Professional Documents

Culture Documents

01) E-1 Piping

Uploaded by

homemechanic26Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01) E-1 Piping

Uploaded by

homemechanic26Copyright:

Available Formats

LIST OF STANDARD SPECIFICATIONS (PIPING) CLUSTER 7 WELL PLATFORM PROJECT

SECTION: E.1 A097-01-16-43-SS-01 Rev. 0

Page 1 of 3

LIST OF STANDARD SPECIFICATIONS (PIPING)

PROJECT OWNER : : CLUSTER 7 WELL PLATFORM PROJECT O.N.G.C. ENGINEERS INDIA LTD. A097

CONSULTANT : JOB NO. :

0 Rev. No

01.12.10 Date

ISSUED FOR BIDS Purpose

SANJEEV Prepared by Checked by Approved by

Format No. EIL-1641-1924 Rev.1

Copyright EIL All rights reserved

LIST OF STANDARD SPECIFICATIONS (PIPING) CLUSTER 7 WELL PLATFORM PROJECT

SECTION: E.1 A097-01-16-43-SS-01 Rev. 0

Page 2 of 3

LIST OF STANDARD SPECIFICATIONS S.No. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. TITLE Standard specification for PMI at suppliers 0work Standard specification for PMI at Construction Sites Standard Specification for Piping Fabrication & Installation for Offshore Application Standard Specification for Piping Drawings for Offshore Application Standard Specification for Insulation for Offshore Application Standard Specification for Scale/Corrosion/ Biological Probes for Offshore Application Standard Specification for Strainers for Offshore Application Standard Specification for Life Preservers (Life jackets) and Marine Work Vests for Offshore Application Standard Specification for Life Ring Buoys for Offshore Application Standard Specification for Inflatable Life Rafts for Offshore Application Standard Specification for First Aid Kit for Offshore Application Standard Specification for Continuous Drainers for Offshore Application Standard Specification for Chemical & Utility Hoses & Hose Connections for Offshore Application Standard Specification for Stretcher for Offshore Application Standard Specification for Choke Valve for Offshore Application Standard Specification for Utility Hose Reels for Offshore Application Standard Specification for Personnel Baskets & Scramble Nets for Offshore Application Standard Specification for Helicopter Rescue Kit for Offshore Application Standard Specification for Personnel Protection Equipments from H2S Exposure for Offshore Application Standard Specification for Motor Operated for Offshore Application Valves Standard Specification for Sample Bomb for Offshore Application Standard Specification for 5D radius bends for Offshore Application SPECIFICATION NO. 6-81-0001 6-82-0002 6-44-0503 6-44-0504 6-44-0507 6-44-0508 6-44-0509 6-44-0510 0 6-44-0511 6-44-0512 6-44-0513 6-44-0514 6-44-0515 0 6-44-0516 6-44-0517 6-44-0518 6-44-0519 6-44-0520 6-44-0521 0 6-44-0522 6-44-0523 6-44-0524 0 0 0 0 0 0 0 0 0 0 0 0 Rev No. 1 1 0 0 0 0 0

Format No. EIL-1641-1924 Rev.1

Copyright EIL All rights reserved

LIST OF STANDARD SPECIFICATIONS (PIPING) CLUSTER 7 WELL PLATFORM PROJECT

SECTION: E.1 A097-01-16-43-SS-01 Rev. 0

Page 3 of 3

S.No. 23. 24. 25.

TITLE Standard Specification for Hinged Closure for Offshore Application Standard Specification for Pig Detectors for Offshore Application Standard Specification for Scraper Tees for Offshore Application

SPECIFICATION NO. 6-44-0525 6-44-0526 6-44-0527

Rev No. 0 0 0

Format No. EIL-1641-1924 Rev.1

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 2 of 13

Abbreviations: GAD : NB : P & ID : ASME : ASTM : NACE : WPS : PQR : General Arrangement Drawing Nominal Bore Piping & Instrumentation Diagram American society of Mechanical Engineers American society for Testing and Materials National Association of Corrosion Engineers Welding Procedure Specification Procedure Quality Record

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 3 of 13

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0

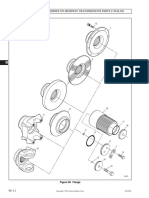

SCOPE..........4 CODES AND STANDARDS...4 FABRICATION....4 WELDING....5 EXAMINATION, INSPECTION AND TESTING.6 INSTALLATION.9 REQUIREMENT OF BOLT TENSIONING AND BOLT TORQUING..10 PROTECTIVE COATING.11 INSULATION11 SHIPPING AND HANDLING..11 FIG-1 DIMENSIONAL TOLERANCES..13

8.0 9.0 10.0 11.0

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 4 of 13

1.0

SCOPE This specification covers the requirements governing the fabrication, installation, inspection & testing of piping assemblies in shop or field. This specification is to be used with the individual specification and/or drawings, if furnished. In case of conflict, the individual specification and /or drawings shall govern.

2.0

CODES AND STANDARDS All piping shall be designed, fabricated and installed as per codes & standards as mentioned in Piping Design Criteria except as modified by this specification.

3.0

FABRICATION 3.1 Carbon steel pipes shall be cut by mechanical or thermal cutting depending upon thickness and size however thermal cutting shall not be employed for galvanized and stainless steel materials. Bevel end preparation shall be done by bevel cutting machines and suitably grinded. For pipes up to 2 Inch NB, the internal burrs shall be removed by suitable grinding. Dimensional tolerances: In addition to the tolerances contained within specified codes and standards, dimensional tolerances for finished fabricated piping shall conform to those shown in Figure-1 attached herewith. Care shall be taken during cutting & welding such that the final dimensions of spools are within the applicable tolerances. Minimum spacing of circumferential welds between centerlines shall not be less than four times the pipe wall thickness or 100 mm, whichever is greater. Threaded, Socket Weld & Brazed Piping 3.7.1 Threads shall be clean cut with no burrs or stripping and shall be according to ASME B1.20.1, tapered. Dies shall be new, sharp and properly designed for the piping material. Ends shall be reamed to remove burrs. 3.7.2 Immediately before erecting the piping all threads of pipe and fittings shall be thoroughly cleaned of cuttings, dirt, oil or other foreign matter. The male threads shall be coated with thread sealant and the piping made up sufficiently for the threads to seize. Sealant shall be Teflon tape. 3.7.3 Threaded connections shall be gauge checked or chased after welding or heat treatment. 3.7.4 When socket weld/brazed fittings or valves are used, pipe shall be spaced approximately 1/16-inch to avoid bottoming which could result in excessive weld stresses. 3.7.5 The inside of the brazed fitting and outside of the tube shall be cleaned with sand paper. Flux paste to be evenly applied to the joint. 3.7.6 Brazing temperature shall be achieved as quickly as possible using a suitably sized torch.

3.2 3.3 3.4

3.5

3.6

3.7

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 5 of 13

3.7.7 Seal welding of threaded connections when specified shall include the first block valve, cover all threads and be done with electrodes not to exceed 1/8 inch in diameter. The joint shall be cleaned of all cutting oil & other foreign material and made up of dry to full thread engagement. Thermo wells shall not be seal welded. 3.8 Branch connections

3.8.1 All branch connections shall be joined to the header with full penetration welds. 3.8.2 Reinforcing pads shall be added only after external and internal visual inspection of the attachment. Reinforcing pads shall be provided with tapped weep hole. Weep holes shall be plugged after completion of welding. 3.9 Exposed machined and threaded surfaces shall be protected from oxidation during heat treatment.

3.10 Flange bolt holes shall straddle the established horizontal and vertical centerlines of the pipe except where connection to equipment dictates otherwise. 3.11 Cleaning of the piping after fabrication and heat treatment shall be performed externally and internally to remove all loose scale, weld spatter, sand and other foreign materials. 3.12 All piping supports shall be fabricated and installed as per approved drawings/standards.

4.0

WELDING 4.1 Welders and welding procedure shall be qualified per ASME B 31.3, latest edition. For 90-10 Cu-Ni piping, welders and welding procedures shall be qualified as per ASME Code Section IX. Welding shall be performed as per approved WPS and PQR. No chill rings or backup rings are to be used. The joints to be field welded shall be beveled as per ASME B 16.25 The deposited filler metal shall match the chemistry and minimum physical properties when similar metals are welded.

4.2

4.3 4.4 4.5 4.6

4.7 4.8

Stress relieving shall be as per ASME B 31.3. Welding of low sulphur NACE carbon steel and duplex stainless steel shall be as per 6-79-0012 and 6-79-0016 as applicable.

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 6 of 13

5.0

EXAMINATION, INSPECTION & TESTING 5.1 Random radiography shall be performed on one weld in each 10 welds for each welder on the following: a) b) c) d) e) f) g) h) i) 5.2 Water (in case of Carbon steel) Air Chemicals Diesel Closed drain Relief Hydraulic oil Oily water Slops

25% Radiography shall be performed on the following: a) Glycol & Therminol b) Vent gas c) Lube oil & seal oil

5.3

100% Radiography shall be performed on size 2 and above and 25% on sizes below 2 for the following: a) b) c) d) e) f) g) h) Crude oil Jet fuel Fuel gas / Instrument gas Process gas Production flow lines (Well fluid) Injection water Hydrocarbons (process) HP & LP flare lines

5.4

For fillet welds and brazed joints where carrying out radiography is not possible, magnetic particle or dye penetrant test shall be carried out. The extent of inspection shall remain same as for radiography. All the lines, which are stress relieved or have design pressure more than 50 kg/cm2 shall be fully radio graphed (100%) even if not required as per clause 5.1 to 5.3. Radiographic procedure shall be as per ASME B 31.3. Acceptance criteria based on visual, radiography and other types of examination shall be as per ASME B 31.3 with the following modifications. 5.7.1 The internal weld protrusion on pigged lines shall not exceed 1.6 mm (1/16 inch). Orifice flange butt welds shall be internally ground smooth and flush. For 90-10 Cu-Ni piping, radiographic examination of welds shall be as per ASME Section VIII, UW 51.

5.5

5.6 5.7

5.7.2 5.7.3

5.8

Hydrostatic testing is not required for shop-fabricated piping where the pipe is to be field-tested. Hydrostatic testing is required on skid-mounted

Copyright EIL All rights reserved

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 7 of 13

assemblies. Pressure test shall be performed as per ASME B 31.3 and the appropriate specification class chart. 5.9 5.10 5.11 All instruments shall be excluded during hydro test. All piping shall be flushed prior to hydro testing. Those field weld joints, which cannot be leak tested due to unavoidable reasons, shall always be 100% radiographed. Requirements as given above in clause 5.1 to 5.11 are general however in case of any conflict with welding and weld inspection specification, the welding specification shall govern.

5.12

TESTING Pressure test shall be performed as per ASME B31.3, latest edition. 5.12.1 The following items coming in line with piping shall not be subjected to field pressure testing: a) Strainers and Filter elements. b) Pressure relieving devices such as rupture discs and pressure relief valves. c) Locally mounted pressure gauges. d) Control valves, shutdown valves etc. e) Vessel and equipment like pumps, compressors etc. vessel may be tested along with a piping system, provided the vessel test pressure is not less than the piping system test pressure. f) Any other equipment designated by the Company. 5.12.1.1 All the elements which are not to be tested along with the piping shall either be blanked off during testing or spool pieces inserted during testing. 5.12.1.2 Any temporary corrosion protection coating given on piping at manufactures shop / fabrication yard is to be removed at all inspection points, before final testing. 5.12.1.3 Prior to hydrotesting, vessels & piping are to be flushed by high pressure, high Volume fresh water or inhibited sea water. However for using Inhibited sea water company approval shall be required. 5.12.1.4 All piping shall be supported as per approved drawing before pressure testing, spring and other variable type supports shall be locked to prevent movement. 5.12.2 Following are the general requirements for testing of piping. 5.12.2.1 Test pressure shall be maintained for a sufficient length of time to permit thorough inspection of all the joints for leakage or sign of failure. The duration shall in no case be less than four (4) hours.

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 8 of 13

5.12.2.2 Instrument take-off piping up to the first block valve shall be tested with the connected piping. 5.12.2.3 Lines open directly to atmosphere such as vents, drains, safety valve discharge etc. shall be leak tested and all the joints shall be visually inspected. 5.12.2.4 Maximum allowable valve test pressure: Seats of all valves shall not be subjected to a pressure in excess of maximum cold working pressure of the valve. Test pressure applied to valves shall not be greater than the manufacturers recommendation nor less than required by applicable code. Where the test pressure is greater than the allowable seat pressure, test shall be made through the open valve. 5.12.3 Hydrostatic test fluid 5.12.3.1 Fresh potable water shall be used as the testing medium for hydrostatic testing of piping in fabrication yard and at offshore, if available. 5.12.3.2 For Austenitic Stainless Steel piping, water with pHvalve not over 7 and chlorides less than 350 ppm shall only be used for hydrostatic testing. The lines shall be completely drained and dried by air immediately after the successful completion of testing. 5.12.3.3 Salt water may be permitted for testing non austenitic piping, provided the Contractors test procedures are approved by the Company and that they include the following:

5.12.3.4 Chemical treatment (inhibition, oxygen scavenger) to mitigate corrosion if salt water is used. 5.12.3.5 Method of isolating austenitic piping and connected equipment from contact with salt water.

5.12.3.6 Adequate steps are taken to ensure complete removal of salt water from the system after testing. 5.12.3.7 A strainer shall be installed in the line to minimize the possibility of foreign matter being introduced into the system during the pressure test and flushing operations. 5.12.3.8 Test medium shall be hydraulic oil for hydraulic service. 5.12.4 Pneumatic Testing 5.12.4.1 Pneumatic testing of instrument air, utility air, starting air and instrument gas piping shall be performed with compressed air. The test pressure shall be 110 percent of design pressure. Test duration shall be as given in 5.12.2.1.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 9 of 13

5.12.4.2 Pneumatic testing of other piping is acceptable if the test procedure and test pressures have been approved by the Company. 5.12.4.3 When pneumatic testing at over 25 psi, a preliminary test at 25 psi shall be made to locate major leaks. Then the pressure shall be increased gradually to test pressure. 5.12.5 Test Procedure 5.12.5.1 All vents and other connections, which serve as vents, shall be open during filling so that all air is vented prior to applying test pressure to the system. 5.12.5.2 At least two nos. gauges will be installed for testing as close as possible to the highest point of the piping system & will be caliberated and checked for accuracy. 5.12.5.3 Care shall be exercised to avoid increase in pressure due to temperature variation during the test. 5.12.5.4 After completion of hydrostatic test, the pressure shall be released gradually in steps. All the vents and drains shall be kept open till the lines are fully drained. The contractor shall then dry the system by blowing compressed dry air and reinstall items removed during hydrotesting. 5.12.5.5 All testing and calibration of gauges, instrument etc. will be carried out in presence of company or its authorised representative. Record shall be made of each piping system during the testing. These records shall be prepared in tabulated forms and shall include a) Date of Test b) Identification of piping and equipment tested with medium. c) Test medium. d) Test Pressure. e) Test Duration. f) Acceptance of Test result by Company. 5.12.5.6 Testing shall be deemed as complete only after defects noticed during testing have been rectified and retesting of the system/line has been done to the satisfaction of the companys representative. 5.12.5.7 Temporary supports shall be provided wherever required during testing.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 10 of 13

6.0

INSTALLATION 6.1 6.2 6.3 6.4 6.5 Piping shall be installed in accordance with the approved piping drawings. Piping installation shall include the supply and installation of supports shown in the drawing. All lines shall be installed true and plumb except where specifically noted on the drawing. Installation of piping shall be scheduled so that no undue strain shall be inflicted on equipment due to lack of support, dead weight or misalignment. Piping shall be removed after installation at all rotating equipment connecting points to check the alignment with and without piping to ensure that the piping does not affect the alignment of the equipment. After checking the alignment, piping shall be re-installed. Flange bolts shall be tightened evenly and sequentially to avoid distortion or overstressing of equipments. During installation/fabrication, care shall be taken at all times to protect the entry of foreign materials by providing protector caps and covers or other suitable means. Before installing prefabricated piping, the inside of the pipe shall be inspected by the contractor to ensure that all foreign mater is removed. Stainless steel materials shall be lifted with nylon or other approved slings, which are free from dirt or ferritic particles. Under no circumstances, chain or wire ropes shall be used.

6.6 6.7 6.8 6.9

6.10 To prevent damage to valve seal and seat surfaces, valves when installed shall be left in following open/close positions: Ball and plug valves Globe and gate valves Fully open Fully closed.

7.0

REQUIREMENT OF BOLT TENSIONING & BOLT TORQUING 7.1 Hydraulic Bolt Tensioning shall be used for all flange joints in class 900# and above with bolt diameter 25 mm Stud bolt shall be longer by one diameter to suit the length of the bolt tensioner for all sizes. Excess threads shall be protected by a threaded cap with a grease nipple. Bolt Torquing - For all other bolts not falling in the range of hydraulic bolt tensioning. Bolt torquing shall be applied to all the flange joints of the above said parameters. Torque wrenches shall be used with specific value, reviewed/approved by the company.

7.2 7.3 7.4 7.5

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 11 of 13

7.6

Mechanical integrity of all flange joints has to be ensured. A standard checklist for the activity along with post box-up checkup should be developed & practiced. The checklist shall include the following: a) i) Alignment of flanges ii) Inspection of gasket surface for possible defects such as bends or greases. iii) Inspection of mating flanges for dirt, mechanical damage and corrosion. Use suitable solvent to clean the surface. The contact area of flanges shall be free from excess pitting and radial scratches. iv) Ensuring the gasket is properly seated v) Ensuring that fasteners are tightened as per tightening procedures and using specific values with well maintained tools and torque wrenches. b) c) d) e) Each joint shall be boxed up and tightened by only skilled technician. Ensuring right type of gaskets & fasteners etc confirming to the specifications. Ensuring that the stud & nuts are free of dirt and corrosion. The studs should be straight and threads free from nicks, burr and chips etc. Checking of individual joint for any leak during commissioning/ pressure testing by special tapes, soap solution or as per relevant code.

QUALITY ASSURANCE: Tool Calibration: 1. The calibration of the torque wrench and tensioner shall be checked against manufacturers specifications upon receipt. Any tool that is out of calibration shall be rejected.

2. A recheck of calibration shall be made on regular basis. Any

tool found to be out of calibration shall be immediately be taken out of service for repair. 3. All flange joints secured with tool found to be defective shall be rechecked with a properly functioning and calibrated tool. A complete specification shall be developed for bolt tensioning and bolt torque values, line wise and size wise, stud/bolt tightening pattern, lubricants to be used and all other requirements. 8.0 PROTECTIVE COATING Protective coating shall be applied as stated in the Specification for Protective coating.

9.0

INSULATION Insulation shall be provided as per Specification for Insulation (6-44-0507).

10.0

SHIPPING AND HANDLING 10.1 All openings shall be protected after inspection as follows:

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 12 of 13

10.1.1

Flange faces (gasket contact surfaces) shall be adequately protected by coating with a removable rust preventive and attaching a bolted or steel strapped 20 mm thick wood/plastic or metal blank. Unpainted steel blanks shall not be used where rust would discolor the coated surface of skidassembled components. Gasket contact surfaces shall not be painted. If the surface is painted, it shall be restored to original specification condition before installation. Threaded connections shall be closed with a steel/plastic pipe plug. Plain or bevelled ends shall be closed with metal or a plastic cover to protect the inside of the pipe.

10.1.2 10.1.3

10.2 Each spool piece shall be clearly marked on both ends with the line number. Marking shall not be done by stenciling the pipe. Marking shall be done by a method which will ensure that it will withstand exposure to the hazards during shipping to the job site. 10.3 Small diameter branches shall have x 1 steel plate tack welded to branch and header to prevent bending of branch pipe during transportation. 10.4 Extra caution shall be exercised when handling Cu-Ni pipe to prevent damage. 10.5 Piping materials to be shipped shall be made dry, clean and free from moisture, dirt and loose foreign material of any kind. 10.6 Piping materials shall be protected from rust, corrosion and mechanical damage during transportation, shipment and storage. 10.7 Rust preventive used on machined surfaces shall be easily removable with a petroleum solvent and the same shall not be harmful to welding. 10.8 Both ends of pipes, valves & flanges shall be protected securely with the following material Plain end Bevel end Threaded end Flange face : : : : Plastic cap Wood, metal or plastic cover Metal or plastic threaded cap Wood or Plastic cover

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING FABRICATION AND INSTALLATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0503 Rev. 0

Page 13 of 13

FIGURE-1 DIMENSIONAL TOLERANCES

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING DRAWINGS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0504 Rev. 0

Page 2 of 6

Abbreviations: GAD : NB : P & ID : General Arrangement Drawings Nominal Bore Piping & Instrumentation Diagram

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING DRAWINGS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0504 Rev. 0

Page 3 of 6

CONTENTS

1.0 2.0

SCOPE........4 MINIMUM REQUIREMENTS TO BE COVERED IN PIPING GENERAL ARRANGEMENT DRAWINGS (GAD)..4 GENERAL LAYOUT REQUIREMENTS4 MINIMUM REQUIREMENTS TO BE COVERED IN PIPING ISOMETRICS.6

3.0 4.0

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING DRAWINGS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0504 Rev. 0

Page 4 of 6

1.0

SCOPE This standard contains minimum requirements for the preparation of piping drawings, line numbering system and line schedule.

2.0

MINIMUM REQUIREMENT TO BE COVERED IN PIPING GENERAL ARRANGEMENT DRAWINGS (GADS) The following shall be minimum to be shown on the piping general arrangement drawing wherever applicable. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 Line Number Instrument Tag Number Instrument Connections Orientation of North Arrow Battery/Area limit as per area division/skid Title block, drawing nos. as per area division/drawing schedule Key plan Reference drawings Legends and Notes Equipment name, Tag number, Reference elevation i.e. Centerline elevation/ Bottom Tangent Line elevation Table of Nozzle orientation and location Match line, continuation drawing number Location of equipment as per equipment layout P&IDs special notes to be listed Mark slope and working point (WP) elevations at grid crossing and at every change in direction/elevation. Dimension and equipment elevations with reference to data sheets, vendor drawing/data & other reference drawings. Hook-up/ Tie-in point numbers

3.0

GENERAL LAYOUT REQUIREMENTS 3.1 All piping drawings shall be drawn to scale 1:33 1/3 and in metric system only.

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR PIPING DRAWINGS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0504 Rev. 0

Page 5 of 6

3.2 3.3

Area division plan where necessary (key plan) shall be prepared prior to preparation of piping general arrangement drawings (GAD). All deck levels shall be divided into two parts (for clarity) as explained hereunder: e.g. for Cellar Deck there shall be two piping GADs: i) Above Cellar Deck ii) Below Cellar Deck Title of each drawing shall be marked with the elevation (i.e. From.. To ..) covered in the drawings

3.4 3.5

Piping 12 Inch NB and below shall be shown in single line for sake of clarity while piping 14 Inch NB and above shall be shown in double lines. All the information regarding instrument, equipment and line identification, direction of flow for lines, elevations and dimensions shall be clearly marked on piping plans. Efforts shall be made to provide maximum possible information including operating platforms, ladders, monorails, other material handling equipments, electrical and instrument cable trays, etc. shall be shown on piping plans to avoid reference to other drawings. Dimensioning shall be done with equipment centerlines or main structural columns only. For any portion of a line where complete details i.e. dimensions, elevations etc. cannot be furnished in piping plan, a detailed isometric for that portion shall be indicated at a suitable place in the same GAD only. As far as possible all such details shall be shown together at a particular space provided for the purpose. The bracing structural members up to 2.3 meters above the deck level shall be shown on equipment layouts and piping plans. Nozzles on equipment shall be shown in double line (thin & firm). Actuators, valve hand wheels shall be shown to scale for all valves. Piping plans shall show all lines indicated in piping and instrument diagrams. Pipe supports shall be marked on separate piping plans and support drawings shall be furnished separately for companys review. Piping arrangement drawings for skid mounted equipment/ vessels, shall be furnished separately for review and approval. Piping isometrics shall be prepared for all lines. Piping material specification breaks shall be shown on all GADs and Isometrics. All the future line shown in P&IDs shall be routed and shown as chain dotted on GADs with full details indicating dimensions, line numbers, location etc. Escape route and Safety Equipment Layouts shall be prepared separately showing all the escape routes, Fire Safety and Life Saving equipments etc.

Copyright EIL All rights reserved

3.6 3.7

3.8 3.9 3.10 3.11 3.12 3.13 3.14 3.15 3.16 3.17

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR PIPING DRAWINGS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0504 Rev. 0

Page 6 of 6

3.18 3.19 4.0

Piping under other double line pipe, structure and any other items shall be shown in dotted. Monorails with Tag number, Bottom of rail elevation and capacity etc. shall be shown in the GADs

MINIMUM REQUIREMENTS TO BE COVERED IN PIPING ISOMETRICS: The following shall be minimum to be shown on the isometric drawing wherever applicable: 4.1 4.2 4.3 4.4 4.5 4.6 Line number Instrument connection with tag number. Orientation of north direction in the left hand top corner. North arrow should be either left side upwards or right side upwards. Location of origin and destination w.r.t. structural column grids along with equipment numbers. All connected lines with line numbers and continuation references. All special fittings & speciality items e.g. strainers, traps, shutdown valves, control valves, pig detectors, hinged closures, scraper tees etc. shall be marked with their tag numbers. High point vents and low point drains. Out of rating items shall be called out. Working point elevations of slope lines as per the slope requirements marked in the P&IDs. Nozzle number, size, rating and facing, center line elevation. Centerline elevations for valves. Isometrics shall be properly dimensioned from fabrication and erection point of view. Item wise bill of material. Process parameters regarding pressure, temperature & hydrotesting. Insulation type and thickness. NDT & stress relieving requirements. Items/Instruments mounted on the equipments shall be shown on Vessel trim drawing.

4.7 4.8 4.9 4.10 4.11 4.12 4.13 4.14 4.15 4.16 4.17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 2 of 17

Abbreviations: SS CS BW DP NACE ASME ASTM AISI NACE : : : : : : : : : Stainless Steel Carbon Steel Butt Welded Dye Penetrant National Association of Corrosion Engineers American Society of Mechanical Engineers American Society for Testing and Materials American Iron and Steel Institute National Association of Corrosion Engineers

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(Const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION CONTENTS

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 3 of 17

1.0 2.0 3.0 4.0 5.0 6.0

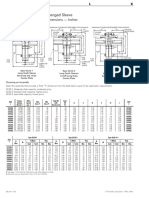

SCOPE.... EXTENT OF INSULATION ON PIPING SYSTEMS AND EQUIPMENTS.. INSULATION THICKNESS...... MATERIAL.... TESTS/CHECKS FOR MATERIALS.... APPLICATION. ANNEXURE 1 TO 8 - INSULATION THICKNESS TABLES

4 4 5 5 7 7

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 4 of 17

1.0

SCOPE This specification covers the minimum requirements for thermal and acoustic insulation materials and method of its application for piping, vessels and equipment.

2.0 2.1 2.2

EXTENT OF INSULATION ON PIPING SYSTEMS & EQUIPMENTS Requirement of insulation shall be as indicated in the P&IDs & line lists. Items shall be insulated for the purpose of conservation of heat, temperature stabilization, personnel protection, condensation prevention (anti-sweat), heat tracing or limiting noise levels. Piping and equipment operating with fluid temperatures in excess of 54C shall be insulated as burn protection for personnel. Exposed surface of such piping and equipment located within 600 mm horizontally or 2100 mm vertically of a normal access, walkway or work area shall be provided with safety insulation. However, exhaust lines operating above 200C shall be fully insulated. Insulated piping system shall have straight pipe, bend, tees and pipe fittings completely insulated. All valves and flange joints shall be completely insulated only in hot oil lines, heat traced lines or lines where the temperature is more than 300C. Heat transfer equipment in hot services, other than coolers and condensers shall be completely insulated except for supporting members and flanges. Shell flanges, channel flanges and nozzle flanges shall not be insulated. Nozzle necks shall be insulated up to the nozzle flange. All accessories such as level controllers, level gauges, pipe bridles, etc. which are attached to insulated equipment shall be insulated with equivalent thickness and materials required for the equipment. Piping that is considered a potential source of noise should be acoustically insulated to reduce noise to acceptable limits. The following parts shall not be insulated, unless otherwise specified: Manways on hot vessels Connectors and tube unions on fin-tube exchangers Flanges of piping and equipment Valves including control valves, relief valves and flanges except as noted in Cl. 2.5. However, personnel protection insulation for these items shall be applied, as required. Pipe union fittings, expansion joints & hose assemblies. Sight flow indicators. Thermo well bosses and pressure tappings. Fans, compressors, blowers or other rotating or reciprocating equipment. Surface coolers and condensers. Nameplates of all equipment items.

2.3

2.4 2.5

2.6

2.7

2.8 2.9

2.10

Piping and vessels whose normal operating temperatures are below 27C shall be insulated to prevent condensation.

Copyright EIL All rights reserved

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 5 of 17

2.11 2.12

Insulation shall be provided such that an absolute minimum clearance of 25mm is available between the outside surface of any insulation finishing material and any adjacent surfaces. Where insulated horizontal piping is supported on steel shoes, the height of shoe shall be such that the underside of the insulation finishing material is clear of the supporting structure upon which the shoe rests by 25 mm minimum. Support skirts of insulated vertical vessel greater than 1200 mm diameter shall be insulated both internally and externally for a minimum distance of 600 mm below the bottom tangent line. The insulation shall terminate not less the 300 mm above the support or steel wok. Support skirts of insulated vertical vessels of 1200 mm and less shall be insulated externally only, as described in para 2.13. Bottom heads of insulated vertical vessels enclosed by a support skirt shall be insulated without finishing material and shall be insulated only when the vessel outside diameter is greater than 1200 mm. INSULATION THICKNESS Insulation thickness shall be as per the Annexure-1 through Annexure-8 to this specification, as applicable. Thickness of insulation for acoustic shall be min. 75 mm. Thickness for Anti Sweat insulation shall be as follows: 1 & smaller : 2 to 4 6 to 10 12 & above : : : 25 mm 30 mm 35 mm 40 mm

2.13

2.14 2.15

3.0 3.1 3.2 3.3

4.0 4.1 4.1.1

MATERIAL General All material shall be of high quality and good appearance. Insulation material shall be of low chloride content, chemically inert, non-sulphurous, rot proof, verm in proof, noninjurious to health and non-corrosive to steel and aluminum. The use of insulation or finishing materials containing Asbestos in any form is not permitted. No flammable material shall be attached to the insulation. Removable box type insulation in calcium silicate material, unless otherwise specified, shall be provided over flanged joints and valves for process services above 300C. It should also be provided with a drain. In general the insulation material shall be as per Indian standards or ASTM/BS standards/Codes. For electrically traced pipe, Polyurethane foam (PUF) or Poly isocyanurate (PIR) shall be used in combination with rockwool as inner layer. For low temperature services (i.e. upto 125C), a suitable moisture barrier shall be used.

Copyright EIL All rights reserved

4.1.2 4.1.3 4.1.4

4.1.5 4.1.6

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 6 of 17

4.1.7

Insulation materials to be used over austenitic stainless steel surfaces shall be zinc free and shall be inhibited with sodium silicate as per ATM C-795. The amounts of leachable chloride in the insulation material (except for calcium silicate) before application shall not exceed 10ppm. In case of calcium silicate, it should not exceed 50ppm. For the chemical analysis of insulation material, ASTM C-871 shall be referred. Material for Anti Sweat insulation shall be Polyurethane foam (PUF) or Poly isocyanurate (PIR). Moisture barrier for anti-sweat insulation shall be water emulsion polyvinyl acetate type mastic used with reinforcing mesh as recommended by the mastic manufacturer. Moisture barrier shall cover insulation completely before weather proofing is installed. Insulation Materials Calcium silicate insulation material shall have density of 200 to 280 kg/m3 and suitable for temperature upto 760C. Filler material like Thermobestos, KAYLO, or equal shall be used. Rockwool and Glass wool shall be of long fibred rock or glass material processed from a molten state into fibrous form bonded with a binder and suitable for the intended operational temperature range. Slagwool is not acceptable.

4.1.8

4.2 4.2.1

4.2.2

4.2.2.1 Rock wool shall be suitable for operational temperature range from ambient to 550C. Minimum density shall be 140 kg/m3 for resin bonded pipe sections and 128 kg/m3 for resin bonded LRB mattresses. Maximum resin content at the above mentioned densities shall be 2%. 4.2.2.2 Glass wool shall be suitable for operational temperature range from ambient to 350C. Minimum density shall be 80 kg/m3 for resin bonded pipe sections and 64 kg/m3 for resin bonded curved beveled segments or LRB slabs. Maximum resin content at the above mentioned densities shall be 5%. 4.2.3 Rigid Polyisocyanurate foam block, pipe and fitting insulation shall be manufactured with polyester or polyether resins, flammability retarding agents, special catalyst and a blowing agent. This can be used up to a temperature of 125C. The density shall be 40-64 kg/m3. Rigid Polyurethane foam material shall be self-extinguishing type. PUF block, pipe and fitting insulation shall be produced by reacting polyisocynates with polyhydroxyl compounds and expanded with a blowing agent. This can be used up to a temperature of 120C. The finish foam in the form of half sections shall be with uniform closed cell structure, free from un-reacted materials, shrinkage and distortion. The density shall be 35 - 39.9 kg/m3. For impulse lines, insulation material shall be Glass fibre braided Ceramic fibre rope insulation unless otherwise mentioned. Ceramic fibre rope shall be made up of Ceramic Fibre insulation of min. density 200 kg/m3. Weather Protection Jacket Insulation weather proofing for regular surfaces on insulation in all services shall be 3000 series aluminum sheet as per ASTM B209. 0.71-mm thick sheet (22 SWG) with 32 mm (1-1/4) corrugations on vertical vessels shall be used. On heat transfer equipment and horizontal vessels, use 0.71 mm (22 SWG) thick flat sheets, which shall be smooth, embossed or have 5mm (3/16) corrugations.

Copyright EIL All rights reserved

4.2.4

4.2.5

4.3 4.3.1 4.3.2 4.3.3

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 7 of 17

4.3.4 4.3.5 4.3.6

Piping insulation shall be covered with 0.71 mm (22 SWG) thick flat sheets. Aluminum shall be epoxy coated on exterior surface for all services and also on interior surface when used over calcium silicate. Moisture barrier shall be installed between calcium silicate and aluminum. The moisture barrier may be attached to the jacketing and shall be either polyethylene and Kraft paper or Eagle-Picher Insulseal or equal. Weatherproofing for irregular surface shall be polyvinyl acetate mastic used with reinforcing mesh as recommended by the mastic manufacturer. Ancillary Materials Bands for equipment insulation Bands to secure insulation shall be 13mm (1/2 inch) wide by 0.5 mm. (0.02 inch) thick for vessels 2.5 M diameter and smaller and 19mm (3/4 inch) wide by 0.5 mm (0.02 inch) thick for vessels larger than 2.5m diameter. Band material shall be stainless steel. 12% or more chrome. Bands to secure aluminum jacket on equipment shall be 0.5 mm thick X 19 mm wide (0.02 inch thick X inch wide) stainless steel, 12% or more chrome.

4.3.7 4.4 4.4.1

4.4.2

Bands for piping insulation Bands to secure insulation shall be 0.5 mm thick X 13 mm wide (0.02 inch thick, inch wide) stainless steel, 12% or more chrome. Bands to secure aluminium jacket on piping shall be made 0.5 mm thick x 13 mm wide (0.02 inch thick, inch wide) stainless steel, 12% or more chrome.

4.4.3 4.4.4 5.0 5.1

The wire for securing rigid insulation shall be no. 16 gauge stainless steel, 12% or more chrome, annealed. Sealer for calcium silicate shall be Eagle-Picker super 66 or equal. Sealer for foam glass shall be Pittsburgh cornings Pittseal III or equal. TESTS/CHECKS OF MATERIALS Periodical checks for density, thickness, shape and size as per the requirements shall be repeated at site, as per norms and frequency decided at site as per the direction of Engineer-in-charge. Special attention is required for fibrous material as its installed thickness could be reduced to compaction affecting performance. APPLICATION General The application methods, given in this specification are general in nature. Contractor is responsible for providing an insulation system that will give a satisfactory operational performance and requirements given here shall be regarded as acceptable minimum.

6.0 6.1

6.1.1

The insulation work shall be carried out in accordance with the best practice of insulation application with the minimum of waste and debris and the final job shall have a neat, efficient and workman like appearance.

Copyright EIL All rights reserved

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 8 of 17

6.1.2 6.1.3 6.1.4

The insulation shall be so designed/ applied such that ingress of water is prevented, leaked product can drain off and vapors can escape. Surface to be insulated shall be thoroughly cleaned, dried and made free from loose scale, oil or grease before applying insulation. All carbon steel and low alloy steel piping, turbines and equipment operated intermittently or continuously below 100C and stainless steel at all temperatures shall be protected against corrosion by painting under insulation as per Job Specification for Protective Coating. Insulation on equipment and piping shall be stopped far enough from flanges to permit removal of bolts. Insulation shall be finished, beveled, and weatherproofed at all terminal points where it is required to remove bolts etc. without damage to insulation. Wet or damaged insulation shall not be used under any circumstances. Material awaiting its protective cover shall be adequately protected from damage, rain and contamination and shall be covered with cladding at a minimum loss of time. Pieces of insulation with crushed and damaged ends shall not be used. On the bottom heads of vertical vessels, block insulation shall be secured in place by wiring to lugs welded to the surface of the head and skirt. Insulation at solid welded or clamped supports shall be cut and shaped to fit around the support and banded securely to enable the insulation to be carried with the pipe movement.

6.1.5

6.1.6

6.1.7 6.1.8 6.1.9

6.1.10 Anti-sweat insulation shall be applied over valves, flanges, fittings and external pipe attachments e.g. lugs, dummy pipe etc. 6.2 6.2.1 Inspection Windows Plug type inspection windows shall be provided for all insulated pipe lines having dia 2 and above. One inspection window shall be provided at a distance of every 20 m of straight length of pipe. It should be provided at the bottom i.e. at 4-6-8 O clock position whichever is convenient. There must be at least one inspection window between two bends, which are minimum 10 m apart. At least 50% of the bends shall be provided with inspection windows. The sheet metal of the inspection window shall be of the gauge as of the sheet metal cladding on insulation. For exchangers, all the heads shall be provided with one inspection window each. Minimum two inspection window shall be provided on the shell side. For other vessels, heads shall be provided with one inspection window each. Minimum two inspection window shall be provided in the shell portion. Insulation of equipment and piping The following procedure shall be followed for the application of insulation on equipment and piping: 6.3.1 Clean outside surface of the equipment/ piping, removing rust and scale by hand wirebrushing, prepare outside surface and apply paint, if required as per clause 6.1.4, in accordance with the Specification for protective coatings. Apply insulation according to the temperature requirement.

Copyright EIL All rights reserved

6.2.2 6.2.3 6.3

6.3.2

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 9 of 17

6.3.3

Secure the insulation in place with stainless steel bands on 300-mm centers for vertical equipment and on 225-mm centers for horizontal equipment. Secure piping insulation in place with bands on 225-mm centers. If insulation is for anti-sweat, apply vapor barrier mastic over insulation. Install moisture barrier between calcium silicate and aluminium. Apply weather proofing mastic on all irregular surfaces. Weather proof the insulation with aluminium jacketing. A 75-mm overlap shall be provided at both vertical and horizontal joints and all joints shall shed water. Z clips shall be placed on 450-mm centers in all horizontal joints on vertical equipment. All cutouts in aluminium jacketing shall be weatherproofed by flashing with aluminium sheet and/or caulking with mastic flashing. Secure the aluminum jacketing in place using one of the following methods: Band the jacketing on 0.9 m centers and fasten all edges of the jacketing using 8 x 13 mm (1/2 inch) long aluminium sheet metal screws or aluminium pop rivets on 150 mm centers. Band the jacketing on 1.8 mm centers and fasten all edges of the jacketing using 8mmx 13mm (1/2 inch) long aluminium sheet metal screws or aluminium pop rivets on 100 mm centers.

6.3.4 6.3.5 6.3.6 6.3.7

6.3.8

6.3.9

On vertical vessels with a diameter of 1.8 m or larger, the corrugated aluminium jacketing shall be further supported by attachment to horizontal metal bands running circumferentially around the outside layer of insulation. One band shall be used for each horizontal row of aluminium sheets and shall be located beneath the jacketing halfway between the top and bottom edges of the sheets. The metal bands shall be atleast 24-gauge stainless steel (12% of more chrome) material, 75 mm (3 inch) wide. Band shall be applied directly over the finished insulated surface, pulled tight with a banding machine and held in place by crimp seals. The aluminum jacketing shall be attached to the bands by the use of aluminium screws or pop rivets on approximately 100 mm (4 inch) centers. Insulation of Impulse Lines For impulse lines, the insulation (Ceramic rope) of required thickness shall be tightly wrapped. A 3 mm thick coating of mastic shall be applied to the surface of the insulation. Whilst this coat is still wet, glass cloth shall be laid over the surface and embedded in the mastic. Care shall be taken to ensure that glass cloth is laid smooth and free from wrinkles and that no pocket of air is trapped beneath the surface. At junctions in the glass cloth, the overlap shall not be less than 75 mm. A second 3 mm thick coat of mastic shall be applied after approx. 12 hrs. When dry, this coating shall be a minimum of 1.5 mm thick. A coat of aluminum paint of DFT 25 microns shall be applied over the mastic after it has dried completely. A suitable sealant shall be provided to stop the water ingress at the termination points of insulation.

6.4

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 10 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 11 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 12 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 13 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 14 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 15 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 16 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INSULATION FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0507 Rev. 0

Page 17 of 17

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR SCALE/ CORROSION/ BIOLOGICAL PROBES FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0508 Rev. 0

Page 2 of 5

Abbreviations: SS :

Stainless Steel

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR SCALE/ CORROSION/ BIOLOGICAL PROBES FOR OFFSHORE APPLICATION CONTENTS

STANDARD SPECIFICATION No.

6-44-0508 Rev. 0

Page 3 of 5

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

SCOPE.. TECHNICAL REQUIREMENTS . TAGS.... QUANTITY.. SITE CONDITIONS VENDOR DATA. INSPECTION AND TESTS SPARES. . WARRANTY.................................................................................... ATTACHMENTS. 5

4 4 5 5 5 5 5 5

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR SCALE/ CORROSION/ BIOLOGICAL PROBES FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0508 Rev. 0

Page 4 of 5

1.0

SCOPE This specification describes the requirements for the supply of scale/corrosion/biological probes to be installed on the offshore platform.

2.0 2.1 2.1.1

TECHNICAL REQUIREMENTS The scale/corrosion/biological unit shall consist of the following assemblies: The access fitting assembly consisting of three parts: Access Fitting Body (Non Tee) Access fitting body shall be of a nominal 2 system. Body shall have a weldolet (Flare Weld) base and 3 Acme Threads on the outlet. Weldolet Base shall be 2 Flare-weld size.

2.1.2 2.1.3

Plug Assembly A solid plug assembly for holding scale/corrosion/biological probe coupon. Protective Cover A steel protective cover for the Acme Threads

2.2 2.2.1 Corrosion Coupons and Coupon Holder Multiple disc coupons and holders shall be supplied for a nominal 2 system. Holder shall be supplied with mounting and insulating hardware. Each holder shall position three discs, one each at top of line, middle of line, and bottom of the line. Coupons shall be multiple disc type. 2.2.2 Scale Coupons and Coupon Holder Strip coupons of 150 mm (6) length shall be supplied for a nominal 2 system. Scale coupons shall have a range of predrilled holes suitable for monitoring scale buildup. Holder shall be supplied with mounting and insulating hardware. Each holder shall position two strips for bottom of line monitoring. 2.2.3 Biological coupons and coupon holder Biological coupons and coupon holders shall be supplied for nominal 2 system. Holder shall be supplied with mounting and insulating hardware. NOTES: 2.2.3.1 2.2.3.2 2.2.3.3 Holder sizing shall be done by the Vendor. Coupons shall be ground grit blasted. Coupons shall be individually packed for one-year life and certified for weight and dimensions. Access fitting, plug, holder and scale/biological and corrosion coupon material shall be compatible with relevant piping class indicated in the job datasheet for scale/corrosion/biological probes. All probes shall be suitable for installation in any position. Vendor shall provide a complete illustrative procedure for the insertion & retrieval of the probes. Retrieval Tool Kit A retrieval tool kit shall consist of complete kit for insertion and removal of corrosion coupons. The retrieval tool kit shall be for nominal size of 2 system. The retrieval tool

Copyright EIL All rights reserved

2.2.3.4 2.2.3.5 2.3 2.3.1

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR SCALE/ CORROSION/ BIOLOGICAL PROBES FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0508 Rev. 0

Page 5 of 5

kit shall be sized for the largest line size and pressure rating and shall be suitable for retrieving all scale/corrosion/biological probes during operation on the platform. 2.3.2 Tool kit shall be complete with full bore ball valve. Material specification shall be compatible with applicable piping class as specified in the job data sheets for scale/corrosion/biological probes. TAGS Tag No. shall be marked on SS 316 material and permanently attached. 4.0 QUANTITY Quantity for scale/corrosion/biological probes and the retrieval tool kit shall be as per the job data sheets for scale/corrosion/biological probes. 5.0 SITE CONDITIONS Each item shall be designed for an offshore location where the atmosphere is salt laden and corrosive. 6.0 VENDOR DATA Vendor shall furnish dimensional drawings with part list, installation and operational requirements, test reports and dossier for test conducted during manufacturing of the product. Necessary documents as per the Purchase Specification shall be submitted for company review. 7.0 8.0 8.1 8.2 9.0 9.1 INSPECTION AND TESTS Company or its representative(s) reserve(s) the right to witness the tests. SPARES Vendor shall recommend and provide spare parts needed for start-up and commissioning. Vendor shall also recommend a list of spare parts (with prices) needed for one (1) year operation and maintenance. WARRANTY Vendor shall have final and total responsibility for the design, fabrication and performance of all equipments supplied under this specification. Vendor shall warrant the equipment furnished by him and the performance of the said equipment in line with purchase specification/material requisition. ATTACHMENTS 1. Job Data Sheet for scale/corrosion/biological probes

3.0

9.2 10.0

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR STRAINERS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0509 Rev. 0

Page 2 of 6

Abbreviations: SS CS BW DP NACE ASME ASTM AISI NACE : : : : : : : : : Stainless Steel Carbon Steel Butt Welded Dye Penetrant National Association of Corrosion Engineers American Society of Mechanical Engineers American Society for Testing and Materials American Iron and Steel Institute National Association of Corrosion Engineers

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(Const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR STRAINERS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0509 Rev. 0

Page 3 of 6

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0

SCOPE.. TECHNICAL REQUIREMENTS TAGS SITE CONDITIONS VENDOR DATA INSPECTION AND TESTS. SPARES.. WARRANTY ATTACHMENTS .

4 4 5 5 5 5 5 5 6

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR STRAINERS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0509 Rev. 0

Page 4 of 6

1.0

SCOPE This specification describes the requirements for the supply of strainers to be installed on the offshore platforms.

2.0 2.1 2.2

TECHNICAL REQUIREMENT All codes and Standards for manufacture, testing and inspection etc. shall be of latest editions. Body material shall be as indicated in the job data sheet; for parts not mentioned in the data sheet, vendor shall guarantee the material used for the service conditions specified. Screen material shall be as follows: Body Material C.S. C.S. (NACE) Other than C.S. Screen Material SS316 SS316L (NACE) Compatible with Piping Class.

2.3

2.4

All basket type strainers shall be designed as per ASME Section VIII Div.1 and others as per ASME B31.3. Ends of body shall either be Flanged, BW, SW or Screwed as specified in the job data sheet. The ends for strainers shall correspond to the following standards: FLGD BW SW SCRD ASME B16.5/B16.47 Series B ASME B16.25 ASME B16.11 ASME B16.11

2.5 2.5.1

2.6 2.7

Mesh size for all strainers shall be 40, unless otherwise specified. All other items e.g. flanges, valves, gaskets, bolts etc. shall be as per the respective piping class. Drains with ball valve & blind shall be provided for all strainers. Basket type strainers shall be provided with vent (with ball valve and blind) also. Size of vent & drain shall be for 2 & above and for less than 2 size strainers. All strainers shall be hydrostatically tested at two times the design pressure. All butt welds shall be 100% radio graphed and all fillet welds shall be 100% DP tested. Open area of strainer shall be minimum 300% of the cross-section area of pipe. Body construction shall be seamless unless otherwise specified. Welded body shall not be of stub-in type and shall be normalized and tempered and 100% radiographed. All weld joints other than SS material shall be stress relieved. Stainless Steel Strainers:

2.8

2.9 2.10 2.11 2.12

2.13 2.14

2.14.1 All austenitic stainless steel items shall be supplied in solution annealed condition.

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR STRAINERS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0509 Rev. 0

Page 5 of 6

2.14.2 For all austenitic stainless steel items Inter Granular Corrosion (IGC) test shall be conducted as per the following: ASTM A 262 Practice B with acceptance criteria of 60 mils/year (max.). Or ASTM A 262 Practice E with acceptance criteria of No cracks as observed from 20X magnification & Microscopic structure to be observed from 250X magnification.

2.14.3 When specifically asked for high temperature applications of some grades of austenitic stainless steel (eg. SS309, 310,316,316 H etc.) ASTM A 262 Practice C with acceptance criteria of 15 mils/year (max.) shall have to be conducted. When testing is conducted as per practice E photograph of microscopic structure shall be submitted for record. 2.14.4 All types of SS321 or SS347 material shall be in stabilized heat treated condition. Stabilizing heat treatment shall be carried out subsequent to normal solution annealing. Soaking temperature and holding time for stabilizing heat treatment shall be 900 C and 4 hours respectively. 3.0 TAGS Tag Nos. shall be marked on SS-316 material and permanently attached. 4.0 SITE CONDITIONS Each item shall be designed for an offshore location where the atmosphere is salt laden and corrosive. 5.0 VENDOR DATA Vendor shall furnish dimensional drawings with part list installation and operational requirements, test reports and dossier for test conducted during manufacturing of the product. Necessary documents as per the Purchase Specification shall be submitted for company review. INSPECTION AND TESTS Company or its authorised representative(s) reserve(s) the right to witness stagewise inspection of all mandatory/applicable supplementary tests. Test reports shall be supplied for all mandatory tests as per the relevant material specifications/requisition. Test reports shall also be furnished for hydrotest and other supplementary tests as specified in the requisition. Material Test Certificates (Physical Properties, Chemical Composition and heat Treatment Report) shall also be furnished. SPARES Vendor shall recommend and provide spare parts needed for start-up and commissioning. Vendor shall also recommend a list of spare parts (with prices) needed for one (1) year trouble free operation and maintenance. WARRANTY Vendor shall have final and total responsibility for the design, fabrication and performance of all equipments supplied under this specification.

Copyright EIL All rights reserved

6.0 6.1

6.2

6.3

7.0 7.1 7.2

8.0 8.1

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR STRAINERS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0509 Rev. 0

Page 6 of 6

8.2

Vendor shall warrant the equipment furnished by him and the performance of the said equipment in line with purchase specification/material requisition. ATTACHMENTS 1. Job Data sheet for Strainers

9.0

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE PRESERVERS AND MARINE WORK VESTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0510 Rev. 0

Page 2 of 6

Abbreviations: USCG : BSI : FAA : SOLAS: United States Coast Guard British Statutory Instruments Federal Aviation Administration International Convention on Safety of Life at Sea

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE PRESERVERS AND MARINE WORK VESTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0510 Rev. 0

Page 3 of 6

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

SCOPE... 4 CODES AND STANDARDS.... 4 TECHNICAL REQUIREMENTS 4 GENERAL EQUIREMENT. 5 APPROVALS .. 5 SITE CONDITIONS. 5 VENDOR DATA.. 5 INSPECTION AND TESTS..... 5 WARRANTY.. 5

ATTACHMENTS 6

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE PRESERVERS AND MARINE WORK VESTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0510 Rev. 0

Page 4 of 6

1.0

SCOPE This specification defines the minimum requirements for life preservers (Life Jackets) and Marine Work vests to be used on the offshore platform.

2.0

CODES AND STANDARDS The following codes and standards (latest edition) are referenced to and made a part of this specification:

2.1 2.2 2.3

USCG-CG-320: "Rules and Regulations for Artificial Islands and Fixed Structures on the Outer Continental Shelf". BSI-486: "The Offshore Installation (Life Saving Appliances) Regulation". International Convention on Safety of Life at Sea (SOLAS) : the 1974 SOLAS convention, the 1978 SOLAS protocol and its amendments till date. TECHNICAL REQUIREMENTS Life Preservers Each life jacket shall comply with the following requirements: The materials used in the construction shall not be adversely affected by exposure to seawater, oil, oil products and sunlight. It shall be made of materials of low flammability and be rot- proof and corrosion resistant. It shall be so constructed as to eliminate as far as possible all risk of its being put on incorrectly but it shall be capable of being worn inside out. It shall be capable of lifting the face of an exhausted or unconscious person out of water within 5 seconds of entering still water and holding it above the water with the body inclined backwards from its vertical position. It shall be capable of turning the body in the water from any position to a safe floating position with the body inclined backwards from the vertical floating position. It shall provide a minimum buoyancy of 16 kg (35 pounds) in fresh water for 24 hours. The buoyancy of the life jacket shall not decrease by more than 5% after 24 hours of submergence in fresh water. Each life jacket shall be fitted with a whistle firmly secured by a chord. Each life jacket shall be fitted with a strong ring or loop to facilitate rescue. This ring or loop shall be so located such that it cannot be used for fastening the jacket. Each life jacket shall be suitable for use by a fully grown male adult. Life jacket shall comply with the regulations of SOLAS. Each life jacket shall be fitted with light. Marine Work Vest These are personal floatation device that enable the wearer to freely work with the vest on in an area where there is risk of falling into the sea. These vests shall comply with the following requirements:

3.0 3.1 3.1.1 3.1.2

3.1.3 3.1.4

3.1.5 3.1.6

3.1.7 3.1.8 3.1.9 3.1.10 3.1.11 3.2

3.2.1 3.2.2

Compliance with the requirements of USCG. All floatation material shall be coated with chemical, which is tough, fire resistant, self extinguishing and highly abrasion resistant. The material shall be unaffected by oil, gas or basic chemicals.

Copyright EIL All rights reserved

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR LIFE PRESERVERS AND MARINE WORK VESTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0510 Rev. 0

Page 5 of 6

3.2.3 3.2.4 3.2.5

Vests shall be fitted with adjustable 1" black nylon web straps securely sewn with nylon thread which is rot-proof and mildew proof. Vests shall be fitted with Heavy-duty bronze hardware, corrosion resistant. Certified and tested for USCG and FAA' Specifications. Vests shall be fitted with shoulder straps strong enough so that a man could be lifted comfortably from water simply by attaching hook or line to either shoulder strap and with no distortion to the floatation material. GENERAL REQUIREMENTS Color Life jacket & Marine work vest shall be bright orange in color so as to be highly visible.

4.0 4.1

4.2

Marking Marking and labeling is screen printed in water resistant, vinyl ink.

4.3

Life jacket & Marine work vests requirements shall be as per the job data sheet for Life Preservers and Marine Work Vests. Conflict In the event of conflict between this specification and other documents listed herein this specification shall govern.

4.4

5.0

APPROVALS Each item shall be as approved by Mercantile Marine Department of Govt. of India or equivalent statutory authority like USCG, SOLAS etc. Adequate Certificates shall be furnished in this respect.

6.0

SITE CONDITIONS Each item shall be designed for an offshore location where the atmosphere is salt laden and corrosive.

7.0

VENDOR DATA Vendor shall furnish dimensional drawings with part list, installation and operational requirements, test reports and dossier for test conducted during manufacturing of the product. Necessary documents as per the Purchase Specification shall be submitted for company review.

8.0

INSPECTION AND TESTS Company or its authorized representative(s) reserves(s) the right to witness the tests.

9.0 9.1

WARRANTY Vendor shall have final and total responsibility for the design, fabrication and performance of all equipments supplied under this specification. Vendor shall warrant the equipment furnished by him and the performance of the said equipment in line with purchase specification/material requisition.

Copyright EIL All rights reserved

9.2

Format No. 8-00-0001-F1 Rev. 0

STANDARD SPECIFICATION FOR LIFE PRESERVERS AND MARINE WORK VESTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0510 Rev. 0

Page 6 of 6

10.0

ATTACHMENTS 1. Job Data Sheet for Life Preservers (Life Jackets) and Marine Work Vests.

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE RING BUOYS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0511 Rev. 0

Page 2 of 5

Abbreviations: USCG : BSI : SOLAS: United States Coast Guard British Statutory Instruments International Convention on Safety of Life at Sea

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE RING BUOYS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0511 Rev. 0

Page 3 of 5

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

SCOPE... 4 CODES AND STANDARDS.... 4 TECHNICAL REQUIREMENTS 4 GENERAL EQUIREMENT. 4 APPROVALS .. 5 SITE CONDITIONS. 5 VENDOR DATA.. 5 INSPECTION AND TESTS..... 5 WARRANTY.. 5

ATTACHMENTS 5

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE RING BUOYS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0511 Rev. 0

Page 4 of 5

1.0

SCOPE This specification defines the minimum requirements for life ring buoys to be installed on the offshore platform.

2.0

CODES AND STANDARDS The following codes and standards (latest edition) are referenced to and made a part of this specification: USCG-CG-320 "Rules and Regulations for Artificial Islands and Fixed Structures on the Outer Continental Shelf". BSI-486 The Offshore Installation (Life Saving Appliances) Regulations". International Convention on Safety of Life at Sea (SOLAS) the 1974 SOLAS convention, the 1978 SOLAS protocol and its amendments, till date.

3.0 3.1

TECHNICAL REQUIREMENTS Material The life buoy shall be made of suitable material that shall be capable of retaining its buoyancy and durability in seawater or oil products under variations of temperature or climatic changes prevailing in open sea. It should be capable of withstanding a drop test into water from a height of at least 38 meters.

3.2

Buoyancy The life buoy shall be capable of floating in fresh water at least for 24 hours, with a weight of 14.5 kg of iron suspended from it. The buoyancy shall not depend upon air compartments, which require to be inflated.

3.3 3.3.1

Each life ring buoy shall be supplied with: An efficient self-igniting light secured to the buoy with a lanyard 1 to 2 meters in length. The lanyard should be attached to the light at the level of the center of floatation to prevent inclination of the signal in the sea. The light shall be capable of withstanding immersion test of 1.5 ft. without adversely affecting the operation of light. The selfigniting light shall be such that it cannot be extinguished by sea water and shall be capable of burning for not less than 2 hours with a luminous intensity of not less than 2 candela power in all directions of upper hemisphere. The water light shall be mounted in a bracket near the life ring buoy so that when the buoy is cast loose, the water light will put free from bracket. A buoyant lifeline shall be at least 55 meters long. Suitable bracket for securing the buoy to the platform hand railing shall be provided. They shall be such that the buoy can be easily removed for use. Life Ring Buoys shall meet the requirement of the applicable regulations of SOLAS. GENERAL REQUIREMENTS The life-buoy shall be of a highly visible color.

3.3.2 3.3.3

3.4 4.0 4.1

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR LIFE RING BUOYS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0511 Rev. 0

Page 5 of 5

4.2

Marking Each life buoy shall be marked in Block Letters with the legend as mentioned in the job data sheet for life ring buoys.

4.3

Quantity Quantity shall be as mentioned in the job data sheet for life ring buoys.

4.4

Conflict In the event of conflict between this specification and other documents listed herein, this specification shall govern.

5.0

APPROVALS Each item shall be approved by Mercantile Marine Department of Govt. of India or equivalent statutory authority like USCG etc. Adequate Certificates shall be furnished in this respect.

6.0

SITE CONDITIONS Each item shall be designed for an offshore location where the atmosphere is salt laden and corrosive.

7.0

VENDOR DATA Vendor shall furnish dimensional drawings with part list, installation and operational requirements, test reports and dossier for test conducted during manufacturing of the product. Necessary documents as per the Purchase Specification shall be submitted for company review.

8.0

INSPECTION AND TESTS Company or its authorized representative(s) reserves(s) the right to witness the tests.

9.0 9.1

WARRANTY Vendor shall have final and total responsibility for the design, fabrication and performance of all equipments supplied under this specification. Vendor shall warrant the equipment furnished by him and the performance of the said equipment in line with purchase specification/material requisition. ATTACHMENTS 1. Job Data Sheet for Life Ring Buoys.

9.2

10.0

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INFLATABLE LIFE RAFTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0512 Rev. 0

Page 2 of 5

Abbreviations: USCG : BSI : SOLAS: United States Coast Guard British Statutory Instruments International Convention on Safety of Life at Sea

Piping Standards Committee Convenor : Members : Mr S Chanda Mr Mr Mr Mr Mr Mr Mr Mr Mr V K Bhatli AT Dharmik P K Bali R Nanda L B Ajwani D Khare(HMTD) PP Lahiri/S Ghosal(SMMS) GK Iyer(const.) R K Bhandari(Proj.)

Format No. 8-00-0001-F1 Rev. 0

Copyright EIL All rights reserved

STANDARD SPECIFICATION FOR INFLATABLE LIFE RAFTS FOR OFFSHORE APPLICATION

STANDARD SPECIFICATION No.

6-44-0512 Rev. 0

Page 3 of 5

CONTENTS

1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

SCOPE.. CODES AND STANDARDS TECHANICAL REQUIREMENTS .... GENERAL REQUIREMENTS APPROVALS .. SITE CONDITIONS VENDOR DATA . INSPECTION AND TESTING .. .. .. WARRANTY ATTACHMENTS

4 4 4 5 5 5 5 5 5 5