Professional Documents

Culture Documents

Conditioned Monitoring Syllabus

Uploaded by

Ravikumar NagulaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conditioned Monitoring Syllabus

Uploaded by

Ravikumar NagulaCopyright:

Available Formats

VTU Computer Integrated Manufacturing Syllabus Condition Based Monitoring

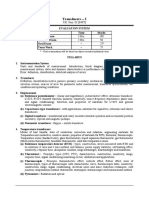

CONDITION BASED MONITORING Sub Code : 08 MCM 151 IA Marks : 50 No. of Lecture Hrs/week : 04 Exam Hours : 03 Total Lecture Hrs : 52 Exam Marks : 100 Practical/Field work/Assignment Hrs/week : 02 First Semester : 18 weeks 1. Introduction, Principles, Economics and Application; Condition Monitoring Methods. Economics of Condition Monitoring, Setting up a CM Activity, Implementation of Condition Based Maintenance, Consequences of implementation of CBM. Information System, Selection of Monitoring Methods, Assessment of monitoring techniques, Case studies. (06 Hrs) 2. Vibration Monitoring and analysis Introduction, Machinery signatures, Selection of Transducers. Analysis Techniques, Machine failure modes, Measurement location, Vibration severity criteria, Vibration frequency analysis. Permanent Monitoring, Case studies. (06 Hrs) 3. Vibration Monitoring of ball and roller bearings Introduction, Shock pulse method, SPM for testing Antifriction bearings, Manual Monitoring Continuous monitoring, The Kurtosis method, Fiber optics system, Vibration signature analysis, Contact resistance method, Case studies. SPM and its Applications. (06 Hrs) 4. Non-Destructive testing Introduction, Visual testing, Liquid Penetrate inspection, Water-washable method. Precleaning, Penetrant application, Dwell time, Excess surfacepenetrate removal, Surface drying, Developer application, Interpretation, Postemulsifiable

penetrants, Solvent-Soluble penetrants. Radiographic examination, X-ray Apparatus, X-ray generation, Tube shielding, Control console, Other X-ray sources, Electrostatic or Ven De Graffgenerators, Linear accelerators. Gamma-ray Radiography- Sources-Radium, Thallium 170, Iridium 192, Cobalt 62. Isotope Projectors-Geometric factors, Radiographic film, Radiograph. Safety Hazards and Government control; Cost. Sonics, Ultra Sonics, Pulse echo technique, Transmission technique, Resonance technique, Frequency modulation techniques. (07 Hrs) 5. Specialized techniques of condition monitoring Acoustic imaging, Ultra sonic triangulation fault location Acoustic emission technique (AET)- Instrumentation, Transducers, Preamplifier and filter, Main amplifier and Signal processing/ Display unit, Signals and processing, Magnetic testing Methods, Current flow Magnetisation, Induction Magnetic Flow Method, Induction Threading bar method, Induction Magnetising Coil method, Induced Current flow method, Magnetic particle Inspection Inks, Strippable Magnetic film, Eddy Current apparatus, Thermography-Thermographic Equipment, Application of Thermography, Corrosion monitoring, Need for corrosion monitoring, Fields of application, Monitoring Techniques, Resistance techniques. Other probe techniques-Analytical technique and others. (07 Hrs) 6. Performance Trend monitoring Introduction, Thermodynamic and Fluid dynamic analysis, Primary and Secondary, performance parameter, Steam turbine performance parameters, Case examples. (06 Hrs) 7. Mechanical Fault Diagnosis By Wears Monitoring & Lubricant Analysis Introduction, Source of Contamination, Significant oil contaminants, Used oil Contamination-time trends, Changes in the carrier fluid, Ferratic wear debris. Wear process monitoring techniques- Direct debris detection methods, Debris collection methods. Lubricant sampling & analysis-Sampling, Lubricant sampling methods, Lubricant analysis methods, Interpretation of results, Indications from the amount of debris present, Indication from the size distribution of debris, Application of chemical analysis of debris, Wear detection using proximity monitors, Case examples. (08 Hrs) 8. Condition Monitoring case Studies & Applications Failure of fan bearings- History of failures, Analysis of the failures, Solution. High frequency vibration of gas compressor-History of trouble, Analysis of trouble, Solution. Monitoring of cracks in rotors- Turbocompressor misalignment. Detection of faulty electrical components. Turbine shell distortion. Symptoms and Detections. (06 Hrs)

Text Books: 1. R.A., Caollacatt Chapman Mechanical Fault Diagnosis and Condition Monitoring, Chapman and hall 1977. 2. References: 2. L.F.Pau Marcel Deker Failure Diagnosis and Performance Monitoring. 3. Update CEP ISTE New Delhi Condition Monitoring and condition based maintenance.

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Condition Monitoring and Condition Based Maintenance (CBM)Document9 pagesCondition Monitoring and Condition Based Maintenance (CBM)jaggy elgarNo ratings yet

- Catalogue of Physics Csir Net by Rahul R SekharDocument227 pagesCatalogue of Physics Csir Net by Rahul R SekharMARAR മാരാർNo ratings yet

- Condition Based MaintenanceDocument27 pagesCondition Based Maintenanceseminarproject100% (1)

- NDT Notes1 PDFDocument48 pagesNDT Notes1 PDFnagarajan224No ratings yet

- MPTDocument25 pagesMPTAMIT SHAH100% (2)

- PMT QM Mep 004Document25 pagesPMT QM Mep 004AMIT SHAHNo ratings yet

- Vibration Vs UltrasoundDocument8 pagesVibration Vs UltrasoundallmcbeallNo ratings yet

- Unbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsDocument2 pagesUnbalanced Magnetic Pull and Air-Gap Monitoring For Large HydrogeneratorsbasilecoqNo ratings yet

- Relay Setting CoordinationDocument8 pagesRelay Setting CoordinationNoli Oteba100% (1)

- NDT (Methods & Applications)Document16 pagesNDT (Methods & Applications)Ahmed Adel100% (1)

- Sensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesFrom EverandSensing and Monitoring Technologies for Mines and Hazardous Areas: Monitoring and Prediction TechnologiesNo ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic Are ViewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic Are ViewVaibhav JainNo ratings yet

- Qualification Process For Phased Array UT Using DNV RP-F118Document12 pagesQualification Process For Phased Array UT Using DNV RP-F118aztec20100% (1)

- ISO 9001 2015 TrainingDocument242 pagesISO 9001 2015 TrainingDurgamadhaba MishraNo ratings yet

- Sop52 08 0000 00 015Document11 pagesSop52 08 0000 00 015Ali RafiqueNo ratings yet

- Unit 50 Condition Monitoring and Fault Diagnosis - Part 01Document44 pagesUnit 50 Condition Monitoring and Fault Diagnosis - Part 01alexandre_motta_3No ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic Are ViewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic Are ViewSmit ShahNo ratings yet

- Measurement and Instrumentation: Theory and ApplicationFrom EverandMeasurement and Instrumentation: Theory and ApplicationRating: 4.5 out of 5 stars4.5/5 (5)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Conceptual Physics Equation SheetDocument2 pagesConceptual Physics Equation SheetjeremytimmonsNo ratings yet

- What To Study For The ExamsDocument6 pagesWhat To Study For The ExamsvinchandNo ratings yet

- NDT Composite ComponentsDocument37 pagesNDT Composite ComponentsNarendra Palande100% (1)

- Condition MonitoringDocument37 pagesCondition Monitoringkedeejoshi100% (2)

- Lab Report For Venturi MeterDocument9 pagesLab Report For Venturi MeterFirzana AmiraNo ratings yet

- Vibration Analysis Techniques For Gearbox Diagnostic: A ReviewDocument10 pagesVibration Analysis Techniques For Gearbox Diagnostic: A ReviewBao-Phuc NguyenNo ratings yet

- Level3 TopicsDocument2 pagesLevel3 TopicsBPHIRABUNo ratings yet

- Me 8676: Advances in TribologyDocument1 pageMe 8676: Advances in Tribology4li121312No ratings yet

- Rotating Machine Fault Diagnostics Using Vibration and Acoustic Emission SensorsDocument2 pagesRotating Machine Fault Diagnostics Using Vibration and Acoustic Emission Sensorsdino_bosnjakovicNo ratings yet

- Condition Monitoring of Low Speed Bearings PDFDocument10 pagesCondition Monitoring of Low Speed Bearings PDFluciano GarciaNo ratings yet

- Condition Monitoring Methods and TechniquesDocument2 pagesCondition Monitoring Methods and TechniquesMohamed Al-OdatNo ratings yet

- Pocketbook On Ultrasonic Testing of Rail (Need-Based)Document25 pagesPocketbook On Ultrasonic Testing of Rail (Need-Based)ME TECHNOLOGYNo ratings yet

- Annexure - I Syllabus For Written Examination: Paper I (Objective Type) (200 Questions)Document2 pagesAnnexure - I Syllabus For Written Examination: Paper I (Objective Type) (200 Questions)kunusenseiNo ratings yet

- Seminar III Report FinalDocument39 pagesSeminar III Report Finalganesh gundNo ratings yet

- Application of Vibration Analysis in The Condition Monitoring of Electrical EquipmentDocument6 pagesApplication of Vibration Analysis in The Condition Monitoring of Electrical EquipmentAlexis AguillonNo ratings yet

- Transducers PDFDocument2 pagesTransducers PDFNahush BapatNo ratings yet

- Mtech Syllabus Eie 2009Document15 pagesMtech Syllabus Eie 2009Raja Prathap SinghNo ratings yet

- Bearing DefectsDocument13 pagesBearing Defectsjoshibec100% (1)

- Advance Instrumentation Techniques QBDocument11 pagesAdvance Instrumentation Techniques QBSindhu ShedbaleNo ratings yet

- Design of A Multi-Model Observer-Based Estimator For Fault Detection and Isolation (Fdi) Strategy: Application To A Chemical ReactorDocument12 pagesDesign of A Multi-Model Observer-Based Estimator For Fault Detection and Isolation (Fdi) Strategy: Application To A Chemical ReactorAfshaNo ratings yet

- Detailed Content SEM 6Document16 pagesDetailed Content SEM 6HIMANSHU KUMARNo ratings yet

- Btme 503 Mechancial Measurements and Metrology Internal Marks: 40 External Marks: 60 Total Marks: 100Document4 pagesBtme 503 Mechancial Measurements and Metrology Internal Marks: 40 External Marks: 60 Total Marks: 100taak41No ratings yet

- 2005 Nondestructive Testing GuideDocument8 pages2005 Nondestructive Testing GuideHamzaNoumanNo ratings yet

- Integrated Condition Monitoring Scheme For Bearing Fault Diagnosis of A Wind Turbine GearboxDocument14 pagesIntegrated Condition Monitoring Scheme For Bearing Fault Diagnosis of A Wind Turbine GearboxSrinidhikumar KumarNo ratings yet

- Resolving Radiation Interference Problems Due To Neighboring Installed Radiation Detection and Scanning InstrumentsDocument4 pagesResolving Radiation Interference Problems Due To Neighboring Installed Radiation Detection and Scanning InstrumentsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Non-Destructive Evaluation of Powder Metallurgy PartsDocument17 pagesNon-Destructive Evaluation of Powder Metallurgy PartsMuhammad AdilNo ratings yet

- Learning GuideDocument12 pagesLearning GuideANBUKKANINo ratings yet

- Phase 2 ReportDocument20 pagesPhase 2 ReportSusheel PoonjaNo ratings yet

- NDT SeminarDocument23 pagesNDT SeminarManjunath g100% (2)

- Different: Techniques of Condition MonitoringDocument6 pagesDifferent: Techniques of Condition MonitoringCh ArsalanNo ratings yet

- Machinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFDocument8 pagesMachinery Vibration Signals Analysis and Monitoring For Fault Diagnosis and Process Control PDFأحمد دعبسNo ratings yet

- Assessment of Gear Damage Monitoring Techniques Using Vibration MeasurementsDocument18 pagesAssessment of Gear Damage Monitoring Techniques Using Vibration MeasurementsLutfi SandiNo ratings yet

- Syllabus Barc Rtl2 160714Document7 pagesSyllabus Barc Rtl2 160714DeepakNo ratings yet

- Algorithms 09 00019Document13 pagesAlgorithms 09 00019Joel Morales PerezNo ratings yet

- VIb MonitorDocument14 pagesVIb Monitorrounaq77No ratings yet

- MF4092 NDT - PGDocument1 pageMF4092 NDT - PGJeganNo ratings yet

- About Diagnosis TechniqDocument3 pagesAbout Diagnosis TechniqRaid AbdemezianeNo ratings yet

- Saj Engineering and Trading CompanyDocument20 pagesSaj Engineering and Trading CompanyShahin Manjurul AlamNo ratings yet

- Dash Utrtmtptvt Bro 2014Document6 pagesDash Utrtmtptvt Bro 2014dashNo ratings yet

- Assignment 2 CMDocument7 pagesAssignment 2 CMAhmad RazaNo ratings yet

- Vibro-Acoustic Testing Applied On Tap Changers and Circuit BreakersDocument28 pagesVibro-Acoustic Testing Applied On Tap Changers and Circuit Breakerspoeta_oscuroNo ratings yet

- Syllabus of Machinery Fault Diagnosis and Signal ProcessingDocument2 pagesSyllabus of Machinery Fault Diagnosis and Signal ProcessingshreyaNo ratings yet

- Electrical Measuring Instruments: (Voltmeter, Ammeter, and Ohmmeter)Document4 pagesElectrical Measuring Instruments: (Voltmeter, Ammeter, and Ohmmeter)angelo macatangayNo ratings yet

- ACTIVITY I Linear MotionDocument4 pagesACTIVITY I Linear MotionAra Nicole Dela VegaNo ratings yet

- AssignmentDocument11 pagesAssignmentjapjot singhNo ratings yet

- Intrinsic BrightnessDocument4 pagesIntrinsic BrightnessAditNo ratings yet

- Chapter # 21 Nuclear PhysicsDocument7 pagesChapter # 21 Nuclear PhysicsAsif Rasheed RajputNo ratings yet

- Experiment 2: Uniformly Accelerated Motion Using Ticker-Tape TimerDocument8 pagesExperiment 2: Uniformly Accelerated Motion Using Ticker-Tape TimerLouise AltheaNo ratings yet

- Edexcel GCE: Mechanics M4Document28 pagesEdexcel GCE: Mechanics M4yvg95No ratings yet

- Finding Extrasolar Planets V4Document4 pagesFinding Extrasolar Planets V4orfanakNo ratings yet

- Kyambogo University Faculty of Science Department of Chemistry Semester One Examinations 2019-2020 CHE412-Chemical Reaction Engineering IDocument6 pagesKyambogo University Faculty of Science Department of Chemistry Semester One Examinations 2019-2020 CHE412-Chemical Reaction Engineering Ikivumbi AchileoNo ratings yet

- Shaft TorsionDocument2 pagesShaft Torsionindra purnamaNo ratings yet

- Ram Prasad - Full PDFDocument236 pagesRam Prasad - Full PDFJ.Gopala KrishnaNo ratings yet

- Chemical Equilibrium: The Concept of EquilibriumDocument20 pagesChemical Equilibrium: The Concept of Equilibriumshashank shriNo ratings yet

- Conventions Concerning Electric and Magnetic Circuits PDFDocument36 pagesConventions Concerning Electric and Magnetic Circuits PDFArunTomarNo ratings yet

- Science - 2ND SummativeDocument2 pagesScience - 2ND SummativeericksonNo ratings yet

- E4pa NDocument8 pagesE4pa NSaturnhauiNo ratings yet

- Class 11Th Physics Yt - Padhai Ak Mazza Magic HandbookDocument492 pagesClass 11Th Physics Yt - Padhai Ak Mazza Magic Handbookaarohibhatt285No ratings yet

- Dirac-Delta Function and Different Limit Representation of Dirac-Delta FunctionDocument28 pagesDirac-Delta Function and Different Limit Representation of Dirac-Delta FunctionAshok KumarNo ratings yet

- Csa A23.3-04 RC-BM-001Document7 pagesCsa A23.3-04 RC-BM-001Khuất Trần ThanhNo ratings yet

- Partial Differential EquationsDocument10 pagesPartial Differential EquationsBogdan Carauleanu100% (1)

- MatlabSession1 PHAS2441Document5 pagesMatlabSession1 PHAS2441godkid308No ratings yet

- Question Report 12706111 75Document18 pagesQuestion Report 12706111 75izharulowadud341No ratings yet

- Sheet (6) Dimensional AnalysisDocument4 pagesSheet (6) Dimensional AnalysisABDELRHMAN ALINo ratings yet

- Plasmonics Chapter 1Document13 pagesPlasmonics Chapter 1Fahad ZiaNo ratings yet

- Solar Aircraft Final Seminar Report PDFDocument39 pagesSolar Aircraft Final Seminar Report PDFRohit HarpudeNo ratings yet

- Assignment (3) Fluid Statics (Hydrostatic Force On A Plane Surface)Document3 pagesAssignment (3) Fluid Statics (Hydrostatic Force On A Plane Surface)Mahmoud EmamNo ratings yet