Professional Documents

Culture Documents

Kanban Signaling: Company Confidential

Uploaded by

Eldori1988Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kanban Signaling: Company Confidential

Uploaded by

Eldori1988Copyright:

Available Formats

Kanban Signaling

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling : Two Pillars of TPS The Toyota Production System Cost reduction through relentless elimination of waste MUDA or non-value-added work

The two pillars of Toyotas Global Production System

Just in Time

Autonomation (Jidoka)

Leveled Production

(Production Smoothing)

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling: Toyotas Production System

Cost Reduction Increase of Capital Turnover Ratio Elimination of Waste

Continuous Flow of Production

Just-In-Time Production

Production Methods

Small lots Short set-up Multi-skilled worker Jobs finish within cycle time

Self-Stop Automation

Control by Teamwork Automatic Stop

Information System

Kanban

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

What is a Kanban ?? Kanban (Japanese) : Card or Visual Record. In The Modern Lean Terminology A Kanban is a Visual Information System established to maintain the DISCIPLINE of a JIT System on the shop floor.

A SIGNAL THAT AUTHORIZES PRODUCTION

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Pillars of Just In Time

The Three Main Principles of JIT :

Takt Pull Flow :

Material People Information : Kanban Signaling

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

What is a Supermarket ? Does a Supermarket fit any production environment ? Ideal Production Environments for Supermarkets :

High Commonality of parts Relatively Flat (Smooth) Demand Pattern Part Number (SKU) has many customers Component has many usages Inadequate Process Capabilities : not able to produce the desired mix due to capacity issues.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Waste in Replenishment Systems

Replenishment System

* All the activity associated with any replenishment system is non-value added (Waste Muda). * The target for improvement should be to eliminate or streamline each activity associated with the replenishment system.

Copyright NN, Inc. 2004

Company Confidential

Whats Wrong with a Little Inventory?

Over-Production Inventory

Transport & Handling

Hidden Problems

Production Imbalance

Delay & Long Lead Time

Long Setups

Wasted Space

People

Equipment

Late Supplier Deliveries

Downtime

Storage Costs

Energy

Defects

Resources Tied Up Deterioration or Damage in Storage and Handling

Costs and Delays that Reduce Profitability

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Waste in Replenishment Systems Before Manufacturing Process Improvement

VA NVA Response Time

After Manufacturing Process Improvement

Response Time

After Replenishment System Improvement

Response Time

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: MRP vs. Kanban

Push vs. Pull

manufacturing

customer

I N V E N T O R Y customer manufacturing

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling:

Push vs. Pull

Push System : Work releases are scheduled based on anticipated demand with no consideration of the status of the plant (MRP). Pull System : Work releases are authorized based upon the status of the plant, that is the status of downstream operations dictate the production requirements for upstream operations.

MRP Upstream inventory Kanban Upstream inventory Kanban signals

Copyright NN, Inc. 2004 Company Confidential

Assembly

Assembly

Full containers

Kanban Signaling

Prerequisites of a Kanban Pull System

For a Pull System to perform effectively, Level 3 Building Blocks should be in place :

Quick Changeovers : Set-Up Kaizen Cellular Manufacturing : Flow Kaizen One Piece Flow : Flow Kaizen Low Variability :Variability Reduction Kaizen (6 Sigma tools) Reliable Process : TPM Kaizen Stable, Flat Demand : JIT Principles

If these are not done first, implementing Kanban Pull will force these to take place.

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling

How Does a Kanban System Work ?

Single Card Kanban :

In a Single Card Kanban System, the operator of a down stream operations requires a Production Card and the necessary Material to be authorized to begin processing. He/she simply removes the Card and sends it back to the upstream process, signaling production to replenish the material used by his/her station prior to processing the job.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Single Card Kanban

Outbound Stock Point Outbound Stock Point Outbound Stock Point

When stock is removed place production card in hold box. Production card authorizes start of work.

When stock is removed place production card in hold box. Production card authorizes start of work.

Workstation Kanban card Production Box

Full Container Container being filled Container being emptied

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Two Card Kanban

A Two Card Kanban is used when WIP cannot be effectively handed from one process to the next, thus necessitating an Inbound Stock Point and an Outbound Stock Point for processing stations. Mainly this system is utilized in heavy transaction, high complexity parts (huge number of parts)

In this System Two Cards are used :

Move (Conveyance) Card : To authorize the Movement of material

Production Card : To authorize the Production.

Copyright NN, Inc. 2004 Company Confidential

Two Card Kanban System

A

Dispatch Box Production kanban detached, placed in dispatch box

Move kanban attached to new stock

INBOUND STOCK AREA

OUTBOUND STOCK AREA

New stock moved into Process 2

C B

Production kanbans direct the production sequence

Production kanban attached to finished quantity Move kanban detached

PROCESS 1

PROCESS 2

MOVE KANBAN (1-2-3) Each process has an inbound and an outbound stock area. The inbound area contains raw materials used in the process. The outbound area holds completed output from the process. When Process 2 begins to consume the contents of a container, the Move Kanban is taken off the container and brought to the outbound stock area of Process 1. There the Move Kanban is attached to a new, full container, which is taken back to the inbound stock area of Process 2, ready for use.

Copyright NN, Inc. 2004

Company Confidential

Two Card Kanban System

A

Dispatch Box Production kanban detached, placed in dispatch box

Move kanban attached to new stock

INBOUND STOCK AREA

OUTBOUND STOCK AREA

New stock moved into Process 2

C B

Production kanbans direct the production sequence

Production kanban attached to finished quantity Move kanban detached

PROCESS 1

PROCESS 2

PRODUCTION KANBAN (A-B-C) A Production Kanban is attached to every container in the outbound stock area at Process 1. When Process 2 comes to remove a container of parts, the Production Kanban is taken off and put in a dispatch box for Process 1. Process 1 may make parts for several other processes, therefore, it builds the new parts in the order in which the kanban are placed in the dispatch box. When a container is full, the Production Kanban is attached to it and it is placed in the outbound stock area ready for withdrawal by Process 2.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling : Kanban Cards

Two Card System / Move Card

Downstream work center: K123 Part number : 33311-3501 Stock location no.: A-12

Container capacity : 50

No. of kanban released : 7 of 12 Stock location no.: A-07 Upstream work center: Y321

Copyright NN, Inc. 2004

Company Confidential

Shop Supplies Kanban system at NN in Veenendaal

W.I.P. Kanban system at NN in Mountain City

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling : Kanban Cards

Two Card System / Production Card

Work Center no.: Y321 Part number to be produced: 33311-3501 Container capacity: 50 units Stock capacity at which to store: A-07 Materials Required: Material no. 33311-3504 Stock location: A-05 Part no. 33825-2474 Stock location: B-03

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Calculations

Kanban Size

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling : Calculations / Kanban Size

METHOD

Basic kanban size calculation PLUS demand variation factor

Kanban Size

Dd x R x MAD

Dd = Daily demand:

- Last years customers shipments / number of production days. - Next X week forecast / production days.

R = Replenishment time:

- Total time from the signal until product is back in the Kanban.

MAD = Mean average deviation to the daily rate.

- Any distinct order patterns?

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Calculations / Kanban Size Example 1 Dd x R x MAD

Item A B C D E F Daily Replenishment Demand, Dd Time, R (days) 500 900 750 500 500 1200 3 2 3 4 2 4 MAD 1.40 1.25 1.80 2.01 1.50 2.00 Kanban Replenishment Point 2100 2250 4050 4020 1500 9600

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Calculations / Kanban Size Another Example Our customer shipments last year were 100,000 of part A, 250,000 of part B, and 400,000 of part C. There are 240 production days in this year. Calculate the parts per day of each item. A = 417 parts/day B = 1042 parts/day C = 1667 parts/day The time to replenish part A is 2 days, part B is 4 days, and part C is 1 Day. Analysis of last years demand patterns shows that part A had a MAD of 1.50, part B 1.25, and part C 1.20. Calculate the replenishment level. Dd x R x MAD

Part A: 417 x 2 x 1.50 =

A = 1251 parts B = 5210 parts C = 2000 parts

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Calculations / Kanban Size Process Capability

- Establish daily rate for all items in the process.

METHOD

Alternative kanban size calculation based on process capability

- Total run time required.

- Hours available for the process. ( Breaks, Lunches, Historical Downtime )

Formulas

Hours Available - Run Time = Hours Available for Set-Up Hours Available for Set-Up / Time per Set-Up = Set-Ups per Day Number of items / Set-Ups per day = Days of Demand (min lot size)

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Calculations / Kanban Size

EXAMPLE 1

Item

Daily Demand

Run Time/Pc

Total RT

A

B C

500

900 750

5 sec

4 sec 7 sec

2500 sec

3600 sec 5250 sec

D

E F

500

500 1200

6 sec

5 sec 4 sec

3000 sec

2500 sec 4800 sec

Total Sec 21,650

1 machine x 7.2 available hours x 3600 sec/hr = 25,920 sec available

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling: Calculations / Kanban Size

EXAMPLE 1 : (continued)

25,920 sec available -21,650 sec run time 4,270 sec available for Set-Ups Each Set-Up takes 1/2 hour (1800 sec.) 4270 sec available for set-up / 1800 sec per set-up = 2.4 SetUps/day Round 2.4 down to 2 set-ups / day 6 Items / 2 set-up per day = 3 Days of Demand (min lot size)

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Calculations / Kanban Size

EXAMPLE 1 : (continued)

Item

Daily Demand

x3

Kanban Size

A

B C

500 * 3= 1500 piece Kanban = size 1500 pcs

900 750 2700 pcs 2250 pcs

D

E F

500

500 1200

1500 pcs

1500 pcs 3600 pcs

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Calculations

Number of Cards

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Number of Cards

The number of authorized Cards / Containers in a JIT system controls the amount of inventory in the system at any given time. The number of Cards / Containers in the system directly impacts the the WIP inventory and safety stock. Material spends some time in actual processing, waiting in queue, waiting in a storage location or in transit. So at any given time in the system, containers carrying material are in one of the above stages. The Key to determining the number of Cards/ Containers is estimating the average Lead Time needed to produce a container of parts :

Lead Time = L

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling

Number of Cards

# of Cards = Average Demand during Lead Time plus Safety Stock Size of the Container (Kanban Size)

Where Lead Time is a function of the processing time per container at the upstream supplier station and the waiting time at the down stream production process and for material handling.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Kanban Bins and Cards

EXAMPLE

Item A B C D E F

Kanban Size 1500 2700 2250 1500 1500 3600

Kanban Bin Bins/Cards Capacity Required 500 900 750 750 300 600 3 3 3 2 5 6

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Demand Patterns

Demand pattern is the actual pattern which finished goods are consumed by the customer. This can be magnified by the way that we transmit replenishment signal back to manufacturing. (Weekly buckets) Average

Actual Demand

Predictable Demand.

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling

Demand Patterns

One or Two Customer Seasonal

(Demand)

(Time)

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Demand Patterns

Unpredictable

(Demand)

(Time)

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling

Demand Patterns

Components Push

Replenishment time to Customer

Form

Mach

Finish

Pack

Pull

Replenishment time to Kanban

Replenishment time to Kanban

Replenishment time to Customer

Highest level of commonality, closest to the customer.

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling

Sequencing / Mixed Modeling

What is Mixed Modeling: The ability to produce the desired daily mix of products as specified by the customer. Therefore,sequencing is a method of refining the daily build schedule by determining the order in which the product will be produced. The objective of Sequencing:

To create a linear cyclical demand pattern during the course of each day.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling Example Daily Build Quantity Takt Time / 240 = 2 Min. / 120 = 4 Min. / 80 = 6 Min. 12 Minute Period

Product A B C

Minutes in a Work Day 480 Minutes 480 Minutes 480 Minutes

The takt time results indicate that in a 12-minute period: 12/2 = 6As, 12/4 = 3Bs, and 12/6 = 2Cs need to be made. 2. Lay in the 12 Minute product sequence in the most rhythmical fashion while not exceeding (6) As, (3) Bs, and (2) Cs

=ABACABACABA

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling: Signals, Options, and Presentation Two Bin Replenishment No Work

Full

Full

Work till bin is full

Empty

Full

Something is wrong in the system

Empty Empty

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation Multiple Container Kanban

Full Full Full 3of 3 Full 1 of 3 Full 2 of 3 Full 3 of 3

1 of 3 2 of 3

Do not work

Empty 1 of 3 Full 2 of 3

Full 3 of 3

Full 1 of 3

Full 2 of 3

Full 3 of 3

Do not work

Empty Empty 1 of 3 2 of 3 Full 3 of 3 Full 1 of 3 Full 2 of 3 Full 3 of 3

Do not work

Empty Empty Empty 1 of 3 2 of 3 3 of 3 Full 1 of 3 Full 2 of 3 Full 3 of 3

Work to fill 3 bins

Empty Empty Empty Empty 1 of 3 2 of 3 3 of 3 1 of 3 Full 2 of 3 Full 3 of 3

Work to fill 3 bins

Empty Empty Empty Empty Empty 1 of 3 2 of 3 3 of 3 1 of 3 2 of 3 Full 3 of 3

Work to fill 6 bins

Empty Empty Empty Empty Empty Empty 1 of 3 2 of 3 3 of 3 1 of 3 2 of 3 3 of 3

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Basic Information for Kanban Card

Quantity Per Container Number of Cards (1 of 3)

Part Number

Description Consuming Process (Location)

Supplying Process

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Optional Information for Kanban Card

Bill of Materials Drawing Numbers Labor Information What do you need? Etc... Remember: Changes, require card maintenance. Bill of Material, Process changes, etc...

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Visual Signals

There have been many different ways that signaling has been performed in many different situations. The Main Objective is Visual, Easy to Understand, Practical way to send a clear signal that authorizes the production or movement of material : Traditional Cards Containers Painted areas on floor Carrying bags Bins Andon Lights Golf Balls

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Card Examples

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Card Examples

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation Signal Kanban = Single card or lot size greater than replenishment quantity Replenish Point 2 Bins Lot Size 10 Bins

Part Number

Description

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Non- Replenishable Cards

A way to increase Kanban size for a short period of time. Normally, to handle short term increased demand. (Promotions) Card must be distinguishable as a one time use only card. Color, Size, Shape, etc...

Quantity Per Container Number of Cards (1 of 3)

Part Number

Description

Supplying Process Consuming Process (Location)

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

KANBAN CARDS = $$ MONEY $$$

DO YOU LEAVE YOUR MONEY LAYING AROUND, UNATTENDED??

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Wait Work Board

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Schedule Board 1 2 3

PART#44367

PART # 58221

PART # 28873

PART #78651

PART # 34529

PART 38994

6

WHEN THE NUMBER OF CARDS EQUALS THE STARTING POINT( EX. 3 CARDS) THEY MOVE TO SCHEDULE SIDE.

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Visual Kanban Board

Part Number

123456

126574

123244 123209

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Visual Kanban Board

Time Slot Board 7-8 8-9 Time of Day 9-10

Part Number Description

Part Number Description

10-11

11-12 12-1

Part Number Description

Part Number Description

Part Number Description

1-2

2-3

Copyright NN, Inc. 2004

Part Number Description

Part Number Description

Part Number Description

Part Number Description

Jobs to be completed

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

Visual Presentation

Visual metal cards bend and put on rail.

Consuming Process

Supplying Process

Replenish Point 2 Bins

Lot Size 10 Bins

Part Number

Description

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Signals, Options, and Presentation

How to Cards get Back to the Previous Process ?

Drop off at process Central card collection Collection point for vendor cards Use visual signals vs. cards Kanban Collection Post Whatever works for you !!

MINIMIZE NON-VALUE ADDED !!

Copyright NN, Inc. 2004 Company Confidential

THINGS TO BE CAUTIOUS OF!!

Copyright NN, Inc. 2004

Company Confidential

Kanban Signaling: Kanban Rules

According to Taiichi Ohno

The Pull System as defines by Taiichi Ohno can not sustain its effectiveness unless the following rules are strictly adhered to: Upstream Processes are authorized to produce by Downstream Processes not the other way around Upstream Processes adhere to the Kanban information regarding Quantity of Production No Items are to be transported (moved) without a Card Always attach a Card to the Goods Do not send Defective Goods Downstream Reducing the number of Kanban Cards increases their sensitivity Strive to reduce.

Copyright NN, Inc. 2004 Company Confidential

Kanban Signaling: Kanban Function

According to Taiichi Ohno

A Kanban Pull System : Promotes Visual Management Provides Pick-Up or Transport Information Prevents Overproduction and Excessive Transportation Controls the amount of WIP in the system Serves as a visual work order Prevents defective items by identifying the process producing the defects Exposes waste and forces a root cause solution

Copyright NN, Inc. 2004

Company Confidential

You might also like

- Amway Lean Office Hdi 2Document30 pagesAmway Lean Office Hdi 2Ignacio Guerra100% (1)

- Kanban: Presented byDocument12 pagesKanban: Presented byshrutesNo ratings yet

- STEP1MANDocument101 pagesSTEP1MANRPM28XI100% (1)

- Chapter 5 Measure - GBDocument134 pagesChapter 5 Measure - GBKaranShindeNo ratings yet

- Chapter 5 Lean Manufacturing System ConceptDocument29 pagesChapter 5 Lean Manufacturing System ConceptcandraNo ratings yet

- Lean Manufacturing 1Document70 pagesLean Manufacturing 1AbhiNo ratings yet

- Hoshin Kanri - Policy DeploymentDocument75 pagesHoshin Kanri - Policy DeploymentugurcemyildizNo ratings yet

- KANBANDocument11 pagesKANBANUNF2012No ratings yet

- Handout - TPS & LeanDocument92 pagesHandout - TPS & LeanLyne LerinNo ratings yet

- Lean ClassDocument425 pagesLean ClassElena Montero CarrascoNo ratings yet

- 3a 2 Card Kanban System CalculationsDocument2 pages3a 2 Card Kanban System CalculationsJose OrtegaNo ratings yet

- Visual Management: Using Visual Elements To Control Work and Monitor StatusDocument9 pagesVisual Management: Using Visual Elements To Control Work and Monitor StatusFran JimenezNo ratings yet

- VSM Template (LEan Six Sigma)Document8 pagesVSM Template (LEan Six Sigma)DearRed FrankNo ratings yet

- Waste EliminationDocument31 pagesWaste Eliminationaarun01No ratings yet

- JIT - JidokaDocument23 pagesJIT - JidokaViraj DhuriNo ratings yet

- Opex VSM Training Module 100711001122 Phpapp02Document53 pagesOpex VSM Training Module 100711001122 Phpapp02Jesus Jose Hernandez GuerreroNo ratings yet

- Statistical Process Control QPSPDocument166 pagesStatistical Process Control QPSPRAVISSAGARNo ratings yet

- Error Proof AssemblyDocument30 pagesError Proof AssemblySergioRiveroSalcidoNo ratings yet

- Operations Management: Toyota Production System (TPS), Just-in-Time (JIT), and Lean Manufacturing HandoutDocument92 pagesOperations Management: Toyota Production System (TPS), Just-in-Time (JIT), and Lean Manufacturing Handoutjitendrasutar1975No ratings yet

- Standardization Basics-24 Jul 09Document11 pagesStandardization Basics-24 Jul 09Dilfaraz KalawatNo ratings yet

- TPS and Lean ProductionDocument18 pagesTPS and Lean ProductionMikey ChuaNo ratings yet

- KANBANDocument24 pagesKANBANSalwin Joseph ANo ratings yet

- A Method For TPT ReductionDocument114 pagesA Method For TPT ReductionEbrahim HanashNo ratings yet

- Chapter 10. Initial Flow Control ManualDocument10 pagesChapter 10. Initial Flow Control ManualVivek KumarNo ratings yet

- Smed PDFDocument17 pagesSmed PDFVinay BansalNo ratings yet

- Training Material For Kanban, Heijunka and Pull SystemDocument15 pagesTraining Material For Kanban, Heijunka and Pull SystemMD ABDULLAH AL MANSURNo ratings yet

- Kaizen Kyosei and ObeyaDocument25 pagesKaizen Kyosei and ObeyaRavikumarrd Ravi0% (1)

- Poka-Yoke Team 4Document14 pagesPoka-Yoke Team 4Ratandeep PandeyNo ratings yet

- Basic Concepts of 5S-KAIZEN-TQM ApproachDocument33 pagesBasic Concepts of 5S-KAIZEN-TQM Approachsandeep singhNo ratings yet

- 10 Days Nos TrainingDocument511 pages10 Days Nos Trainingdayat hidayatNo ratings yet

- IE Training CourseDocument67 pagesIE Training CourseAbdelkhalek MohammedNo ratings yet

- Yamada Concepts14aDocument30 pagesYamada Concepts14aPedro Apodaca SamNo ratings yet

- 12 Tools To Make Waste VisibleDocument37 pages12 Tools To Make Waste VisibleMichael WuNo ratings yet

- Submitted By,: Jarzid Alam Alomgir Badsha Saif MahabubDocument26 pagesSubmitted By,: Jarzid Alam Alomgir Badsha Saif MahabubSaif KhanNo ratings yet

- Unblocking BottlenecksDocument3 pagesUnblocking BottlenecksMaggie GonzalesNo ratings yet

- The Lean Stack - Part 1Document15 pagesThe Lean Stack - Part 1iNFuT™ - Institute for Future TechnologyNo ratings yet

- Cost of Quality: "Cost of Quality Is The Expense of Noncomformance - The Cost of Doing Things Wrong."Document18 pagesCost of Quality: "Cost of Quality Is The Expense of Noncomformance - The Cost of Doing Things Wrong."sandeep_rana65No ratings yet

- 1.0 Define Target VisionDocument23 pages1.0 Define Target VisionAngel PintorNo ratings yet

- SDW 1632665243Document49 pagesSDW 1632665243Michel ZsambokrethyNo ratings yet

- 3) LeanDocument14 pages3) LeanSnehaNo ratings yet

- Another Contribution From Dr. Shigeo Shingo: Poka YokeDocument23 pagesAnother Contribution From Dr. Shigeo Shingo: Poka Yokekeerti_1984No ratings yet

- Kaizen EventsDocument35 pagesKaizen EventsIndhu SharmaKSNo ratings yet

- Kanban Tutorial LESS2010 PDFDocument40 pagesKanban Tutorial LESS2010 PDFVasanth RajaNo ratings yet

- Lean ManagementDocument22 pagesLean ManagementRowdy HbkNo ratings yet

- Total Quality ManagementDocument7 pagesTotal Quality ManagementmansoorliveNo ratings yet

- SMEDDocument26 pagesSMEDSAURAV KUMARNo ratings yet

- 10 Commandmens of KaikakuDocument3 pages10 Commandmens of Kaikakupolypro78No ratings yet

- Kanban SizingDocument102 pagesKanban Sizingsribalaji22No ratings yet

- 7 Slides Cell DesignDocument30 pages7 Slides Cell DesignLuis Alberto Lamas LavinNo ratings yet

- Mistake Proofing & Poka-Yoke: A Strategy For Performance ExcellenceDocument73 pagesMistake Proofing & Poka-Yoke: A Strategy For Performance Excellencekumarkk1969No ratings yet

- TPM Steps 1 JHDocument10 pagesTPM Steps 1 JHGyanesh_DBNo ratings yet

- Kaizen - Group 5 Present ItDocument46 pagesKaizen - Group 5 Present ItreezcoolrizNo ratings yet

- Air Plane Game Exercise: - Flow, Line Balancing, KaizenDocument19 pagesAir Plane Game Exercise: - Flow, Line Balancing, KaizenJose SantosNo ratings yet

- Kaizen PQMDocument16 pagesKaizen PQMVashisht Agarwal100% (1)

- Total Quality Management: TQM TQM Tools and Techniques Case 7.1 Process Variation ExerciseDocument30 pagesTotal Quality Management: TQM TQM Tools and Techniques Case 7.1 Process Variation Exercisesanaa84No ratings yet

- Seven Basic Quality Tools: List / Use / InteractionDocument56 pagesSeven Basic Quality Tools: List / Use / InteractionmangofaNo ratings yet

- An Introduction To Otal Roductive AintenanceDocument31 pagesAn Introduction To Otal Roductive AintenanceJack Philips100% (1)

- Lean Techniques: Are You Looking To Lead The Industry?Document10 pagesLean Techniques: Are You Looking To Lead The Industry?vijaypaterNo ratings yet

- ConfidenceDocument4 pagesConfidenceEldori1988No ratings yet

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartEldori1988No ratings yet

- Assembly in A BoxDocument2 pagesAssembly in A BoxEldori1988No ratings yet

- Sports Pictionary Poster 1 Vocabulary Worksheet PDFDocument2 pagesSports Pictionary Poster 1 Vocabulary Worksheet PDFSy Hafizah100% (1)

- SIROLL Furnace Optimization enDocument0 pagesSIROLL Furnace Optimization enEldori1988No ratings yet

- SuspensiondfDocument3 pagesSuspensiondfAhmad UsamaNo ratings yet

- HUCK Hucktainer enDocument8 pagesHUCK Hucktainer enEldori1988No ratings yet

- Toyota Business Practices and Academe - Industry Linkage - GasparDocument7 pagesToyota Business Practices and Academe - Industry Linkage - GasparEldori1988No ratings yet

- Demonstration For Certification (Participants Copy)Document2 pagesDemonstration For Certification (Participants Copy)Eldori1988No ratings yet

- Onsert GB 0250 PDFDocument12 pagesOnsert GB 0250 PDFmazacotesNo ratings yet

- Rivset Gen2 GB 6705Document6 pagesRivset Gen2 GB 6705Eldori1988No ratings yet

- Lean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteDocument20 pagesLean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteEldori1988No ratings yet

- Fishbone DiagramDocument2 pagesFishbone DiagramEldori1988No ratings yet

- Magna-Bulb Blind Fastener: Previous ScreenDocument3 pagesMagna-Bulb Blind Fastener: Previous ScreenEldori1988No ratings yet

- Bolt Depot - Metric Tap and Drill Size TableDocument1 pageBolt Depot - Metric Tap and Drill Size TableEldori1988No ratings yet

- HUCK FloorTight enDocument8 pagesHUCK FloorTight enEldori1988No ratings yet

- Huck Hucklok enDocument4 pagesHuck Hucklok enEldori1988No ratings yet

- Böllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Document3 pagesBöllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Eldori1988No ratings yet

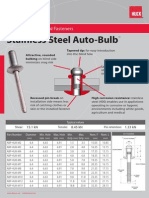

- HUCK Autobulb Stainless Steel enDocument1 pageHUCK Autobulb Stainless Steel enEldori1988No ratings yet

- Bolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableDocument2 pagesBolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableEldori1988No ratings yet

- The Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise InstituteDocument27 pagesThe Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise InstituteEldori1988No ratings yet

- Lean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument18 pagesLean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988No ratings yet

- Huck BOM: The Highest Strength Blind Fasteners in The WorldDocument5 pagesHuck BOM: The Highest Strength Blind Fasteners in The WorldEldori1988No ratings yet

- Bolt Depot - Machinery Eye Bolt DimensionsDocument2 pagesBolt Depot - Machinery Eye Bolt DimensionsEldori1988No ratings yet

- CPF PresentationDocument13 pagesCPF PresentationEldori1988No ratings yet

- Lean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument20 pagesLean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988No ratings yet

- Simulation and Optimization of Metal Forming ProcessesDocument27 pagesSimulation and Optimization of Metal Forming ProcessesTamer HagasNo ratings yet

- 561Document27 pages561Eldori1988No ratings yet

- German Presentation Feb 03Document8 pagesGerman Presentation Feb 03Eldori1988No ratings yet

- Ohm's Law and Kirchhoff's LawsDocument22 pagesOhm's Law and Kirchhoff's LawsTiarra MojelNo ratings yet

- 1 Introduction To Thermal System DesignDocument43 pages1 Introduction To Thermal System DesignAbhishek KullurNo ratings yet

- Boiling MechanismDocument16 pagesBoiling MechanismherawanadifNo ratings yet

- HKTM StokDocument406 pagesHKTM Stokfratk8093No ratings yet

- Carbon Regeneration KilnsDocument3 pagesCarbon Regeneration KilnsLuis LabradorNo ratings yet

- SET-1: Answer To The Interview QuestionsDocument9 pagesSET-1: Answer To The Interview QuestionsÆshok IncreĐible KingNo ratings yet

- PPTDocument22 pagesPPTMuhamMad TaufikNo ratings yet

- TS 34Document2 pagesTS 34Sunil Maurya0% (1)

- PD 8010 2 Presentation April 2005 NewDocument40 pagesPD 8010 2 Presentation April 2005 NewSuphi YükselNo ratings yet

- May PMDocument45 pagesMay PMR MathirajNo ratings yet

- Cored Wires - ESAB - OK TubrodDocument87 pagesCored Wires - ESAB - OK TubrodElias KapaNo ratings yet

- Euro Tempered Glass Industries Corp. - Company ProfileDocument18 pagesEuro Tempered Glass Industries Corp. - Company Profileunited harvest corpNo ratings yet

- Table 1. Data Set and CalculationDocument5 pagesTable 1. Data Set and CalculationliliNo ratings yet

- 3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDDocument9 pages3.re Situation in Suez Canal - M.V EVER GIVEN SUCCESSFULLY REFLOATEDaungyinmoeNo ratings yet

- Building A Model Steam Engine From Scratch Chapter 1, 150 121Document19 pagesBuilding A Model Steam Engine From Scratch Chapter 1, 150 121Liam Clink100% (2)

- NPT Thread Dimensions PDFDocument1 pageNPT Thread Dimensions PDFRamnandan MahtoNo ratings yet

- Textile Shop Management SystemDocument6 pagesTextile Shop Management SystemVedha TechnologiesNo ratings yet

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocument39 pagesThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodNo ratings yet

- Course Catalog 2019Document34 pagesCourse Catalog 2019Mehaboob BashaNo ratings yet

- Vray Material Settings: COMP 423: Cadd For ArchitectureDocument18 pagesVray Material Settings: COMP 423: Cadd For ArchitectureMarvin GonzalesNo ratings yet

- HSE FRM 32 Final Incident ReportDocument6 pagesHSE FRM 32 Final Incident ReportDilshad aliNo ratings yet

- Propeller (PRELIMS LESSON)Document34 pagesPropeller (PRELIMS LESSON)Aidrian AidNo ratings yet

- DataDocument194 pagesDataddlaluNo ratings yet

- 300-430-ENWLSI Implementing Cisco Enterprise Wireless Networks PDFDocument3 pages300-430-ENWLSI Implementing Cisco Enterprise Wireless Networks PDFEdu100% (1)

- Gopez Wood Craft Spot Rep Feb 06, 2022Document2 pagesGopez Wood Craft Spot Rep Feb 06, 2022Eller-Jed Manalac MendozaNo ratings yet

- Comparacion Planta Meg - TegpdfDocument18 pagesComparacion Planta Meg - TegpdfJulian RomeroNo ratings yet

- Joraform JK Series Operating PrinciplesDocument6 pagesJoraform JK Series Operating Principlesapi-236782993No ratings yet

- Aircon Maintenance Singapore NdurwDocument5 pagesAircon Maintenance Singapore Ndurwchinfrench0No ratings yet

- Profimat MT: United Grinding Technologies Blindtext Key DataDocument9 pagesProfimat MT: United Grinding Technologies Blindtext Key DataMiskoNo ratings yet

- Resun Price List Solar Panel-20211227Document1 pageResun Price List Solar Panel-20211227Nemesu LorentNo ratings yet