Professional Documents

Culture Documents

The Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise Institute

Uploaded by

Eldori19880 ratings0% found this document useful (0 votes)

49 views27 pagesModern management (the Alfred Sloan school of management) vs. Lean management (the Eiji toyoda gemba school of management), a side-by-side comparison. Modern: "if the process is right the results will be right. Manage by process instead of results" lean: "the scientific method can only be evaluated through the form of PDCA"

Original Description:

Original Title

womackmodernvsleanmanagement-1282741420-phpapp01

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentModern management (the Alfred Sloan school of management) vs. Lean management (the Eiji toyoda gemba school of management), a side-by-side comparison. Modern: "if the process is right the results will be right. Manage by process instead of results" lean: "the scientific method can only be evaluated through the form of PDCA"

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

49 views27 pagesThe Challenge of Lean Management: James P. Womack, Chairman, Lean Enterprise Institute

Uploaded by

Eldori1988Modern management (the Alfred Sloan school of management) vs. Lean management (the Eiji toyoda gemba school of management), a side-by-side comparison. Modern: "if the process is right the results will be right. Manage by process instead of results" lean: "the scientific method can only be evaluated through the form of PDCA"

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 27

10th Lean Manufacturing Conference Wroclaw, Poland

June 22-23, 2010

The Challenge of Lean Management

James P. Womack, Chairman, Lean Enterprise Institute

What Does Lean Need Now?

To think about the type of management system we need in order to make lean deployment sustainable. A good place to start: Comparing modern with lean management. (As we do this, please ask yourself what type of management system your organization has and what type it needs for a lean transformation.)

2

Two Choices for Managers:

Modern management

(The Alfred Sloan School of Management)

versus

Lean management

(The Eiji Toyoda Gemba School of Management)

Lets perform a side-by-side comparison of the principles of these schools.

Modern vs. Lean Management

Primary focus on vertical functions and departments, as mechanisms of optimization and control. Primary focus on horizontal flow of value across organizational units to the customer.

Modern vs. Lean Management

Clear grants of managerial authority by leaders of organizational units (vertical delegation). Clear grants of managerial responsibility to solve problems (especially crossfunctional, horizontal problems) over which managers have no authority, within vertical organizations (including Toyota.)

Modern vs. Lean Management

Line managers judged on end-of-theperiod results for their span of control, increasingly financial in recent times. Line managers judged on the state of their process, with rapid feedback loops with next-level management.

If the process is right the results will be right. Manage by process instead of results.

Modern vs. Lean Management

Planning & direction from top down, with bosses giving answers:

Leads to compliance focus: Make your plan or explain the variances.

Planning & direction in circular feedback loops, with bosses asking questions:

What do you think the important issue is? Is there a problem? Whats the root cause of the problem?

What do you think the potential solutions (countermeasures) are?

What countermeasure do you think we should select? Who must do what when where to test this countermeasure?

7

Modern vs. Lean Management

Conviction from the top that a good plan, once properly implemented, produces the desired results. (Justifying the compliance focus.) Conviction that all plans are experiments and can only be evaluated through the scientific method in the form of PDCA, followed by appropriate countermeasures. Planning is invaluable; plans rapidly become worthless.

8

Modern vs. Lean Management

Generalist line mangers, rotated frequently with weak process knowledge, supported by deeply knowledgeable technical staffs (including finance.) Line mangers on extended assignments, with deep process knowledge, lacking the need for extensive staff support.

9

Modern vs. Lean Management

Managers developed through formal education, often ex-company (e.g., management schools, consulting firms) or sink-or-swim rotations. Managers developed through incompany gemba learning through repetitive A3 analysis embedding PDCA, led by mentors throughout their careers.

10

Modern vs. Lean Management

Decisions made far from the point of value creation, by analyzing data. (Conference room management.) Decisions made at the point of value creation, by converting data into facts (Go see, ask why, show respect gemba management.)

11

Modern vs. Lean Management

Problem solving and improvement conducted by staffs, often through programs. Problem solving and improvement conducted by line managers, often responsible for cross-function teams, with staffs reserved for unique technical problems.

12

Modern vs. Lean Management

Standardization (if any) of activities conducted by staffs, often with little gemba interaction and little auditing. Standardization of (all) activities conducted by line managers in collaboration with work teams, with frequent auditing by directly observing actual work not just work standards.

13

Modern vs. Lean Management

Go fast as a general mandate:

Jump to solutions (with the consequence of going slow through the complete cycle of product & process development, launch & fulfillment.)

Go slow as a general mandate:

Start with the problem and consider many potential counter-measures in parallel (with higher costs & more time at the beginning, followed by lower costs, less time & happier customers at the end.)

14

Modern vs. Lean Management

Strong emphasis on the vertical flow of authority, looking upward toward the CEO.

Performance usually evaluated at single points.

Strong emphasis on the horizontal flow of value, looking toward customers.

Performance evaluated in terms of optimizing the whole process (all of the points).

Control reconciled with flexibility!

15

Conclusion from This Comparison

Modern management isnt conducive to creating sustainable lean enterprises. We need to transition to lean management (or something better!) through PDCA. How can we you do this?

16

What Is the Value-Creating Work of Management?

Gaining agreement across the organization on whats important for customers and the enterprise (purpose), through strategy deployment (a process). Deploying on important strategy deployment initiatives, solving problems (every day), & evaluating proposals from lower levels, with A3 analysis (a process).

17

What Is The Value-Creating Work of Management?

Creating basic stability throughout the organization, by means of standardized work with standardized management (a process). Educating the next generation of managers, by enaging direct reports in endless cycles of strategy deployment, A3 analysis, & standardized management (a process!)

18

Methods of Lean Management

To employ at different levels: Strategy deployment to align and engage employees on the few critical issues the value-creating work of top management in particular. Note: The transition from modern to lean management might be an objective identified by strategy deployment!

19

Strategy Deployment X-Matrix

20

Methods of Lean Management

A3 analysis to deploy top-level mandates, solve daily problems as they arise, and (very important) evaluate proposals from lower levels of the organization the valuecreating work of mid-level management in particular. Never a solo assignment; always done in vertical and horizontal dialogue. (An excuse to have a constructive conversation about where you are and where you need to go.)

21

22

Methods of Lean Management

Standardized management of standardized work with continuous kaizen to stabilize the organization and permit steady improvement the value-creating work of front-line management in particular.

23

Methods of Lean Management

Educating the next level of management to create lean managers through continuing dialogue the valuecreating work of every level of management every day! Indeed, the most important valuecreating work of managers?

24

In the Absence of Lean Methods

The predominant work of management is re-work workarounds for things gone wrong. In other words, most of the work of modern managers is actually waste!

25

An A3 Project for Your Management Team

Analyze your organizations management system. Characterize its current condition.

Determine the ways it hinders lean deployment. (The Gap.)

26

An A3 Project for Your Management Team

Identify the most promising countermeasures. (The Plan.) Test these countermeasures. (The Do.)

Assess the results. (The Check/Reflect.)

Make changes as necessary. (The Act/Adjust.)

27

You might also like

- 1D - Womack - Da Gestao Moderna A Gestao LeanDocument38 pages1D - Womack - Da Gestao Moderna A Gestao LeanGabrielMoranBarrosNo ratings yet

- Creating Lean Management - WomackDocument18 pagesCreating Lean Management - WomackElkin BernalNo ratings yet

- Lean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteDocument20 pagesLean For The Long Term: James P. Womack Chairman, Lean Enterprise InstituteEldori1988No ratings yet

- The Power of Purpose, Process, PeopleDocument22 pagesThe Power of Purpose, Process, Peopleblurami100% (1)

- Lean Change ManagementDocument35 pagesLean Change ManagementfbonnefoiNo ratings yet

- Creating a Project Management System: A Guide to Intelligent Use of ResourcesFrom EverandCreating a Project Management System: A Guide to Intelligent Use of ResourcesNo ratings yet

- 2007-01 The Challenge of Lean TransformationDocument3 pages2007-01 The Challenge of Lean Transformationroman_xxNo ratings yet

- Volunteer Workers Students: 1) Quality CircleDocument3 pagesVolunteer Workers Students: 1) Quality CircleNitin ArvindakshanNo ratings yet

- Managing With Measures For Performance ImprovementDocument68 pagesManaging With Measures For Performance Improvementpakeya77420No ratings yet

- IT GOVERNANCE APPROACHES FOR AGILE SOFTWARE DEVELOPMENT INVESTMENTSFrom EverandIT GOVERNANCE APPROACHES FOR AGILE SOFTWARE DEVELOPMENT INVESTMENTSRating: 4 out of 5 stars4/5 (1)

- Lean Management - The Role of Lean Leaders - PlanviewDocument7 pagesLean Management - The Role of Lean Leaders - PlanviewaarivalaganNo ratings yet

- Building Winning Organisations: A complete guide to sustaining best-in-class performance for all organisationsFrom EverandBuilding Winning Organisations: A complete guide to sustaining best-in-class performance for all organisationsNo ratings yet

- Managing Operations: Your guide to getting it rightFrom EverandManaging Operations: Your guide to getting it rightNo ratings yet

- 4 - BOOK REVIEW - Creating A Lean Culture - Key LearningsDocument6 pages4 - BOOK REVIEW - Creating A Lean Culture - Key Learningsvatan99No ratings yet

- Lean Enterprise: A One Step at a Time Entrepreneur's Management Guide to Building and Continuously Scaling Up Your Business: Boost Productivity and Achieve Goals by Implementing Six Sigma and KanbanFrom EverandLean Enterprise: A One Step at a Time Entrepreneur's Management Guide to Building and Continuously Scaling Up Your Business: Boost Productivity and Achieve Goals by Implementing Six Sigma and KanbanNo ratings yet

- The Irreverent Guide to Project Management: An Agile Approach to Enterprise Project Management, Version 5.0From EverandThe Irreverent Guide to Project Management: An Agile Approach to Enterprise Project Management, Version 5.0No ratings yet

- Introduction of Japanese Good Management: EthiopianDocument46 pagesIntroduction of Japanese Good Management: Ethiopiansinte100% (1)

- Introduction To CMMI V2Document75 pagesIntroduction To CMMI V2Rustam RustamajiNo ratings yet

- Managing in Reverse: The 8 Steps to Optimizing Performance for LeadersFrom EverandManaging in Reverse: The 8 Steps to Optimizing Performance for LeadersNo ratings yet

- Chapter 1: Introduction: Project ManagementDocument69 pagesChapter 1: Introduction: Project ManagementHay JirenyaaNo ratings yet

- Lean Analytics: The Ultimate Guide to Improve Your Company. Learn Profitable Strategies to Use Data and Optimize Your Business.From EverandLean Analytics: The Ultimate Guide to Improve Your Company. Learn Profitable Strategies to Use Data and Optimize Your Business.No ratings yet

- CH 3Document73 pagesCH 3Hasan ImamNo ratings yet

- Handout ProcessImprovementWorkshopPPTDocument159 pagesHandout ProcessImprovementWorkshopPPTHường LêNo ratings yet

- Lean Thinking & 21 Ways To Success LeanDocument7 pagesLean Thinking & 21 Ways To Success LeanPalkesh TrivediNo ratings yet

- Sustaining Creativity and Innovation in Organizations: a Tool Kit: Employee Suggestion SystemFrom EverandSustaining Creativity and Innovation in Organizations: a Tool Kit: Employee Suggestion SystemNo ratings yet

- Agile Project Management: The Ultimate Step by Step Guide. Discover Effective Agile Tools to Manage Projects and Productivity to Improve Your Business and Leadership.From EverandAgile Project Management: The Ultimate Step by Step Guide. Discover Effective Agile Tools to Manage Projects and Productivity to Improve Your Business and Leadership.No ratings yet

- Unit 5Document39 pagesUnit 5aman shamsiNo ratings yet

- Business Process Reengineering:: Instructor Dr. Syed Amir IqbalDocument69 pagesBusiness Process Reengineering:: Instructor Dr. Syed Amir IqbalBILAL FAROOQUINo ratings yet

- The Ultimate Guide to Successful Lean Transformation: Top Reasons Why Companies Fail to Achieve and Sustain Excellence through Lean ImprovementFrom EverandThe Ultimate Guide to Successful Lean Transformation: Top Reasons Why Companies Fail to Achieve and Sustain Excellence through Lean ImprovementRating: 4.5 out of 5 stars4.5/5 (3)

- Reengineering the Corporation (Review and Analysis of Hammer and Champy's Book)From EverandReengineering the Corporation (Review and Analysis of Hammer and Champy's Book)No ratings yet

- Lead and Mang Mod 2 Notes PDFDocument131 pagesLead and Mang Mod 2 Notes PDFRobinNo ratings yet

- Week 1 Lec 2 BPEDocument25 pagesWeek 1 Lec 2 BPEDaniyal QaiserNo ratings yet

- Lean: The Ultimate Guide to Lean Startup, Lean Six Sigma, Lean Analytics, Lean Enterprise, Lean Manufacturing, Scrum, Agile Project Management and KanbanFrom EverandLean: The Ultimate Guide to Lean Startup, Lean Six Sigma, Lean Analytics, Lean Enterprise, Lean Manufacturing, Scrum, Agile Project Management and KanbanNo ratings yet

- Benchmarking - Note 1Document18 pagesBenchmarking - Note 1Rameswar NayakNo ratings yet

- Unit I: Software Process Maturity Software Maturity FrameworkDocument27 pagesUnit I: Software Process Maturity Software Maturity FrameworkAnushaNo ratings yet

- Becoming Lean: Practical Steps to Build CompetitivenessFrom EverandBecoming Lean: Practical Steps to Build CompetitivenessRating: 5 out of 5 stars5/5 (1)

- Lecture 1 - Introduction To Operations ManagementDocument91 pagesLecture 1 - Introduction To Operations ManagementPriyankaNo ratings yet

- Org and ManagementDocument46 pagesOrg and ManagementAiyanah SuruizNo ratings yet

- KAIZENDocument29 pagesKAIZENRobby SharmaNo ratings yet

- Step 12 Rev C 1-25 - Rev12Document88 pagesStep 12 Rev C 1-25 - Rev12SMAKNo ratings yet

- How to Use PDCA Cycle of Improvement to Develop Lean Leaders: Toyota Production System ConceptsFrom EverandHow to Use PDCA Cycle of Improvement to Develop Lean Leaders: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (2)

- Operational Excellence - Education and DevelopmentDocument9 pagesOperational Excellence - Education and Developmentjesus784No ratings yet

- NotesDocument5 pagesNotesrishiNo ratings yet

- Mine Management EMI 5102: Gwanda State University Dr. K. ChitekaDocument19 pagesMine Management EMI 5102: Gwanda State University Dr. K. ChitekaHILLARY FRANCIS SHENJERENo ratings yet

- Lecture Topic 1.3.1Document25 pagesLecture Topic 1.3.1Farha Khan NazNo ratings yet

- Operational LeadershipDocument12 pagesOperational LeadershipBusiness Expert Press50% (2)

- HRCI SHRM Case Study HR Manager ApproachDocument28 pagesHRCI SHRM Case Study HR Manager ApproachFloyd DSouzaNo ratings yet

- ConfidenceDocument4 pagesConfidenceEldori1988No ratings yet

- Bolt Grade Markings and Strength ChartDocument2 pagesBolt Grade Markings and Strength ChartEldori1988No ratings yet

- Assembly in A BoxDocument2 pagesAssembly in A BoxEldori1988No ratings yet

- Sports Pictionary Poster 1 Vocabulary Worksheet PDFDocument2 pagesSports Pictionary Poster 1 Vocabulary Worksheet PDFSy Hafizah100% (1)

- SIROLL Furnace Optimization enDocument0 pagesSIROLL Furnace Optimization enEldori1988No ratings yet

- SuspensiondfDocument3 pagesSuspensiondfAhmad UsamaNo ratings yet

- HUCK Hucktainer enDocument8 pagesHUCK Hucktainer enEldori1988No ratings yet

- Toyota Business Practices and Academe - Industry Linkage - GasparDocument7 pagesToyota Business Practices and Academe - Industry Linkage - GasparEldori1988No ratings yet

- Demonstration For Certification (Participants Copy)Document2 pagesDemonstration For Certification (Participants Copy)Eldori1988No ratings yet

- Onsert GB 0250 PDFDocument12 pagesOnsert GB 0250 PDFmazacotesNo ratings yet

- Rivset Gen2 GB 6705Document6 pagesRivset Gen2 GB 6705Eldori1988No ratings yet

- Fishbone DiagramDocument2 pagesFishbone DiagramEldori1988No ratings yet

- Magna-Bulb Blind Fastener: Previous ScreenDocument3 pagesMagna-Bulb Blind Fastener: Previous ScreenEldori1988No ratings yet

- Bolt Depot - Metric Tap and Drill Size TableDocument1 pageBolt Depot - Metric Tap and Drill Size TableEldori1988No ratings yet

- HUCK FloorTight enDocument8 pagesHUCK FloorTight enEldori1988No ratings yet

- Huck Hucklok enDocument4 pagesHuck Hucklok enEldori1988No ratings yet

- Böllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Document3 pagesBöllhoff International With Companies In:: Partner of The Aerospace Industry Joining Together!Eldori1988No ratings yet

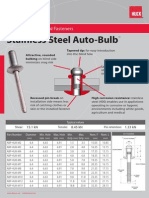

- HUCK Autobulb Stainless Steel enDocument1 pageHUCK Autobulb Stainless Steel enEldori1988No ratings yet

- Bolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableDocument2 pagesBolt Depot - Metric Bolt Head, Wrench Size, and Diameter TableEldori1988No ratings yet

- Lean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument18 pagesLean Thinking For Flight: The Long View: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988No ratings yet

- Bolt Depot - Machinery Eye Bolt DimensionsDocument2 pagesBolt Depot - Machinery Eye Bolt DimensionsEldori1988No ratings yet

- Huck BOM: The Highest Strength Blind Fasteners in The WorldDocument5 pagesHuck BOM: The Highest Strength Blind Fasteners in The WorldEldori1988No ratings yet

- Lean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteDocument20 pagesLean Counting: Jim Womack, Senior Advisor, Lean Enterprise InstituteEldori1988No ratings yet

- CPF PresentationDocument13 pagesCPF PresentationEldori1988No ratings yet

- 561Document27 pages561Eldori1988No ratings yet

- Simulation and Optimization of Metal Forming ProcessesDocument27 pagesSimulation and Optimization of Metal Forming ProcessesTamer HagasNo ratings yet

- German Presentation Feb 03Document8 pagesGerman Presentation Feb 03Eldori1988No ratings yet

- Local Media577597190528174418Document34 pagesLocal Media577597190528174418James Eugene CaasiNo ratings yet

- MRegnard CV Senior Project CoordinatorDocument3 pagesMRegnard CV Senior Project CoordinatormaddyNo ratings yet

- Automation Process QAACDocument23 pagesAutomation Process QAACKannan SNo ratings yet

- MODULE 1 Lesson 2 Retail PlanningDocument21 pagesMODULE 1 Lesson 2 Retail PlanningANALIZA PANIMDIMNo ratings yet

- The Effects of Leadership Style On The Employees' Job Satisfaction and Organizational Commitment From The Hotel IndustryDocument9 pagesThe Effects of Leadership Style On The Employees' Job Satisfaction and Organizational Commitment From The Hotel IndustryOprea AlinaNo ratings yet

- Commodity Managemenet Vs Category Mangement PDFDocument6 pagesCommodity Managemenet Vs Category Mangement PDFSoujanyaNo ratings yet

- BNS 3rd YEAR 2023 ReviseDocument17 pagesBNS 3rd YEAR 2023 ReviseshadabkhanskNo ratings yet

- Lisa Almehsen Resume 2018 FDDocument4 pagesLisa Almehsen Resume 2018 FDLisa AlmehsenNo ratings yet

- Strategic Performance Management SystemDocument3 pagesStrategic Performance Management SystemMaham FatimaNo ratings yet

- Unit 8 Strategic Management What Is Strategy?Document10 pagesUnit 8 Strategic Management What Is Strategy?Nisha SherpaNo ratings yet

- Leadership Role in Resolving ConflictDocument5 pagesLeadership Role in Resolving Conflictdynamic_edgeNo ratings yet

- Product Life Cycle ManagementDocument2 pagesProduct Life Cycle ManagementAshley_RulzzzzzzzNo ratings yet

- Human Resource ManagementDocument19 pagesHuman Resource ManagementShadab AliNo ratings yet

- Lesson Plan Let's Work It Out - Applying Conflict Resolution SkillsDocument11 pagesLesson Plan Let's Work It Out - Applying Conflict Resolution SkillsPsiho LoguseNo ratings yet

- 3rd Quarter - Contemporary IssuesDocument19 pages3rd Quarter - Contemporary IssuesAdrian CorpinNo ratings yet

- Fundamentals of Management 10Th Edition Robbins Solutions Manual Full Chapter PDFDocument43 pagesFundamentals of Management 10Th Edition Robbins Solutions Manual Full Chapter PDFjacobdnjames100% (9)

- Sop - UbsDocument1 pageSop - UbssayankunduNo ratings yet

- Instructions: Complete The Following Chart. You May Choose To Take Point Form NotesDocument2 pagesInstructions: Complete The Following Chart. You May Choose To Take Point Form Notesapi-295095657No ratings yet

- CH 7 Management Info SystemsDocument2 pagesCH 7 Management Info SystemsMelissa Jean Hinton100% (1)

- Director User Experience Project Manager in Charlotte NC Resume Parvez DaruvalaDocument2 pagesDirector User Experience Project Manager in Charlotte NC Resume Parvez DaruvalaParvezDaruvalaNo ratings yet

- PCF Final Documents Overview 11 June 2018Document13 pagesPCF Final Documents Overview 11 June 2018BizzleJohnNo ratings yet

- Primal Leadership Realizing The Power of Emotional Intelligence PRESENTATIONDocument10 pagesPrimal Leadership Realizing The Power of Emotional Intelligence PRESENTATIONNadhira Larasati0% (1)

- Interview Assessment FormDocument1 pageInterview Assessment FormCathleya Marie CoNo ratings yet

- 17 4 Rosch2Document16 pages17 4 Rosch2Mohammad Al-arrabi AldhidiNo ratings yet

- McKinsey 7s ModelDocument9 pagesMcKinsey 7s ModelriteshNo ratings yet

- 3 1 Brief Intro To ISO55000Document37 pages3 1 Brief Intro To ISO55000Arif Miftahur Rohman100% (2)

- Volkswagon Case StudyDocument10 pagesVolkswagon Case StudyNIKHILESHNo ratings yet

- 1533 4986 1 PBDocument8 pages1533 4986 1 PBAerika Delos SantosNo ratings yet

- Ethical Leadership in OrganizationsDocument5 pagesEthical Leadership in OrganizationsensyongNo ratings yet

- Project Management ExamDocument45 pagesProject Management ExamIrfan Muhammad100% (1)