Professional Documents

Culture Documents

Marine Microalgae

Uploaded by

Rafael SotanaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Marine Microalgae

Uploaded by

Rafael SotanaCopyright:

Available Formats

Strategies of the Agriculture Sector in Korea for the post-Kyoto Regime

SEARCA Agriculture & Development Discussion Paper Series No. 2010-3

Screening of Local Marine Microalgae for Biodiesel Production

Zeily Nurachman Lily Maria Goretti Panggabean Syahfitri Anita

SOUTHEAST ASIAN REGIONAL CENTER FOR GRADUATE STUDY AND RESEARCH IN AGRICULTURE Science and education for agriculture and development

2 Strategies of the Agriculture Sector in Korea for the post-Kyoto Regime Primary Researcher Dr. Zeily Nurachman Associate Professor Biochemistry Department Bandung Institute of Technology Jl. Ganesha 10, Bandung 40132, Indonesia Tel +62 22 250 2103 Fax +62 22 250 4154 Mobile +628122318938 E-mail: zeily@chem.itb.ac.id Associate Researchers Lily Maria Goretti Panggabean Syahfitri Anita

DISCLAIMER The SEARCA Agriculture and Development Discussion Paper Series aims to disseminate information on current trends or researches to inspire discussion between the author and other stakeholders in the same field of interest. SEARCA encourages readers to directly contact the author through the address provided. The point of view taken by this paper is entirely that of the authors and does not reflect in any way, SEARCAs position.

Screening of Local Marine Microalgae for Biodiesel Production

Abstract

orld attention in renewable energy sources, such as biofuels, has been increasing since the decline in petroleum supplies. In the quest to find a viable and sustainable resource for biofuel, recent studies have shown that microalgae can be used as feedstock in biodiesel production. This study was undertaken to screen marine microalgae for biodiesel, to upscale microalgae culture for biomass, to extract fatty acids for biofuel, and to determine biodiesel productivity from different microalgal strains. Two of seven screened marine microalgal strains, Thalassiosira sp. and Nannochloropsis sp., were cultured in the laboratory. Starting with the same cell concentration, the cell density of Thalassiosira sp. in a Walne medium, either with free air bubbling or with an air/CO2 mixture, was less than Nannochloropsis sp. Thalassiosira sp. and Nannochloropsis sp. had high specific growth rates of 0.17 and 0.19, and cell densities (in 10 days) at 0.49 g/l and 2.63 g/l, respectively. To release oils from inside the cells, a sonication method seemed to be effective for disrupting microalgae, followed by Soxhlet extraction using a chloroform/methanol solvent to extract more fatty acids. Biodiesel productivity of Thalassiosira sp. was 150 l/l culture/d. This is higher than other biodiesel feedstock like palm oil.

Screening of Local Marine Microalgae for Biodiesel Production

Introduction

Due to the declining supply and increasing demand for pertroleum, world attention to find alternative sources of fuel has increased. Moreover, great concern is placed on renewable energy development as it has fewer effects on the environment. It has been previously reported that worldwide energy demand for transport will nearly double by 2020 (EIA 1999). The potential worldwide effects of global warming, that is, the observed increase in average atmospheric and oceanic temperatures, have led to an increase in efforts to develop reliable, economically feasible, and sustainable alternative energy sources to replace coal and petroleum (Pak et al. 1991; Huntley and Redalje 2006). The need for renewable sources of portable, liquid fuel is starting to receive greater attention, and much of this attention has been focused on biomass-derived liquid fuels, or biofuels (Schneider 1994; Haag 2007). Rationale and Objectives Currently, biofuel production has focused on terrestrial plants and ethanol production from starches and sugar cane. Terrestrial plants have been popular for biofuel production because of the low price for cultivation and production (Huntley and Redalje 2006). However, it is severely limited by land availability, which inherently limits the amount of fuel that can be produced and utilized. If biomass were to supply all primary energy currently used, the production of biomass would have to increase by a factor of seven. Currently, 30 to 40 percent of worldwide primary terrestrial productivity is appropriated for food, fiber, and energy (Huesemann 2006). It is simply not feasible to dramatically increase biomass production of terrestrial plants without causing harmful impacts on the environment.

Screening of Local Marine Microalgae for Biodiesel Production

One type of biofuel that is gaining great attention, being widely used and is very promising, is biodiesel. Nowadays, the use of biodiesel worldwide has been increasing significantly (Figure 1). Biodiesel is made from renewable biological sources such as vegetable oils and animal fats. It is biodegradable, nontoxic and has a low emission profile, making it less harmful to the environment compared with petroleum-based fuels (Krawczyk 1996). Sources of commercial biodiesel that are being used currently are soybean, canola oil, animal fat, palm oil, corn oil, waste cooking oil (Felizardo et al. 2006; Kulkarni and Dalai 2006) and jatropha oil (Barnwal and Sharma 2005). In all cases, the current and projected production cost of biodiesel is two to three times higher than petroleum-based products. Based on these projections, it has been assumed that biodiesel cannot be a competitive alternative to petroleum-based fuels. Besides, biodiesel production from plant oils encounters certain limitations such as land competition with agricultural plants. It could also affect the availability and prices of oil-seed supplies in substantial quantities (Lykidis and Ivanova 2008). However, microbial metabolic engineering presents a unique opportunity to lower the costs associated with the raw materials used in biodiesel production.

Figure 1. World biodiesel production, 1991-2005

4,000 3,500 3,000 million liters 2,500 2,000 1,500 1,000 500 0 1991 1993 1995 1997 1999 2001 2003 2005

Screening of Local Marine Microalgae for Biodiesel Production

Recent advances in bioresource studies proved that some microorganisms, including microalgae, yeast, and fungi which contain a large amount of fatty acids, may also be used as sources for biodiesel production (Ratledge 1989; Ratledge and Wynn 2002; Chisti 2007). Compared to other sources of biodiesel, microalgae yields higher quantities (Table 1). Moreover, Yusuf Chisti (2007) states optimistically that it is the only renewable biodiesel that can potentially displace liquid fuels derived from petroleum. However, the economics of producing microalgae for biodiesel need to be improved substantially to make it competitive with petroleum diesel, and the level of improvement necessary appears to be attainable. Biodiesel from algae is a potential alternative since it gives the highest yield per hectare compared to oil crops, has rapid growth rates, and could easily double their biomass within 24 hours. In fact, the biomass doubling time for microalgae during exponential growth can be as short as 3.5 hours (Chisti 2007). This is significantly quicker than the doubling time for oil crops. Algal biofuel also contains no sulfur, is non-toxic, and is highly biodegradable. In addition, algae consume carbon dioxide (CO2) as they grow, so they could be used to capture CO2 from power stations and other industrial plants. Finally, algal culture, unlike crop-based biofuels, does not entail a decrease in food production, since it requires neither farmland nor freshwater (Wagner 2007).

Table 1. Comparison of some sources of biodiesel (Krawczyk 1996)

Crop Corn Soybean Canola Jatropha Coconut Oil Palm Microalgae Oil yield (l/ha) 172 446 1,190 1,892 2,689 5,950 136,900

Screening of Local Marine Microalgae for Biodiesel Production

Engineering design and cost studies were conducted by the Aquatic Species Program, Department of Energy Offices of Fuel Development of the United States of America, with an ever-increasing realism in the design assumptions and cost estimates. These estimates showed that algal biodiesel cost would range from USD1.40 to USD4.40 per gallon based on current and long-term projections for the performance of the technology (Benemann et al. 1978). Even with the assumption of USD50.00 per ton of CO2 as carbon credit, the cost of biodiesel could never compete with the projected cost of petroleum diesel. A pilot plant of a photobioreactor producing two to four kilograms per day of dry microalgal biomass, designed by AlgaeLink NV, would need an initial investment of USD85,000.00. However, while biodiesel from algae has many advantages, its application on a commercial scale is still rare to find. One of the reasons is the limited references on the best algal strain that could offer the most efficient biodiesel production. Yet, feasibility studies have been conducted to overcome this obstacle. The best algal strain is the one with high lipid content and fast growth rate. Also, the algae should not be too difficult to harvest and must have a suitable and cost-effective cultivation system, specifically with the type of photobioreactor used (Wagner 2007). Furthermore, to enhance efficiency, the cost of producing microalgae biodiesel should be reduced substantially by using a bio-refinery-based production strategy, improving capabilities of microalgae through genetic engineering, and advances in the engineering of photobioreactors (Chisti 2007). More work still needs to be done in order to achieve a competitive algae-based biodiesel production, particularly to make considerable commercial production. In this light, this research was conducted to screen and identify local marine microalgal strains to produce biodiesel. The targeted microalgae is one that could produce a high lipid content with a short growth rate through the improvement of related parameters, namely: carbon which could be derived from CO2,

Screening of Local Marine Microalgae for Biodiesel Production

essential salts and minerals for growth that could be introduced from water input, light quantity and quality that influence photosynthetic processes, and suitable space design (bioreactor). Background Biodiesel Production Biodiesel is defined as the mono-alkyl esters of a long chain fatty acid. It constitutes an alternative fuel for compression-ignition (diesel) engines. The most common biodiesel constituent used today is fatty acid methyl esters from triacylglycerols (TAGs) recovered from vegetable oils and animal fats (Lykidis and Ivanova 2008). Oil used in making biodiesel consists of triglycerides in which three fatty acid molecules are esterified with a molecule of glycerol. Triglycerides are made to react with methanol in a process known as transesterification or alcoholysis. Transesterification produces methyl esters of fatty acids, which are biodiesel and glycerol (Figure 2). The reaction occurs stepwise: triglycerides are first converted to diglycerides, then to monoglycerides, and then finally to glycerol. Transesterification requires 3 mole (mol) of alcohol for each mole of triglyceride to produce 1 mol of glycerol and 3 mol of methyl esters (Chisti 2007). The process of making biodiesel occurs as follows: 1) the triglycerides, methanol, and a catalyst are placed in a controlled reaction chamber to undergo transesterification, 2) the initial product is placed in a separator to remove the glycerin by-product, 3) the excess methanol is recovered from the methyl esters through evaporation, and 4) the final biodiesel is rinsed with water, pH neutralized, and dried (Xu et al. 2006). Industrial processes use 6 mol of methanol for each mole of triglyceride (Fukuda et al. 2001). This considerable excess of methanol ensures that the reaction is driven towards methyl esters

Screening of Local Marine Microalgae for Biodiesel Production

Figure 2. Transesterification of oil to biodiesel

O CH2 O C R1 O CH O C R2 O + 3CH3OH O R1 C O CH3 O R2 C O CH3 O + CH2OH + CH2OH

CH2 O C R1 *R1-3 are hydrocarbon groups

R3 C O CH3

+ CH2OH

or biodiesel. The yield of methyl esters exceeds 98 percent on a weight basis (Fukuda et al. 2001). Transesterification is catalyzed by acids, alkalis (Fukuda et al. 2001; Meher et al. 2006), and lipase enzymes (Sharma et al. 2001). Alkali-catalyzed transesterification is about 4,000 times faster than the acid catalyzed reactions (Fukuda et al. 2001). Consequently, alkalis, such as sodium and potassium hydroxide, are commonly used as commercial catalysts at a concentration of about one percent by weight of oil. Alkoxides, such as sodium methoxide, are even better catalysts than sodium hydroxide and are being used increasingly. Compared to the acid and alkali methods, enzymatic transesterification offers an environmentalfriendly option and has been suggested as a realistic alternative to conventional processes. The key factor to a successful enzymatic process is lipase immobilization. This makes it easier for recovery and reuse (Kaieda et al. 1999; Shimada et al. 1999; Xiong et al. 2008). Methanol and oil do not mix; hence, the reaction mixture contains two liquid phases. Other alcohols can be used, but methanol is the least expensive. To prevent yield loss due to saponification reactions or soap formation, the oil and alcohol must be dry and the oil

Screening of Local Marine Microalgae for Biodiesel Production

should have a minimum of free fatty acids. Biodiesel is recovered by repeated washing with water to remove glycerol and methanol (Chisti 2007). Biodiesel from Microalgae Algae have been long known to accumulate lipids, particularly TAGs (Guschina and Harwood 2006). The effect of various growth parameters (nutrient limitation, CO2, light intensity) on the lipid composition of several algal species has been studied. Factors that favor increased intracellular TAG levels include nutrient limitation, increased CO2 concentration, and increased light density (Lykidis and Ivanova 2008). The algae used in biodiesel production are usually aquatic unicellular green algae. This type of algae is a photosynthetic eukaryote characterized by high growth rates and high population densities. Under good conditions, green algae can double its biomass in less than 24 hours. Additionally, green algae have huge lipid content, frequently over 50 percent (Schneider 1994; and Chisti 2007). High yield and high density biomass are ideal for intensive agriculture and may be an excellent source for biodiesel production (Table 2). Algae have a number of unique benefits. As an aquatic species, they do not require land for cultivation. This means that algal cultivation does not need to compete with agricultural commodities for growing space. In fact, algae cultivation facilities can be built on marginal land that has few uses. The water used in algal cultivation can be fresh water or saline with salt concentrations up to twice that of seawater. Both can be used effectively (Brown and Zeiler 1993; Aresta et al. 2005). This means that algae need not compete with other users for fresh water. Algae also have a greater capacity to absorb CO2 than land plants, and are not prone to photosynthetic inhibition under conditions of intense sunlight (Brown and Zeiler 1993). After oil extraction from algae, the remaining biomass fraction can be used as a high protein feed for livestock (Schneider 1994; Haag 2007). This gives further value to the process and reduces wastes as well.

Screening of Local Marine Microalgae for Biodiesel Production

Algal cultivation is typically performed in two ways: open ponds and bioreactors. Open race-way-based ponds are the preferred method of large scale algal cultivation. They have been used since the 1950s to produce food supplements and pharmaceuticals (Chisti 2007). Unfortunately, the race-way system suffers from relatively low algal densities, environmental variability, water evaporation, and a high land footprint (Haag 2007; Chisti 2007). Bioreactors are the preferred method for scientific researches, and recently, for some newer, innovative production designs. These systems are more expensive to build and operate, however, they allow for a very controlled environment. This means that gas levels, temperature, acidity (pH), mixing, media concentration, and light can be optimized for maximum production. Unlike open ponds, bioreactors can ensure that a single algal species is grown without interference or competition (Chisti 2007). Microalgae are the most primitive of plants. While the mechanism of photosynthesis is similar to that of higher plants, they are generally more efficient converters of solar energy because of their simple cellular structure. In addition, because the cell grows in an aqueous suspension, they have more efficient access to water, CO2, and other

Table 2. Oil content of some microalgae (Krawczyk 1996)

Microalgae Botryococcus braunii Chlorella sp. Crypthecodium cohnii Dunaliella primolecta Isochrysis sp. Monallanthus salina Nannochloris sp. Nannochloropsis sp. Neochloris oleoabundans Nitzschia sp. Phaeodactylum tricornutum Schizochytrium sp. Tetraselmis sueica Oil content (% dry weight) 2575 2832 20 23 2533 >20 2035 3168 3554 4547 2030 5077 1523

10

Screening of Local Marine Microalgae for Biodiesel Production

nutrients. For these reasons, microalgae are capable of producing 30 times the amount oil per unit area of land, compared to terrestrial oilseed crops. Biologists have categorized microalgae in a variety of classes, mainly distinguished by their pigmentation, life cycle, and basic cell structures. The four most important, at least in term of abundance, (Barclay et al. 1986) are: 1) the diatoms (Bacillariophyceae) which are the dominating phytoplankton of the oceans with approximately 100,000 species known to exist, 2) the green algae (Chlorophyceae) which are quite abundantly found in freshwater, 3) the blue-green algae (Cyanophyceae) which play an important role in fixing nitrogen from the atmosphere with approximately 2,000 species found in a variety of habitats, and 4) the golden algae (Crysophyceae) with approximately 1,000 species found mainly in freshwater systems. For this research, we focused on the screening of local marine microalgae of the diatoms class provided by the Microalgae Culture Collection of the Research Center for Oceanography of the Indonesian Institute of Sciences (LIPI).

Screening of Local Marine Microalgae for Biodiesel Production

11

Methodology

Research Strategy This research was divided into five sections. The first section determined the algal strains to be studied and the preparation of the culture medium. The second section covered the cultivation of the algae in a simple photobioreactor. The third section explored optimizing biomass production further by cultivating the strain in a simple photobioreactor. The fourth section covered lipid extraction. The final section of the research was transesterification of lipid to form biodiesel. Analytical procedures Microalgae and Media Conditions The culture of microalgae obtained from the Microalgae Culture Collection of the LIPI included: Chaetoceros sp., Skeletonema sp., Navicula sp., Melosira sp., and Nitzchia sp. These microalgae were activated and then cultivated in a Guillard f/2 or Walne seawater medium using a simple photobioreactor. Besides the five species of microalgae, Thalassiosira sp. and green microalgae, Nannochloropsis sp., obtained from collection of the School of Life Sciences, Institut Teknologi Bandung (ITB), were also cultivated. Guillard f/2 (Guillard 1975) and the Walne medium are commonly and widely used as general enriched-seawater medium designed for growing coastal marine algae, especially diatoms. Walnes medium is an enriched seawater medium designed for mass culture of marine phytoplankton used as feed for shellfish (Andersen 2005). In general, the mineral content of both media is similar (the ingredient and preparation techniques of the media are listed in Appendix A).

12

Screening of Local Marine Microalgae for Biodiesel Production

Microalgae Cultivation Instrumentation (Photobioreactor Scheme). Two kinds of photobioreactor schemes were tested (Figures 3 and 4). The first included using two liter transparent plastic bottles, an air pump, a manifold, and a membrane filter. The second was similar to the first, differing on reactor material using transparent glass bottles with 20 cm in length and 6 cm in diameter. Based on the experiment, the use of transparent glass bottles as a reactor was more convenient and safer for the culture as it was easy to sterilize with the autoclave. Transparent glass bottles with low light absorption properties were better than transparent plastic bottles. For an upscaling experiment, however, one gallon transparent plastic bottles were used because of its availability. In the upscaling experiment, light intensity used was higher.

Figure 3. Simple photobioreactor using transparent plastic bottles

Flexible pipe connect to CO2 source

Rubber Plug and L-Glass pipe

Aeration stone Membrane filter Connector

Connector

Screening of Local Marine Microalgae for Biodiesel Production

13

Figure 4. Simple photobioreactor using transparent glass bottles

Growth Conditions of the Microalgae. The inoculum microalgae in the final concentration of 10 percent volume to volume (v/v) was cultured in 50500 ml transparent glass bottles containing 30 parts per thousand (ppt) salinity of seawater. The microalgae was incubated at room temperature (26 1oC), under a light intensity of 3800 lux, and under a photobioreactor surface. It was bubbled with air. The culture was photoilluminated for 12 hours, followed by a dark period of 12 hours. Microalgal growth, specifically, daily changes in cell numbers and optical density, were observed. Cell numbers were counted under a microscope with an improved Neubauer hemocytometer. Optical density was measured using ultravioletvisible spectrophotometry (UV-Vis) at wavelength 682 nanometers (nm) for Nannochloropsis sp. and 530 nm for Thalassiosira sp.) Since microalgae can be distinguished by their pigmentation, growth of the cells can be observed by increasing their optical density at specific wavelengths.

14

Screening of Local Marine Microalgae for Biodiesel Production

Biomass Optimization in a Photobioreactor Biomass optimization started after the microalgal cell reached great numbers in the cultivation process. These upscaling experiments were carried out in a photobioreactor consisting of two plastic gallons with 15 L volume each under the same illumination and medium conditions as in the cultivation process. Scale-up experiments were conducted with two variations on aeration sources. The first culture was bubbled with free air; meanwhile, the second culture was bubbled with an air/CO2 mixture (98/2, v/v). Cultures were prepared in 13.5 L seawater containing Walne medium and 10 percent (v/v) inoculums from previous cultivations. Microalgal growth was measured by daily changes in optical density and cell numbers is described above. Lipid Extraction After finishing cultivation, microalgal cells were harvested at a stationary phase using the centrifugation method (7,000g, 15 min, 4oC). The cells were then collected and weighed. To get high concentrations from lipid extraction, two kinds of cell treatment were investigated: 1) cells were dried using lyophilization or freeze drying method, and 2) cells in an organic solvent were sonicated for 15 minutes with a frequency of 50 Hertz. The Soxhlet extractor method was subsequently adopted to extract total lipid in the algae cells. There were two solvent variations conducted for the lipid extractions: using hexane and using chloroform/methanol (1:1 v/v for Thalassiosira sp. and 1:2 v/v for Nannochloropsis sp.). Extraction was achieved by washing the sample repeatedly with pure solvent until no lipid was left in the cells. The weight of lipids measured after removing the solvent by rotary evaporator and then lipid content was calculated. Fatty acid contents were analyzed using a gas chromatography-mass spectrophotometer (GC-MS) instrument.

Screening of Local Marine Microalgae for Biodiesel Production

15

Transesterification of lipids In this step, only the lipids produced by Thalassiosira sp. were used and determined quantitatively. The transesterification of lipid was performed by refluxing lipid samples of the microalgae in KOH/ methanol (1:4 v/v) for one hour at 70oC. The oily phase of ester products was centrifugated at 2,000g for five minutes. This was followed by determining the ester concentration using the Nile red fluorescence method (Greenspan and Fowler 1985). Briefly, a 3 ml reaction mixture containing 0.3 parts per million (ppm) Nile red, 100 micro liters (l) ester sample, and 2.89 ml chloroform was incubated at 40oC for 10 minutes. The fluorescence intensity of the mixture was measured at an excitation wavelength of 485 nm and an emission wavelength of 593 nm. Ester of palm oils in Nile red was employed as a standard.

16

Screening of Local Marine Microalgae for Biodiesel Production

Results and Discussion

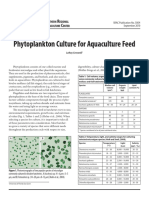

Algal Growth Seven marine microalgal strains have been screened either in Guillard f/2 medium or Walne medium. Five of those strains, including Chaetoceros sp., Skeletonema sp., Navicula sp., Melosira sp., and Nitzchia sp., were unable to adapt into the new medium conditions. Two strains, namely, Thalassiosira sp. and Nannochloropsis sp. (Figure 5), showed good adaptation levels under the experimental medium and both were used for further characterization. Eight ml inoculum of the microalgal starter was cultured in 800 ml of Walne medium with a final cell density of 1106 cell/ml under the following conditions: 25 ppt seawater salinity, 2,500 lux light intensity, and 1,000 ml/min air-bubbling. During the microalgal growth observation, the culture was photoilluminated continuously. The temperature in 0.8 L of culture varied from 2527oC with a mean value of 26.3 1oC. Growth of Thalassiosira sp. and Nannochloropsis sp. under this condition is shown in Figure 6.

Figure 5. Screening of microalgae Thalassiosira sp. (a) and Nannochloropsis sp. (b)

(a)

(b)

Screening of Local Marine Microalgae for Biodiesel Production

17

The growth curve of microalgae was also determined. The initial microalgal density applied for both Thalassiosira sp. and Nannochloropsis sp. was 1106 cell/ml. Until the first four days, no increase in cell densities was observed for both microalgae because it was during their period of adaptation. Parameters such as initial cell concentration, photoillumination intensity, and aeration rate for producing microalgal biomass may play an important role during the adaptation period. After the survival period, the microalgal cell showed significant growth (Figure 7). The exponential growth of Thalassiosira sp. was observed until the 10th day with a cell density of 5.96106 cell/ml. Meanwhile, Nannochloropsis sp. reached the highest cell density of 13.3106 cell/ml on the 14th day.

Figure 6. Culture of microalgae with starting cell density of 1106 cell/ml

a. Thalassiosira sp.

Day 0 Day 18

b. Nannochloropsis sp.

Day 0 Day 17

18

Screening of Local Marine Microalgae for Biodiesel Production

Figure 7. Growth curves of microalgae in 0.8 L of culture

16 14

Nannochloropsis sp.. N a n n o c h lo r o p s is s p Thalassiosira s p . T h a la s s io s ir a sp.

/ml) Cell density (x10

12 10 8 6 4 2 0 0

10 T im e ( d a ys )

15

20

Biomass productivity

To perform biomass optimization, the initial step was to identify which days during the cultivation process the microalgal cells reach their maximum growth rate. By the end of the lag phase, microalgal cells adapted to the new conditions of growth (logarithmic [log] phase). The growth of the biomass at the log phase can be described quantitatively by plotting the log of the cell number against time (Crueger and Crueger 1982). By observing the cell density per day, the growth rate is determined using the formula below. rx = ((ln xn-ln xo)/t) . xn x = rx/xn Where: rx = average rate x = specific growth rate xn = cell number on day-n ln = x0 = t = time Biomass optimization begins after the microalgal cells reach great

Screening of Local Marine Microalgae for Biodiesel Production

19

numbers during the cultivation process (Appendix B). The best time for harvesting microalgal biomass is when the specific growth rate value is at its maximum. Thalassiosira sp. and Nannochloropsis sp. had the highest specific growth rate at 0.17 and 0.19, respectively. The specific growth rate values of both microalgae were obtained after 10 days of the cultivation process. The cells were then ready for upscaling experiments. The upscaling experiments were carried out in a photobioreactor that consisted of two plastic gallons with a 15 L volume, each under the same illumination and medium conditions as in the cultivation process (Figure 8). Two variations on aeration sources in upscaling experiments were investigated. The first culture used free air, while the second culture consisted of mix aeration (air/ CO2, 98/2 (v/v)). Cultures were prepared using 13.5 L of seawater that contained Walne medium, and 10 percent (v/v) inoculums from previous cultivations. Carbon dioxide is the only carbon source for the photosynthesis of microalgae. On exploring the effects of CO2 concentration on biomass accumulation, two variations in aeration sources for biomass production were applied: free air and air+CO2. As generally known, microalgae are capable of taking CO2 and converting it into a high density of biomass. Of course, a higher density of algal biomass will bring about higher lipid concentrations.

Figure 8. Upscaling experiments for producing microalgal biomass

Thalassiosira sp.

Nannochloropsis sp.

20

Screening of Local Marine Microalgae for Biodiesel Production

Table 3. Biomass productivity of microalgae

Microalgae Thalassiosira sp. Aeration condition Air Air + CO2 Air Air + CO2 Biomass concentration (g/l) 0.49 0.31 2.63 0.32

Nannochloropsis sp.

Table 3 shows the biomass productivity of the microalgae. Approximately 0.49 g/l Thalassiosira sp. and 2.63 g/l Nannochloropsis sp. were obtained from the microalgal culture with free air bubbling for 10 days and 14 days, respectively. However, an unexpected result was shown in the microalgal culture bubbled with the air/CO2 mixture. Both microalgae Thalassiosira sp. and Nannochloropsis sp. densities in the culture bubbled with air/CO2 mixture were lower than that of densities of the culture bubbled with free air. It may be explained that the addition of the high CO2 concentration into the microalgal culture caused the decrease in the pH of the medium. This may have poisoned cell growth. Similar results were reported in other studies where increasing the acidity of the culture, owing to addition of high CO2 concentrations, inhibited the growth of the microalgae (Silva and Pirt 1984; Sung et al. 1999; Chang and Yang 2003; de Morais and Costa 2007). The fatty acids content in the lipids produced from the microalgal biomass are listed in Table 4. Thalassiosira sp. produced 51.4 percent of fatty acid from the culture under free air bubbling and 41.2 percent fatty acid from the culture under air/CO2 mixture. A similar phenomenon was also observed in Nannochloropsis sp. (65.5% fatty acid from the culture under free air bubbling and 53.9% fatty acid from the culture under air/CO2 mixture). This result suggests that in order to get high lipid products the CO2 concentration in the microalgal culture medium should be noted.

Screening of Local Marine Microalgae for Biodiesel Production

21

Table 4. Total fatty acid content obtained from microalgae

a. Thalassiosira sp. Variation A B C D Aeration Pre-treatment Solvent Total fatty acid (%) 37.3 39.3 51.4 41.2

Chlo:Met Air CO2 Sonication Freeze drying Hexane (1:1)

b. Nannochloropsis sp. Variation A B C D E Aeration Pre-treatment Solvent Chlo:Met (1:1) Total fatty acid (%) 29.9 30.5 65.5 30.5 53.9

Air CO2 Sonication Freeze drying Hexane

Lipid content Prior to extracting lipids using an organic solvent, two different pretreatments of microalgal pellets were undertaken, namely, the drying cell and the sonicating cell. Lyophilization, or the freezedrying method, was applied to the dry cell, while the ultrasound disruption of the cell was used for the sonicating cell. Fatty acid contents were analyzed using the GC-MS instrument (Appendix C). The percentages of total fatty acid content obtained from pretreatment using the dry cell were 39.3 percent and 30.5 percent for Thalassiosira sp. and Nannochloropsis sp., respectively (Table 4). Higher fatty acid content (51.4% for Thalassiosira sp. and 65.5% for Nannochloropsis sp.) was obtained from cells that have already been disrupted. These results suggest that the disruption of the microalgal pellet followed by lipid extraction provides more fatty acid.

22

Screening of Local Marine Microalgae for Biodiesel Production

Two kinds of organic solvents for extracting lipid, namely hexane and chloroform/methanol, were also investigated. The percentages of total fatty acid content extracted using hexane solvent were 37.3 percent and 29.6 percent for Thalassiosira sp. and Nannochloropsis sp., respectively. Lipid extraction using chloroform/methanol solvent produced higher fatty acid content, with 39.3 for Thalassiosira sp. and 30.5 percent for Nannochloropsis sp. Tornabene et al. (1982) reported that solvents extracted lipids from the microalgae, such as, hexane (acyclic hydrocarbons), benzene (cyclic hydrocarbons, polyunsaturated hydrocarbons, sterols, and xanthophylls), chloroform (mono-, di-, and triacylglicerols, free fatty acids, and pheophytin a), methanol (phospholipids and chlorophyll c), and acetone (glycolipids, carotenoids, and chlorophyll a and b). Thus, the best solvent to extract triacylglicerols and phospholipids from microalgae is the chloroform/methanol mixture. The extracted oils from both microalgae gave different appearances. Brown oils were obtained from Thalassiosira sp. pellet extracted using the hexane solvent, while, clear yellow oils were obtained from the chloroform/methanol extraction (Figure 9). Lipid extraction using the hexane solvent took most of the nonpolar chemicals, including the pigments, out. Oils from Nannochloropsis sp. also

Figure 9. Oil products obtained from Thalassiosira sp. using solvent hexane (a) and chloroform/methanol mixture (b)

(a)

(b)

Screening of Local Marine Microalgae for Biodiesel Production

23

showed similar colors to the oils from Thalassiosira sp. (Figure 10). The fatty acid content of the microalgal lipids are listed in Table 5. More free fatty acids, such as palmitic acid and oleic acid, were extracted using the chloroform/methanol mixture as compared to using hexane (Tornabene et al. 1982).

Figure 10. Some oil products obtained from Nannochloropsis sp.

Table 5. Fatty acid content of microalgal lipid extracted with different solvents.

a. Thalassiosira sp. Fatty Acid (%) No. Solvent Myristic Palmitic Stearic acid acid acid 17.4 41.7 9.8 Oleic Acid 17.5 47.4 Total 34.9 98.9

1 Hexane 2 Chloroform:methanol b. Nannochloropsis sp.

Fatty Acid (%) No. 1 2 Solvent Hexane Chloroform:methanol Palmitic Hexadecadienoic Oleic Acid acid acid 29.9 23.8 3.66 3.03 Total 29.9 30.5

24

Screening of Local Marine Microalgae for Biodiesel Production

Biodiesel productivity To calculate biodiesel productivity, Thalassiosira sp. was used as a model mainly because the cell culture was relatively easy to handle. Also, because it was inexpensive, its modified growth medium can be developed easily. The previous methods such as air bubbling for culturing microalgae, sonication for disrupting cells, and solvents for extracting lipids, were applied. The experimental conditions, microalgal density, and calculation of biodiesel productivity are enclosed in Appendix D. Briefly, the microalgal cells were grown to a late log phase, harvested, sonicated, and extracted with the chloroform/methanol mixture followed by refluxing with an alkaline methanol. The amount of biodiesel in the form of methyl ester of fatty acids was determined using the Nile red fluorometric assay. This study defined biodiesel productivity as the total amount of ester (l) produced from one liter of microalgal culture (l culture) for seven days (d) or until the late log phase. The trials showed that the average Thalassiosira sp. density for seven days was 4.36 g/l, while the biodiesel product was 241 l esters/g biomass. This gave a biodiesel productivity of 150 l ester/l culture/d. Extrapolation to large-scale calculations of biodiesel productivity can be done with the assumption that this relationship is linear, although in reality, there are other factors that must be considered. Theoretically, biodiesel productivity of Thalassiosira sp. was 547,500 l/ha/y, much higher than the biodiesel productivity of palm oil (5,950 l/ha/y). This value agrees with biodiesel productivity of microalgae reported by Chisti (2007). This fact should make scientists/researchers in tropical archipelagic countries advance the research and development of marine microalgae for biodiesel.

Screening of Local Marine Microalgae for Biodiesel Production

25

Summary and Conclusions

Worldwide efforts exploring the use of microalagae for producing biodiesel have been in progress for several decades. This study successfully cultured two of seven screened marine microalgal strains for biodiesel production. These were Thalassiosira sp. and Nannochloropsis sp. Results showed that both microalgae produced fatty acids that can serve as raw material for biodiesel. The growth of Thalassiosira sp. and Nannochloropsis sp. in Walne medium using free air bubbling had the highest specific growth rate of 0.17 and 0.19, respectively, in 10 days. Biomass concentration obtained from the cultures of Thalassiosira sp. and Nannochloropsis sp. were 0.49 g/l and 2.63 g/l, respectively. To release oils from inside the cells, the sonication method is the most effective in disrupting microalgae, followed by the Soxhlet extraction using the chloroform/methanol mixture which produced more fatty acids. The biodiesel productivity of Thalassiosira sp. was 150 l/l culture/d. This is higher than other biodiesel feedstock like palm oil. This research shows that tropical marine microalgae can potentially produce biodiesel in a large scale. However, more work still needs to be done in order to achieve a competitive commercial production This study recommends further research on the efficiency of producing biodiesel from microalgae, focusing on cultivating highly productive microalgae and developing low-cost and rapid harvesting techniques. Finally, to fully harness the benefits of using algae for fuel and other potential feedstock, more government and/or private investment on research in this area should be appropriated.

26

Screening of Local Marine Microalgae for Biodiesel Production

References

Andersen, R.A. 2005. Algal Culturing Techniques. Elsevier Academic Press. USA. Aresta, M., Dibenedetto, A., Carone, M., Colonna, T. and C. Fagale. 2005. Production of Biodiesel from Macroalgae by Supercritical CO2 Extraction and Thermochemical Liquefaction. Environmental Chemistry Letters, 3: 136139. Barclay, W., Johansen, J., Chelf, P., Nagle, N., Roessler, R, and P. Lemke. 1986. Microalgae Culture Collection, 19861987. Solar Energy Research Institute, Colorado, USA. Barnwal, B.K. and M.P. Sharma. 2005. Prospects of biodiesel production from vegetables oils in India. Renewable and Sustainable Energy Review, 9: 363378. Benemann, J.R., Persoff, P. and W.J. Oswald. 1978. Cost Analysis of Microalgae Biomass Systems. Final report prepared for the Department of Energy, USA Brown, L. M. and K.G. Zeiler. 1993. Aquatic Biomass and Carbon Dioxide Trapping. Energy Conversion Management, 34(9-11): 10051013. Chang, E.H. and S.S. Yang. 2003. Some Characteristics of Microalgae Isolated in Taiwan for Biofixation of Carbon Dioxide. Botanical Bulletin of Academia Sinica, 44: 4352. Chisti, Y. 2007. Biodiesel from Microalgae. Biotechnology Advances, 25: 294306.

Screening of Local Marine Microalgae for Biodiesel Production

27

Crueger, W. and A. Crueger. 1982. Biotechnology: A Textbook of Industrial Microbiology. Sinauer Associates, Inc., USA. de Morais, M.G. and J.A.V. Costa. 2007. Isolation and Selection of Microalgae from Coal Fired Thermoelectric Power Plant for Biofixation of Carbon Dioxide. Energy Conversion and Management, 48: 21692173. EIA (Energy Information Administration). 1999. International Energy Outlook. Department of Energy, Washington DC, USA. Felizardo, P., Correia, M.J.N., Raposo, I., Mendes, J.F., Berkemeier, R. and J.M. Bordado. 2006. Production of Biodiesel from Waste Frying Oil. Waste Management, 26(5): 487494. Fukuda, H., Kondo, A. and H. Noda. 2001. Biodiesel Fuel Production by Transesterification of Oils. Journal of Bioscience and Bioengineering, 92: 405416. Greenspan, P. and S.D. Fowler. 1985. Spectrofluorometric Studies of the Lipid Probe, Nile Red. The Journal of Lipid Research, 26: 781789. Guillard, R.R.I. 1975. Culture of Phytoplankton for Feeding Marine Invertebrates. Pages 296-360 in Culture of Marine Invertebrate Animals. W.L. Smith and M. H. Chanley (eds). Plenum Publishing Corp., New York. Guschina, I.A. and J.L. Harwood. 2006. Lipids and Lipid Metabolism in Eukaryotic Algae. Progress in Lipid Research, 45: 160186. Haag, A. L. 2007. Algae Bloom Again. Nature, 447: 520521.

28

Screening of Local Marine Microalgae for Biodiesel Production

Huesemann MH. 2006. Can Advances in Science and Technology Prevent Global Warming? A Critical Review of Limitations and Challenges. Mitigation and Adaptation Strategies for Global Change, 11: 539-577. Huntley, M.E. and D.G. Redalje. 2006. CO2 Mitigation and Renewable Oil from Photosynthetic Microbes: A New Appraisal. Mitigation and Adaption Strategies for Global Change, 12(4): 573-608. Kaieda, M., Samukawa, T. and T. Matsumoto. 1999. Biodiesel Fuel Production from Plant Oil Catalyzed by Rhizopus oryzae Lipase in a Water-Containing System without an Organic Solvent. Journal of Bioscience and Bioengineering, 88: 627631. Krawczyk, T. 1996. BiodieselAlternative fuel makes inroads but hurdles remain. INFORM, 7: 801829. Kulkarni, M.G. and A.K. Dalai. 2006. Waste Cooking Oil An Economical Source for Biodiesel: A Review. Industrial & Engineering Chemistry Research, 45: 29012913. Lykidis, A. and N. Ivanova. 2008. Genomic Prospecting for Microbial Biodiesel Production. Department of Energys Office of Science, Biological and Environmental Research Program, USA. Meher, L.C., Vidya, S.D. and S.N. Naik. 2006. Technical Aspects of Biodiesel Production by Transesterification A Review. Renewable and Sustainable Energy Review, 10: 248268. Pak, J.H., Lee, S.Y., Shin, W.C. and H.Y. Lee. 1991. Optimization of Producing Liquid Fuel from Photosynthetic Algal Growth. Journal of Microbiology and Biotechnology, 1(2): 111115.

Screening of Local Marine Microalgae for Biodiesel Production

29

Ratledge, C. 1989. Biotechnology of Oils and Fats. Pages 567-668 in Microbial lipids Vol. 2. C. Ratledge and S.G. Wilkinson (eds). Academic Press, London, UK. Ratledge, C. and J.P. Wynn. 2002. The Biochemistry and Molecular Biology of Lipid Accumulation in Oleaginous Microorganisms. Advances in Applied Microbiolology. 51: 151. Schneider, D. 2006. Grow your Own: Would the Wide Spread Adoption of Biomass-Derived Transportation Fuels Really Help the Environment? American Scientist, 94: 408409. Sharma, R., Chisti, Y. and U.C. Banerjee. 2001. Production, Purification, Characterization, and Applications of Lipases. Biotechnology Advances, 19: 627662. Shimada, Y., Watanbe, Y., and T. Samukawa. 1999. Conversion of Vegetable Oil to Biodiesel Using Immobilized Candida Antarctica Lipase. Journal of the American Oil Chemists Society, 76: 789792. Silva, H.J. and S.J. Pirt. 1984. Carbon Dioxide Inhibition of Photosynthetic Growth of Chlorella. Journal of General Microbiology, 130: 28332838. Sung, K.D., Lee, J.S., Shin, C.S., Park, S.C. and M.J. Choi. 1999. CO2 Fixation by Chlorella sp. KR-1 and Its Cultural Characteristics. Bioresource Technology, 68, 269273. Tornabene, T.G., Ben-Amotz, A. and J.S. Hubbart. 1982. Isolation, Analysis and Identification of Lipids. Solar Energy Research Institute. Colorado, USA. Wagner, L. 2007. Biodiesel from algae oil, research report. http:// www.moraassociates.com/content/publications/ (accessed 18 July 2008).

30

Screening of Local Marine Microalgae for Biodiesel Production

Xiong, W., Li, X., Xiang, J., and Q. Wu. 2008. High-Density Fermentation of Microalgae Chlorella protothecoides in Bioreactor for Microbio-Diesel Production. Applied Microbiology and Biotechnology. 78: 2936. Xu, H., Miao, X. and Q. Wu. 2006. High Quality Biodiesel Production from a Microalga Chlorella Protothecoides by Heterotrophic Growth in Fermenters. Journal of Biotechnology, 126: 499507.

Screening of Local Marine Microalgae for Biodiesel Production

31

Appendices

Appendix A. Recipe for Diatom Seawater Medium 1. Guillard f/2 Medium Add the following components into 950 ml of filtered natural seawater: NaNO3, NaH2PO4 H2O, Na2SiO39H2O, trace metals solution (see mix below), and a vitamin solution (see mix below). Bring the final volume to 1 liter with filtered natural seawater. Then use an autoclave to reduce precipitation. If silicate is not required, omit.

1.1 Trace Metal Solution Dissolve the EDTA and other components identified in the table below into 950 ml of dH2O. Bring the final volume to 1 liter with dH2O.

1.2 Vitamins Solution Dissolve the thiamine HCl into 950 ml of dH2O and then add 1 ml of the primary stocks. Bring final volume to 1 liter with dH2O. Filter, sterilize and store frozen.

32

Screening of Local Marine Microalgae for Biodiesel Production

2. Walne Medium Dissolve the following components into 900 ml of high quality dH2O: NaNO3, H3BO3, Na2 EDTA, NaH2PO4 H2O, FeCl3 6H2O into MnCl2 4H2O and trace metal solution (see mix below). Bring final volume to 1 liter with high-quality dH2O. Filter, sterilize, and store at 4C.

2.1 Trace Metal Solution Dissolve the components of the table below into 900 ml of high quality dH2O. This solution is normally cloudy. Acidify with a few drops of concentrated HCl to give a clear solution. Bring final volume to 1 liter with high-quality dH2O. Filter, sterilize, and store at 4C.

Screening of Local Marine Microalgae for Biodiesel Production

33

2.2 Vitamins Solution Dissolve the thiamine HCl and cyanocobalamine into 950 ml of dH2O. Bring final volume to 1 liter. Filter, sterilize, and freeze.

Appendix B. Growth Curve of Microalgae 1. Growth Curve from Initial Cultivation 1.1 Thalassiosira sp. Growth Curve

1.2 Nannochloropsis sp. Growth Curve

34

Screening of Local Marine Microalgae for Biodiesel Production

2. Growth Curve from Biomass Optimization 2.1 Thalassiosira sp. Growth Curve with Air/CO2 Mixture (98/2, v/v) aeration

2.2 Nannochloropsis sp. Growth Curve with Air/CO2 Mixture (98/2, v/v) Aeration

Screening of Local Marine Microalgae for Biodiesel Production

35

Appendix C. GC-MS of Lipids 1. GC-MS Profile of Lipid Extracted from Thalassiosira sp. using Solvent Hexane

1.1 Myristic Acid

1.2 Oleic Acid

36

Screening of Local Marine Microalgae for Biodiesel Production

2. GC-MS Profile of Lipid Extracted From Thalassiosira sp. using Solvent Chloroform:Methanol (1:1)

2.1 Palmitic Acid

2.2 Stearic Acid

Screening of Local Marine Microalgae for Biodiesel Production

37

3. GC-MS Profile of Lipid Extracted from Nannochloropsis sp. using Solvent Chloroform:Methanol (1:2)

3.1 Hexadecadienoat Acid

3.2 Palmitic Acid

3.3 Oleic acid

38

Screening of Local Marine Microalgae for Biodiesel Production

4. GC-MS Profile of Lipid Extracted from Nannochloropsis sp. using Solvent Hexane

4.1 Palmitic Acid

5. GC-MS Profile of Lipid Extracted from Nannochloropsis sp. (cultivated in air/CO2 mixture) using Solvent Chloroform:Methanol (1:2)

Screening of Local Marine Microalgae for Biodiesel Production

39

5.1 Palmitic Acid

5.2 Oleic Acid

6. GC-MS Profile of Lipid Extracted from Nannochloropsis sp. (cultivated in air/CO2 mixture) using Solvent Hexane

6.1 Palmitic Acid

40

Screening of Local Marine Microalgae for Biodiesel Production

Appendix D. Data For Calculating Biodiesel Productivity 1. Culture Conditions Type of microalga Medium of culture Light intensity Photoperiod Starting cell density Agitation Temperature Each single culture volume : Thalassiosira sp. : Walne medium : 3,000 lux (40.5 mol m-2 s-1) : light/dark (24:0) : 1 105 cells/ml : free air bubbling : room temperature : 800 ml

2. Thalassiosira sp. Cell Density For oil production, Thalassiosira sp. cells are harvested to late of logarithmic phase (7th day). Duration of culture Average Thalassiosira sp. density : 7 days : 4.36 g/l culture

Screening of Local Marine Microalgae for Biodiesel Production

41

3. Calculation of Biodiesel Productivity Calibration curve of esters of palm oil

Lipid determination method Standard used Biodiesel product

: Nile red fluorometric assay : esters of palm oil : 241 l esters/g biomass

Biodiesel productivity of Thalassiosira sp. is defined as the total amount of ester (l) produced from one liter of microalgal culture for seven days (until its late logarithmic phase) at experimental conditions. Thus, biodiesel productivity of Thalassiosira sp. = Biodiesel product (l esters/g biomass) biomass density (g/l culture) duration of culture (d) = 241 l ester/g 4.36 g/l 7 d = 150 l esters/l culture/d Theoretical calculation of biodiesel productivity of 107 L culture (equivalent to volume one ha area with 1 m in depth) for one year is = (150 l ester/l culture/d) (365 d/y) (107 l culture/ha) = 547,500 l esters/ha/y

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Algae Biofuel Research Yields Promising ResultsDocument10 pagesAlgae Biofuel Research Yields Promising ResultsMohsinKhanNo ratings yet

- Progress of Microalgae Biofuels CommerciDocument10 pagesProgress of Microalgae Biofuels CommerciNthambi MiriamNo ratings yet

- Biotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeDocument46 pagesBiotecnologia de Microalgas (1988 R) - (De La Noue and de Pauw) - The Potential of Microalgal Biotechnology A Review of Production and Uses of MicroalgaeAlexsandro ClaudinoNo ratings yet

- Culturing-Algae-Carolina Biological Supply Company - Atomization Method and Algal Media FormulaDocument28 pagesCulturing-Algae-Carolina Biological Supply Company - Atomization Method and Algal Media FormulaAmir IzhamNo ratings yet

- Culturing AlgaeDocument28 pagesCulturing AlgaesertNo ratings yet

- 2013 - Biotechnological Applications of Microalgae - Biodiesel and Value Added ProductsDocument251 pages2013 - Biotechnological Applications of Microalgae - Biodiesel and Value Added ProductsHugo LunaNo ratings yet

- Operation and Management of Shrimp HatcheryDocument54 pagesOperation and Management of Shrimp HatcheryPamungkas T.No ratings yet

- Phytoplankton Culture For Aquaculture Feed: S R A CDocument16 pagesPhytoplankton Culture For Aquaculture Feed: S R A CFen TZNo ratings yet

- Training Manual On Live Feed - 1Document16 pagesTraining Manual On Live Feed - 1anusoumyaNo ratings yet

- Use of algae as a sustainable energy sourceDocument26 pagesUse of algae as a sustainable energy sourceFatjona LevaniNo ratings yet

- Week 12 - MicroAlgae-BiodieselDocument31 pagesWeek 12 - MicroAlgae-BiodieselAniq AmirahNo ratings yet

- Microalgae Notes by MeDocument8 pagesMicroalgae Notes by Mesaurabh pandeyNo ratings yet

- Algae Article Fong 1503324Document63 pagesAlgae Article Fong 1503324Alejandra AragónNo ratings yet

- 1 s2.0 S0981942816301917 MainDocument11 pages1 s2.0 S0981942816301917 MainBlue SkyNo ratings yet

- Development of A Process Model For Simultaneous Saccharification and Fermentation SSF of Algal Starch To Third Generation BioethanolDocument10 pagesDevelopment of A Process Model For Simultaneous Saccharification and Fermentation SSF of Algal Starch To Third Generation BioethanolSukhendra Singh RaghuvanshiNo ratings yet

- Manual On The Production and Use of Live Food For Aquaculture (Tugas Planktonologi)Document305 pagesManual On The Production and Use of Live Food For Aquaculture (Tugas Planktonologi)asepirwan100% (1)

- 1 s2.0 S2211926423000280 MainDocument17 pages1 s2.0 S2211926423000280 Mainadi arthaNo ratings yet

- WP1A3.01 EnAlgae SOP Report-V10 FINALDocument395 pagesWP1A3.01 EnAlgae SOP Report-V10 FINALAli MohsinNo ratings yet

- 11 AlgaeDocument38 pages11 AlgaeHarry DouglasNo ratings yet

- Microalgal Mass Culture Systems and Methods PDFDocument2 pagesMicroalgal Mass Culture Systems and Methods PDFAmmar BouzouerNo ratings yet

- Algae 101 Part Nine - Algal Cultivation - Algae Industry MagazineDocument6 pagesAlgae 101 Part Nine - Algal Cultivation - Algae Industry Magazineaish_paniNo ratings yet

- Microbial Applications Vol 1 Bioremediation and Bioenergy PDFDocument335 pagesMicrobial Applications Vol 1 Bioremediation and Bioenergy PDFFernando cisneros prietoNo ratings yet

- Classification of Algal GroupsDocument25 pagesClassification of Algal GroupsHemal Patel Sam50% (2)

- Applied Energy: M. Fatih DemirbasDocument8 pagesApplied Energy: M. Fatih DemirbasArif HidayatNo ratings yet

- Photobioreactors For Microalgae Cultivation-An OveDocument11 pagesPhotobioreactors For Microalgae Cultivation-An OveZAk1No ratings yet

- Biodiesel Production From MicroalgaeDocument5 pagesBiodiesel Production From MicroalgaeKavin100% (1)

- Live Feeds in AquaDocument5 pagesLive Feeds in Aquakamei321No ratings yet

- Michael Borowitzka: Topic 8: Algal Culture and BiotechnologyDocument44 pagesMichael Borowitzka: Topic 8: Algal Culture and BiotechnologyFenila XavierNo ratings yet

- Making Biofuels From Microalgae - A ReviDocument8 pagesMaking Biofuels From Microalgae - A ReviMargarita ChochosNo ratings yet

- Assessing The Potential of Polyculture To Accelerate Algal Biofuel ProductionDocument14 pagesAssessing The Potential of Polyculture To Accelerate Algal Biofuel ProductionChechoQuiqueNo ratings yet