Professional Documents

Culture Documents

Bus Bar Protection REV 1

Uploaded by

Jai GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bus Bar Protection REV 1

Uploaded by

Jai GuptaCopyright:

Available Formats

BUS BAR PROTECTION AND LBB PROTECTION.

By Y. k. Pandharipande.

BUS BAR PROTECTION AND LBB PROTECTION

PERFORMANCE REQUIREMENTS Stability

High Speed Operation Selectivity Reliability Sensitivity Suitable for Use with moderate CT Ratings. Extendable to changes in Bus Bar configuration & addition of Circuits.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION

CIRCULATING CURRENT DIFFERENTIAL PRINCIPLE

CURRENT DISTRIBUTION EXTERNAL FAULT

CURRENT DISTRIBUTION INTERNAL FAULT

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PRIOTECTION

A. HIGH IMPEDANCE TYPE

Relay Branch made High Impedance to limit differential current due to unequal CT saturation on external fault. Requires exclusive CT core of identical ratio and rating. Simple in design and execution.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION

B. LOW IMPEDANCE (BIASED) TYPE

Through current Bias increases differential pick-up on external fault to ensure stability. Tolerant to CT mismatch and can use shared core. Comparatively more complex in design and execution. Practical schemes provide CT saturation detectors to enhance stability.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION (87)

HIGH IMPEDANCE SCHEME

If B CT fully saturates on external fault, Vs = If/n (Rct + 2Rl) Volts. Relay Branch Impedance = Vs/Is, where Is = Setting current of Relay. External Stabilising Resistor RST = Vs/Is VA /Is, where VA = Relay VA burden at setting current.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION (87)

HIGH IMPEDANCE SCHEME- Typical Setting Workout.

Max. Through fault Current (If) = 20,000A (Prim) / 20A(SEC)

Vs = 20 (5 + 1) = 120V

Stabilising Resistor (RST) = 120/0.2 1.0/0.2 = 600 - 25 = 575 ,

(assuming relay VA burden = 1 VA)

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION

HIGH IMPEDANCE SCHEME Typical Setting Workout.

Primary Fault Current setting (assuming number of circuits connected to Bus Bar, N=10) = CT Ratio (Is + N. Im) = 1000 (0.20 + 10 x 0.03) = 500A.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION (87)

HIGH IMPEDANCE SCHEME Need For Metrosils.

Peak Voltage across CT Secondary for Max. Internal Fault = 2 2 [Vk x (Vp Vk)] Vk = 240V, Vp = 20 (575 + 25) = 12000V Peak Voltage = 22 [(240 x (12000-240)] = 5300V

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION

HIGH IMPEDANCE SCHEME Need For Metrosils.

If Peak voltage exceeds 3000V threatening secondary insulation, Metrosils (Non-linear resistors) are used to limit voltage to safe value (within 1000V) on internal fault. Metrosil offers high resistance at lower voltage levels which drastically reduces at higher voltages, thereby quenching the voltage across relay branch. Typical Metrosil Equation V = C x I ( C = 900 , = 0.25)

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION

HIGH IMPEDANCE SCHEME -CT SUPERVISION (95)

Required to detect CT open circuit on load to prevent maloperation. Connected for alarm & short CT bus wires on operation. Time delayed to avoid operation on internal / external faults (3Sec) Voltage relay with sensitive setting (2 -14V) is used. Normally set to detect primary unbalance of 25A or 10% of least loaded circuit. Also should not operate with normal unbalance on load.

BUS BAR PROTECTION AND LBB PROTECTION

BUS BAR PROTECTION CT SWITCHING.

BUS BAR PROTECTION AND LBB PROTECTION

TYPICAL 2 ZONE SCHEME WITH INDEPENDANT CHECK

BUS BAR PROTECTION AND LBB PROTECTION

TYPICAL 2 ZONE SCHEME WITH INDEPENDANT CHECK

D.C. CIRCUITS.

20K resistor on negative side used for cathodic protection.

BUS BAR PROTECTION AND LBB PROTECTION

LOCAL BREAKER BACKUP (LBB) PROTECTION NEED

Provides local isolation when breaker gets stuck on fault. Ensures comparatively faster clearance than remote backup.

Avoids wide spread interruption and enables fast restoration.

BUS BAR PROTECTION AND LBB PROTECTION

LBB PROTECTION OPRATING PRINCIPLE & CT CKTS.

BUS BAR PROTECTION AND LBB PROTECTION

LBB PROTECTION

D.C. CKTS USING BUS BAR PROTECTION TRIP LOGIC.

LBB CURRENT CHECK RELAY (50) Current Setting Range 20-320% or 5 -80%In (Recommended setting - 5% for Generator & 20% for Other Circuits) LBB TIMER (2/50) Range o.11.0 S (Recommended 0.20S)

BUS BAR PROTECTION AND LBB PROTECTION

LBB PROTECTION TIMER SETTING CRIETERIA

TLBB = TCB + TDO + TM TPU, Where TCB = C.B. Trip Time, TDO = Current Check relay DO time, TM = Safety margin, TPU = Current Check relay PU Time

Normally,200ms delay recommended which is faster than remote backup and allows sufficient time for normal C.B. tripping.

You might also like

- Surge Arresters Application and SelectionDocument36 pagesSurge Arresters Application and SelectionJaleesNo ratings yet

- Security GuideDocument444 pagesSecurity GuideRahul JaiswalNo ratings yet

- Lecture 5b. Insulation-Coordination PDFDocument19 pagesLecture 5b. Insulation-Coordination PDFwakolesha TadeoNo ratings yet

- SM PC300-8 SN01983-01Document44 pagesSM PC300-8 SN01983-01aldy yasi79% (14)

- 7SJ61 As High Impedance RelayDocument36 pages7SJ61 As High Impedance Relayzarun1No ratings yet

- Transformer ProtectionDocument21 pagesTransformer ProtectioncalecaleNo ratings yet

- Work Essay QuotesDocument15 pagesWork Essay QuotesJai GuptaNo ratings yet

- Floating Neutral Impact in Power DistributionDocument9 pagesFloating Neutral Impact in Power DistributionSugeng Sumarno100% (1)

- Abstract of National Electrical Code For Transformer's ProtectionDocument2 pagesAbstract of National Electrical Code For Transformer's ProtectionJignesh ParmarNo ratings yet

- Relay CoordinationDocument68 pagesRelay CoordinationrajuNo ratings yet

- Presentation On Insulation CoordinationDocument17 pagesPresentation On Insulation CoordinationBhavik PrajapatiNo ratings yet

- Transient Overvoltages On Ungrounded Systems From Intermittent FaultsDocument40 pagesTransient Overvoltages On Ungrounded Systems From Intermittent Faultsgeorge_cpp2No ratings yet

- Basic Protection and Relaying SchemesDocument58 pagesBasic Protection and Relaying SchemesputrasejahtraNo ratings yet

- S.C Calculations: Short Circuit StudyDocument17 pagesS.C Calculations: Short Circuit StudyAhmedRaafatNo ratings yet

- CT and VTDocument32 pagesCT and VTSamarendu BaulNo ratings yet

- Bus Bar Arrangement of SubstationDocument17 pagesBus Bar Arrangement of SubstationBbimafidon_248613673No ratings yet

- Article - Characteristics of Circuit Breaker Trip Curves and CoordinationDocument4 pagesArticle - Characteristics of Circuit Breaker Trip Curves and CoordinationHassenLNo ratings yet

- Study of 132 KV Transmission Line Design and Calculation of Its ParametersDocument8 pagesStudy of 132 KV Transmission Line Design and Calculation of Its ParametersamghklkrniNo ratings yet

- Bus ReactorDocument6 pagesBus Reactorbibhoo100% (1)

- Case Study of Nestle and AnswersDocument6 pagesCase Study of Nestle and AnswersTharishka Kumarasiri100% (2)

- Relay ApplicationsDocument248 pagesRelay Applicationsfrodo frodoNo ratings yet

- Line Differential Protection - FinalDocument69 pagesLine Differential Protection - FinalJosé Miguel Ochoa AcerosNo ratings yet

- Over Current Relay Types and ApplicationsDocument11 pagesOver Current Relay Types and ApplicationskishansaiNo ratings yet

- CT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5Document20 pagesCT Requirements - Summary - Rev 3p2 - 090121 - ABB Relays - New - v0p5goalex100% (1)

- Power System Protection - Part 08Document16 pagesPower System Protection - Part 08Rahul MandalNo ratings yet

- Power System Protection PDFDocument12 pagesPower System Protection PDFBala MNo ratings yet

- 07-BKH-coordination & Fault EliminationDocument56 pages07-BKH-coordination & Fault Eliminationshawon_darkNo ratings yet

- CT-PT ReqtsDocument32 pagesCT-PT Reqtsዛላው መና100% (1)

- RELAY COORDINATION USING ETAP Ijariie12420Document9 pagesRELAY COORDINATION USING ETAP Ijariie12420Rakesh ShinganeNo ratings yet

- Arc FlashDocument7 pagesArc Flashniksharris100% (1)

- Power System Protection Lectures - Feeder ProtectionDocument38 pagesPower System Protection Lectures - Feeder ProtectionavishekNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Ccie Routing SwitchingDocument20 pagesCcie Routing SwitchingMusaib SyedNo ratings yet

- Study On Current TranformersDocument9 pagesStudy On Current TranformersRoshan AkaravitaNo ratings yet

- Techint Trainee Manual Transformer Sizing CalculationsDocument10 pagesTechint Trainee Manual Transformer Sizing CalculationsYogesh MittalNo ratings yet

- Power System Protective Relaying-Part FourDocument103 pagesPower System Protective Relaying-Part FourMohammedSaadaniHassani100% (2)

- BEF Calculation - Part 2 PDFDocument8 pagesBEF Calculation - Part 2 PDFLin HengNo ratings yet

- CMC - 01 08 2012 FinalDocument44 pagesCMC - 01 08 2012 FinalJai Gupta67% (3)

- Permanent / Fixed Technical LossesDocument11 pagesPermanent / Fixed Technical Lossesyogesh100% (1)

- Study of KV Switch YardDocument35 pagesStudy of KV Switch YardRamana ParavastuNo ratings yet

- Standby & Restricted Earth FaultDocument7 pagesStandby & Restricted Earth FaultanjnaNo ratings yet

- Transformer Protection HosurDocument35 pagesTransformer Protection HosurNaga BinduNo ratings yet

- Chapter-3 Electrical Protection SystemDocument101 pagesChapter-3 Electrical Protection Systemgerrzen64No ratings yet

- Free Simple Quality Control Plan TemplateDocument6 pagesFree Simple Quality Control Plan TemplateMohamed Abo RyaNo ratings yet

- Site Selection ProcessDocument11 pagesSite Selection ProcessAgnes Cheverloo CastilloNo ratings yet

- Fault Current CalculationDocument3 pagesFault Current CalculationfarhanajnNo ratings yet

- Types of Switching Surges Found in MV Motors Fed Via Cables and Switched by Vacuum Circuit BreakersDocument19 pagesTypes of Switching Surges Found in MV Motors Fed Via Cables and Switched by Vacuum Circuit BreakersRatoka LekhemaNo ratings yet

- Power Line Carrier Communication: WelcomeDocument25 pagesPower Line Carrier Communication: WelcomeS BanikNo ratings yet

- Bus Bar Protection Scheme 2003Document34 pagesBus Bar Protection Scheme 2003srinu247No ratings yet

- 7SJ80xx Manual A5 V041001 UsDocument550 pages7SJ80xx Manual A5 V041001 UsAlexandre Moreno100% (1)

- Paper On Automatic Reclosing Transmission Lines Applications and Its ConsiderationsDocument8 pagesPaper On Automatic Reclosing Transmission Lines Applications and Its ConsiderationsGagan GillNo ratings yet

- R5582E RELAY Selection GuideDocument14 pagesR5582E RELAY Selection GuideChandra Hamidi KautsarNo ratings yet

- 12 - Transformer ProtectionDocument40 pages12 - Transformer ProtectionSarthak Vats100% (2)

- PGCIL ET Salary in Hand, Structure & Allowances - OlxamDocument3 pagesPGCIL ET Salary in Hand, Structure & Allowances - OlxamAravindanNo ratings yet

- Fuse and Types of Fuses - Electrical Technology-OkDocument7 pagesFuse and Types of Fuses - Electrical Technology-Okdrastir_777100% (1)

- Transmission Line Protections 1Document22 pagesTransmission Line Protections 1Y V JOSHINo ratings yet

- Spec HT CapacitorDocument35 pagesSpec HT CapacitorJAY PARIKH100% (1)

- Distance Relay - Thesis's ProposalDocument5 pagesDistance Relay - Thesis's ProposalQuan DangNo ratings yet

- Current Transformer 1Document33 pagesCurrent Transformer 1Noli Oteba100% (1)

- ABB Busbar Protection REB670 2.0 ANSIDocument498 pagesABB Busbar Protection REB670 2.0 ANSIksg9731No ratings yet

- Projects Titles For Protection - W2017Document3 pagesProjects Titles For Protection - W2017Ahmad AbunassarNo ratings yet

- BCUDocument8 pagesBCUJigyesh SharmaNo ratings yet

- Operating Temperature Within LV Switchgear - EEPDocument6 pagesOperating Temperature Within LV Switchgear - EEPSundaresan SabanayagamNo ratings yet

- ABB REG 650 ManualDocument740 pagesABB REG 650 ManualMysha ShaqeenaNo ratings yet

- Pds Synchro Control LTR en LRDocument2 pagesPds Synchro Control LTR en LRJai GuptaNo ratings yet

- PDS SYNCHRO Field LTR EN LRDocument2 pagesPDS SYNCHRO Field LTR EN LRJai GuptaNo ratings yet

- PDS SYNCHRO Field LTR EN LRDocument2 pagesPDS SYNCHRO Field LTR EN LRJai GuptaNo ratings yet

- Rethinking The Cost Estimating Process Through 5D BIM A Case Study 1Document9 pagesRethinking The Cost Estimating Process Through 5D BIM A Case Study 1Jai GuptaNo ratings yet

- Rethinking The Cost Estimating Process Through 5D BIM A Case Study 1Document9 pagesRethinking The Cost Estimating Process Through 5D BIM A Case Study 1Jai GuptaNo ratings yet

- Bim & The 5D Project Cost Manager: SciencedirectDocument10 pagesBim & The 5D Project Cost Manager: Sciencedirectsaad hussainNo ratings yet

- Reading Material - BIM Tools Matrix 2Document5 pagesReading Material - BIM Tools Matrix 2AhmadjakwarNo ratings yet

- Pds Synchro Control LTR en LRDocument2 pagesPds Synchro Control LTR en LRJai GuptaNo ratings yet

- 00 Insights Prelims Test Series 2017 SCHEDULEDocument4 pages00 Insights Prelims Test Series 2017 SCHEDULEJai GuptaNo ratings yet

- COVID 19 SOPs and Guidelines For Construction Sites PDFDocument8 pagesCOVID 19 SOPs and Guidelines For Construction Sites PDFshashanksaranNo ratings yet

- Energy Scan Issue 51Document13 pagesEnergy Scan Issue 51Jai GuptaNo ratings yet

- Insights Prelims Test Series 2017 SCHEDULEDocument11 pagesInsights Prelims Test Series 2017 SCHEDULESurajit DasNo ratings yet

- INSIGHT CSP 2017 Test 02 PDFDocument38 pagesINSIGHT CSP 2017 Test 02 PDFRam KumarNo ratings yet

- 0401 PF RulesDocument40 pages0401 PF RulesJai Gupta0% (1)

- Non Conventional Energy Resources NishaDocument11 pagesNon Conventional Energy Resources NishaJai GuptaNo ratings yet

- ST NZMDocument1 pageST NZMJai GuptaNo ratings yet

- Economic Survey PPT - Part 1Document104 pagesEconomic Survey PPT - Part 1Jai GuptaNo ratings yet

- Oasis Grandstand 1, 2,3BHK Residential Apartments and Flats in Yamuna ExpresswayDocument3 pagesOasis Grandstand 1, 2,3BHK Residential Apartments and Flats in Yamuna ExpresswayJai GuptaNo ratings yet

- Unit-4 TG Desk Engineer'S Log BookDocument6 pagesUnit-4 TG Desk Engineer'S Log BookJai GuptaNo ratings yet

- Weekly Current Affairs Update For IAS Exam Vol 22 28th April 2014 To 4th May 2014Document44 pagesWeekly Current Affairs Update For IAS Exam Vol 22 28th April 2014 To 4th May 2014Jai GuptaNo ratings yet

- Americas Energy SecurityDocument5 pagesAmericas Energy SecurityJai GuptaNo ratings yet

- Weekly Current Affairs Update For IAS Exam Vol 26 26th May 2014 To 1st June 2014Document40 pagesWeekly Current Affairs Update For IAS Exam Vol 26 26th May 2014 To 1st June 2014Jai GuptaNo ratings yet

- Weekly Current Affairs Update For IAS Exam Vol 22 28th April 2014 To 4th May 2014Document44 pagesWeekly Current Affairs Update For IAS Exam Vol 22 28th April 2014 To 4th May 2014Jai GuptaNo ratings yet

- IES2013 GeneralAbilityKey Set DDocument18 pagesIES2013 GeneralAbilityKey Set DARjit ChaudharyNo ratings yet

- Weekly Current Affairs Update For IAS Exam Vol 27 2nd May 2014 To 8th June 2014Document40 pagesWeekly Current Affairs Update For IAS Exam Vol 27 2nd May 2014 To 8th June 2014Jai GuptaNo ratings yet

- IES2013 GeneralAbilityKey Set DDocument18 pagesIES2013 GeneralAbilityKey Set DARjit ChaudharyNo ratings yet

- 6 Industrial and Urban SocietyDocument10 pages6 Industrial and Urban SocietyAkhil ShastryNo ratings yet

- RS04 Oxygen Master HK7715D Total Air FlowDocument1 pageRS04 Oxygen Master HK7715D Total Air FlowJai GuptaNo ratings yet

- Cisco Unified CME DocumentationDocument3 pagesCisco Unified CME DocumentationChristian Trésor KandoNo ratings yet

- Operational Landing Distances A New Standard For In-Flight Landing Distance AssessmentDocument5 pagesOperational Landing Distances A New Standard For In-Flight Landing Distance AssessmentJehan IchhaporiaNo ratings yet

- Samson 4763Document4 pagesSamson 4763Douglas Henrique LionsNo ratings yet

- Canon Ir 3045 Brochure 0Document14 pagesCanon Ir 3045 Brochure 0irteenNo ratings yet

- A085hydraulicactuators PDFDocument2 pagesA085hydraulicactuators PDFCesar PomposoNo ratings yet

- Configuring SLD Security RolesDocument3 pagesConfiguring SLD Security Roleshaja5419No ratings yet

- Argus IntroDocument12 pagesArgus IntroJuan HernandezNo ratings yet

- Segmentation, Targeting and PositioningDocument18 pagesSegmentation, Targeting and PositioningHussain AhmedNo ratings yet

- IIM Raipur - Adv For Non-Faculty PositionsDocument5 pagesIIM Raipur - Adv For Non-Faculty PositionsCareerNotifications.comNo ratings yet

- D54122Document450 pagesD54122Ronal BurgosNo ratings yet

- CCNA+3+Module+7+Version+4 0+answersDocument6 pagesCCNA+3+Module+7+Version+4 0+answersMinoli_Silva_7409No ratings yet

- Link Belt298 HSLTDocument36 pagesLink Belt298 HSLTIvan Sevillano Sanchez100% (1)

- Timeslots On The Abis InterfaceDocument18 pagesTimeslots On The Abis InterfaceHouss HoussiNo ratings yet

- Comparison of Ansi Aisc 360-05 To 1989 Asd SpecificationDocument32 pagesComparison of Ansi Aisc 360-05 To 1989 Asd SpecificationRicardo MGNo ratings yet

- FMS-L7R Chassis Assembly GuideDocument5 pagesFMS-L7R Chassis Assembly GuideWalter R. FriggiNo ratings yet

- Socomec Ups Netys - RT - 1100-3000-Operating - ManualDocument28 pagesSocomec Ups Netys - RT - 1100-3000-Operating - ManualalvinkertNo ratings yet

- Guidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCDocument26 pagesGuidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCchem_taNo ratings yet

- Spain Iban Number - Google SearchDocument1 pageSpain Iban Number - Google Search7jfp2yys8fNo ratings yet

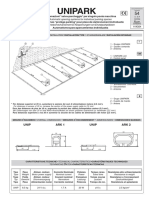

- Unipark SchémaDocument4 pagesUnipark SchémaIMEN DHIBINo ratings yet

- Presentación TDEDocument35 pagesPresentación TDEleogilrNo ratings yet

- MIS500 Assessment 1 Brief - EssayDocument5 pagesMIS500 Assessment 1 Brief - Essaysherryy619No ratings yet

- ISO 7483 - 1991 - Е - angDocument40 pagesISO 7483 - 1991 - Е - angse781No ratings yet

- Binary and Decimal Number Systems: Addressing The Network - Ipv4Document3 pagesBinary and Decimal Number Systems: Addressing The Network - Ipv4Mase Astrid C. BarayugaNo ratings yet

- Opc Lm1 Il Manual Si47 1087a eDocument13 pagesOpc Lm1 Il Manual Si47 1087a eخالدعبداللهNo ratings yet