Professional Documents

Culture Documents

Siemens GT Compressor & Turbine

Uploaded by

kahar_saniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Siemens GT Compressor & Turbine

Uploaded by

kahar_saniCopyright:

Available Formats

SIEMENS GT COMPRESSOR & TURBINE

SIEMENS GAS TURBINE V94.2

ROTOR

Function of Rotor

To carries the compressor & turbine blades. Compressor convert the torque into kinetic energy Turbine convert the kinetic energy into torque.

Components of the Rotor

1.

2. 3. 4. 5. 6. 7.

8.

9.

Front hollow shaft Balance planes Compressor wheel Central hollow shaft Turbine wheel Rear hollow shaft Tie rod Damping ring O-ring seal

Function of Compressor Stator Blades

To deflect the air stream passing through the blade passages in a direction of rotation of the rotor. VIGV to vary the inlet air flow. This improve the efficiency of the unit under part load condition.

Compressor Stator Blade

Dovetail root

Stator Blade carrier

Outer ring

Airfoil

Inner Double hook ring

Variable Inlet Guide Vane

Pin Stator Blade carrier

Outer ring

Airfoil

Inner ring

Pin

Function of Compressor Stator

To secure the stator blades rings with the stator blades in position. To transmit the reaction forces due to flow & pressure to the outer casing The VIGV is to vary the sucked-in air mass flow & to improve the partial load efficiency.

SET RING

BEARING

VIGV ADJUSTING SYSTEM

TRANSMISSION ROD

MOTOR

Function of Compressor Rotor Blades

To convert mechanical energy into kinetic & potential energy of the air. To pressurize the air. (16 stages) (compression ratio: 1 : 10)

Airfoil

Blade root

Compressor Rotor Blade

Blow-off valves

3 Blow-off valves. 2 blow-off valves at stage 5

Blow-off V1.1 & 1.2 close at 2900rpm

1 blow-off valve at stage 10

Blow-off V2 close at 2300rpm

To prevent compressor surge. Surge : Air flow unstable, hunting & causes vibration.

Compressor surge protection

GT will trip when Speed more than 42 Hz (2520rpm) and Differential pressure less than 30mbar

COMPRESSOR SURGE PROTECTION

Air from filter house

Compressor 2nd Stage

DP SW

Comp Surge Protection Speed > 2520rpm(42Hz) DP < 30 mbar GT trip Drain

Compressor Technical Data

Compressor flow rate : 468kg/s Compressor ratio : 1 : 10 Compressor stages : 16 Compressor outlet press : 10 bars Compressor outlet temp : 330 deg C Blow-off valves : 3 Blow-off valve 1.1 & 1.2 at stage 5 close at speed : 2900rpm Blow-off valve 2 at stage 10 close at speed : 2300rpm

Function of Turbine Rotor Blades

To convert the thermal energy of the hot gas into mechanical energy. (4 stages) To drive the compressor & the generator.

Turbine rotor blades.

They are made from high temperature alloys to withstand the high mechanical & thermal stress. The first stage rotor blades are cast hollow blades with ducts for guiding the cooling air. The 2nd stage rotor blades are provided with several ducts extending radial through the airfoil. The blades are coated to reduce high temperature corrosion.

Cooling air inlet

Cooling air outlet

Turbine rotor blade

Hottest at bigger end (4)

Function of Turbine Stator

To secure the stator blades in position. To transmit the reaction forces due to flow & pressure to the outer casing.

Function of Turbine Stator Blades

Together with the rotor blades, the turbine stator blades convert the energy of the working fluid into mechanical energy.

Function of Center Casing

To connect stator blade carrier to the exhaust casing. To contain the internal pressure. To accommodate the compressor & turbine internals. To connect the combustion chambers.

Function of Exhaust Casing

To support the bearing at the turbine end. To provide flow paths for the gas. Act as stationary diffuser to minimize the exhaust loss.

Function of Exhaust Diffuser

To pass the exhaust gas into the stack or HRSG To decrease the gas velocity & resulting in a rise in static pressure.

Function of Inner Casing

To direct the flow of hot gas from the two combustion chambers to the turbine blades. To provide compressor air passing over its outer surface of all sides.

Function of Compressor Shaft Glands

To prevent the ingestion of air containing oil at the compressor intake. To reduce the internal leakage losses between the individual stages at the inner diameter of the stator blades. To adjust the flow of seal air to the turbine inlet at the compressor exit.

Stator blade row

Seal air duct

Compressor bearing housing

Shaft Gland Shim

Rotor disc Front hollow shaft Labyrinth seal

9 Central hollow shaft 10 Ducts

11 Labyrinth seal 12 Compressor exhaust diffuser 13 Protective liner

Function of Turbine Shaft Glands

To minimize the clearance losses. To prevent the hot gases from leaking through the spaces between the stator & rotor. The shaft gland at the turbine exit prevents the escape of the hot gas into the atmosphere & the ingress of seal air into the bearing space.

1 Second-stage stator blade 2 Third-stage stator blade 3 Fourth-stage stator blade 4 X-ring 5 Seal ring 6 L-ring

7 Inner shroud

8 Hole 9 L-ring 10 Inner shroud

11 Hole

Function of Cooling & Seal Air

To cool turbine rotor & stator metal temperature to below permissible operating temperature. To protect components not designed for high temperature application from direct contact with the combustion gas flow.

Function of Compressor Bearing Housing

To support the rotor & the turbine/ compressor unit. It forms part of the outer casing & connect stator blade carrier to the compressor intake casing.

Function of Turbine Bearing Housing

To support the rotor in the exhaust casing. To house the turbine bearing

Function of Combine Journal & Thrust bearing

Support the rotor at the compressor end. To compensate the axial thrust & To locate the rotor in axial position.

Function of Journal Bearing

To support the rotor in the bearing housing at the turbine end.

You might also like

- Ge Frame 9e Comp & Turbine DesignDocument26 pagesGe Frame 9e Comp & Turbine DesignMuhammad Naveed Akhtar100% (3)

- Gas Turbine NotesDocument40 pagesGas Turbine NotesSarah Cohen92% (12)

- GE Gas Turbine Training Manual PDFDocument290 pagesGE Gas Turbine Training Manual PDFmehrzad rahdar100% (12)

- Siemens Barcelona v94.2 PDFDocument16 pagesSiemens Barcelona v94.2 PDFbehtam240767% (3)

- GearboxDocument16 pagesGearboxMehul zareNo ratings yet

- Start-Up in Steps Siemens V94.2 Gas Turbine at KAPCODocument13 pagesStart-Up in Steps Siemens V94.2 Gas Turbine at KAPCOFazalur Rehman Babar89% (19)

- Gas Turbine and Auxiliaries AlstomDocument54 pagesGas Turbine and Auxiliaries Alstomnabil160874100% (7)

- Learn Gas Turbine by SimulationDocument41 pagesLearn Gas Turbine by SimulationAnonymous 8RRc42G100% (1)

- GT Trips List (Generic)Document13 pagesGT Trips List (Generic)Ovais Siddiqui100% (6)

- Kawasaki Gas TurbineDocument45 pagesKawasaki Gas Turbinepramasenja100% (2)

- Gas Turbine Start SystemDocument108 pagesGas Turbine Start Systemhumane2896% (28)

- Gas Turbine Training Manual PDF - Google SearchDocument6 pagesGas Turbine Training Manual PDF - Google SearchPahe DriveNo ratings yet

- Gas Turbine MaintenanceDocument60 pagesGas Turbine Maintenancehelmybh100% (15)

- GE Frame 9Document4 pagesGE Frame 9Umar Saeed100% (1)

- GE Gas Turbine ControlDocument35 pagesGE Gas Turbine ControlAmpornchai Phupol100% (6)

- Gas Turbine Equivalent Op Hours For MaintenanceDocument10 pagesGas Turbine Equivalent Op Hours For MaintenanceFazalur Rehman Babar86% (14)

- 02 Ms5001 DescriptionDocument58 pages02 Ms5001 DescriptionHafiz Usman Mahmood100% (5)

- GT Various Systems (G)Document62 pagesGT Various Systems (G)shtiwari2002100% (2)

- Trip OilDocument3 pagesTrip Oilchdeepak96100% (1)

- T48 SpreadDocument1 pageT48 SpreadKarim MuhammedNo ratings yet

- Gas Turbine ControlDocument81 pagesGas Turbine ControlMubarak Kirkusawi78% (9)

- 02 GG Pgt25 Dle Description VCNGDocument138 pages02 GG Pgt25 Dle Description VCNGolegprikhodko2809100% (4)

- 6 Gas Turbine - Fuel SystemsDocument124 pages6 Gas Turbine - Fuel SystemsFranpin Collahua Salvador100% (2)

- Ger 3957b Gas Turbine Repair TechnologyDocument30 pagesGer 3957b Gas Turbine Repair Technologyimant197812gmail.com100% (1)

- GE Gas TurbineTheoryDocument62 pagesGE Gas TurbineTheorysalamadel100% (2)

- Combustion 6FADocument30 pagesCombustion 6FAprasad5034100% (5)

- Gas-Turbine-Notes - Siemens PDFDocument40 pagesGas-Turbine-Notes - Siemens PDFDayo Idowu100% (3)

- 2.3.2 GT DetailsDocument40 pages2.3.2 GT DetailsSarah Cohen100% (3)

- Gas Turbine Control & Protection: Presentation ONDocument46 pagesGas Turbine Control & Protection: Presentation ONrahulNrana100% (2)

- Ge LM6000 Training 1Document74 pagesGe LM6000 Training 1sasa hh100% (1)

- 2.3.1 GT FundamentalsDocument30 pages2.3.1 GT FundamentalsSarah CohenNo ratings yet

- Gas Turbine Maintenance Manual SampleDocument10 pagesGas Turbine Maintenance Manual SampleArtistic Origins100% (8)

- GT Frame 9 ManualDocument98 pagesGT Frame 9 ManualSANJAY100% (2)

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Gas TurbineDocument256 pagesGas TurbineMohamed Wahid82% (22)

- Training Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncDocument24 pagesTraining Session 1 Gas Turbine Basics: by Jim Noordermeer, P.Eng. Gryphon International Engineering Services IncM Azri Zulkipli100% (1)

- GT Operation (Nanjin)Document146 pagesGT Operation (Nanjin)Ady FardyNo ratings yet

- Gas Turbine30.06.09Document119 pagesGas Turbine30.06.09charzree95% (19)

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air FlowhinaNo ratings yet

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyDocument2 pagesSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- Overview of Start-Up of Gas TurbineDocument38 pagesOverview of Start-Up of Gas TurbineJulio Cesar Barajas Aguilar100% (1)

- GE Steam Turbine D SeriesDocument4 pagesGE Steam Turbine D Seriesvsprobo100% (1)

- 02 BCL PCL IntermediateDocument179 pages02 BCL PCL Intermediaterana usman100% (1)

- Siemens Gas Turbines - Final PDFDocument202 pagesSiemens Gas Turbines - Final PDFQahtan Adnan100% (5)

- Gas Turbine Class PresentationDocument183 pagesGas Turbine Class PresentationMohammad Ibnul Hossain83% (18)

- GE MS6001B - EmissionDocument33 pagesGE MS6001B - EmissionMohamad AfifNo ratings yet

- Gas Turbine ManualDocument48 pagesGas Turbine ManualShivam Kumar100% (3)

- Siemens AGT Trent 60 - Phase 4 IntroductionDocument167 pagesSiemens AGT Trent 60 - Phase 4 Introductionjohn100% (2)

- Generator Control and Protection System PDFDocument159 pagesGenerator Control and Protection System PDFAdetunji Taiwo100% (1)

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- Ge MS 5000 5341Document45 pagesGe MS 5000 5341helmybh100% (3)

- Gas TurbineDocument57 pagesGas TurbineMajid Sattar100% (1)

- Gte Components LastDocument41 pagesGte Components LastTw Carlo BeltranNo ratings yet

- Ge Frame 9e Comp Turbine DesignDocument26 pagesGe Frame 9e Comp Turbine Designchakib gueddoumNo ratings yet

- Comp Amp Turbine COURS 9001EDocument27 pagesComp Amp Turbine COURS 9001Enabil160874100% (1)

- 1 GT5-8 Comp & Turbine DesignDocument27 pages1 GT5-8 Comp & Turbine DesignFazalur Rehman Babar100% (3)

- Chapter 4 - CompressorDocument7 pagesChapter 4 - CompressorAparna RNo ratings yet

- Chapter No 3 Air CompressorsDocument59 pagesChapter No 3 Air CompressorsAchmad Denny DarmawanNo ratings yet

- Air Compressors: Chapter No: 3Document59 pagesAir Compressors: Chapter No: 3Eric CookNo ratings yet

- 4045-6068 Electronicos, Manual ServicioDocument678 pages4045-6068 Electronicos, Manual Serviciojhon jairo trujillo100% (2)

- Adapting PRMS To Unconventional Resources - PresentationDocument25 pagesAdapting PRMS To Unconventional Resources - PresentationParth TrivediNo ratings yet

- How To Size A Pump - Blackmonk EngineeringDocument12 pagesHow To Size A Pump - Blackmonk EngineeringbinoshjamesNo ratings yet

- 1mz FeDocument2 pages1mz FePacaluNo ratings yet

- Drilling. and Casing. Check List.Document24 pagesDrilling. and Casing. Check List.Aderobaki GbengaNo ratings yet

- Manual EZ-K EngDocument71 pagesManual EZ-K Engtruong67% (3)

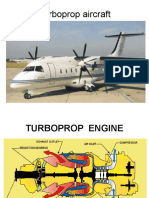

- Turboprop PropDocument46 pagesTurboprop PropJohan100% (2)

- Petronas Details RAPID Project Contract AwardsDocument9 pagesPetronas Details RAPID Project Contract AwardsIzzadAfif1990100% (1)

- XXII Paper 49 PDFDocument8 pagesXXII Paper 49 PDFRansley TongNo ratings yet

- Model Ga6Hzr: Operation and Parts ManualDocument70 pagesModel Ga6Hzr: Operation and Parts ManualBeto Lopez CruzNo ratings yet

- Pool, Car, Policy,, March, 2018 DECEMBERDocument2 pagesPool, Car, Policy,, March, 2018 DECEMBERRiyaz BasheerNo ratings yet

- Assignment On Mitsubishi LancerDocument10 pagesAssignment On Mitsubishi LancerMahrose GilaniNo ratings yet

- Student Handout - Advanced Gas Tanker Training PDFDocument136 pagesStudent Handout - Advanced Gas Tanker Training PDFPrassanna Venkatesh100% (2)

- Marine Engine OilDocument1 pageMarine Engine OilengrsurifNo ratings yet

- DD2 MaintenanceDocument168 pagesDD2 MaintenanceCiprian RaileanuNo ratings yet

- 2812 1Jan08T28423Document12 pages2812 1Jan08T28423Philip_830No ratings yet

- C27 and C32 Generator Sets-Maintenance IntervalsDocument57 pagesC27 and C32 Generator Sets-Maintenance IntervalsRktBatamNo ratings yet

- Short Info M Pro170Document4 pagesShort Info M Pro170slava976No ratings yet

- MU Literature SLIDE GATEDocument15 pagesMU Literature SLIDE GATEJulio PCNo ratings yet

- Turbine Start Up Curve in Cold Start Up: Automatic Speed IncreaseDocument2 pagesTurbine Start Up Curve in Cold Start Up: Automatic Speed Increasekumarmm1234No ratings yet

- Interview QuestionsDocument9 pagesInterview QuestionsSuresh SuryaNo ratings yet

- CBSE X Science Board Paper: (Time Allowed: 2 Hours) (Maximum Marks:60)Document11 pagesCBSE X Science Board Paper: (Time Allowed: 2 Hours) (Maximum Marks:60)Jince JacobNo ratings yet

- Direct Injection: o o o oDocument7 pagesDirect Injection: o o o opardeep4372No ratings yet

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoNo ratings yet

- (181536741) Panel 1-1 Briefing On ASEAN Power GridDocument46 pages(181536741) Panel 1-1 Briefing On ASEAN Power GridlisaaliyoNo ratings yet

- For Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingDocument2 pagesFor Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingcacaunpsNo ratings yet

- Compresor Mobil Atlas Copco XAMS 287 MDDocument4 pagesCompresor Mobil Atlas Copco XAMS 287 MDdicon100% (1)

- A Brief Study of Cylinder DeactivationDocument21 pagesA Brief Study of Cylinder DeactivationwarcellNo ratings yet

- Monoglyceride-Short Path DistillationDocument14 pagesMonoglyceride-Short Path DistillationsdrtfgNo ratings yet

- Piping TheoryDocument20 pagesPiping Theorysonud4u100% (4)