Professional Documents

Culture Documents

Work Measurement-Compressed Version

Uploaded by

John BangayanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Measurement-Compressed Version

Uploaded by

John BangayanCopyright:

Available Formats

WORK MEASUREMENT

Work Measurement

A technique used to determine the best estimate of the time required to perform a task Regardless of the methodology used, the immediate objective of all work measurement studies is the development of standard time Standard time is the time that a person suited to the job and fully trained in the specified method will need to perform the job if he or she works at a normal or standard tempo

How to obtain standard time

1.

2. 3.

4.

Time Study/Stopwatch Method Work Sampling Pre-determined Time Systems (PDTS) Standard Data

Stopwatch Time Study Technique

The method basically involves taking a number of observations for the operation Divide the operation into elements Rate the operators performance Set allowances Check whether a sufficient number of cycles have been timed Compute the standard time

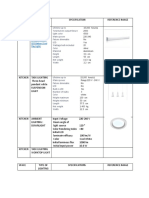

ELEMENTS

10

Average Observed Time

Rating

Normal Time

PICK UP T CARDS AND R POSITION SHUFFLE T

4 4 10

5 37 10

DATE: May 2013 Allowances

R 14 position 47 of cards ACTIVITY BEGINS: ACTIVITY: CARD DEALING Pick-up and OPERATORS ACTIVITY ENDS: NAME: Distribute OCAMPO cards to all players

DISTRIBUTE T CARDS TO ALL PLAYERS R

T R STANDARD TIME PER OUTPUT

18

32

18

65

18

19

18

17

18

30

18

18

Westinghouse Rating Factor

How to set Allowances?

1. Personal Allowance 2. Delay (Unavoidable) 3. Basic Fatigue Between the 5% personal allowance and 4% basic fatigue, most operators are given initial 9% basic allowance, to which other allowances may be added

ILO Recommended Allowances

Formula for Standard Time

Normal Time = Observed Time x R.Factor Standard Time = Normal Time x A.Factor AFjobtime = 1 + A 1 AFworkday = ---------------1A where: A = Allowance % (e.g. 3%, 5%)

Sample Problems

Compute the allowance factor these two (2) cases: 1. The allowance is 20 percent of job time 2. The allowance is 20 percent of work day

Sample Problem No.1

A time study of an assembly operation yielded the following observed times, for which the analyst gave a performance rating of 1.10. Using an allowance of 15 percent of job time, determine the appropriate standard time for this operation.

Sample Problem No.2

Observation Time Observation (mins) Time (mins)

1 2 3 4 5

4.20 4.15 4.08 4.12 4.15

6 7 8 9

4.18 4.14 4.14 4.19

Sample Problem No. 3

Given the following readings : 1 2 3 4 5 0.239 0.052 0.198 0.049 0.080 6 7 8 9 10 0.060 0.068 0.239 0.988 0.239

Sample Problem No. 3

From the above data, determine the representative selected time using :

a. arithmetical method b. modal method

Computation of Number of Cycles

_

n = (zs/ax)2 where : s = standard deviation z = value for a desired confidence level a = accuracy/error (in percent) _ X = mean

Computation of Number of Cycles

n = (zs/e)2

where : s = standard deviation z = value for a desired confidence level e = accuracy/error (in unit of time) _ X = mean

Sample Problem No. 4

Jim and Bob recently conducted time study on a janitorial task. From a sample of 75 observations, they computed an average cycle time of 15 minutes with a standard deviation of 2 minutes. Was their sample large enough that one can be 99% confident that the standard time is with in 5% of the true value. (z = 2.33)

PRACTICE PROBLEMS

WORK MEASUREMENT

Computations for Allowance

COMPUTATIONS FOR ALLOWANCE (MINS) Given : % ALLOWANCE = 15% TASK ALLOWANCE/JOB TIME ALLOWANCE Allowance (minutes) % ALLOWANCE = ---------------------------------------TPT Allowance (minutes) Allowance (minutes) 15% = -------------------------------------------------450 minutes Allowance (minutes)

Computations for Allowance

WORKDAY ALLOWANCE/SHIFT ALLOWANCE Allowance (minutes) % ALLOWANCE = -------------------------------TPT Allowance (minutes) 15% = ------------------------------450 minutes

Work Sampling Technique

A method of finding the percentage occurrence of a certain activity by sampling and random observations Its main objective is to measure the activities and delays of workers or machines and/or working time and nonworking time of a manual operation and establish a standard time for an operation

Work Sampling Sheet

Work Sampling Formula

(total time in mins) x (working time in %) x (performance index in percent) Standard time = ----------------------------------------------- x AF per piece Total number of pieces produced

(480 x 0.85 x 1.10) = ------------------------- x 1.15 = 1.23 mins 420

Number of Sampling Observations

n = [(z/e)2 p(1-p)] n = [(1.65/0.05)2 (0.30)(0.70)] n = [(1.65/0.05)2 (0.30)(0.70)] n = 229 observations

Work Sampling Problems

SAMPLE SOLVED PROBLEMS

Standard Data Concept

SPRAYING TIME AND PRODUCT SURFACE AREA Y =a+b

ST = 20 mins

(x)

ST = ?? ST = 40 mins

Standard Data Formula

a = (x2)(y) - x(xy) n (x2) (x)2 b = n(xy) - x (y) n(x2) - (x)2

y = a + b (x) regresssion line

How to get Standard Time

b = 0.001304 a = 0.10403

Y = 0.10403 + 0.001304 (surface area) Standard Time=0.10403 + 0.001304 (250) Standard Time = 0.429 minutes

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Et200sp Ai 4xrtd TC 2 3 4 Wire HF Manual en-US en-US PDFDocument80 pagesEt200sp Ai 4xrtd TC 2 3 4 Wire HF Manual en-US en-US PDFSrikar TanukulaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Modelling of Short Duration Isopluvial Map For Raichur District KarnatakaDocument4 pagesModelling of Short Duration Isopluvial Map For Raichur District KarnatakaMohammed Badiuddin ParvezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Ring Smart Lighting Transformer Manual ENDocument11 pagesRing Smart Lighting Transformer Manual ENjust let me download assholeNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRDocument3 pages1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRjunior_jazzzNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 1 - ERDAS IMAGINE Viewer PDFDocument20 pages1 - ERDAS IMAGINE Viewer PDFRahmad KurniawanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- BSC (Hons) in Civil EngineeringDocument33 pagesBSC (Hons) in Civil EngineeringFaisal NazeerNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ditch Excavation Procedure - C01Document8 pagesDitch Excavation Procedure - C01Toreson OfuafoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Working Drawings: Key PlanDocument1 pageWorking Drawings: Key PlanSharanyaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- AmarnathDocument26 pagesAmarnathsandeshasNo ratings yet

- 6420 PHENOLS 6420 A. Introduction: 1. Sources and SignificanceDocument6 pages6420 PHENOLS 6420 A. Introduction: 1. Sources and SignificanceNguyen Hien Duc HienNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Drip Legs Definition Purpose Configuration Selection Installation and Sizing PDFDocument4 pagesDrip Legs Definition Purpose Configuration Selection Installation and Sizing PDFFaizal KhanNo ratings yet

- Premier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020Document6 pagesPremier University Department of Computer Science and Engineering (DCSE) Class Schedule (Updated) Session: Fall 2020X streamNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Steam Its Generation and Use 41st Edition PDFDocument1,106 pagesSteam Its Generation and Use 41st Edition PDFAlberto Valdivia91% (11)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Perry 02Document2 pagesPerry 02Thaly MejiaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Fast-Recovery Rectifier Diodes: Ru 4Y Ru 4Z RU4 Ru 4A Ru 4B Ru 4CDocument1 pageFast-Recovery Rectifier Diodes: Ru 4Y Ru 4Z RU4 Ru 4A Ru 4B Ru 4CY. Leonel MolinaNo ratings yet

- Norton Scan 12212Document4 pagesNorton Scan 12212Saurabh KumarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ASCOM Users GuideDocument21 pagesASCOM Users GuideleloalmeidaNo ratings yet

- Emergency Off and Rescue From Helicopter: Ground Rescue Booklet Ec130T2Document20 pagesEmergency Off and Rescue From Helicopter: Ground Rescue Booklet Ec130T2robbertmd100% (1)

- Philips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Document4 pagesPhilips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Shrutie PatilNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Class 10 Science (Physics) MCQs Chapter 11 QuestionsDocument28 pagesClass 10 Science (Physics) MCQs Chapter 11 QuestionsKSA TEXTILENo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Practical Organic BookDocument148 pagesPractical Organic Bookliang102009No ratings yet

- Definitions of Physical QuantitiesDocument41 pagesDefinitions of Physical QuantitiesAnonymous QiMB2lBCJLNo ratings yet

- Statistical Mechanics: Lecture A0: Phase TransitionsDocument5 pagesStatistical Mechanics: Lecture A0: Phase TransitionsTushar GhoshNo ratings yet

- STA505Document10 pagesSTA505kizonzNo ratings yet

- Jar Test Lab Report Environmental EngineeringDocument7 pagesJar Test Lab Report Environmental EngineeringNur Hazimah100% (1)

- Exhibitor 35804 PDFDocument36 pagesExhibitor 35804 PDFulton1237624No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Problem Solving and Program DesignDocument30 pagesProblem Solving and Program DesignNick RushNo ratings yet

- Medellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFDocument16 pagesMedellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFajay d1212No ratings yet

- Assignment Payment 1Document5 pagesAssignment Payment 1Mohamad SafwanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)