design, roads and paving, logistics and infrastructures, temporary facilities, material off-loading and lifting facilities, drainage and primary treatment design, etc. Engineering software programmes used for analysis & design Instrument Engineering Structure of instrument engineering organisation Number, education & yrs of experience of instrument and control engineers CV & track record of chief/lead instrument engineer(s) Specialised knowledge or expertise Familiarity with DEPs (if not already answered) and/or other international standards Practice for interface process control, instrument engineering, etc. Details of specialist for pneumatic &/or electronic systems i.e. local controllers, PLC based systems Details of specialists for special field devices i.e. special control valves etc. Specialists on DCS, IPS and/or SCADA, Base Layer Process Control (simple & complex) & Advanced Process Control Experts in computer applications, integrated control systems, safeguarding systems, analysers, sample systems, gas detection, etc., plant communication systems & optimal integration instrument system architecture Explanation of demarcation between instruments & other facilities, example electrical, package units, rotating Process how instrument drawings verified, approved & released Database & tools for cable schedules, connection schedules, etc Experience in instrumentation based on field bus Experience in instruments & instrument systems commissioning, loop testing, incl permit to work system, espec on Brownfield projects Electrical Engineering Structure of the electrical engineering organisation

13.4 13.5 14 14.1 14.2 14.3 14.4 14.5 14.6 14.7 14.8 14.9

14.10 14.11 14.12 14.13 14.14 14.15 15 15.1

15.2 15.3 15.4 15.5 15.6 15.7 15.8 15.9 15.10 16 16.1

Number, education & yrs of experience of electrical engineers CV & track record of chief/lead electrical engineer(s) Experience with power generating facilities; variable speed motors & control systems Expertise in performing hook-up, harmonic studies, etc. Expertise with ETAP modelling or similar Description of management interface electrical & instrument departments Description of experience with LT and HT systems Description of experience with power stability studies Description of experience in setting up temporary electrical supply Commissioning, Flawless Start-up and Operations Experience of OIP or FSI programmes (previous projects & level of involvement). If no experience describe how Ops requirements integrated into project Experience of systems development & construction completion by systems, with system based payment milestones. If no specific experience, describe how to incorporate into project Experience in front end Comm & S/U activities, incl. specific departments in-place & experience of personnel Description how to integrate PRL Ops staff into your organisation when required Maintenance Methodology to ensure maintenance strategy reflected in the project in relation to life cycle costing/ contracting strategy/optimum maintenance strategy Maintenance experts within the organisation - numbers, experience How maintenance philosophies & documentation transferred to the Client from OEMs and/or suppliers How spare parts philosophies of the Client fully incorporated into project Experience with life cycle costing incl details of any consultants used List of Maintenance software Experience in maintenance availability modelling techniques & software used Maintenance management system specified on previous projects Experience with technical integrity tools & use of risk based inspection techniques, incl details of any consultants used Were FMEA reliability systems specified in other projects? If so list projects & explain strategy in recommending the system Experience in specifying requirements for maintenance contracts, incl who was involved in process & duration of contracts (e.g. 2, 5 or 10 years) Experience with planning & executing Maintenance works within Turnaround as part of Project Scope Note The section numbers correspond to the sections in the pre-qualification questionnaire. Section 1 of the pre-qualification questionnaire is made up of project information for Contractors therefore is not applicable in scoring Contractors in this questionnaire. As a result the numbering starts from 2, not 1.

16.2 16.3 16.4 17 17.1 17.2 17.3 17.4 17.5 17.6 17.7 17.8 17.9 17.10 17.11 17.12

Contractors A B C D . .. .

E F G H

. . . ..

A 2.455843 2.5625 2 3 4 1 2 2 3 4 3

Score D

3 3 2 1 1 4 3 3 5 4 3 2 2 2 2.444444 1 1 3 4 3 4 2 2 2 2.526316

3 2 4 1 3 3 2 1 4 4 2 1 2 3 3 3 4 2 1 2.348315

3 3 4

2 3 4

1 2 2 2 3 4 3 1

3 3 3

2 2 4 3 1 3 2

1 1 2 3 1 2 2 2 4 4 3 1

1 2

2 2 2 3 2

3 2

2 2 1 4

2 2 3 3 4 2 1 2 3 3 2 1 4 3 2

1 1 2 3 3

4 2 1 1 2 2 4 3

1 2 3 4

2 2 2.7 3 3 2 1 2 3 4 3 3 3 2.347826 2 2 2 3 3 3 2

1 4 1 2 3 3 2 3 3 1 2 4 3 1 2 2 2.166667 2 2 3 4 1 2 1 1 1 4 2 3 2 2 2 1 1 4 2.333333 2 3 2

4 1 2 3 4 1 2 2 3 4 1 1 2.392857 3 2 3

4 1 2 2 3 4

3 1

1 2 2

3 4 2 1 2

4 3 2 2 4 1 1

4 2.6 2 4 3

2 2 2.533333 2 3 3 3 4 1 1 3 2

2 4 1 2 3 4 2.3 3

2 4 2 1 2 3 4 1 1 2.75 3

2 2 4 2.166667 2 3 4 1 1 1 1 4 3 2 2 2

Action

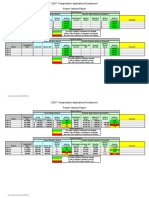

Weighting and Scoring

Weighting (Priorities) i 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Selection Category (SC) Organisation Experience Local Conditions EPCm Project Execution and Management Management of HSE Risks and Sustainable Development Quality Planning, Scheduling and Progress Control Estimating and Cost Control Information management Process Design, Process Engineering and Systems Design Mechanical Engineering Civil Engineering Instrument Engineering Electrical Engineering Commissioning, Flawless Start-up and Operations Maintenance Total (T) Wi (1-4) 4 3 2 4 4 4 3 4 2 4 1 1 1 1 3 3 44

Scoring per Contractor Not acceptable / not compliant with project requirements / information not provided Major non-compliances with project requirements Acceptable, largely compliant with project requirements Fully acceptable, fully compliant with project requirements AS = ( S (Wi x SCi) ) / T where: AS Wi SCi T

W 1 2 3 4

Aggregate Score (0-4) Weight of Selection Category i (1-4) score of Selection Category i (1-4) Total of weights

Note The section numbers correspond to the sections in the pre-qualification

Example of scoring

A 10.25 9 4.88888889 10.1052632 9.39325843 10.8 7.04347826 8.66666667 4 9.33333333 2.39285714 2.6 2.53333333 2.3 8.25 6.5 SUM (S) 108.057079 SUM/TOTAL 2.45584271

Scoring Sheet - Overview

Score 2 Organisation 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 3 Experience 3.1 3.2 3.3 3.4 3.5 3.6 4 Local Conditions 4.1 4.2 4.3.a 4.3.b 4.4 4.5 4.6 4.7 4.8 5 EPCm Project Execution and Management 5.1 5.2 5.3 5.4 5.5 5.6 5.7 Observations

5.8 5.9 5.10 5.11 5.12 5.13 5.14 5.15 5.16 5.17 5.18 5.19 6 Management of HSE Risks and SD 6.1.a.i 6.1.a.ii 6.1.a.iii 6.2.a.i 6.2.a.ii 6.2.b.i 6.3.a.i 6.3.a.ii 6.3.a.iii 6.3.a.iv 6.3.a.v 6.3.a.vi 6.3.a.vii 6.3.a.viii 6.3.b.i 6.3.c.i 6.3.c.ii 6.3.c.iii 6.3.c.iv 6.3.d.i 6.3.d.ii 6.3.d.iii 6.3.d.iv 6.3.e.i 6.3.e.ii 6.3.e.iii 6.3.f.i.1 6.3.f.i.2 6.3.f.i.3 6.3.f.ii 6.3.f.iii 6.3.f.iv 6.3.f.v 6.3.f.vi 6.g.i 6.g.ii 6.g.iii

6.g.iv 6.4.a.i 6.4.a.ii 6.4.b.i 6.4.b.ii 6.4.b.iii 6.4.c.i 6.4.c.ii 6.4.d.i 6.4.e.i 6.4.f.i 6.4.g.i 6.4.g.ii 6.4.h.i 6.4.h.ii 6.5.a.i 6.5.a.ii 6.5.a.iii 6.5.a.iv 6.5.b.i 6.5.b.ii 6.5.c.i 6.5.c.ii 6.5.d.i 6.5.d.ii 6.5.d.iii 6.5.d.iv 6.5.e.i 6.5.e.ii 6.5.e.iii 6.6.a.i 6.6.a.ii 6.6.a.iii 6.6.b.i 6.6.b.ii 6.6.c.i 6.6.d.i 6.6.e.i 6.6.e.ii 6.6.e.iii 6.6.e.iv 6.6.f.i 6.6.f.ii 6.6.f.iii 6.6.f.iv 6.7.a.i 6.7.a.ii 6.7.a.iii 6.7.a.iv 6.8.a.i 6.8.b.i

7 Quality 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 7.10 8 Planning, Scheduling and Progress Control 8.1 8.2 8.3 8.4.a 8.4.b 8.4.c 8.5 8.6.a 8.6.b 8.6.c 8.6.d 8.7 8.8 8.9.a 8.9.b 8.9.c 8.9.d 8.9.e 8.10.a 8.10.b 8.11 8.12 8.13

9 Estimating and Cost Control 9.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.9 9.10 9.11 9.12

10 Information management 10.1 10.2 10.3 10.4 10.5 11 Process Design, Process Engineering and Systems Design 11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 11.9 11.10 11.11 11.12 11.13 11.14 11.15 12 Mechanical Engineering 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 12.10 12.11 12.12 12.13 12.14 12.15 12.16 12.17 12.18 12.19 12.20 12.21 12.22 12.23 12.24

12.25 12.26 12.27 12.28 13 Civil Engineering 13.1 13.2 13.3 13.4 13.5 14 Instrument Engineering 14.1 14.2 14.3 14.4 14.5 14.6 14.7 14.8 14.9 14.10 14.11 14.12 14.13 14.14 14.15 15 Electrical Engineering 15.1 15.2 15.3 15.4 15.5 15.6 15.7 15.8 15.9 15.10 16 Commissioning, Flawless Start-up and Operations 16.1 16.2 16.3 16.4 17 Maintenance 17.1 17.2

17.3 17.4 17.5 17.6 17.7 17.8 17.9 17.10 17.11 17.12

You might also like

- Hikvision Certification ProgramDocument3 pagesHikvision Certification ProgramMithunNo ratings yet

- GU-628 Civil & Building Standard Drawings Index (Formerly SP 1173)Document46 pagesGU-628 Civil & Building Standard Drawings Index (Formerly SP 1173)Ibrahim NaguibNo ratings yet

- Indirect Cost in Primavera P6Document4 pagesIndirect Cost in Primavera P6shahidbolar100% (1)

- 000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowDocument1 page000.100.8100 Baseline Centric Execution - Deliver To The Baseline WorkflowmiltonNo ratings yet

- PT Borneo Mitra Sinergi: Engineering PlanDocument9 pagesPT Borneo Mitra Sinergi: Engineering PlanaswarNo ratings yet

- Cash Flow HistogramDocument7 pagesCash Flow HistogramEyutt HghghNo ratings yet

- SUBCO-FRM-01 Subcontractor's Prequalification FormDocument16 pagesSUBCO-FRM-01 Subcontractor's Prequalification FormMuhammad Umer100% (1)

- Supplier Pre-Qualifi-Eval-Criteria-and-WeightingDocument39 pagesSupplier Pre-Qualifi-Eval-Criteria-and-WeightingPhilippe LAVOISIERNo ratings yet

- Drawing Log - PC 118 (Rev 6)Document29 pagesDrawing Log - PC 118 (Rev 6)Dilshad AhemadNo ratings yet

- Work Package - WBSDocument18 pagesWork Package - WBSRakesh RanaNo ratings yet

- Bid Evaluation ReportDocument23 pagesBid Evaluation ReportSerkalem TayeNo ratings yet

- East Halmahera Ferronickel Plant Development Project Proyek Pengembangan Pabrik Ferronickel Halmahera Timur Document Numbering SystemDocument2 pagesEast Halmahera Ferronickel Plant Development Project Proyek Pengembangan Pabrik Ferronickel Halmahera Timur Document Numbering SystemCoco RhomoNo ratings yet

- Prequalification of Contractors and Suppliers For Fy 2014 - 2015 (Tender Numbers 14 To 84)Document19 pagesPrequalification of Contractors and Suppliers For Fy 2014 - 2015 (Tender Numbers 14 To 84)Dominic IsakaNo ratings yet

- Issue Management Log: Project Management, Project Planning, Templates and AdviceDocument6 pagesIssue Management Log: Project Management, Project Planning, Templates and AdviceMarcelo MansurNo ratings yet

- The Complete Guide To Construction Management: Course ManualDocument49 pagesThe Complete Guide To Construction Management: Course ManualJosé Pedro Agonia100% (1)

- Estimating ProcedureDocument11 pagesEstimating ProcedureSujani Maarasinghe100% (2)

- Low Ball Bid Awarding CriteriaDocument8 pagesLow Ball Bid Awarding CriteriaRASHID HUSSAIN100% (1)

- Andrew Avalon, P.E., PSP: ONG NternationalDocument24 pagesAndrew Avalon, P.E., PSP: ONG NternationalAnonymous 94TBTBRksNo ratings yet

- DOP1000 PRC 002-0-02 Detail DesignDocument10 pagesDOP1000 PRC 002-0-02 Detail DesignkamlNo ratings yet

- Esclation 1 To 4 - Comp Mrket & GPFSDDocument35 pagesEsclation 1 To 4 - Comp Mrket & GPFSDMuhammad KhanNo ratings yet

- Rate of Shedule M - P - 2009Document393 pagesRate of Shedule M - P - 2009Er Tarun PalNo ratings yet

- Construction of Internal Roads and Infrastructure For 354 Residential Plots in Shakhbout CityDocument1 pageConstruction of Internal Roads and Infrastructure For 354 Residential Plots in Shakhbout CityburereyNo ratings yet

- Transmital Log - ACTIVE1Document40 pagesTransmital Log - ACTIVE1Hafeez AhmedNo ratings yet

- wdd-7 0-1 0Document1 pagewdd-7 0-1 0Kevin DomunNo ratings yet

- BPC-2016-TMP-05-2016-V1 Workshop SOW Handout 5 Project Deliverables MatrixDocument6 pagesBPC-2016-TMP-05-2016-V1 Workshop SOW Handout 5 Project Deliverables MatrixSrinivas N Gowda0% (1)

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- MS em STD 0011Document3 pagesMS em STD 0011Chirag ShahNo ratings yet

- 2009v2.2 SubmittalChecklistDocument11 pages2009v2.2 SubmittalChecklistChris Gonzales100% (1)

- Project Work Break Down System - GeneralDocument6 pagesProject Work Break Down System - GeneralAnthony Agner100% (2)

- PM GlossaryDocument253 pagesPM Glossaryalfaroq_almsryNo ratings yet

- Part 1 Vol 1 SWM PDFDocument274 pagesPart 1 Vol 1 SWM PDFSTUPNo ratings yet

- SRD Tollgate BasedProjectManagementDocument9 pagesSRD Tollgate BasedProjectManagementKulanthaivelu RamasamyNo ratings yet

- Overall Bid Evaluation: InstructionsDocument18 pagesOverall Bid Evaluation: InstructionsDolyNo ratings yet

- S-Curve Working RDocument53 pagesS-Curve Working Rderwaishjee100% (5)

- Projects Variance Report v1.0Document2 pagesProjects Variance Report v1.0rheri100% (1)

- Prequalification Document Works - Revised 17 05 2014Document79 pagesPrequalification Document Works - Revised 17 05 2014Larissa100% (1)

- Civil - Concrete Foundation Drawing ChecklistDocument4 pagesCivil - Concrete Foundation Drawing ChecklistZafar100% (1)

- Dgs-Civil WorksDocument18 pagesDgs-Civil WorksMuhammad NazamNo ratings yet

- Technical Evaluation Matrix TemplateDocument1 pageTechnical Evaluation Matrix Templatemuhammad iqbalNo ratings yet

- Geotechnical Investigation SpecificationDocument7 pagesGeotechnical Investigation SpecificationT Bayu PratamaNo ratings yet

- 10 Progress Report PDFDocument72 pages10 Progress Report PDFMary BainoNo ratings yet

- Gantt Chart: Excel 2010 SampleDocument7 pagesGantt Chart: Excel 2010 SampleKevin Jake CasalaNo ratings yet

- JD Lead EstimatorDocument2 pagesJD Lead EstimatorManoj SinghNo ratings yet

- Aais - PMCDocument9 pagesAais - PMCneel78No ratings yet

- Project Standard and Specifications Project Control Procedure Rev01 WebDocument5 pagesProject Standard and Specifications Project Control Procedure Rev01 WebVũ Giang100% (1)

- Assessment CreteriaDocument20 pagesAssessment CreteriaBrian ThompsonNo ratings yet

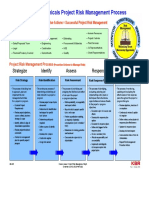

- Energy & Chemicals Project Risk Management ProcessDocument2 pagesEnergy & Chemicals Project Risk Management ProcessnbnbNo ratings yet

- Infrastructure Based Building Based: Civil WorkDocument12 pagesInfrastructure Based Building Based: Civil WorkRajesh MamidalaNo ratings yet

- (2015) Negotiating Subcontract Conditions in The Australian Construction IndustryDocument13 pages(2015) Negotiating Subcontract Conditions in The Australian Construction Industrydefi hidayahNo ratings yet

- Construction ManagerDocument4 pagesConstruction ManageruygarkoprucuNo ratings yet

- Tracking Project Performance PART-1 Schedule Updating-Fall18 PDFDocument77 pagesTracking Project Performance PART-1 Schedule Updating-Fall18 PDFPablo AlarconNo ratings yet

- Transition From Construction To CommissioningDocument30 pagesTransition From Construction To Commissioningian84No ratings yet

- TRISHUL Engineering PresentationDocument63 pagesTRISHUL Engineering PresentationaswarNo ratings yet

- Work Procedure For CCB Installation of Raised Floor 2Document13 pagesWork Procedure For CCB Installation of Raised Floor 2ResearcherNo ratings yet

- Procedure For Change OrderDocument8 pagesProcedure For Change OrderJeojie Jie0% (1)

- Excel Construction Project Management Templates Project Closeout Checklist TemplateDocument4 pagesExcel Construction Project Management Templates Project Closeout Checklist TemplateJeff TuganoNo ratings yet

- Design - Activities - 03081018 R2 PDFDocument15 pagesDesign - Activities - 03081018 R2 PDFSubhashNo ratings yet

- Procurement Tracking SheetDocument12 pagesProcurement Tracking SheetMohannad Abo SulbNo ratings yet

- Documents Distributing Matrix For Management TrainingDocument1 pageDocuments Distributing Matrix For Management TrainingMasoud MirshekarNo ratings yet

- HSE Questionnaire - Dragon Oil. 2Document10 pagesHSE Questionnaire - Dragon Oil. 2saneemlaltp thachaparamban0% (1)

- ZEESHAN ALI RESUME 2021 Safety AdvisorDocument4 pagesZEESHAN ALI RESUME 2021 Safety AdvisorShahid BhattiNo ratings yet

- SLM Eapp12q3m2Document16 pagesSLM Eapp12q3m2Nena HoyohoyNo ratings yet

- Knowledge-Based Systems - Concepts Techniques Examples 08-May-1985Document84 pagesKnowledge-Based Systems - Concepts Techniques Examples 08-May-1985geoanirvanNo ratings yet

- Lesson 5: Media and Information SourcesDocument4 pagesLesson 5: Media and Information SourcesPepay MojicaNo ratings yet

- Thesis Statement Youth CultureDocument6 pagesThesis Statement Youth Culturenicolegetherscharleston100% (2)

- Grade 5 Term 4 Life Skills Lesson Plan Name of Lesson: Become A Disease Detective!Document3 pagesGrade 5 Term 4 Life Skills Lesson Plan Name of Lesson: Become A Disease Detective!Raeesa SNo ratings yet

- Megaman X by AzamorDocument118 pagesMegaman X by AzamorJonathan Azamor0% (1)

- Ebook Rethinking Social Studies in The 21st CentDocument451 pagesEbook Rethinking Social Studies in The 21st CentAIZA MAE SEGUERRA100% (1)

- (Facione 2015) Critical Thinking, What It Is and Why It Counts PDFDocument30 pages(Facione 2015) Critical Thinking, What It Is and Why It Counts PDFZack100% (4)

- Understanding and Integrating Multiple Science Texts: Summary Tasks Are Sometimes Better Than Argument TasksDocument40 pagesUnderstanding and Integrating Multiple Science Texts: Summary Tasks Are Sometimes Better Than Argument TasksArkantos TirbaNo ratings yet

- Teaching Outside of Their ExpertiesDocument2 pagesTeaching Outside of Their ExpertiesCbrc ViganNo ratings yet

- Volvo Group ThesisDocument6 pagesVolvo Group Thesisxgkeiiygg100% (2)

- KARINA FINCATI Senior Researcher VenetoNanotech 7ProgrammaQuadroDocument57 pagesKARINA FINCATI Senior Researcher VenetoNanotech 7ProgrammaQuadroMirco MiorinNo ratings yet

- Love Marriage SpecialistsDocument3 pagesLove Marriage SpecialistsIndianvashikaran SpecialistNo ratings yet

- Reed1987 PDFDocument16 pagesReed1987 PDFmaslaeniNo ratings yet

- Moral 1: Slow & Steady Wins The RaceDocument71 pagesMoral 1: Slow & Steady Wins The RaceFall Out BoyzNo ratings yet

- Illinois State University ThesisDocument4 pagesIllinois State University Thesisaouetoiig100% (1)

- IELTS Discuss Both Views QuestionDocument2 pagesIELTS Discuss Both Views QuestionOngky SetiawanNo ratings yet

- Studyguide - C17 GFM MSC 01 - 201802071553 PDFDocument160 pagesStudyguide - C17 GFM MSC 01 - 201802071553 PDFAfnindar FakhrurroziNo ratings yet

- NI Module 2 TheoriesDocument17 pagesNI Module 2 TheoriespnlgnkrstnNo ratings yet

- Nursing RoundDocument7 pagesNursing RoundBishwajitMazumder100% (5)

- Universities in The Knowledge Society: Models of Generative Learning EnvironmentDocument12 pagesUniversities in The Knowledge Society: Models of Generative Learning EnvironmentKarpovNo ratings yet

- The Psychology of Problem Solving-16-43Document28 pagesThe Psychology of Problem Solving-16-43Hanum Sasmitanisha Ayu MumpuniNo ratings yet

- PHD Thesis On Cultural IdentityDocument6 pagesPHD Thesis On Cultural Identitydnr1yg3p100% (1)

- Chapter 3 FinalDocument58 pagesChapter 3 Finalapi-242289430No ratings yet

- Industrial Design Thesis StatementDocument5 pagesIndustrial Design Thesis Statementshannonjoyarvada100% (2)

- Corpus Linguistics and Terminology Extraction: January 1997Document20 pagesCorpus Linguistics and Terminology Extraction: January 1997GizliustaNo ratings yet

- Thesis LufthansaDocument8 pagesThesis Lufthansaalisonreedphoenix100% (2)

- ARTICLES Organizational Orchestra StructureDocument15 pagesARTICLES Organizational Orchestra Structuresoumya697No ratings yet

- Mathematics Thesis StatementDocument6 pagesMathematics Thesis Statementbsq1j65w100% (2)