Professional Documents

Culture Documents

Heat Exchanger Design Analysis

Uploaded by

Adiela Syuhada RoslanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Design Analysis

Uploaded by

Adiela Syuhada RoslanCopyright:

Available Formats

1

MEC551

THERMAL ENGINEERING

4.0 Heat Exchangers

2

4.0 HEAT EXCHANGER

4.1 Types of Heat Exchanger: Shell and

Tube, Plate - Parallel Flow, Counter

Flow, Cross Flow.

4.2 Overall Heat Transfer Coefficient.

4.3 Log-mean-temperature difference (LMTD)

method & correction

4.4 Effectiveness of NTU (cNTU) method

4.5 Heat Exchanger Design and

Consideration

3

4.1 Heat Exchangers

The process of heat

exchange between two fluids

that are at different

temperatures and separated

by a solid wall occurs in

many engineering

applications.

The device used to make this

exchange is called a heat

exchanger.

4

Heat Exchangers

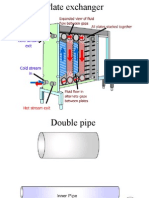

Heat exchangers are typically classified according to

flow arrangement and type of construction.

The simplest heat exchanger is one in which the hot

and cold fluids move in the same direction (parallel

flow) or opposite directions (counter flow) in a

concentric tube (or double pipe construction).

5

Heat Exchangers

(Parallel-flow)

In the parallel-flow

arrangement, the hot

and cold fluids enter

the same end, flow in

the same direction, and

leave at the same end.

6

Heat Exchangers

(Counter-flow)

In the counter-flow

arrangement, the fluids

enter at opposite ends,

in opposite directions,

and leave at opposite

ends.

out

in

cold fluid in

warmed

fluid out

7

Heat Exchangers

(Cross-Flow)

Alternatively, the fluids

may move in cross-flow

(perpendicular) to one

another.

Fluid motion over them

may be mixed or

unmixed. The fluid is

unmixed, because fins

inhibit motion in a

direction that is

transverse to the main

flow direction (x)

8

Heat Exchangers

(Shell and Tube Design)

The most common type of heat exchanger in

industrial applications is the shell and tube heat

exchanger.

9

Heat Exchangers

(Shell and Tube Design)

These designs contain a large number of tubes

(packed in a shell) and heat transfer takes place as

one fluid flows inside the tubes while the other fluid

flows outside the tubes through the shell.

10

Heat Exchangers

(Shell and Tube Design)

Baffles are commonly placed in the shell to force the

shell-side fluid to flow across the shell to enhance

heat transfer and to maintain a uniform spacing

between the tubes.

11

12

Heat Exchangers

(Shell and Tube Multi-pass designs)

Shell and tube heat

exchangers are further

classified by how many shell

and tube passes are involved.

One-shell pass and two-tube

passes devices

Heat exchangers in which all the

tubes make 1 U-turn in the shell

are called

Two-shell passes and four-

tube passes devices

13

Heat Exchangers

(Plate and Frame)

This is an

innovative design

which consists of

a series of plates

with corrugated

flat flow passages.

Hot and cold fluids

flow in alternative

passages, thus the

cold stream is

surrounded by two

hot streams.

14

Heat Exchangers

(Terminology)

Heat exchangers are often given specific names to

reflect the specific application for which they are

used:

Condenser

A heat exchanger in which one of the fluids is cooled

and condenses as it flows through the heat exchanger.

Boiler

A heat exchanger in which one of the fluids absorbs heat

and vaporizes.

Space radiator

A heat exchanger that transfers heat from the hot fluid to

the surrounding space by radiation.

15

4.2 Overall Heat Transfer

Coefficient U, W/m

2

.

o

C

16

Double-pipe Heat Exchanger

A heat exchanger typically

involves two flowing fluids

separated by a solid wall.

Heat is transferred

1. from the hot fluid to the wall

by convection,

2. through the wall by

conduction,

3. from the wall to the cold fluid

again by convection.

17

Inner tube (dimensions)

D

i

D

o

L

t

A

o

= D

o

L

A

i

= D

i

L

t = (D

o

- D

i

)/2 = R

o

- R

i

Outer surface area

inner surface area

Wall thickness

18

Thermal resistances of

the tube wall

R

wall

= ln (D

o

/D

i

)

2 kL

inner surface

R

i

= 1/h

i

A

i

,

outer surface

R

o

= 1/h

o

A

o

19

Double-pipe Heat Exchanger

The thermal resistance of the

network is thus:

( )

o o

D

D

i i

tot

A h kL A h

R

i

o

+ +

=

1

2

ln

1

t

So the thermal resistance in the path of heat flow from hot to

cold fluid in a heat exchanger includes:

i. Skin resistance associated with the flow

ii. Scale resistance from wall fouling (to be discussed later)

iii. Thermal resistance of wall material

20

Overall Heat Transfer Coefficient

The heat transfer is therefore:

Where U = heat transfer coefficient

Note:

T A U T A U T UA

R

T

Q

o o i i

A = A = A =

A

=

`

o i o i

o o i i

A A unless U U

A U A U

= =

=

21

Overall Heat Transfer Coefficient

In this equation, U is called the overall heat transfer

coefficient.

tot

o o i i s

R

A U A U A U

=

1 1 1

22

Since:

where A

m

is called the logarithmic mean area

Overall Heat Transfer Coefficient

( ) ( ) ( ) ( )

( )

( ) ( )

( )

m

A A

L R

L R

R R L

i o

L R

L R

t thickness

i o R

R

D

D

wall

A k

t

k

t

k

t

kL R R

R R

kL kL

R

i

A

o

A

i o

i

o

i o

i

o

i

o

i

o

= = =

= = =

|

|

.

|

\

|

ln

2

2

ln

2

2

2

,

1 1

2

ln

2

ln

2

ln

t

t

t

t

t

t t t

( )

i

o

A

A

i o

m

A A

A

ln

=

23

Overall Heat Transfer Coefficient

Since:

1

1 1

1 1

1 1 1

+

|

|

.

|

\

|

+

|

|

.

|

\

|

=

(

(

+ +

=

=

o m

o

i

o

i

h A A k

t

h A o o

o

h A

A

k

t

A

A

h

A R A

U

o o m i i

24

Overall Heat Transfer Coefficient

And since:

( )

|

|

.

|

\

|

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

i

o o

i

o

i o

o

i

o

i o

o

m

o

D

D

t

D

D

D

D D

D

L D

L D

D D L

L D

A

A

ln

ln

2

2

ln

2

2

t

t

t

t

25

Overall Heat Transfer Coefficient

Therefore substituting this in gives:

1

0

1

1

ln

2

1 1

1

ln

2

1

|

|

.

|

\

|

+

|

|

.

|

\

|

+ =

=

(

+

|

|

.

|

\

|

+

|

|

.

|

\

|

=

i o i

o i

i i

i

o i

o o

i

o

i

o

D

D

h D

D

k

D

h R A

U

h D

D

k

D

D

D

h

U

26

Overall Heat Transfer Coefficient

For a thin tube:

1

1 1

0 ln 1 ; 0

+ = =

=

|

|

.

|

\

|

~

o i

o i

i

o

i

o

h h

U U

D

D

so

D

D

t

27

Overall Heat Transfer Coefficient

When the tubes are finned on one side to enhance the

heat transfer, the total heat transfer surface area on

the finned side becomes:

unfinned fin total s

A A A A + = =

Surface

Area of fins

Surface

Area of Unfinned portion

28

Overall Heat Transfer Coefficient

For short fins of high thermal conductivity, we can use

this total area in the convection resistance relation:

Since in this case the fins will be isothermal.

Otherwise we should determine the effective surface

area from:

( )

unfinned fin s

conv

A A h A h

R

+

=

=

1 1

fin fin unfinned s

A A A + = q

29

Effect of Fouling

The performance of heat exchangers

usually deteriorates with time as a result

of the accumulation of deposits on heat

transfer surfaces.

The layer of deposits represents

additional resistance to heat transfer

and causes Q to decrease.

The net effect is represented by the

fouling factor (R

f

) which is a measure of

the thermal resistance introduced by

fouling.

30

Effect of Fouling

If we define the fouling factors on the inside and the

outside surface to be R

fi

and R

fo

, respectively. Then the

total thermal resistance (R) with fouling and the overall

heat transfer coefficient becomes:

Generally, U

o

is low for a fluid with low k-values (for example

gases and oils).

1

0

1

ln

2

1

1 1

+ +

|

|

.

|

\

|

+

|

|

.

|

\

|

+

|

|

.

|

\

|

=

+ +

+ +

=

o

fo

i

o o

i

o

fi

i

o

i

o

o o

fo

m i

fi

i i

h

R

D

D

k

D

D

D

R

D

D

h

U

h A A

R

A k

t

A

R

h A

R

31

Overall Heat Transfer Coefficient

(Example 11-1 p617)

Example 11-1 Hot oil is to be

cooled in a double-tube counter-

flow heat exchanger. The copper

inner tubes have a diameter of 2 cm

and negligible thickness. The inner

diameter of the outer tube (shell) is

3 cm. Water flows through the tube

at 0.5 kg/s and oil flows through the

shell at 0.8 kg/s. Taking the average

temperatures of the water and the

oil to be 45C and 80C,

respectively, determine the overall

heat transfer coefficient of this heat

exchanger.

Assumptions

1) Thermal resistance of the

inner tube is negligible since

the tube is highly conductive

and its thickness is negligible.

2) Both oil and water flow are

fully developed.

3) Properties of oil and water are

constant.

32

Overall Heat Transfer Coefficient

(Example 11.1)

Properties of water at 45C (Table A-9):

Properties of oil at 80C (Table A-16):

s

m

water C m

W

water

water

m

kg

water

k

2

3

6

10 602 . 0 637 . 0

91 . 3 Pr 990

= = =

= =

s

m

oil C m

W

oil

oil

m

kg

oil

k

2

3

6

10 5 . 37 138 . 0

490 Pr 852

= =

= =

v

33

Overall Heat Transfer Coefficient

(Example 11.1)

Since the thickness is small:

The hydraulic diameter for a circular tube is the diameter of the

tube itself, D

h, water

= D = 0.02 m

Therefore the mean velocity (V

m

) for water is:

o i

h h U

1 1 1

+ ~

( )

( ) ( ) | |

s

m

m

kg

s

kg

water h water

water

c water

water

water

m

m

D

m

A

m

V

61 . 1

02 . 0 990

5 . 0

2

4

1

2

, 4

1

3

=

=

=

=

t

t

` `

34

Overall Heat Transfer Coefficient

(Example 11.1)

The Reynolds number for the water is:

Since Re > 4,000, which is the Re

crit

for a pipe, the flow of water is

turbulent. The Nusselt number is thus:

( ) ( )

490 , 53

10 602 . 0

02 . 0 61 . 1

Re

2

6

,

=

=

s

m

s

m

water

water h

water

m

water

m

D V

v

( ) ( ) 6 . 240 91 . 3 490 , 53 023 . 0

Pr Re 023 . 0

4 . 0 8 . 0

4 . 0 8 . 0

= =

=

=

water water

water

h

water

k

D h

Nu

35

Overall Heat Transfer Coefficient

(Example 11.1)

Then:

( )

C m

W C m

W

water

water h

water

water

m

Nu

D

k

h

= =

=

2

663 , 7 6 . 240

02 . 0

637 . 0

,

36

Overall Heat Transfer Coefficient

(Example 11.1)

Now we repeat the analysis for oil.

The mean velocity of the oil is:

m

D D D

i o oil h

01 . 0 02 . 0 03 . 0

,

= =

=

( ) ( )

( ) ( ) | |

s

m

m

kg

s

kg

i o oil

oil

c oil

oil

oil m

m

D D

m

A

m

V

39 . 2

02 . 0 03 . 0 852

8 . 0

2 2 2

4

1

2 2

4

1

,

3

=

=

=

t

t

` `

37

Overall Heat Transfer Coefficient

(Example 11.1)

So the Reynolds number for oil is:

Re

crit

for oil in a pipe is higher, so the flow of oil is laminar.

The Nusselt number can be found from Table 13-3 (in text) for

D

t

/D

s

= 0.667 as:

( ) ( )

637

10 5 . 37

01 . 0 39 . 2

Re

2

6

, ,

=

=

s

m

s

m

oil

oil h oil m

oil

m

D V

v

45 . 5 =

oil

Nu

38

Overall Heat Transfer Coefficient

(Example 11.1)

Therefore:

since

Then the overall heat transfer coefficient (U) for this heat

exchanger becomes:

( )

C m

W C m

W

oil

oil h

oil

oil

m

Nu

D

k

h

=

|

|

.

|

\

|

= =

2

2 . 75 45 . 5

01 . 0

138 . 0

,

C m

W

C m

W

C m

W

o i

h h

U

=

+

=

+

=

2

2 2

5 . 74

2 . 75

1

663 , 7

1

1

1 1

1

o i

h h U

1 1 1

+ ~

39

Effect of Fouling

(Example 11.2)

Example 11.2 A double-pipe

(shell and tube) heat exchanger

is constructed of a stainless

steel inner tube with inner

diameter (D

i

) of 1.5 cm and

outer diameter (D

o

) of 1.9 cm.

and an outer shell of inner

diameter 3.2 cm.

For the convection values and

fouling factors given, determine

the thermal resistance of the

heat exchanger and heat

transfer coefficients U

i

and U

o

.

40

Effect of Fouling

(Example 11.2)

The areas are:

The thermal resistance is:

( )

o o o

o f D

D

i

i f

i i

o o i i s

A h A

R

kL A

R

A h

A U A U A U

R

i

o

+ + + +

=

1

2

ln

1

1 1 1

, ,

t

( ) ( )

( ) ( )

2

2

0597 . 0 1 019 . 0

0471 . 0 1 015 . 0

m m m L D A

m m m L D A

o o

i i

= = =

= = =

t t

t t

41

Effect of Fouling

(Example 11.2)

Therefore:

( )

( ) ( )

( ) ( ) ( ) ( )

( )

W

C

W

C

C m

W

W

C m

C m

W

W

C m

C m

W

o o o

o f D

D

i

i f

i i

m m m

m

m

m m

A h A

R

kL A

R

A h

R

i

o

=

+ + + + =

+ +

|

|

.

|

\

|

+

+ +

+ + + +

=

0532 . 0

001396 . 0 00168 . 0 0025 . 0 00849 . 0 02654 . 0

0597 . 0 1200

1

0597 . 0

0001 . 0

1 1 . 15 2

015 . 0

019 . 0

ln

0471 . 0

0004 . 0

0471 . 0 800

1

1

2

ln

1

2 2

2 2

, ,

2

2

2

2

t

t

.

.

42

Effect of Fouling

(Example 11.2)

Note that 19% of the total resistance in this case is due to fouling

and about 5% of it is due to the steel tube separating the two

fluids. The rest of the 76% is due to convective resistances on

the two sides of the inner tube.

Now know the thermal resistances, the overall heat transfer

coefficients can be found:

( ) ( )

( ) ( )

C m

W

W

C

o

o

C m

W

W

C

i

i

m A R

U

m A R

U

=

=

=

=

2

2

315

0597 . 0 0532 . 0

1 1

399

0471 . 0 0532 . 0

1 1

2

2

43

4.3 Log Mean Temperature

Difference Method

44

Analysis of Heat Exchangers

The first law of

thermodynamics requires

that the heat transfer to

the cold fluid must be

equal to the heat transfer

from the hot fluid.

Where the subscripts c and h

stand for cold and hot.

( )

( )

out h in h ph h

in c out c pc c

T T C m Q

T T C m Q

, ,

, ,

=

= +

`

`

`

`

45

Analysis of Heat Exchangers

In heat exchanger analysis it is convenient to combine

the product of the mass flow and the specific heat of a

fluid into a single quantity called the heat capacity

rate.

( )

( )

out h in h h

in c out c c

T T C Q

T T C Q

, ,

, ,

=

= +

`

`

ph h h

c m C

`

=

pc c c

c m C

`

=

46

Analysis of Heat Exchangers

Consider an incremental area of the heat exchanger surface (as

shown for either a counter-flow or parallel flow heat exchanger).

Parallel Flow Counter-flow

T

o

dA

Hot

Cold

T

h,in

T

c,in

T

c,out

T

L

T

o

T

h,in

T

c,out

T

h,out

T

L

T

h,out

T

c,in

Hot

Cold

dA

47

Analysis of Heat Exchangers

The heat transfer over the area (dA) can be expressed in three

ways:

1) The heat flow between hot fluids:

2) The heat gain by the cold fluid:

3) The heat given up by the hot fluid:

T dA U Q d A =

`

c c

dT C Q d =

`

h h

dT C Q d =

`

48

Log Mean Temperature

Difference Method

However, since the temperature difference (T)

between the hot and cold fluids varies with distance

along the heat exchanger. It is convenient to use a

mean temperature difference (T

m

) between the hot

and cold fluids, so that:

m

T U A Q A =

`

49

LMTD Method

Consider a parallel double-

pipe heat exchanger. The

heat transfer on each fluid in

the differential section can

be expressed as:

c c

h h

dT C Q

dT C Q

=

=

`

`

o

o

50

LMTD Method

Solving these equations gives:

Taking their difference gives:

c

c

h

h

C

Q

dT

C

Q

dT

` `

o o

= =

( )

|

|

.

|

\

|

+ = =

c h

c h c h

C C

Q T T d dT dT

1 1

`

o

51

LMTD Method

The rate of heat transfer in the differential section can

be expressed as:

Substituting this into the previous equations gives:

( ) dA T T U Q

c h

=

`

o

( )

|

|

.

|

\

|

=

c h c h

c h

C C

dA U

T T

T T d 1 1

52

LMTD Method

Integrating from the inlet to the heat exchanger to its

outlet, we get:

( )

} }

(

L

c h

L

c h

c h

dA

C C

U

T T

T T d

0 0

1 1

+ For parallel-flow

- For counter-flow

53

LMTD Method

Solving the integral for parallel flow

(where T

1

=T

h,in

-T

c,in

and T

2

=T

h,out

-T

c,out

) we get:

|

|

.

|

\

|

+ =

|

|

.

|

\

|

+

=

|

|

.

|

\

|

A

A

|

|

.

|

\

|

+ =

|

|

|

|

.

|

\

|

A

A

h c

h

c h

c

c h

c h

c h

T

in c in h

T

out c out h

C C

C

C C

C

A U

C C

C C

A U

T

T

C C

A U

T T

T T

1 1

ln

1 1

ln

1

2

, ,

, ,

1

2

_

54

LMTD Method

( )

(

(

+

|

|

.

|

\

|

+

=

|

|

.

|

\

|

A

A

h in h out h

in c out c

c in c out c

in h out h

C T T

T T

C T T

T T

A U

T

T 1 1

ln

, ,

, ,

, ,

, ,

1

2

Since:

Then:

( )

( )

in h out h

in c out c

c

h

in c out c

in h out h

h

c

T T

T T

C

C

and

T T

T T

C

C

, ,

, ,

, ,

, ,

=

=

55

LMTD Method

Solving:

( ) ( )

(

A A

+ =

(

+

=

(

+

+

=

|

|

.

|

\

|

A

A

Q

T T

A U

Q

T T T T

A U

Q

T T

Q

T T

A U

T

T

in c in h out c out h

in c out c in h out h

`

`

` `

1 2

, , , ,

, , , ,

1

2

ln

56

LMTD Method

Therefore:

This is the log mean temperature difference

m

e temperatur Mean

T

T A U

T

T

T T

A U Q

m

A =

(

(

(

(

(

|

|

.

|

\

|

A

A

A A

=

A

_

`

1

2

1 2

ln

57

LMTD Method

The log mean temperature difference method (LMTD) can be used

for both parallel and counter-flow heat exchangers, if the

following terms are used for T:

Parallel Heat Exchangers Counter-flow Heat Exchangers

58

Correction factors

for LMTD Method

The LMTD method is strictly limited to single pass parallel and

counter-flow heat exchangers only.

However, similar relations are also developed for cross-flow

and multi-pass shell and tube heat exchangers, but these are

very complicated expressions.

In these cases it is more convenient to relate the equivalent

temperature difference relation for the counter-flow case as:

flow counter

LMTD m

T F T

A = A

,

Log Mean Temperature Difference

for counter-flow heat exchanger

Correction factor

59

Correction factors

for LMTD Method

Correction factors (F) for several common

configurations are available from standard charts.

Figure 11-18 (in text) shown on the next slide, lists

some for common shell and tube cross-flow heat

exchangers. The correction factor used for this is:

( )

( )

side shell

p

side tube

p

c m

c m

t t

T T

R

t T

t t

P

=

`

`

1 2

2 1

1 1

1 2

60

Correction factors

for LMTD Method

61

LMTD Method

(Example 6.3)

Example 6.3 Alcohol is to be cooled at a rate of 0.2

kg/s from 75C to 35C in a counter-flow heat

exchanger. Cooling water enters the heat exchanger

at 12C at a rate of 0.16 kg/s. The convective

coefficient between alcohol and the tube wall and

water is 0.34 kW/(m

2

K) and between the tube wall

and water is 0.225 kW/(m

2

K). The tube may be

assumed to be thin. The specific heat for the alcohol

is 2.52 KJ/(kgK) and water is 4.187 KJ/(kgK).

Calculate the capacity ratio (C), effectiveness (),

and heat exchanger surface area (A

s

).

62

LMTD Method

(Example 6.3)

T

h,in

= 75C

T

c,out

= ?

T

c,in

= 12C

T

h,out

= 35C

T

T

h,in

T

c,out

T

h,out

T

c,in

T

1

T

2

K m

kW

o

K m

kW

i

h

h

=

=

2

2

225 . 0

340 . 0

63

LMTD Method

(Example 6.3)

The heat capacity ratio

(C) is:

since: C

c

> C

h

( ) ( )

( ) ( )

752 . 0

670 . 0

504 . 0

670 . 0 187 . 4 16 . 0

504 . 0 52 . 2 20 . 0

max

min

min max

= = = =

= =

= = =

= = =

c

h

h c

s K

kJ

K kg

kJ

s

kg

pc c c

s K

kJ

K kg

kJ

s

kg

ph h h

C

C

C

C

C

C C C C

c m C

c m C

`

`

64

LMTD Method

(Example 6.3)

Energy balance:

( ) ( ) ( )

( ) ( ) ( )

C C T

C C

C T

T c m T c m

Q Q

out c

K kg

kJ

s

kg

out c K kg

kJ

s

kg

alcohol ph h water pc c

loss gain

= + =

=

A = A

=

1 . 42

67 . 0

16 . 20

12

35 75 52 . 2 2 . 0

12 187 . 4 16 . 0

,

,

` `

` `

65

LMTD Method

(Example 6.3)

The effectiveness is thus:

C

min

is used for Q

max

because the fluid with the smaller

heat capacity rate will experience the largest

temperature change and thus be the first to

experience the maximum temperature, at which point

heat transfer stops.

( )

( )

( )

( )

635 . 0

12 75

35 75

, , min

, ,

max

=

=

= =

C C

C C

T T C

T T C

Q

Q

in c in h

out h in h h

`

`

c

66

LMTD Method

(Example 6.3)

The temperature differences are:

Therefore the LMTD is:

C C C T T T

C C C T T T

out c in h

in c out h

= = = A

= = = A

9 . 32 1 . 42 75

23 12 35

, , 1

, , 2

( ) ( )

C

C C T T

T

C

C

T

T

m

=

=

A A

= A

A

A

7 . 27

ln

9 . 32 23

ln

9 . 32

23

1 2

1

2

67

LMTD Method

(Example 6.3)

For a thin tube (as given) then r

o

~ r

i

, the overall heat

transfer coefficient is:

Finally, the surface area is:

K m

kW

o i

i

h h

U

=

(

+ =

(

+ =

2

1354 . 0

225 . 0

1

34 . 0

1 1 1

1

1

( ) ( )

2

495 . 0

273 7 . 27 1354 . 0

16 . 20

2

m

K

kW

T U

Q

A

K m

kW

m

s

=

+

=

A

=

`

68

LMTD Correction

(Example 6.4)

Example 6.4 Cooling water (C

pc

=4.187 kJ/(kgK))

flows through a two-shell pass, four-tube pass heat

exchanger at the rate of 2 kg/s and temperatures at

entry of 20 and exit at 80C. Hot oil enters through

the shell side of the heat exchanger at 140C and

leaves at 90C. Calculate the heat exchanger surface

area if the overall heat transfer coefficient (U) is 300

W/(m

2

C).

69

LMTD Correction

(Example 6.4)

T

h,in

= 140C

T

h,out

= 90C

T

c,out

= 80C

T

c,in

= 20C

70

LMTD Correction

(Example 6.4)

The LMTD is:

( ) ( )

C

C C

C C

C C C C

T

T

T T

T

m

=

|

.

|

\

|

=

|

|

.

|

\

|

A

A

A A

= A

9 . 64

80 140

20 90

ln

80 140 20 90

ln

2

1

2 1

71

LMTD Correction

(Example 6.4)

Parameters to use the LMTD correction chart:

833 . 0

20 80

90 140

5 . 0

20 140

20 80

, ,

, ,

, ,

, ,

=

=

=

=

=

=

C C

C C

T T

T T

R

C C

C C

T T

T T

P

in c out c

in h out h

in c in h

in c out c

72

LMTD Correction

(Example 6.4)

From chart (Figure 13-18 in text) the value F= 0.97

0.97

73

LMTD Correction

(Example 6.4)

Therefore the surface area (A

s

) is:

( )

( ) ( ) ( )

( ) ( ) ( )

2

3

, ,

6 . 26

9 . 64 97 . 0 10 300

20 80 187 . 4 2

2

m

C

C C

T F U

T T C m

A

C m

kW

K kg

kJ

s

kg

m

in c out c pc c

s

=

=

A

=

`

74

Analysis of Heat Exchangers

Two different design tasks:

1) Specified:

- the temperature change in a fluid stream, and

- the mass flow rate.

Required:

- the designer needs to select a heat exchanger.

2) Specified:

- the heat exchanger type and size,

- fluid mass flow rate,

- inlet temperatures.

Required:

- the designer needs to predict the outlet temperatures and heat transfer

rate.

Two methods used in the analysis of heat exchangers:

the log mean temperature difference (or LMTD)

best suited for the #1,

the effectivenessNTU method

best suited for task #2.

75

LMTD

( )

1 2

1 2

ln

s lm

lm

Q UA T

T T

T

T T

= A

A A

A =

A A

76

77

Correction factors

for LMTD Method

The LMTD method is strictly limited to single pass parallel and

counter-flow heat exchangers only.

However, similar relations are also developed for cross-flow

and multi-pass shell and tube heat exchangers, but these are

very complicated expressions.

In these cases it is more convenient to relate the equivalent

temperature difference relation for the counter-flow case as:

flow counter

LMTD m

T F T

A = A

,

Log Mean Temperature Difference

for counter-flow heat exchanger

Correction factor

78

4.4 The Effectiveness

NTU Method

79

The -NTU Method

This method is useful when the LMTD method cannot

be determined. The required data may instead be

determined from the -NTU method charts of several

common configurations

Definitions:

The heat capacity of the cold stream is given by:

The heat capacity of the hot stream is given by:

pc c c

c m C =

`

ph h h

c m C =

`

80

The -NTU Method

The capacity ratio is defined as:

c h

c

h

c h

h

c

C C if

C

C

C

C C if

C

C

C

< =

> =

;

;

81

The -NTU Method

The -NTU Method is based upon a dimensionless

paramater, Heat Transfer Efectiveness, :

For counter-flow heat exchangers, the actual heat transfer rate

may be written either from the cold stream or from the hot

stream as:

Where and

rate transfer heat possible Maximum

rate transfer heat Actual

Q

Q

=

max

`

`

c

( ) ( )

out h in h h in c out c c

T T C T T C Q

, , , ,

= =

`

pc c c

c m C =

`

ph h h

c m C =

`

82

The -NTU Method

The maximum temperature difference possible in a

heat exchanger is:

The heat transfer in the heat exchanger will reach its

maximum value when:

1) The cold fluid is heated to the inlet temperature of the hot

fluid.

2) The hot fluid is cooled to the inlet temperature of the cold

fluid.

in c in h

T T T

, , max

= A

83

The -NTU Method

However, these two things cannot happen

simultaneously unless: C

c

=C

h

But if C

c

C

h

as is normally the case, the fluid with

the smaller heat capacity will experience the larger

temperature change and thus will be the first to

experience maximum temperature, at which point

heat transfer will come to a halt.

84

The -NTU Method

Therefore, the maximum possible heat transfer rate in

heat exchanger is:

( )

in c in h

T T C Q

, , min max

=

`

h c

C or C of smaller the is C where

min

:

85

The -NTU Method

Therefore the heat exchanger effectiveness for a

counter-flow heat exchanger is:

( )

( )

( )

( )

in c in h

out h in h h

in c in h

in c out c c

T T C

T T C

T T C

T T C

, , min

, ,

, , min

, ,

=

c

c

rate transfer heat possible Maximum

rate transfer heat Actual

Q

Q

=

max

`

`

c

86

The -NTU Method

NTU Number of Heat Transfer Unit

The NTU is a measure of physical size of the heat

exchanger; the larger NTU, the larger heat exchanger

size. It is defined as the ratio of the heat capacity of

the heat exchanger to the minimum heat capacity of

the flow.

( )

min

min p

s s

C m

A U

C

U A

NTU

=

`

87

The -NTU Method

(Step-by-step Procedure)

The -NTU Method Procedure

1) Determine C

min

and C

max

from of the streams

and calculate the capacity ratio C.

max

min

C

C

c =

( )

p

c m

`

88

The -NTU Method

(Step-by-step Procedure)

2) Determine:

( )

( )

( )

( )

in c in h

out h in h h

in c in h

in c out c c

s

T T C

T T C

T T C

T T C

C

A U

NTU

, , min

, ,

, , min

, ,

min

=

=

=

c

89

The -NTU Method

(Step-by-step Procedure)

3) Charts

Knowing , NTU, and C use

the chart (Figure 11-26 in the

text) to determine U and A

s

in question.

OR from standard derivation

Tables 11-4 & 11-5

90

The -NTU Method

(Step-by-step Procedure)

4) Compute the heat transfer rate:

( )

in c in h

T T C Q

, , min

=c

`

91

The -NTU Method

(Step-by-step Procedure)

5) Calculate the outlet temperature:

c

in c out c

h

in h out h

C

Q

T T

C

Q

T T

`

`

=

=

, ,

, ,

92

The -NTU Method

(Example 6.5)

Example 6.5 A single, pass counter-flow shell-and-

tube heat exchanger is used to cool hot mercury

(C

ph

=1.37 kJ/(kgK)) from 110C to 70C flowing at a

rate of 1 kg/s with water (C

pc

=4.187 kJ/(kgK)) entering

at 30C and flowing at a rate of 0.2 kg/s. Calculate

the heat transfer surface area required and the exit

temperature of the water if the overall heat transfer

coefficient (U) is 250 kW/(m

2

K).

93

30C

70C 110C

The -NTU Method

(Example 6.5)

94

The -NTU Method

(Example 6.5)

The temperature difference (T

2

) is:

The heat capacities are:

C C C

T T T

in c out h

= =

= A

40 30 70

, , 2

( ) ( )

( ) ( )

s K

kJ

K kg

kJ

s

kg

pc c c

s K

kJ

K kg

kJ

s

kg

ph h h

C m C

C m C

= = =

= = =

836 . 0 187 . 4 2 . 0

37 . 1 37 . 1 1

`

`

95

The -NTU Method

(Example 6.5)

Since C

h

> C

c

, therefore:

61 . 0

37 . 1

836 . 0

836 . 0

370 . 1

max

min

min

max

= = =

= =

= =

C

C

C

C C

C C

s K

kJ

c

s K

kJ

h

96

The -NTU Method

(Example 6.5)

The total heat transfer (Q) is:

The maximum heat transfer is:

( )

( ) ( ) ( ) | |

kW

K

T T C Q

K kg

kJ

out h in h h

8 . 54

273 70 273 110 37 . 1

, ,

=

+ + =

=

`

( )

( ) ( ) ( ) | |

kW

K

T T C Q

s K

kJ

in c in h

9 . 66

273 30 273 110 836 . 0

, , min max

=

+ + =

=

`

97

The -NTU Method

(Example 6.5)

The heat exchanger effectiveness is:

Now consult the -NTU chart (Figure 11-26 in text)

82 . 0

9 . 66

8 . 54

max

= = =

kW

kW

Q

Q

`

`

c

98

The -NTU Method

(Example 6.5)

0.82

2.7

From the chart:

NTU = 2.7

99

The -NTU Method

(Example 6.5)

Therefore the surface area (A

s

) is:

The exit temperature of the water is thus:

( )

2

min

03 . 9

250

836 . 0 7 . 2

2

m

U

C NTU

A

K m

kW

s K

kJ

s

=

( )

( ) C or K K

kW

T

C

Q

T

T T C Q

s K

kJ

in c

c

out c

in c out c c

= + + =

+ =

=

6 . 95 6 . 368 273 30

836 . 0

8 . 54

, ,

, ,

`

`

100

4.5 Heat Exchanger Design

Considerations

101

Design Considerations

Some design considerations are:

Heat transfer rate

This is the most important quantity. A heat exchanger

must be capable of transferring heat at a specified rate in

order to achieve the desired temperature change of the

fluid at a specified mass flow rate.

Cost

Budgetary limitations always play an important role.

Operating and maintenance costs are also a factor.

Pumping Power

The fluids are normally forced by pumps or fans which

require a pump with associate electrical costs.

102

Design Considerations

Size and weight

Normally the smaller and lighter, the better. This is

especially true for automotive and aerospace industries.

Type

The type of heat exchanger depends on the

requirements, fluids involved, size and weight limitations

etc.

Materials

The materials in the heat exchanger construction may be

an important consideration, especially if thermal

stresses are an issue.

103

End Of Heat Exchanger Section C

C

104

End Of Lectures C

C

Study hard for your finals

I hope you all do well

You might also like

- Heat ExchangerDocument27 pagesHeat ExchangerKashish Mehta75% (4)

- Lect 3Document43 pagesLect 3Mahesh KumarNo ratings yet

- Safety Valve LaserDocument15 pagesSafety Valve Lasersajjad_naghdi241No ratings yet

- Heat Exchanger2009 Proposal#1Document318 pagesHeat Exchanger2009 Proposal#1HarryBouter100% (1)

- Heat ExchangerDocument27 pagesHeat ExchangerPRATIK P. BHOIR100% (1)

- Sthe SSDocument43 pagesSthe SSNathanianNo ratings yet

- Heat ExchangersDocument36 pagesHeat ExchangersKiran KumarNo ratings yet

- Heat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Document34 pagesHeat Exchanger As Per TEMA Design PPT by Rakesh Mishra 31.03.2020Rakesh Mishra100% (1)

- TEMA question and reply document titleDocument24 pagesTEMA question and reply document titleBaher Elsheikh100% (1)

- Design of Pressure VesselDocument18 pagesDesign of Pressure VesselHenok TesfayeNo ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- Heat ExchangersDocument56 pagesHeat ExchangersGeeva Prasanth ANo ratings yet

- Heat ExchangersDocument7 pagesHeat ExchangersAgustin Gago LopezNo ratings yet

- Heat Exchanger ASSUIETDocument229 pagesHeat Exchanger ASSUIETعبدوخطابNo ratings yet

- Shell and Tube Heat ExchangersDocument27 pagesShell and Tube Heat Exchangersalibaba011No ratings yet

- Shell & Tube Installation, Operation & Maintenance ManualDocument14 pagesShell & Tube Installation, Operation & Maintenance Manualnidhul07No ratings yet

- Heat Exchangers SeminarDocument15 pagesHeat Exchangers SeminarShivang Gupta100% (1)

- Heat Exchangers Training MaterialsDocument32 pagesHeat Exchangers Training MaterialsonyekaNo ratings yet

- Efficient Heat Transfer with Counter Flow DesignDocument58 pagesEfficient Heat Transfer with Counter Flow DesigncanyourunNo ratings yet

- Integrity of Corrosion at Heat ExchangersDocument53 pagesIntegrity of Corrosion at Heat Exchangersoperationmanager100% (2)

- Chapter 7 Shell Tube Heat ExchangerDocument138 pagesChapter 7 Shell Tube Heat ExchangerPHƯƠNG ĐẶNG YẾNNo ratings yet

- Essential Guide to Heat ExchangersDocument71 pagesEssential Guide to Heat ExchangersYasaswi NathNo ratings yet

- Chapter 4 FurnacesDocument36 pagesChapter 4 FurnacesMohamed AlkharashyNo ratings yet

- Shell and Tube Heat Exchanger Design ConsiderationsDocument55 pagesShell and Tube Heat Exchanger Design ConsiderationsCc12 22tNo ratings yet

- Steam Turbine Design GuideDocument27 pagesSteam Turbine Design GuideEkta Gupta50% (2)

- Fouling in Heat Exchangers - PRDDocument47 pagesFouling in Heat Exchangers - PRDPradyumna DhamangaonkarNo ratings yet

- Introduction To Heat Transfer and Heat ExchangersDocument335 pagesIntroduction To Heat Transfer and Heat Exchangersmohamed abd eldayem100% (2)

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Cavitation in Centrifugal PumpsDocument34 pagesCavitation in Centrifugal PumpsAlexanderNo ratings yet

- How To Select Shell and Tube HEDocument10 pagesHow To Select Shell and Tube HEgigihpradana100% (1)

- 1-Classification of Heat Exchangers & Selection CriteriaDocument56 pages1-Classification of Heat Exchangers & Selection CriteriaShahid_Rao786100% (1)

- SHELL AND TUBE HEAT EXCHANGER DESIGNDocument60 pagesSHELL AND TUBE HEAT EXCHANGER DESIGNniaaparamita100% (1)

- Types of Heat ExchangersDocument14 pagesTypes of Heat ExchangersMuhammadFahadIjazNo ratings yet

- Heat Transfer Heat Ex ChangersDocument116 pagesHeat Transfer Heat Ex ChangersAbubakkar Siddiq100% (1)

- Heat Exchanger (New)Document38 pagesHeat Exchanger (New)Rochie DiezNo ratings yet

- Presentation On Heat ExchangersDocument54 pagesPresentation On Heat ExchangersNagendrababu Mahapatruni100% (1)

- Shell and Tube Heat Exchanger DesignDocument25 pagesShell and Tube Heat Exchanger DesignSajid Ali100% (1)

- Claus Waste Heat Boiler Economics Part 2: Mechanical ConsiderationsDocument6 pagesClaus Waste Heat Boiler Economics Part 2: Mechanical ConsiderationsAlexNo ratings yet

- HEAT EXCHANGERS MDocument143 pagesHEAT EXCHANGERS Mmujeebmehar67% (3)

- NTIW Tube Sheet PaperDocument10 pagesNTIW Tube Sheet PaperPankaj SinglaNo ratings yet

- Heat Exchangers: Submitted To: Mr. AtifDocument12 pagesHeat Exchangers: Submitted To: Mr. Atifmak412No ratings yet

- CHAPTER 3: Heat ExchangerDocument54 pagesCHAPTER 3: Heat ExchangerSyamsul Rizal Abd ShukorNo ratings yet

- 3 - Heat Transmission Through StuctureDocument48 pages3 - Heat Transmission Through Stucturehasan bishNo ratings yet

- Heat ExchangersDocument71 pagesHeat Exchangersvenkeeku100% (2)

- Heat Exchanger AnimationDocument12 pagesHeat Exchanger AnimationShan AliNo ratings yet

- Classification of Heat ExchangerDocument19 pagesClassification of Heat ExchangerSarayu GowdaNo ratings yet

- Heat ExchangersDocument14 pagesHeat ExchangersAdrian StoicescuNo ratings yet

- Heat ExchangersDocument36 pagesHeat ExchangersSyukri ShahNo ratings yet

- Heat Exchangers: DR Ali JawarnehDocument46 pagesHeat Exchangers: DR Ali Jawarnehprasanthi100% (1)

- Chapter 11 Heat TransferDocument21 pagesChapter 11 Heat TransferaimanrslnNo ratings yet

- Shell and Tube Heat ExchangerDocument6 pagesShell and Tube Heat Exchangereafz111No ratings yet

- Overall Heat Transfer CoefficientDocument15 pagesOverall Heat Transfer CoefficientPrashant PatelNo ratings yet

- Radiation 2Document34 pagesRadiation 2Terna OrlandaNo ratings yet

- Overall Heat Transfer Coefficient 2Document37 pagesOverall Heat Transfer Coefficient 2John Harold CuaresmaNo ratings yet

- HT5Document19 pagesHT5VuiKuanNo ratings yet

- Heat ExchangersDocument29 pagesHeat Exchangersprotoscope photographyNo ratings yet

- Lecture 3-1 - Heat Exchanger CalculationsDocument50 pagesLecture 3-1 - Heat Exchanger CalculationsBilal AhmedNo ratings yet

- Heat ExchangersDocument65 pagesHeat ExchangersDionie Wilson Diestro100% (2)

- Shell and Tube Heat ExchangerDocument36 pagesShell and Tube Heat ExchangerSiti Nurshahira67% (3)

- Heat ExchangerDocument19 pagesHeat ExchangerSydney Jaydean KhanyileNo ratings yet

- Assignment 1 Q1: ELE290 Semester Jan11-Apr11Document1 pageAssignment 1 Q1: ELE290 Semester Jan11-Apr11Adiela Syuhada RoslanNo ratings yet

- DC MachineDocument20 pagesDC MachineAdiela Syuhada RoslanNo ratings yet

- Jominy End Quench Test AnalysisDocument11 pagesJominy End Quench Test Analysisanne2003900% (1)

- MARA University of Technology Faculty of Mechanical EngineeringDocument12 pagesMARA University of Technology Faculty of Mechanical EngineeringAdiela Syuhada Roslan100% (1)

- Learn About Metals and Their PropertiesDocument17 pagesLearn About Metals and Their PropertiesAzzah NazNo ratings yet

- 251 2nd Law MARDocument14 pages251 2nd Law MARAdiela Syuhada RoslanNo ratings yet

- Chapter 8 Mem371 MetrologyDocument14 pagesChapter 8 Mem371 MetrologyAdiela Syuhada RoslanNo ratings yet

- Chap2 (B) MillingDocument21 pagesChap2 (B) MillingAdiela Syuhada RoslanNo ratings yet

- 251 1stlaw Open System MARDocument9 pages251 1stlaw Open System MARAdiela Syuhada RoslanNo ratings yet

- 251 RankineCycle MARDocument17 pages251 RankineCycle MARHelmi ZainalNo ratings yet

- Chap1 Metal FormingDocument25 pagesChap1 Metal FormingAdiela Syuhada RoslanNo ratings yet

- WILMAR™ Protective Relays - 1800 SeriesDocument2 pagesWILMAR™ Protective Relays - 1800 SeriesmateusT850No ratings yet

- COACHING SET 2 MergedDocument17 pagesCOACHING SET 2 Mergedjohn-john castañedaNo ratings yet

- 6MW Wind Turbine Control Design AnalysisDocument8 pages6MW Wind Turbine Control Design Analysisoat_sohoNo ratings yet

- DEY's IED Sustainable DevelopmentDocument236 pagesDEY's IED Sustainable DevelopmentHemaline Rose100% (1)

- FullReport Status Quo Analysis of Various Segments of Electric Mobility-CompressedDocument342 pagesFullReport Status Quo Analysis of Various Segments of Electric Mobility-CompressedNishi MandaviaNo ratings yet

- All Models 1980 To 89 PDFDocument78 pagesAll Models 1980 To 89 PDFGerman HurtadoNo ratings yet

- Total Sulfur + H S Gas Analyzer: Laboratory General PurposeDocument2 pagesTotal Sulfur + H S Gas Analyzer: Laboratory General PurposeAldrin HernandezNo ratings yet

- General Purpose US FusesDocument69 pagesGeneral Purpose US FusesEliasNo ratings yet

- Gel Content & Peel Test: Benjamin Lippke, Romain PénidonDocument14 pagesGel Content & Peel Test: Benjamin Lippke, Romain PénidonKarthikeyanKarthikNo ratings yet

- Engine Lubrication GuideDocument38 pagesEngine Lubrication Guideshimi yayNo ratings yet

- Mesura Nirmal CatalogDocument48 pagesMesura Nirmal CatalogShivBharatNo ratings yet

- Operation Guide 3159: Getting AcquaintedDocument6 pagesOperation Guide 3159: Getting AcquaintedhenkNo ratings yet

- Pressure Vessel Creep Analysis: RuptureDocument7 pagesPressure Vessel Creep Analysis: RuptureFlorin TrNo ratings yet

- Physics AssignmentDocument41 pagesPhysics AssignmentMustapha KaojeNo ratings yet

- Catalogo PNRDocument115 pagesCatalogo PNRKaren Isabel Ambiado RivasNo ratings yet

- Control Major Accidents CausesDocument22 pagesControl Major Accidents CausesJahid HasanNo ratings yet

- 818PetroleumHistory6 PDFDocument1 page818PetroleumHistory6 PDFMazhar BadrNo ratings yet

- Centrifugal Compressor Settle Out Conditions TutorialDocument5 pagesCentrifugal Compressor Settle Out Conditions TutorialJHOEARGNo ratings yet

- Basics of Relays and Different Types of Relays - All InstrumentationDocument10 pagesBasics of Relays and Different Types of Relays - All InstrumentationAlex DavidNo ratings yet

- Microwave Oven Owner's ManualDocument38 pagesMicrowave Oven Owner's ManualjoseaurelianoNo ratings yet

- Difference Between Bi ND NuDocument6 pagesDifference Between Bi ND NuIzuchucku JohnNo ratings yet

- Petrochemical Industry in India - Determinants, ChallengesDocument5 pagesPetrochemical Industry in India - Determinants, Challengesvvk2cool100% (1)

- Energy Star Kids PrintDocument16 pagesEnergy Star Kids Printbala gamerNo ratings yet

- Problem Sheet 3 - External Forced Convection - WatermarkDocument2 pagesProblem Sheet 3 - External Forced Convection - WatermarkUzair KhanNo ratings yet

- The Battle of Ideas 2011 in #3 Bites: #1 EssentialsDocument5 pagesThe Battle of Ideas 2011 in #3 Bites: #1 EssentialsMala McFerretNo ratings yet

- Behaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketDocument15 pagesBehaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketMarcelo Andrés Rojas GonzálezNo ratings yet

- FAB AMT2101 PRELIM MODULE No.1 PDFDocument29 pagesFAB AMT2101 PRELIM MODULE No.1 PDFHanz AlecNo ratings yet

- 4 - Kama - Kde 6500 TWDocument2 pages4 - Kama - Kde 6500 TWJavadNo ratings yet

- Kac 728 628 528Document12 pagesKac 728 628 528solungeNo ratings yet

- Yanmar 3TNV76-DWL Engine Parts CatalogDocument20 pagesYanmar 3TNV76-DWL Engine Parts CatalogDarryl CareyNo ratings yet