Professional Documents

Culture Documents

HYPERMESH

Uploaded by

Sharan AnnapuraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HYPERMESH

Uploaded by

Sharan AnnapuraCopyright:

Available Formats

Xin Yan

M.Sc. Student

Department of Mechanical Engineering

University of Saskatchewan

Supervisor: Prof. Donald Bergstrom

Prof. Daniel Chen

Email: xiy562@mail.usask.ca

Office: 3C89

2

Application of CFD in the research of

bioreactors

Flow inside the scaffolds.

Flow around the scaffolds.

3

[1] http://www.bose-electroforce.com/products/specs/BioDynamic_Test_Instrument.pdf

[1]

Two approaches:

commercial software

in-house codes

Physical

model

Mathematical

model-

governing

equations

Numerical

model-

discretized

governing

equations

Numerical

results

Boundary conditions

Initial conditions

4

Why commercial software??

Complicated geometry

Good visualization

Easy to learn

5

[2] http://www.aspsys.com/userfiles/image/fluent3.jpghttp://www.aspsys.com/userfiles/image/fluent3.jpgv

[2]

[3]

[1]http://www.launchpnt.com/fileadmin/cfd-analysis1.jpg

[1]

[3]http://www.lilitoys.com/Article/changshi/hangmo/200709/11.html

Choices??

CFX

Fluent

Numeca

.

A module in ANSYS

Single environment

User friendly

Quick and straightforward

Fast and accurate CFD

solver

Powerful visualization

capability

6

Useful sources for learning CFX

1. Help in menu bar

2. CFD online

http://www.cfd-online.com

7

Geometry: DesignModeler

Pre-processor Mesh: CFX-Meshing

CFX-Pre

Solver CFX-Solver

Post-processor CFX-Post

Simulation Process

8

Pipe flow (laminar)

U

L

D

Laminar Flow Inlet: U=0.01m/s

D= 20mm L=100mm

Water: density 997kg/m

3

Dynamic viscosity: 8.910

-4

kg/ms

Re

d

=225

Flow rate: 0.00313kg/s

9

ANSYS workbench:DesignModeler (.agdb)

Sketching

Modeling

Import External Geometry file

Modeling

1) Create>Primitives>Cylinder

2) Set up the details

3) Generate

4) How to see the geometry model

10

ANSYS workbench: CFX-Mesh

1) Specify regions

2) Set spacing for each region

3) Inflation mesh

4) Generate the surface mesh

5) Generate the volume mesh

6) Save and create CFD simulation with mesh

11

ANSYS workbench: CFX-Pre

1) Create a domain

2) Set up boundary conditions

3) Set solver control

4) Set material properties

inlet

outlet

solid wall

IF the regions are not specified when meshing.

12

ANSYS Workbench: CFX-Solver

1) Save and write

solver file (.def)

2) Special initial

file if needed

3) Start run

13

ANSYS Workbench: CFX-post

1) Create locations (point, line, plane,)

2) Create contour, vector, stream line,

3) Create chart, table.

14

Laminar flow in a pipe

Potential problems

How to solve it?

|

|

.

|

\

|

|

.

|

\

|

=

2

2 2

1

4 R

r

dz

dp R

u

15

[1]

[1] Pipe flow. Maryam Einian

Before refine

Maximum spacing:5mm

After refine

Maximum spacing: 2mm

16

Laminar flow in a pipe

Result with

Refined mesh

|

|

.

|

\

|

|

.

|

\

|

=

2

2 2

1

4 R

r

dz

dp R

u

17

[1]

[1] Pipe flow. Maryam Einian

18

Finish the simulation.

Compare the velocity profile of developing and

fully developed flow in a pipe.

Plot the mean velocity profile at the exit and

compare it with analytical solution.

Submit your simulation results (including the

velocity profile and the vector figure) and

comments.

Please send it to xiy562@mail.usask.ca

Due day : September 29th

19

You might also like

- Windows Keyboard Shortcuts OverviewDocument3 pagesWindows Keyboard Shortcuts OverviewShaik Arif100% (1)

- Future Work Skills 2020Document19 pagesFuture Work Skills 2020Biblioteca Tracto100% (1)

- Meditations of Maharishi Mahesh YogiDocument192 pagesMeditations of Maharishi Mahesh Yogikpn1967112935100% (7)

- Newton Raphson Method MCQDocument15 pagesNewton Raphson Method MCQmd junaidNo ratings yet

- Aveva Installation GuideDocument48 pagesAveva Installation GuideNico Van HoofNo ratings yet

- App1 RC Building PDFDocument42 pagesApp1 RC Building PDFmanoj_structure100% (1)

- 4 1.soc EncounterDocument181 pages4 1.soc Encounterachew911No ratings yet

- Two Stroke Engine Scavenging SimulationDocument28 pagesTwo Stroke Engine Scavenging SimulationMaheswaran MuthaiyanNo ratings yet

- Fracture Project PresentationDocument16 pagesFracture Project Presentationdhillon_rsdNo ratings yet

- Training 3Document17 pagesTraining 3Thomas George100% (1)

- Arcelor Mittal - Bridges PDFDocument52 pagesArcelor Mittal - Bridges PDFShamaNo ratings yet

- STAR CCM+Foundation Part1sDocument110 pagesSTAR CCM+Foundation Part1smujikag75% (4)

- Anatomy of Neck Spaces and Cervical FasciaeDocument42 pagesAnatomy of Neck Spaces and Cervical FasciaeSharan AnnapuraNo ratings yet

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingFrom EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingRating: 3.5 out of 5 stars3.5/5 (3)

- DSP Lab Manual 15-11-2016 PDFDocument73 pagesDSP Lab Manual 15-11-2016 PDFsmdeepajpNo ratings yet

- Asm Master Oral Notes - As Per New SyllabusDocument262 pagesAsm Master Oral Notes - As Per New Syllabusshanti prakhar100% (1)

- Designing SOCs with Configured Cores: Unleashing the Tensilica Xtensa and Diamond CoresFrom EverandDesigning SOCs with Configured Cores: Unleashing the Tensilica Xtensa and Diamond CoresRating: 5 out of 5 stars5/5 (2)

- Tutorial For Ansys Fluent Porous MediaDocument30 pagesTutorial For Ansys Fluent Porous MediaLykaios Schultz DohrnNo ratings yet

- Calculation of Flow Uniformity IndexDocument19 pagesCalculation of Flow Uniformity IndexOctavio SnNo ratings yet

- Dwarf Boas of The Caribbean PDFDocument5 pagesDwarf Boas of The Caribbean PDFJohn GamesbyNo ratings yet

- CFD Pipe Flow TutorialDocument19 pagesCFD Pipe Flow TutorialAnonymous rEpAAK0iNo ratings yet

- Introduction To Designmodeler and CFX: By: Ephraim Sparrow, John Abraham, Jimmy Tong, Sandra SparrDocument10 pagesIntroduction To Designmodeler and CFX: By: Ephraim Sparrow, John Abraham, Jimmy Tong, Sandra SparrFrank TorresNo ratings yet

- Ansys CFX Student User ManualDocument64 pagesAnsys CFX Student User Manualvdnsit100% (1)

- CFX Tutorial Ductflow Laminar v4p00 PDFDocument25 pagesCFX Tutorial Ductflow Laminar v4p00 PDFSattar Al-JabairNo ratings yet

- Laminar Flow in A Rectangular DuctDocument21 pagesLaminar Flow in A Rectangular Ductbaal981No ratings yet

- Digital Simulation of Flow over Airfoil and Flat Plate Boundary LayerDocument57 pagesDigital Simulation of Flow over Airfoil and Flat Plate Boundary LayerRahul ChowdariNo ratings yet

- CFD NotesDocument17 pagesCFD NotesManuel TholathNo ratings yet

- Tutorial Three Conical Hopper DischargeDocument9 pagesTutorial Three Conical Hopper Dischargemohammadotoom778No ratings yet

- CFDDocument13 pagesCFDMurali S SaranglaNo ratings yet

- Mechanical Inteview QuestionDocument3 pagesMechanical Inteview Questionshubham pandeyNo ratings yet

- Compare aerodynamic forces on box vans at 60 mph using CFD analysisDocument16 pagesCompare aerodynamic forces on box vans at 60 mph using CFD analysispp3986No ratings yet

- DSD & DICA Lab GuideDocument79 pagesDSD & DICA Lab GuideGracyNo ratings yet

- Flu CFD PostDocument44 pagesFlu CFD PostXin-Ni OonNo ratings yet

- VLSI Design Lab PDFDocument109 pagesVLSI Design Lab PDFKvnsumeshChandraNo ratings yet

- TN 217 Mendez DiNardo BenocciDocument45 pagesTN 217 Mendez DiNardo BenocciMarco ChavesNo ratings yet

- Chapter 3: Simulating Flow in A Static Mixer Using WorkbenchDocument30 pagesChapter 3: Simulating Flow in A Static Mixer Using WorkbenchHenry Yañez AliNo ratings yet

- ANSYS CFX Tutorial Laminar Flow in A Rectangular DuctDocument17 pagesANSYS CFX Tutorial Laminar Flow in A Rectangular DuctShafiul AzamNo ratings yet

- Computational Fluid Dynamics: by Dr. A. Nurye Faculty of Mechanical Engineering Nurye@ump - Edu.myDocument20 pagesComputational Fluid Dynamics: by Dr. A. Nurye Faculty of Mechanical Engineering Nurye@ump - Edu.myaditya joshiNo ratings yet

- Chapter 1: CFD Introduction: Dr. Salvador Vargas DíazDocument12 pagesChapter 1: CFD Introduction: Dr. Salvador Vargas DíazSalvador Vargas-DiazNo ratings yet

- VLSI Design Advanced Lab ManualDocument74 pagesVLSI Design Advanced Lab ManualShiraz HusainNo ratings yet

- Vlsi Lab Manual 17ecl77 2020 SaitDocument157 pagesVlsi Lab Manual 17ecl77 2020 Saitsuraj jha100% (1)

- Tutorial 18. Using The VOF ModelDocument28 pagesTutorial 18. Using The VOF Modelبلال بن عميرهNo ratings yet

- 2011 Advanced Computer Architecture: CS/B.TECH (CSE) /SEM-4/CS-403/2011Document7 pages2011 Advanced Computer Architecture: CS/B.TECH (CSE) /SEM-4/CS-403/2011Avik MitraNo ratings yet

- CFD Analysis of UAV Flying WingDocument9 pagesCFD Analysis of UAV Flying WingMacce LoiseNo ratings yet

- OpenSees Days Berkeley 13 OSNDocument71 pagesOpenSees Days Berkeley 13 OSNbladeyusNo ratings yet

- Tut18 PDFDocument30 pagesTut18 PDFTalayeh MshNo ratings yet

- Lab 5Document19 pagesLab 5Khalid MalikNo ratings yet

- Cs LinuxDocument57 pagesCs LinuxVarsha SaddeNo ratings yet

- Software Application Lab Manual 17CVL67 PDFDocument47 pagesSoftware Application Lab Manual 17CVL67 PDFmohan100% (5)

- CE 463.3 - Advanced Structural Analysis Lab 1 - Introduction To SAP2000Document8 pagesCE 463.3 - Advanced Structural Analysis Lab 1 - Introduction To SAP2000Ouafi Saha100% (1)

- Beginning Programming For Engineers: Minoo Aminian Rensselaer Polytechnic InstituteDocument33 pagesBeginning Programming For Engineers: Minoo Aminian Rensselaer Polytechnic InstituteSamuel S. ChanNo ratings yet

- Updated CFD Presentation AzizDocument22 pagesUpdated CFD Presentation AzizWahid zada KhanNo ratings yet

- Xilinx ISE Tutorial 002 - DecryptedDocument7 pagesXilinx ISE Tutorial 002 - DecryptedsalehgazyNo ratings yet

- CAETraining (Fluid)Document129 pagesCAETraining (Fluid)andysarmientoNo ratings yet

- CAD & Design Flow: Motivation: Microelectronics Design EfficiencyDocument18 pagesCAD & Design Flow: Motivation: Microelectronics Design EfficiencyJubin JainNo ratings yet

- Carbon Nanotube Computing: Subhasish Mitra Collaborator: H.-S. Philip WongDocument50 pagesCarbon Nanotube Computing: Subhasish Mitra Collaborator: H.-S. Philip WongnanoteraCHNo ratings yet

- FLUENT - Tutorial - Dynamic Mesh - Solving A 2D Vibromixer ProblemDocument20 pagesFLUENT - Tutorial - Dynamic Mesh - Solving A 2D Vibromixer Problemmm0hammadiNo ratings yet

- Verification and Validation of Turbulent Flow Around A Clark-Y AirfoilDocument57 pagesVerification and Validation of Turbulent Flow Around A Clark-Y AirfoilAnu MCNo ratings yet

- 06 Udf Flow PDFDocument19 pages06 Udf Flow PDFAdrian García MoyanoNo ratings yet

- Intermediate Lab 2 ManualDocument57 pagesIntermediate Lab 2 ManualpRoBoTRoGe OPNo ratings yet

- Cesar Lcpcv5 Tutorial12 v11 GBDocument24 pagesCesar Lcpcv5 Tutorial12 v11 GBJasmin AgriNo ratings yet

- Mock Exam 22 23 KH6063MAA - Computational - ThermoFluids - 2022 2023Document6 pagesMock Exam 22 23 KH6063MAA - Computational - ThermoFluids - 2022 2023Mohamed SaadNo ratings yet

- Fluent Nov 2003Document27 pagesFluent Nov 2003Rajesh RameshNo ratings yet

- Up and Running with AutoCAD 2012: 2D and 3D Drawing and ModelingFrom EverandUp and Running with AutoCAD 2012: 2D and 3D Drawing and ModelingRating: 5 out of 5 stars5/5 (1)

- Embedded Software Design and Programming of Multiprocessor System-on-Chip: Simulink and System C Case StudiesFrom EverandEmbedded Software Design and Programming of Multiprocessor System-on-Chip: Simulink and System C Case StudiesNo ratings yet

- Ee 18me81 Cie 1Document1 pageEe 18me81 Cie 1Sharan AnnapuraNo ratings yet

- Ee 18me81 Cie 2Document1 pageEe 18me81 Cie 2Sharan AnnapuraNo ratings yet

- S.M.A.R.T Portable Fruit Preservation System: InvestigatorsDocument12 pagesS.M.A.R.T Portable Fruit Preservation System: InvestigatorsSharan AnnapuraNo ratings yet

- Ee 18me81 Cie 3Document1 pageEe 18me81 Cie 3Sharan AnnapuraNo ratings yet

- 10.1007@s10098 019 01791 0Document14 pages10.1007@s10098 019 01791 0Sharan AnnapuraNo ratings yet

- 100 QuestionsDocument4 pages100 QuestionsSharan AnnapuraNo ratings yet

- Visvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016Document33 pagesVisvesvaraya Technological University, Belagavi Choice Based Credit System (CBCS) Scheme of Teaching and Examination 2015-2016A VNo ratings yet

- Shortlisted Ideas of CIF2020Document16 pagesShortlisted Ideas of CIF2020Sharan AnnapuraNo ratings yet

- Teacher BookletDocument32 pagesTeacher BookletSharan AnnapuraNo ratings yet

- Geometric Computing For Freeform ArchitectureDocument20 pagesGeometric Computing For Freeform ArchitectureSharan AnnapuraNo ratings yet

- Take The Mosquito QuizDocument7 pagesTake The Mosquito QuizSharan AnnapuraNo ratings yet

- Blooms Verbs 2Document1 pageBlooms Verbs 2api-270396418No ratings yet

- Notification NITKDocument12 pagesNotification NITKSharan AnnapuraNo ratings yet

- Journal Pone 0213918 PDFDocument16 pagesJournal Pone 0213918 PDF3chelonNo ratings yet

- Głowińska2017 Article EffectOfSisalFiberFillerOnTherDocument10 pagesGłowińska2017 Article EffectOfSisalFiberFillerOnTherSharan AnnapuraNo ratings yet

- Motion Coordination of Aerial VehiclesDocument177 pagesMotion Coordination of Aerial VehiclesSharan AnnapuraNo ratings yet

- High-Tech Urban Farming PDFDocument83 pagesHigh-Tech Urban Farming PDFSharan AnnapuraNo ratings yet

- Muscles of The Head, Neck & Trunk (ADAM)Document9 pagesMuscles of The Head, Neck & Trunk (ADAM)Sharan AnnapuraNo ratings yet

- Metrology LabDocument49 pagesMetrology Labsanthu086No ratings yet

- S W P: T, S, A B M A T E: Olar Ater Umps Echnical Ystems ND Usiness Odel Pproaches O ValuationDocument32 pagesS W P: T, S, A B M A T E: Olar Ater Umps Echnical Ystems ND Usiness Odel Pproaches O ValuationAkash TalekarNo ratings yet

- Pneumatic SystemDocument28 pagesPneumatic SystemMohd FazillNo ratings yet

- Artikel CG NAG Photoacoustics Utrecht 2005Document15 pagesArtikel CG NAG Photoacoustics Utrecht 2005Sharan AnnapuraNo ratings yet

- Jwarp 2014112616554316 PDFDocument12 pagesJwarp 2014112616554316 PDFSharan AnnapuraNo ratings yet

- Radio Frequency Puts The Heat On Plant Pests: in TexasDocument3 pagesRadio Frequency Puts The Heat On Plant Pests: in TexasSharan AnnapuraNo ratings yet

- Brochure Call For PapersDocument8 pagesBrochure Call For PapersvempadareddyNo ratings yet

- Krishi Sutra (English)Document242 pagesKrishi Sutra (English)torqtechNo ratings yet

- FPO Helps Farmers Adopt Climate-Resilient Red Gram CultivationDocument100 pagesFPO Helps Farmers Adopt Climate-Resilient Red Gram Cultivation2009ncymNo ratings yet

- Clinical Indications, Treatment and Current PracticeDocument14 pagesClinical Indications, Treatment and Current PracticefadmayulianiNo ratings yet

- Rivalry and Central PlanningDocument109 pagesRivalry and Central PlanningElias GarciaNo ratings yet

- 2019 BioscienceJDocument14 pages2019 BioscienceJPatrícia Lima D'AbadiaNo ratings yet

- Bosch Committed to Outsourcing to Boost CompetitivenessDocument4 pagesBosch Committed to Outsourcing to Boost CompetitivenessPriya DubeyNo ratings yet

- Biotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Document20 pagesBiotechnology Eligibility Test (BET) For DBT-JRF Award (2010-11)Nandakumar HaorongbamNo ratings yet

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocument18 pagesTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNo ratings yet

- Reaction CalorimetryDocument7 pagesReaction CalorimetrySankar Adhikari100% (1)

- Optimum Work Methods in The Nursery Potting ProcessDocument107 pagesOptimum Work Methods in The Nursery Potting ProcessFöldi Béla100% (1)

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Sheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMDocument2 pagesSheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMKhalifa MohamedNo ratings yet

- Culinary Nutrition BasicsDocument28 pagesCulinary Nutrition BasicsLIDYANo ratings yet

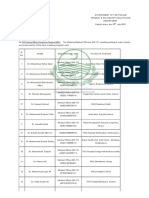

- Government of The Punjab Primary & Secondary Healthcare DepartmentDocument3 pagesGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorNo ratings yet

- Programming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduDocument34 pagesProgramming Language II CSE-215: Dr. Mohammad Abu Yousuf Yousuf@juniv - EduNaruto DragneelNo ratings yet

- Experiment Vit CDocument4 pagesExperiment Vit CinadirahNo ratings yet

- Minimum Fees To Be Taken by CADocument8 pagesMinimum Fees To Be Taken by CACA Sanjay BhatiaNo ratings yet

- Marketing of Agriculture InputsDocument18 pagesMarketing of Agriculture InputsChanakyaNo ratings yet

- MP & MC Module-4Document72 pagesMP & MC Module-4jeezNo ratings yet

- Recent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4Document12 pagesRecent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4sebjangNo ratings yet

- APLI - Annual Report - 2016Document122 pagesAPLI - Annual Report - 2016tugas noviaindraNo ratings yet

- BILL of Entry (O&A) PDFDocument3 pagesBILL of Entry (O&A) PDFHiJackNo ratings yet

- Hotels Cost ModelDocument6 pagesHotels Cost ModelThilini SumithrarachchiNo ratings yet

- Microwave: Microwaves Are A Form ofDocument9 pagesMicrowave: Microwaves Are A Form ofDhanmeet KaurNo ratings yet

- Primary Homework Help Food ChainsDocument7 pagesPrimary Homework Help Food Chainsafnaxdxtloexll100% (1)

- Benefits of Eating OkraDocument4 pagesBenefits of Eating Okraama931No ratings yet