Professional Documents

Culture Documents

01 Welding and Cutting Safety

Uploaded by

Arun Kumar0 ratings0% found this document useful (0 votes)

64 views22 pagessafety

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsafety

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

64 views22 pages01 Welding and Cutting Safety

Uploaded by

Arun Kumarsafety

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 22

WELDING AND CUTTING SAFETY

WELDING AND CUTTING SAFETY

Safe procedures for safe welding and cutting are extensive because the many hazards involved. Common hazards include handling compressed gases and exposure to electricity, fumes, gases, noise, radiation, fire and explosions. Thorough and effective training of workers involved in welding and cutting is critical to ensure the safe use of equipment and processes, along with procedures used to control hazardous conditions. General housekeeping also is important in preventing fires and avoiding injuries, such as a welder tripping over debris or gas hoses due to restricted vision while wearing eye protection.

WELDING AND CUTTING SAFETY

Compressed gases The most frequent OSHA citations related to welding involve the misuse, careless handling and improper storage of compressed gas cylinders. Compressed gas cylinders are difficult to handle because Of their size and weight, and the additional hazards due to the exposed valves and gas contents under pressure. If moving cylinders a short distance, you can tip them and roll them on the bottom edge. Do not drag the cylinders along the floor. Cylinders are best moved with a suitable hand truck. Hoist cylinders by securing a cradle sling board, pallet or special carrier included for this purpose.

WELDING AND CUTTING SAFETY

Do not hoist cylinders by use of an electromagnet or choker sling. Always store and use cylinders in the upright position and secure them against falling. If the cylinders are not labeled, do not use the contents and return them to the supplier. Valve protection caps are used to protect the cylinder valves and the safety devices. Caps should always be in place except when the cylinders are in use. Separate stored oxygen cylinders from fuel-gas cylinders or combustible materials by a minimum distance of 20 feet or by a noncombustible barrier at least 5 feet high having a fire-resistance rating of at least one-half hour

WELDING AND CUTTING SAFETY

Always use a pressure-reducing device when withdrawing gas from gas cylinders used for welding and cutting operations. Inspect connection nuts and fittings before each use to detect faulty seats. Faulty seats may allow leakage once the regulator is attached to the cylinder valves or hoses. Before connecting a regulator to a cylinder valve, wipe the valve outlet with a clean cloth free of oil or lint. Then crack the valve by opening the valve momentarily and closing immediately

WELDING AND CUTTING SAFETY

This clears the valve of dust or dirt that might otherwise enter the regulator. Mark USE NO OIL on gauges used for oxygen service and drain oxygen before attaching to the cylinder. Always open oxygen cylinder valves slowly. Do not use acetylene at a pressure in excess of 15 psig. At about 25 psig acetylene becomes unstable and doesnt need a spark or flame to explode.

WELDING AND CUTTING SAFETY

Distinguish fuel gas and oxygen hoses from each other. Generally recognized colors are red for fuel gas hose, green for oxygen hose and black for inert gas and air hose. Do not interchange the oxygen and fuel gas hoses. You can tape together parallel lengths of oxygen and fuel gas hose for convenience and to prevent tangling, but not more than 4 inches in each 12 inches shall be cover with tape. Repair or replace hoses showing leaks, burns, worn places or other defect.

WELDING AND CUTTING SAFETY

Clean torch tip openings that become clogged with suitable cleaning wires, drills or other devices designed for such purpose. Inspect torches prior to their use for leaking shutoff valves, hose couplings and tip connections. Use friction lighters or other approved devices to light torches, and not matches or hot work.

WELDING AND CUTTING SAFETY

Welding produces molten metal, sparks, slag and hot work surfaces. Workers should wear protective clothing made of suitable materials, which provides sufficient coverage to minimize skin burns caused by sparks, spatter or radiation. Keep sleeves and collars buttoned, and eliminate pockets from the front of clothing to prevent sparks from lodging in rolled-up sleeves, pockets or cuffs of overalls or pants. All welders and cutters must wear protective flame-resistant gloves. Use gloves with insulated linings to protect from exposure to high radiant energy. Employees can use leather or flame-resistant aprons to protect the front of the body against sparks and radiant energy. Flame-resistant leggings are available to provide additional protection to the legs

WELDING AND CUTTING SAFETY

When welding or cutting overhead, wear cape sleeves or shoulder covers with bibs made of leather or other flame-resistant clothing

WELDING AND CUTTING SAFETY

Keep clothing free of grease and oil, and dont carry combustible materials in pockets. The equipment and the processes used in welding and cutting generate noise. Engine-driven generators can emit high noise levels, as do some high-frequency and induction welding processes, such as air carbon arc and plasma arc cutting. If at all possible, control the noise at the source. If this is not possible, use personal protective devices, such as earmuffs or earplugs

WELDING AND CUTTING SAFETY

You must provide adequate ventilation for all welding, cutting and brazing operations. The ventilation must be capable of keeping exposures to hazardous concentrations of airborne contaminants maintained below levels specified.

WELDING AND CUTTING SAFETY

If the airborne contaminants cannot be effectively controlled through natural or mechanical ventilation, workers must wear respirators Whenever the use of respirators is necessary, implement a program to establish the proper selection, fit and use of respirators. Train welders and cutters to avoid breathing the fume plume directly. You can do this by work positioning the head or by ventilation, which directs the plume away from the face.

WELDING AND CUTTING SAFETY

Another significant hazard of welding and cutting operations is the possibility of eye injuries. Ultraviolet radiation is generated during these operations. When the eyes are exposed to excessive ultraviolet radiation, they may develop sharp pains and become red and irritated

WELDING AND CUTTING SAFETY

Employees will wear proper eye and face protection that complies with the standards and the law of the land for Practice for Occupational and Educational Eye and Face Protection. Employees will wear welding helmets with filter lens, which protect the face, forehead, neck and ears from radiant energy from the arc and from weld spatter. Select the filter lens based on the type of welding process being performed, electrode size and arc current. Wear safety glasses or goggles to protect against slag chips, grinding fragments, wire wheel bristles and similar hazards. Welding helmets will not provide adequate protection against severe impact, such as fragmenting grinding wheels or abrasive discs.

WELDING AND CUTTING SAFETY

The welder can avoid electrical shock. Therefore, it is essential that you thoroughly train him or her on how to avoid it. Severity of shock is determined by the path, duration and amount of current flowing through the body, which is dependent upon voltage and contact resistance of the area of skin involved.

WELDING AND CUTTING SAFETY

Faulty installations, improper grounding and incorrect operation and maintenance of equipment are all sources of danger. Ground all electrical equipment and the Work piece

WELDING AND CUTTING SAFETY

The work lead is not a ground lead and is used only to complete the welding circuit. Use the correct cable size because overloading will cause cable failure and result in possible shock or fire hazard. When electrode holders are left unattended, remove the electrodes and the holders placed or protected so they cannot make electrical contact with workers or conducting objects. Do not dip hot electrode holders in water because this may expose the welder or cutter to electric shock.

WELDING AND CUTTING SAFETY

Disconnect or de-energize a welding circuit while charging or adjusting the electrode, torch or gun or to avoid electrical shock. Inspect welding cable regularly since welding cable is subject to severe abuse as it is dragged over work under construction and across sharp corners.

WELDING AND CUTTING SAFETY

Fire protection Welding and cutting should preferably be done in specially designated areas designed and constructed to minimize fire risk. Sparks start many fires, which can travel horizontally up to 35 feet from their source and fall much greater distances. Sparks can pass through or lodge in cracks, holes and other small openings in floors and walls.

WELDING AND CUTTING SAFETY

Material most commonly ignited are combustible floors, roofs, partitions and building contents. This includes trash, wood, paper, textiles, plastics, chemicals, and flammable liquids and gases. Outdoors, the most common combustibles are dry grass and brush

WELDING AND CUTTING SAFETY

When you cannot move work to a designated safe location, remove all movable nearby fire hazards. If the work and fire hazards are immovable, use guards to protect the immovable fire hazards and nearby personnel from the heat, sparks and slag. Have sufficient fire-extinguishing equipment ready for use when welding and cutting. When welding or cutting in areas not normally de Signed for such operations, use a hot work permit system. The hot work permit system includes a check list of safety precautions and also alerts other workers to an extraordinary danger of fire that will exist at a particular time.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- COLLOIDAL GOLD RECIPE - CitrateDocument9 pagesCOLLOIDAL GOLD RECIPE - CitrateDevon Narok100% (4)

- Questions To Client On SAP HCMDocument19 pagesQuestions To Client On SAP HCMeurofighterNo ratings yet

- ARI 700 StandardDocument19 pagesARI 700 StandardMarcos Antonio MoraesNo ratings yet

- Topic: Going To and Coming From Place of WorkDocument2 pagesTopic: Going To and Coming From Place of WorkSherry Jane GaspayNo ratings yet

- Ehandbook Process Safety 1309 PDFDocument15 pagesEhandbook Process Safety 1309 PDFArun KumarNo ratings yet

- Melting Points of MetalsDocument1 pageMelting Points of MetalsArun KumarNo ratings yet

- PoetryDocument2 pagesPoetryArun KumarNo ratings yet

- 13 Parking ControlDocument62 pages13 Parking ControlArun KumarNo ratings yet

- JokesDocument27 pagesJokesArun KumarNo ratings yet

- Natural Gas and LPG DataDocument2 pagesNatural Gas and LPG DataArun KumarNo ratings yet

- Candidate Appraisal FormDocument2 pagesCandidate Appraisal FormArun KumarNo ratings yet

- Load Cell CalculationsDocument6 pagesLoad Cell CalculationsArun KumarNo ratings yet

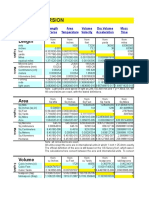

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLNo ratings yet

- Load Cell CalculationsDocument6 pagesLoad Cell CalculationsArun KumarNo ratings yet

- Non Veg DishesDocument99 pagesNon Veg DishesArun KumarNo ratings yet

- QMS For Shah Promotors & Developers PDFDocument52 pagesQMS For Shah Promotors & Developers PDFAhmed El Shafie100% (3)

- Veg DishesDocument45 pagesVeg DishesArun KumarNo ratings yet

- Veg DishesDocument45 pagesVeg DishesArun KumarNo ratings yet

- Industrial Pipe Marking GuideDocument2 pagesIndustrial Pipe Marking GuideArun KumarNo ratings yet

- Nyc-Asme 2013 PDFDocument45 pagesNyc-Asme 2013 PDFEvriMert RüzgArdaNo ratings yet

- Cutting Plate 2Document1 pageCutting Plate 2Arun KumarNo ratings yet

- Pug Mills / Paddle Mixers: Design & Principles of OperationDocument1 pagePug Mills / Paddle Mixers: Design & Principles of OperationArun KumarNo ratings yet

- Melting Points of MetalsDocument1 pageMelting Points of MetalsArun KumarNo ratings yet

- Safety Is Money in The BankDocument3 pagesSafety Is Money in The BankArun KumarNo ratings yet

- Seko Dosing DiaDocument12 pagesSeko Dosing DiaSeptriani LaoliNo ratings yet

- Windows 10 TipsDocument7 pagesWindows 10 TipswofebaNo ratings yet

- Geometry Formula SheetDocument1 pageGeometry Formula SheetArun KumarNo ratings yet

- Risk Ranking TemplateDocument4 pagesRisk Ranking TemplateArun KumarNo ratings yet

- Glass Bead Making F'urnaceDocument3 pagesGlass Bead Making F'urnaceArun KumarNo ratings yet

- Earthing RulesDocument9 pagesEarthing RulesArun KumarNo ratings yet

- SKF BRGDocument22 pagesSKF BRGVijeth99No ratings yet

- Ims Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageDocument9 pagesIms Iso 9001 Iso 14001 Ohsas 18001 Documentation PackageArun KumarNo ratings yet

- Safety Management SystemDocument17 pagesSafety Management SystemPradeep NegiNo ratings yet

- Glass GlossaryDocument3 pagesGlass GlossaryArun Kumar100% (1)

- Recognizing Fractures and Dislocations: Corpuz, Rachella Nicole PDocument46 pagesRecognizing Fractures and Dislocations: Corpuz, Rachella Nicole PRachella Nicole CorpuzNo ratings yet

- Boge FLEX PET SystemsDocument4 pagesBoge FLEX PET SystemsAir Repair, LLCNo ratings yet

- Msla Business FeesDocument1 pageMsla Business FeesNBC MontanaNo ratings yet

- Governance, Business Ethics, Risk Management and Internal ControlDocument4 pagesGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganNo ratings yet

- EML Prosedur ManualDocument1,019 pagesEML Prosedur Manualzrohim bapetenkfk2023No ratings yet

- Training and BreathingDocument6 pagesTraining and BreathingMIIIBNo ratings yet

- Primary Tooth Pulp Therapy - Dr. Elizabeth BerryDocument52 pagesPrimary Tooth Pulp Therapy - Dr. Elizabeth BerryMihaela TuculinaNo ratings yet

- Interventional Cardiology and SurgeryDocument19 pagesInterventional Cardiology and SurgeryDEV NANDHINI RNo ratings yet

- Sample UploadDocument14 pagesSample Uploadparsley_ly100% (6)

- CHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosDocument26 pagesCHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosHARSHVARDHAN KHATRINo ratings yet

- Supply Chain Logistics Manager in Dallas FT Worth TX Resume Calvin HarperDocument2 pagesSupply Chain Logistics Manager in Dallas FT Worth TX Resume Calvin HarperCalvinHarperNo ratings yet

- Fundamental Unit of Life 1-25Document25 pagesFundamental Unit of Life 1-25Anisha PanditNo ratings yet

- What Is A Solar Storm?Document2 pagesWhat Is A Solar Storm?Shawn SriramNo ratings yet

- Akin To PityDocument356 pagesAkin To PityPaul StewartNo ratings yet

- GLYSANTIN+G48+bg+IN 000000000030667689 SDS GEN US en 8-1Document11 pagesGLYSANTIN+G48+bg+IN 000000000030667689 SDS GEN US en 8-1Ali RidloNo ratings yet

- 2 Avaliação Edros 2023 - 7º Ano - ProvaDocument32 pages2 Avaliação Edros 2023 - 7º Ano - Provaleandro costaNo ratings yet

- 45relay Rm4ua PDFDocument1 page45relay Rm4ua PDFtamky SubstationNo ratings yet

- Functional Capacity Evaluation: Occupational Therapy's Role inDocument2 pagesFunctional Capacity Evaluation: Occupational Therapy's Role inramesh babu100% (1)

- CITEC Genesis & GenXDocument45 pagesCITEC Genesis & GenXPutra LangitNo ratings yet

- Lab Safety RulesDocument2 pagesLab Safety RulesChristine ManuelNo ratings yet

- ECO-321 Development Economics: Instructor Name: Syeda Nida RazaDocument10 pagesECO-321 Development Economics: Instructor Name: Syeda Nida RazaLaiba MalikNo ratings yet

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocument7 pagesCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaNo ratings yet

- DS Flow SwitchesDocument51 pagesDS Flow SwitchesAnonymous Xnaj1g8Y3100% (1)

- Plumber (General) - II R1 07jan2016 PDFDocument18 pagesPlumber (General) - II R1 07jan2016 PDFykchandanNo ratings yet

- 9701 w03 QP 4Document12 pages9701 w03 QP 4Hubbak KhanNo ratings yet

- FRMUnit IDocument17 pagesFRMUnit IAnonNo ratings yet