Professional Documents

Culture Documents

Machine Guarding Safety Requirements

Uploaded by

m_alodat6144Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Guarding Safety Requirements

Uploaded by

m_alodat6144Copyright:

Available Formats

Machine Guarding Safety CFR 1910.

211

University of Wisconsin-Eau Claire Facilities Planning & Management

By: Chaizong Lor

Machine Guarding Safety

Training Objectives:

Basics of Machine Safeguarding Methods of Machine Safeguarding Requirements for Safeguards Safeguard Training Summary

Machine Guarding Safety

Basics of Machine Safeguarding

Hazardous Mechanical Motions & Actions Requirements For Safeguarding

Where Mechanical Hazards Occur

Machine Guarding Safety

Where Mechanical Hazards Occur

The Point of Operation:

Power Transmission:

Performing on the material such as cutting, shaping, boring, or forming of stock.

Include components such as flywheels, pulleys, belts, connecting rods, couplings, cams, spindles, chains, cranks, and gears.

All parts of the machine which move while the machine is working. These can be reciprocating, rotating, and transverse moving parts.

Other Moving Parts:

Machine Guarding Safety

Types of Hazardous mechanical:

Hazardous Mechanical Motions & Actions

Motions:

Rotating Motion - can be dangerous because it can grip clothing, and through mere skin contact force an arm or hand into a dangerous position. These includes:

Collars, couplings, cams, clutches, flywheels, shaft ends, spindles, meshing gears.

Machine Guarding Safety

Types of Hazardous mechanical Cont.

Motions Cont.

Hazardous Mechanical Motions & Actions

In-running nip point hazards can be caused by the rotating parts on machinery. There are 3 major types of in-running nips:

Parts rotating in opposite directions such as:

Gear wheels, rolling mills, mixing rolls, between material and a roll where material is being drawn between two rolls. A conveyor belt & any of its pulleys and a rope and its storage reel. Create a shearing, crushing, or abrading action

Rotating & tangentially moving parts such as:

Rotating & fixed parts

Machine Guarding Safety

Types of Hazardous mechanical Cont.

Hazardous Mechanical Motions & Actions

Motions Cont.

Reciprocating motions

Create hazards during their back and forth or up and down motion that may strike a worker. Moving in one direction, straight, and continuous line. Creates a hazard because employee may be struck or caught in a pinch or shear point by a moving part .

Transverse motion

Machine Guarding Safety

Types of Hazardous mechanical Cont.

Actions:

Cutting Action Exposure Punching Action Exposure

Hazardous Mechanical Motions & Actions

Shearing Action Exposure Bending Action Exposure

Machine Guarding Safety

Cutting Exposure Action

The danger exists at the point of operation where flying chips or scrap material can strike the head, particularly in the area of the eyes or face

Example: cutting wood, metal, or other materials

Machine Guarding Safety

Punching Exposure Action

Results when blanking, drawing, or stamping metal or other materials. Danger occurs at the point of operation where stock is inserted, held, and withdrawn by hand

Example: power press

Machine Guarding Safety

Shearing Exposure Action

Involves trimming or shearing metal or other materials

Example: machinery used for shearing operations are mechanically, hydraulically, or pneumatically powered shears

Machine Guarding Safety

Bending Exposure Action

Results when power is applied to a slide in order to draw or stamp metal or other materials Hazard occurs when stock is inserted, held, and withdrawn

Example: power presses, press

brakes, & tubing benders

Machine Guarding Safety

Methods of Machine Safeguarding

To determine the proper safeguarding method, determine:

Type of operation Size & shape of stock Method of handling Physical layout of work area Type of Material Production requirements or limitations

Machine Guarding Safety

Methods of Machine Safeguarding Cont.

5 General Classifications of Safeguards

Guards

Devices

Location & Distance

Feeding & Ejection Methods

Miscellaneous Aids

Machine Guarding Safety

There are four general types of guards:

Fixed Guard:

Acts as a barrier, protection fingers from exposure to the blade Guards Example: use fixed guard on a press brake to protect

the operator from the unused portion of the die

Interlocked:

When opened or removed, automatic shut off or disengages machine power until guard is put back in place. May use electrical, mechanical, hydraulic, pneumatic or any combination of these.

Machine Guarding Safety

There are four general types of guards Cont.

Adjustable:

Guards

Allow flexibility in accommodating various sizes of stock being machined.

Example: a band saw with an adjustable guard to protect the operator form the unused portion of the blade. This guard can be adjusted according to the size of stock

Self-Adjusting:

As the operator moves the stock into the danger area, the guard is pushed away, providing an opening only large enough for the stock to be machined This guard protects the operator by placing a barrier between the danger area and operator.

Machine Guarding Safety

Devices

May perform several functions:

Stop machine automatically Prevent access to danger areas Provide barrier that is synchronized with machine operating cycle to prevent access to danger area during the hazardous part of the cycle Types of Devices:

Presence-Sensing Pullback Restraint

Safety Controls Gates

Machine Guarding Safety

Devices

Types of Devices cont.

Presence-Sensing

Photoelectric - a system of light sources &

controls that can interrupt the machines operating cycle

Radiofrequency a radio beam that is part

of the machine control circuit

Electromechanical a probe or contact bar

which descends to a predetermined distance when the operator initiates the machine cycle

Machine Guarding Safety

Devices

Types of Devices Cont.

Pullback

Use a series of cables attached to the operators hands, wrists, and/or arms Primarily used on machines with stroking action When the slide/ram is up between cycles, the operator is allowed access to the point of operation When the slide/ram begins to cycle to by starting its descent, a mechanical linkage automatically assures withdrawal of the hands from the point of operation

Machine Guarding Safety

Devices

Types of Devices Cont.

Restraint

Use cables and straps that are attached to the operators hands at a fixed point. Cables and straps must be adjusted to let the operators hands travel within a predetermined safe area.

Rely on a pressure-sensitive body bar to provide a quick means for deactivating the machine in an emergency situation.

Safety Trip Control

Machine Guarding Safety

Devices

Types of Devices Cont.

Two-hand control & Two-hand trip

Require concurrent use of both of the operators hands on control buttons to activate the machine, thus preventing the hands from being in danger area when machine cycle starts.

A movable barrier which protects the operator at the point of operation before the machine cycle can be started.

Gate

Machine Guarding Safety

Location & Distance

Makes it virtually impossible to contact moving parts Separates operators from the equipment Limited by the available workspace Examples:

Building enclosures Putting a wall between machine & operator Designing a safe location for the machine to prevent access

Machine Guarding Safety

Feeding & Ejection Methods

These methods do not require the operator to place his/her hands in the danger area and involvement after the machine starts to function. Types of feeding & ejection methods:

Automatic feed Semiautomatic feed Automatic ejection Semiautomatic ejection

Machine Guarding Safety

Miscellaneous Aids

May not give complete protection from machine hazards, but may provide the operator with an extra margin of safety. Examples of possible applications:

Awareness barriers - remind workers of approach to danger area Protective shields - protect workers from flying particles, splashing cutting oils, or coolants Holding Tools - can place or remove stock Push stick or block - used when feeding stock into a saw blade

Machine Guarding Safety

Requirements for Safeguards

Prevent Contact Remain Secure Exposure Protect from Falling Objects

Six General Requirements of Safeguards

Create no new Hazards

Create no Interference

Allow Safe Lubrication

Machine Guarding Safety

Requirements for Safeguards Cont.

Prevent Contact

Remain Secure

Safeguards must minimize the possibility of the operator or another worker placing their hands into hazardous moving parts. Workers should not be able to easily remove or tamper with the safeguard.

Machine Guarding Safety

Requirements for Safeguards Cont.

Protect from Falling Objects

Safeguards should ensure that no objects can fall into moving parts.

A safeguard defeats its purpose if it creates a hazard of its own such as a shear point, a jagged edge, and etc.

Create no new Hazards

Machine Guarding Safety

Requirements for Safeguards Cont.

Create no Interference

Allow Safe Lubrication

A safeguard should not create an unacceptable impediment for the worker. It should be possible to lubricate the machine without removing the safeguard.

Machine Guarding Safety

Training should involve the following areas:

A description and identification of the potential hazards associated with the machine. A description of the safeguards and their functions. Instruction on how to use the safeguards. Precautions to take when machine is unguarded during maintenance and repair. Instruction on what to do if a safeguard is missing, damaged, or inadequate.

Note: Employees shall be trained upon initial assignment or when any

new guards are put in place.

Summary

Safeguards are essential for protecting workers from unwanted and preventable machineryrelated injuries The point of operation, as well as all parts of the machine that move while the machine is working, must be safeguarded A good rule to remember is: Any machine part, function, or process which may cause injury must be safeguarded

Any Questions

??

You might also like

- Machine Safeguarding Hazards and SolutionsDocument43 pagesMachine Safeguarding Hazards and Solutionsfaizijust4uNo ratings yet

- Machine Guarding SafetyDocument31 pagesMachine Guarding SafetyAnonymous iI88LtNo ratings yet

- Machine GuardingDocument47 pagesMachine GuardingPrestone Napiloy Kalang-adNo ratings yet

- Technical Seminar (Mechanical Engg.)Document45 pagesTechnical Seminar (Mechanical Engg.)Akshay Raturi100% (1)

- Machinery and Machine GuardingDocument13 pagesMachinery and Machine GuardingRanganayaki Tirumale Srinivasa Rangachar0% (1)

- Machine Guarding PresentationDocument35 pagesMachine Guarding PresentationChristian Meana100% (1)

- Machine Guarding Program Rev 2Document18 pagesMachine Guarding Program Rev 2gauti0102No ratings yet

- OSHA machine guarding standards summaryDocument6 pagesOSHA machine guarding standards summaryMBAHNo ratings yet

- Machine Safety: Members: Matthew Liu Mharvin Chua Rupert Mangibunong Nadine Te Gillian Luceno Samantha VeranoDocument22 pagesMachine Safety: Members: Matthew Liu Mharvin Chua Rupert Mangibunong Nadine Te Gillian Luceno Samantha VeranoCyrus RivasNo ratings yet

- Bosh Machine Safety 2Document9 pagesBosh Machine Safety 2Rovic VistaNo ratings yet

- Machine GuardingDocument25 pagesMachine Guardingbalamurugan sNo ratings yet

- Basics of Machine Guarding: Hazards and SolutionsDocument44 pagesBasics of Machine Guarding: Hazards and SolutionsRaziuddin FarooqiNo ratings yet

- Mechanical Hazards and Machine SafeguardingDocument29 pagesMechanical Hazards and Machine SafeguardingVam ArmodiaNo ratings yet

- Physical Hazards of MachineryDocument3 pagesPhysical Hazards of MachineryNamitaNo ratings yet

- Machine and Equipment Guarding: Group 5Document29 pagesMachine and Equipment Guarding: Group 5Ronald James DiazNo ratings yet

- SafetyMgt Handouts Topic9Document7 pagesSafetyMgt Handouts Topic9ALyzha Mae LacuestaNo ratings yet

- MCN 401 Ise Module 4-1Document122 pagesMCN 401 Ise Module 4-1Sheena ShajiNo ratings yet

- MCN 401 Ise Module 4-1Document97 pagesMCN 401 Ise Module 4-1taapseveniaavaniNo ratings yet

- 5 Machine SafetyDocument8 pages5 Machine SafetyCharles NunezNo ratings yet

- Machine Safeguarding 101Document12 pagesMachine Safeguarding 101ashok nakumNo ratings yet

- Mechanical Hazards and Common Mechanical InjuriesDocument4 pagesMechanical Hazards and Common Mechanical Injuriesabegail capistranoNo ratings yet

- Machine Guarding 1Document80 pagesMachine Guarding 1m_alodat6144No ratings yet

- Rog-Hse-Pro-015, Procedure For Machine GuardingDocument3 pagesRog-Hse-Pro-015, Procedure For Machine GuardingvladNo ratings yet

- Reporting 70 75Document33 pagesReporting 70 75Patrick Joseph BugayNo ratings yet

- Group 12 Machine SafetyDocument21 pagesGroup 12 Machine SafetydorojajobertNo ratings yet

- Protecting Workers From Machine and Point of Operation HazardsDocument6 pagesProtecting Workers From Machine and Point of Operation Hazardsikperha jomafuvweNo ratings yet

- Machine GuardingDocument30 pagesMachine GuardingJericho DagamiNo ratings yet

- Machine Guarding BasicsDocument30 pagesMachine Guarding BasicsAjay meena Ajay meenaNo ratings yet

- Machine Guarding PDFDocument133 pagesMachine Guarding PDFbrsharmaNo ratings yet

- Machine Guarding - Barry BlodgettDocument66 pagesMachine Guarding - Barry BlodgettmanimeczNo ratings yet

- Mechanical Hazards and Machine SafeguardingDocument19 pagesMechanical Hazards and Machine Safeguardingm_alodat6144No ratings yet

- TUP Graduate School Guide to Machinery Safeguards (40Document32 pagesTUP Graduate School Guide to Machinery Safeguards (40MikhaylovMikkelsenNo ratings yet

- Machine Safety Guide for OSH OfficersDocument19 pagesMachine Safety Guide for OSH OfficersGing FreecsNo ratings yet

- Mechanical Hazards and Safeguarding RequirementsDocument2 pagesMechanical Hazards and Safeguarding RequirementsVimal SudhakaranNo ratings yet

- Machine Guarding (EN and SP)Document2 pagesMachine Guarding (EN and SP)pruncu.alianmNo ratings yet

- Cosh EngineeringDocument67 pagesCosh EngineeringjeromeNo ratings yet

- Why Machinery Safety ImportantDocument3 pagesWhy Machinery Safety ImportantmechjogeswardasNo ratings yet

- IG2 Element 9 Key Learning PointsDocument3 pagesIG2 Element 9 Key Learning Pointspaulin tenoNo ratings yet

- Ise Module 4 KtuDocument40 pagesIse Module 4 Ktuvcb57xbtd5No ratings yet

- Microsoft PowerPoint - Mechanical Hazards Jan07Document44 pagesMicrosoft PowerPoint - Mechanical Hazards Jan07Bhalvindrakumar MaranNo ratings yet

- Safety of OperationsDocument7 pagesSafety of OperationsMuhammad Hamzah HabibburrahmanNo ratings yet

- Physhaz 0Document3 pagesPhyshaz 0Toka MohamedNo ratings yet

- AC2 Module 3Document123 pagesAC2 Module 3Jonah Lyn AsendidoNo ratings yet

- Machine Guarding: 29 CFR 1910.211 To 1910.219Document45 pagesMachine Guarding: 29 CFR 1910.211 To 1910.219Kim Lien TrinhNo ratings yet

- Machine GuardingDocument32 pagesMachine GuardingVipin SomasekharanNo ratings yet

- Machine Guarding PrinciplesDocument5 pagesMachine Guarding Principlesliveconnectionz282No ratings yet

- Moving Equipment HazardsDocument35 pagesMoving Equipment HazardsMuhammad Faisal JavedNo ratings yet

- Safe Machine Design and GuardingDocument18 pagesSafe Machine Design and GuardingPemesinan Am FPTVNo ratings yet

- Machine Guarding Methods and Safety StandardsDocument8 pagesMachine Guarding Methods and Safety StandardsEvan Charl MoraledaNo ratings yet

- Machine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource ManualDocument4 pagesMachine Safeguarding: Using The Quarter-Inch Rule: Safety and Health Resource ManualAhmed ReguiegNo ratings yet

- Workshop Safety GuideDocument58 pagesWorkshop Safety GuideMonikandonNo ratings yet

- Basics of Machine SafeguardingDocument51 pagesBasics of Machine SafeguardingComputer Maintainance Hardware and softwareNo ratings yet

- Chapter 15-Machine Guarding (Bonete, Labay and Moraleda)Document6 pagesChapter 15-Machine Guarding (Bonete, Labay and Moraleda)Evan Charl MoraledaNo ratings yet

- Machine Guards and SafetiesDocument20 pagesMachine Guards and SafetiesJabber Reyes Ambor100% (1)

- Benchwork Powerpoint PresentationDocument100 pagesBenchwork Powerpoint PresentationStewart StevenNo ratings yet

- Machine Safety EssentialsDocument7 pagesMachine Safety EssentialsHurty James DayonNo ratings yet

- Basics of Equipment Guarding: Mining and Petroleum Training ServiceDocument51 pagesBasics of Equipment Guarding: Mining and Petroleum Training ServiceKim Lien TrinhNo ratings yet

- Module 4Document164 pagesModule 4Vimal SankarNo ratings yet

- Machine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningFrom EverandMachine Reliability and Condition Monitoring: A Comprehensive Guide to Predictive Maintenance PlanningRating: 4.5 out of 5 stars4.5/5 (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

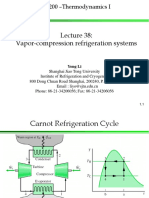

- Vapor Compression Cycle ImprovementsDocument12 pagesVapor Compression Cycle Improvementsm_alodat6144No ratings yet

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 pagesLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNo ratings yet

- Compound Vapor Refrigeration System ExamplesDocument65 pagesCompound Vapor Refrigeration System Examplesm_alodat6144100% (1)

- Capítulo 5 - IncroperaDocument7 pagesCapítulo 5 - IncroperaCaio Muniz100% (2)

- Unsteady Heat ConductionDocument8 pagesUnsteady Heat ConductionRamesh KonakallaNo ratings yet

- Chapter 6-Multiple Evaporator and CompressorDocument27 pagesChapter 6-Multiple Evaporator and Compressorm_alodat6144No ratings yet

- Flow of Viscous Fluids and Boundary Layer Flow-SetDocument18 pagesFlow of Viscous Fluids and Boundary Layer Flow-Setm_alodat6144No ratings yet

- Boundary Layer ThoryDocument120 pagesBoundary Layer ThoryTSIGE ABERANo ratings yet

- Advanced Fluid Mechanics Inclined Plane FlowDocument33 pagesAdvanced Fluid Mechanics Inclined Plane Flowm_alodat6144No ratings yet

- Flow of Viscous Fluids and Boundary Layer Flow-SetDocument18 pagesFlow of Viscous Fluids and Boundary Layer Flow-Setm_alodat6144No ratings yet

- Fluid Flow EquationsDocument24 pagesFluid Flow Equationsm_alodat6144No ratings yet

- 0 C3 01Document24 pages0 C3 01danytiger132No ratings yet

- Vapor Compression Refrigeration SystemDocument11 pagesVapor Compression Refrigeration Systemm_alodat6144No ratings yet

- Chapter 5-Compounded Vapor Compression CycleDocument40 pagesChapter 5-Compounded Vapor Compression Cyclem_alodat6144100% (1)

- Fundamentals of Mass Transfer in Multi-Component SystemsDocument8 pagesFundamentals of Mass Transfer in Multi-Component SystemsWs LimNo ratings yet

- Chapter 4-Simple Vapour Compression Refrigeration SystemDocument40 pagesChapter 4-Simple Vapour Compression Refrigeration Systemm_alodat614450% (2)

- Steady Conduction Heat TransferDocument14 pagesSteady Conduction Heat TransferAmirNo ratings yet

- Refrigeration and Air Conditioning Chapter8Document51 pagesRefrigeration and Air Conditioning Chapter8Richard Weimer100% (2)

- MCE 407 Refrigeration and Air Conditioning CourseDocument100 pagesMCE 407 Refrigeration and Air Conditioning Coursem_alodat6144No ratings yet

- Refrigeration and Heat Pump SystemsDocument26 pagesRefrigeration and Heat Pump SystemsJojolasNo ratings yet

- Vapor Compression Refrigeration SystemDocument11 pagesVapor Compression Refrigeration Systemm_alodat6144No ratings yet

- Rev BraytonDocument7 pagesRev BraytonAnil Kumar RoutNo ratings yet

- Types of Vapour Compression CyclesDocument9 pagesTypes of Vapour Compression CyclesFully YoursNo ratings yet

- Innovative Refrigeration Systems: Sameer KhandekarDocument16 pagesInnovative Refrigeration Systems: Sameer Khandekarm_alodat6144No ratings yet

- 620 28 PDFDocument28 pages620 28 PDFwaraNo ratings yet

- CHE 311 Transport I Course NotesDocument234 pagesCHE 311 Transport I Course Notesm_alodat6144No ratings yet

- Vapor-Compression Refrigeration SystemsDocument28 pagesVapor-Compression Refrigeration Systemsm_alodat6144No ratings yet

- Dimensional Analysis for Similarity Between Models and PrototypesDocument50 pagesDimensional Analysis for Similarity Between Models and Prototypesm_alodat6144No ratings yet

- CH 4 Flowing Fluids and Pressure Variation Compatibility Mode PDFDocument93 pagesCH 4 Flowing Fluids and Pressure Variation Compatibility Mode PDFm_alodat6144No ratings yet

- Dimensional Analysis for Similarity Between Models and PrototypesDocument50 pagesDimensional Analysis for Similarity Between Models and Prototypesm_alodat6144No ratings yet

- Cope Web 11012013 r0Document280 pagesCope Web 11012013 r0Iee XpNo ratings yet

- 03 Intro ERP Using GBI Story (Letter) en v2.11Document11 pages03 Intro ERP Using GBI Story (Letter) en v2.11Gugun MaulanaNo ratings yet

- Can Graphic Design Save Your Life - Review - Thrills, Pills and Big Pharma - Art and DesignDocument4 pagesCan Graphic Design Save Your Life - Review - Thrills, Pills and Big Pharma - Art and DesignTxavo HesiarenNo ratings yet

- Evolution of Science and TechnologyDocument1 pageEvolution of Science and TechnologyHya NicoleNo ratings yet

- Flexicoking ProcessDocument4 pagesFlexicoking ProcessJHONNY100% (2)

- Aluminium Brazing 7 - StepsDocument6 pagesAluminium Brazing 7 - StepsPrashant NankarNo ratings yet

- Corrosion Prevent at Ion TechnologyDocument12 pagesCorrosion Prevent at Ion TechnologyandraspappNo ratings yet

- Introduction to Operations SchedulingDocument252 pagesIntroduction to Operations SchedulingSyphax TensaoutNo ratings yet

- Bituproof 300Document58 pagesBituproof 300Saeed Mahmood Gul KhanNo ratings yet

- Modular System For Immediate Market Entry: Scan and Watch Animation!Document6 pagesModular System For Immediate Market Entry: Scan and Watch Animation!Adeoti OladapoNo ratings yet

- Mineral Processing UG2 Concentrator Process Flow ReportDocument41 pagesMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeNo ratings yet

- ASM Catalysts ceramic and alumina support ball data sheetDocument1 pageASM Catalysts ceramic and alumina support ball data sheetBamrung SungnoenNo ratings yet

- Syallabus of PGDC PDFDocument61 pagesSyallabus of PGDC PDFSaurabh KumarNo ratings yet

- Operations Management of Toyota: A Study of The Operational Activities of ToyotaDocument19 pagesOperations Management of Toyota: A Study of The Operational Activities of ToyotaalekhyaNo ratings yet

- AR-82 Painting MetalworkDocument5 pagesAR-82 Painting MetalworkAmal ChinthakaNo ratings yet

- ITER Cryostat Field Joint Welding StudyDocument1 pageITER Cryostat Field Joint Welding StudyMukesh JindalNo ratings yet

- FMEADocument6 pagesFMEANavnath TamhaneNo ratings yet

- Beaver Engineering GroupDocument3 pagesBeaver Engineering GroupAzenith Margarette Cayetano100% (2)

- Rural FinanceDocument92 pagesRural FinanceDeepNo ratings yet

- Repair RCC Columns Beams SlabsDocument4 pagesRepair RCC Columns Beams SlabsNirmal KishorNo ratings yet

- CavinkareDocument22 pagesCavinkarepravin pawar100% (1)

- Grainger Catalog 401Document1 pageGrainger Catalog 401sam_wolf009No ratings yet

- Algoma SteelDocument18 pagesAlgoma Steelsahzaidi544No ratings yet

- Outokumpu Corrosion Management News Acom 1 2014 PDFDocument8 pagesOutokumpu Corrosion Management News Acom 1 2014 PDFJoshua WalkerNo ratings yet

- Gator Chuck ManualDocument38 pagesGator Chuck ManualReynaldo PesqueraNo ratings yet

- FRIALIT Standard ProductsDocument48 pagesFRIALIT Standard ProductsSeth_cpsNo ratings yet

- 4587 - 2179 - 10 - 1486 - 54 - Unit CostingDocument24 pages4587 - 2179 - 10 - 1486 - 54 - Unit CostingApoorv TiwariNo ratings yet

- Test Bank For Operations and Supply Chain Management The Core 2nd Canadian Edition by JacobsDocument26 pagesTest Bank For Operations and Supply Chain Management The Core 2nd Canadian Edition by Jacobsa852137207No ratings yet

- Barra Emulsion 57Document2 pagesBarra Emulsion 57Doby Yuniardi100% (3)

- Roller Cone Bits CatalogDocument32 pagesRoller Cone Bits Catalogruzzo2003100% (2)