Professional Documents

Culture Documents

Project - 1 PPT (Cooling Tower)

Uploaded by

harshilshah122Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project - 1 PPT (Cooling Tower)

Uploaded by

harshilshah122Copyright:

Available Formats

PROJECT WORK ON

COLLING TOWER

GUIDED BY: MR. H.K.PATEL (L.M.E) MR. M.M.PATEL(L.M.E) PREPARED BY: NAME CHINMAY S PATEL HARSHIL.V SHAH BRIJESH.P.PATEL KAUSHAL A. TANDEL ENROLL.NO 106550319132 106550319122 106550319069 106550319080

Energy losses :Regardless of the type of system , be it open or closed, if it meets with any of the above problems, either the cooling tower nozzles are blocked resulting in reduced Delta T and/or the deposits/scales are formed on the heat transfer surfaces. Drift loss:Now a-days most of the end user specification calls for 0.02% drift loss.

Cooling Tower Fans

The purpose of a cooling tower fan is to move a specified quantity of air through the system, overcoming the system resistance which is defined as the pressure loss

Feet soft water plant inlet of a cooling tower. Use of Fibre reinforced plastic blade for Energy losses. Replacement of aluminum blades with light-weight FRP blades reduces the load on cooling tower fan motors & brings down energy consumption Change blade angle for drip loss. Use eliminator for drip loss Correct excessive and/or uneven fan blade tip clearance and poor fan balance. On old counter-flow cooling towers, replace old spray type nozzles with new square spray ABS practically non-clogging nozzles. Balance flow to cooling tower hot water basins.

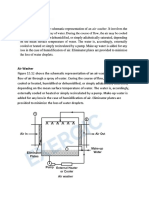

Cooling towers are a very important part of many chemical plants. The primary task of a cooling tower is to reject heat into the atmosphere. They represent a relatively inexpensive and dependable means of removing low-grade heat from cooling water. The make-up water source is used to replenish water lost to evaporation. Hot water from heat exchangers is sent to the cooling tower. The water exits the cooling tower and is sent back to the exchangers or to other units for further codling. Typical closed loop cooling tower system is shown in Figure

Range

:- This is the difference between the cooling tower water inlet and outlet temperature. Approach:- This is the difference between the cooling tower outlet coldwater temperature and ambient wet bulb temperature.

L(T1 T2) = G(h2 h1) L/G = (h2 h1) / (T1 T2)

Where: L/G = liquid to gas mass flow ratio (kg/kg) T1 = hot water temperature (0oC) T2 = cold-water temperature (0oC) h2 = enthalpy of air-water vapor mixture at exhaust wet-bulb temperature (same units as above) h1 = enthalpy of air-water vapor mixture at inlet wet-bulb temperature (same units as above)

Frame and casing: Support exterior enclosures Fill: Facilitate heat transfer by maximizing water / air contact Cold water basin: Receives water at bottom of tower Drift eliminators: Capture droplets in air stream Air inlet: Entry point of air Louvers: Equalize air flow into the fill and retain water within tower Nozzles: Spray water to wet the fill Fans: Deliver air flow in the tower

OBJECTIVE OF THE MODEL (To analyze how well an organization is positioned to achieve its intended objective Usage Improve the performance of a company Examine the likely effects of future changes within a company Align departments and processes during a merger or acquisition Determine how best to implement a proposed strategy

www.spxcooling.com www.retscreen.net www.wikipedia.com/cooling tower

REFERENCES BOOK

ASHRAE Handbook NPC Case Studies Bureau of Energy Efficiency

You might also like

- 5VZ-FE Engine Timing BeltDocument4 pages5VZ-FE Engine Timing BeltAlexander B Quinto0% (1)

- 5 Steps To Chiller EfficiencyDocument10 pages5 Steps To Chiller EfficiencyEdmund YoongNo ratings yet

- Ductsox Updated Engineering DesignManualJ - Sept2009Document20 pagesDuctsox Updated Engineering DesignManualJ - Sept2009anaNo ratings yet

- Dean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDocument40 pagesDean Paul Cueto 2 0 0 6 - 1 8 3 0 8: Me 188: Powerplant EngineeringDean Paul100% (1)

- Cooling Tower Basics Calculation Formulas - Cooling Tower EfficiencyDocument9 pagesCooling Tower Basics Calculation Formulas - Cooling Tower EfficiencySantosh JayasavalNo ratings yet

- Cooling Tower SeminarDocument67 pagesCooling Tower SeminarRupesh Desai100% (1)

- Cooling Tower Water CalculationsDocument11 pagesCooling Tower Water CalculationsShesadri ChakrabartyNo ratings yet

- Cycle of Concentration in Cooling Tower PDFDocument1 pageCycle of Concentration in Cooling Tower PDFNgoc Vũ TrầnNo ratings yet

- Cooling Tower Efficiency and ApproachDocument8 pagesCooling Tower Efficiency and Approachjeevitha jeeviNo ratings yet

- Lacos Sweeping Basin SystemDocument18 pagesLacos Sweeping Basin SystemSanto ENo ratings yet

- Cooling Tower - BaltimoreDocument7 pagesCooling Tower - BaltimoreОсама А.ШоукиNo ratings yet

- Cooling Towers ProjectDocument25 pagesCooling Towers ProjectSuhail A MansooriNo ratings yet

- 12.0 Cooling Towers and LightingDocument55 pages12.0 Cooling Towers and LightingNesarkiran BagadeNo ratings yet

- Chiller ConfigurationDocument8 pagesChiller Configurationavid_ankurNo ratings yet

- Cooling Water System DesignDocument66 pagesCooling Water System Designraghuragoo100% (2)

- Cooling Tower Selection and SizingDocument30 pagesCooling Tower Selection and SizingGausul Azam100% (1)

- Cooling Tower DefinitionsDocument68 pagesCooling Tower Definitionszubi13No ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 2 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 2 PDFAnonymous vwbLPTpjNo ratings yet

- Unit 22 CondensersDocument42 pagesUnit 22 CondenserssprotkarNo ratings yet

- Cooling Tower 434Document15 pagesCooling Tower 434arslan MaqboolNo ratings yet

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocument30 pagesB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYNo ratings yet

- Air WasherDocument5 pagesAir WasherManral SaurabhNo ratings yet

- Cooling TowerDocument23 pagesCooling TowerHasan Farooq100% (1)

- Duct Sealing in Large BuildingsDocument31 pagesDuct Sealing in Large BuildingsShiyamraj ThamodharanNo ratings yet

- Air Cooled and Water Cooled ChillerDocument17 pagesAir Cooled and Water Cooled ChillerAbdelhameed NadyNo ratings yet

- Kigali Amendment To The Montreal Protocol: HFC Phase DownDocument2 pagesKigali Amendment To The Montreal Protocol: HFC Phase DownPaulin PahNo ratings yet

- EF303 - Climate Systems - AHU SystemDocument175 pagesEF303 - Climate Systems - AHU SystemAizat Faliq100% (2)

- Knowledge Sharing Session: - Cooling Tower FundamentalsDocument47 pagesKnowledge Sharing Session: - Cooling Tower Fundamentalsgauravalok85No ratings yet

- Description of Useful HVAC TermsDocument64 pagesDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- Cooling Tower Project Report: Drift Air To Atmospher eDocument24 pagesCooling Tower Project Report: Drift Air To Atmospher eDinesh VermaNo ratings yet

- CTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Document9 pagesCTI Test Summary Report (Advent IT Park) T43A 178 16A 2016nagrajuNo ratings yet

- Water Cooled PackageDocument37 pagesWater Cooled PackageLeed EN100% (1)

- Reference BooksDocument536 pagesReference BooksAung San HtweNo ratings yet

- Master Chilled Wate Entrance No HX Rev JMD 20120817-1Document8 pagesMaster Chilled Wate Entrance No HX Rev JMD 20120817-1AshNo ratings yet

- Absorption Chiller Descaling (RIC)Document9 pagesAbsorption Chiller Descaling (RIC)mikey6666No ratings yet

- Faculty of Engineering TechnologyDocument11 pagesFaculty of Engineering TechnologyRidzwan IqbalNo ratings yet

- Cooling TowersDocument10 pagesCooling TowersAvipsita DasNo ratings yet

- District CoolingDocument17 pagesDistrict CoolingNexus Zubin KondoorNo ratings yet

- Chiller Cooling Tower AHUDocument9 pagesChiller Cooling Tower AHUAli Hassan RazaNo ratings yet

- Chiller Water Treatment GuildlineDocument7 pagesChiller Water Treatment GuildlinehuyNo ratings yet

- Your Problems & Our Solutions: Problems Related To Cooling Water TreatmentDocument6 pagesYour Problems & Our Solutions: Problems Related To Cooling Water TreatmentBidyut ChakrabortyNo ratings yet

- Cooling Tower InfoDocument78 pagesCooling Tower Infopitong_manning100% (1)

- Chiller BasicsDocument38 pagesChiller BasicsGiftson ImmanuelNo ratings yet

- Cooling Towers: Training Session On Energy EquipmentDocument38 pagesCooling Towers: Training Session On Energy EquipmentVijay KumarNo ratings yet

- Chilled Water System Introduction, MyanmarDocument20 pagesChilled Water System Introduction, MyanmaracmvorgNo ratings yet

- 25-01-10 Networking Event EMS FinalDocument41 pages25-01-10 Networking Event EMS FinalajeeshsivanNo ratings yet

- Ishrae Variable Volume Pumping SystemDocument14 pagesIshrae Variable Volume Pumping SystemAidrus AliNo ratings yet

- Cooling Tower Fundamentals PDFDocument27 pagesCooling Tower Fundamentals PDFDarshan Raghunath100% (3)

- Chiller Water TemperatureDocument3 pagesChiller Water TemperatureMohamed Munaver100% (1)

- ERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerDocument18 pagesERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerNorzaifee NizamudinNo ratings yet

- G Temperature Glide MF EN PDFDocument14 pagesG Temperature Glide MF EN PDFKanaga RajNo ratings yet

- Variable Primary FlowDocument58 pagesVariable Primary FlowAlfredo Merizalde Aviles100% (2)

- 04 IEV2011 CHLR Plant AutoDocument32 pages04 IEV2011 CHLR Plant AutoGreg BelthurNo ratings yet

- Design of Cooling TowerDocument4 pagesDesign of Cooling TowerHadis ShojaeiNo ratings yet

- Cooling TowersDocument35 pagesCooling TowersSingaravelu MariappanNo ratings yet

- CFD SimulationDocument39 pagesCFD SimulationSambhav JainNo ratings yet

- General Types of Cooling Tower IllustrationsDocument10 pagesGeneral Types of Cooling Tower IllustrationsanisalyaaNo ratings yet

- Cooling Towers - Downloaded SkillsDocument22 pagesCooling Towers - Downloaded SkillsVuthpalachaitanya KrishnaNo ratings yet

- Cooling Tower1Document66 pagesCooling Tower1Er Bali Pandhare100% (1)

- 10 - KX-DB-147 VRF Inverter Multi-System Air Conditioners 220V (FDC224-FDC335)Document325 pages10 - KX-DB-147 VRF Inverter Multi-System Air Conditioners 220V (FDC224-FDC335)dovasanNo ratings yet

- May 2014 GEARSDocument84 pagesMay 2014 GEARSRodger Bland100% (2)

- JMC 70x15 DC FanDocument3 pagesJMC 70x15 DC FanJMCproductsNo ratings yet

- 1.0 Scope of WorkDocument16 pages1.0 Scope of WorkLakshmi NarayanaNo ratings yet

- York Heat-Pump enDocument29 pagesYork Heat-Pump enFalak KhanNo ratings yet

- Positioning of Air Cooled CondensersDocument9 pagesPositioning of Air Cooled CondensersAlexNo ratings yet

- 161 Axial VibrationDocument21 pages161 Axial VibrationsatfasNo ratings yet

- MT Unit 6 Fluid Moving Machines Pumps Prof R R JoshiDocument25 pagesMT Unit 6 Fluid Moving Machines Pumps Prof R R Joshiaditya panchalNo ratings yet

- Rotary Drum DryersDocument12 pagesRotary Drum Dryersjanardhangajula100% (3)

- DVM Catalogue (080108 Ver3)Document62 pagesDVM Catalogue (080108 Ver3)Razvan HuzlauNo ratings yet

- WM 101Document24 pagesWM 101Alisher AshurovNo ratings yet

- TRNSYS TutorialDocument10 pagesTRNSYS Tutorialmo_roNo ratings yet

- LG Room Air Conditioner: Owner'S ManualDocument41 pagesLG Room Air Conditioner: Owner'S ManualDavid NavarroNo ratings yet

- Air Condition DatesheetDocument16 pagesAir Condition DatesheetleonardomarinNo ratings yet

- Air-Inlet Grille FlowGrid enDocument8 pagesAir-Inlet Grille FlowGrid enspscribd1No ratings yet

- Centrimaster GT1 Technical Catalogue 2002 11 ENGDocument62 pagesCentrimaster GT1 Technical Catalogue 2002 11 ENGCarlos PintoNo ratings yet

- Ovens: 5011.02.26 7-1 Food Service Technology CenterDocument31 pagesOvens: 5011.02.26 7-1 Food Service Technology CenterWidya PradiptaNo ratings yet

- Fired Heater - 2013 FW TalkDocument38 pagesFired Heater - 2013 FW TalkSong Hoe100% (2)

- Axial Fans, Turbo MachineryDocument50 pagesAxial Fans, Turbo MachineryalijazizaibNo ratings yet

- Boiler Operation Manual QN1 SEC G 04 TP 003Document277 pagesBoiler Operation Manual QN1 SEC G 04 TP 003Bui Vanluong0% (1)

- 996 Spcs. For 1 PH Ac & Universal MotorsDocument50 pages996 Spcs. For 1 PH Ac & Universal Motorsamitbslpawar100% (1)

- Aib Ga11-30cDocument40 pagesAib Ga11-30ctheloniussherek100% (1)

- Admisie Aer-En 2013Document8 pagesAdmisie Aer-En 2013ionut2007No ratings yet

- Chillers & Fan Coil Units: Catalogue 2012Document20 pagesChillers & Fan Coil Units: Catalogue 2012birlograresNo ratings yet

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- CouplingDocument92 pagesCouplingviksursNo ratings yet

- AbstractDocument10 pagesAbstractabushasolomon75% (4)

- Manual Motor DC (Siemens)Document104 pagesManual Motor DC (Siemens)andri ludfiNo ratings yet