Professional Documents

Culture Documents

Rotating Machines in Boilers

Uploaded by

sudhirkumar99Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotating Machines in Boilers

Uploaded by

sudhirkumar99Copyright:

Available Formats

This

project

entitled

ROTATING

MACHINES

IN

BOILERS is framed on the needs of boiler auxiliaries for a

power plant.

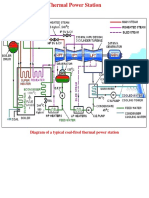

A boiler is defined as a closed vessel in which steam is produced from water by the combustion of fuel.

Here the discussions are made on major components of

rotating machines in boilers. It includes maintenance of

boilers in power plant.

The following parts come under major rotating machines in boilers :

Coal Fans Air

mills

pre-heater

Coal mill is a machine in which the 20mm size of coal from the coal feeder is grounded into fine powder. Coal mill contains four pipes surrounding a center one. Through the center pipe coal enters the mill and fine coal powder is taken to the furnace through surrounding pipes. Ungrounded particles of coal come out through the Bottom Reject Gate (BRG).

The main functions of fans are: To supply to the furnace the required quantity of air for complete combustion of fuel. To remove the gaseous products of combustion from the furnace and throw these through chimney or stack to atmosphere.

Primary air fan Forced draft fan Induced draft fan Seal air fan Scanner air fan

The main purpose of the primary air fan is to supply primary air to carry the pulverized fuel from the mill and to discharge into the furnace. It is a radial type. Primary air fan sucks the air from atmosphere pressurizes it and sends it to coal mill through primary air preheater which heats up this pressurized air.

The main purpose of this fan is to supply adequate amount of air to the furnace for maximum combustion. It is an axial type fan. The air supplied by the PAF is not sufficient for combustion process. The additional air required is supplied using FD fans.

The main purpose of this fan is to suck the flue gases from the furnace and send it to the atmosphere through chimney and maintain furnace draft. It is an axial entry and radial discharge type. It also maintains the pressure inside the furnace.

The main purpose of this fan is to supply seal air to mills to avoid contamination of gear box oil and bearings by coal entry. It is a centrifugal type fan.

The furnace consists of scanners to sense the flame. The main purpose of this fan is to supply air cleaning and cooling the flame scanners.

Air pre-heater is a general term to describe any device designed for heating air before any other process (here combustion in the boiler). The purpose of air pre-heater is to recover the heat from the flue gases exiting the boiler and transferring it to air being supplied for combustion of fuel in the boiler, thus increasing the efficiency of the boiler, and reducing useful heat loss from flue gas in the form of radiation Thus the gases are sent to chimney at a lower temperature, hence meeting the emission regulations.

20% of Total heat transfer in the boiler by APH. Decrease in boiler efficiency due to poor performance of APH 1% decrease in efficiency due to 20 oC rise in flue gas temperature. 1% improvement in boiler efficiency for each 22 oC rise in the combustion air temperature. The total fuel saving due to pre heating combustion air may be 5 to 10 %. Air heaters also make pulverized coal firing practical by drying and providing transport medium.

Fans are helpful in the regulation of pressure inside the boiler. Fans are also used in providing excess air for complete combustion. Air pre-heaters are responsible for the increase of boiler efficiency. Air pre-heaters are employed for waste heat recovery. Coal mills are used for crushing the coal into fine powder i.e. pulverization. Therefore rotating machines namely air pre-heater, fans and coal mills are necessary for the generation of steam efficiently

THANK YOU

You might also like

- Christine Holgate's Australia Post SubmissionDocument151 pagesChristine Holgate's Australia Post SubmissionNatasha RudraNo ratings yet

- Piping System DesignDocument139 pagesPiping System DesignNatty SarathunNo ratings yet

- Me Machine Design Notes 09Document26 pagesMe Machine Design Notes 09Ravi YadavNo ratings yet

- Sample Piping System Included: Valves, Reducers and ExpandersDocument10 pagesSample Piping System Included: Valves, Reducers and ExpandershpcasioNo ratings yet

- PFD Vs PIDDocument65 pagesPFD Vs PIDashirNo ratings yet

- PID Control of Heat Exchanger SystemDocument6 pagesPID Control of Heat Exchanger SystemTuấn Anh Nguyễn100% (1)

- Texas FlangeDocument76 pagesTexas FlangeDANIEL JIMENEZNo ratings yet

- Weston 981 Alignment ProcedureDocument2 pagesWeston 981 Alignment ProcedureRenato DeákNo ratings yet

- Air Pre HeaterDocument13 pagesAir Pre HeaterRaghav RajputNo ratings yet

- Study The Efficiency of Air PeheaterDocument3 pagesStudy The Efficiency of Air PeheaterManoj PatilNo ratings yet

- Furnace OperationsDocument53 pagesFurnace OperationsRana Shahid Raza100% (1)

- Boiler & AuxiliariesDocument13 pagesBoiler & Auxiliariesprats123456No ratings yet

- Gas Turbin Mark VIDocument42 pagesGas Turbin Mark VIpradeeps2007_1777402100% (3)

- Thermal Power Plant PDFDocument16 pagesThermal Power Plant PDFMoustafa MahmoudNo ratings yet

- Gas Turbine Combustion Chamber DesignDocument13 pagesGas Turbine Combustion Chamber DesignADVAITH P SHETTYNo ratings yet

- Fundamentals of Combustions and Combustion EquipmentDocument18 pagesFundamentals of Combustions and Combustion EquipmentEngr Mujahid MehdiNo ratings yet

- Thermal Power StationDocument6 pagesThermal Power StationAnkit RajNo ratings yet

- Combustion ChamberDocument3 pagesCombustion ChamberShreyash ChandakNo ratings yet

- Steam Power Plant Components & ProcessesDocument37 pagesSteam Power Plant Components & ProcessessureshlalNo ratings yet

- Air PreheaterDocument2 pagesAir PreheaterDwight AsetreNo ratings yet

- Gas Turbine Combustion Chamber Design Aspects & Current TrendsDocument24 pagesGas Turbine Combustion Chamber Design Aspects & Current TrendsPRAVEENNo ratings yet

- ON Internship IN Boiler House & Coal Plant: AT Aurobindo Pharma Ltd. Unit V PashmylaramDocument13 pagesON Internship IN Boiler House & Coal Plant: AT Aurobindo Pharma Ltd. Unit V PashmylaramKesari VelamanchiNo ratings yet

- Primary Air Fan For Thermal Power PlantsDocument6 pagesPrimary Air Fan For Thermal Power PlantsSagar AgarwalNo ratings yet

- Essential Equipment of Steam Power PlantsDocument101 pagesEssential Equipment of Steam Power Plantsjamunaa83100% (1)

- 2013edusat Lecture On STEAM PLANTDocument101 pages2013edusat Lecture On STEAM PLANTKishore KrishnaNo ratings yet

- Gas Turbine Power plantDocument14 pagesGas Turbine Power plantBouhadNo ratings yet

- Boiler Case StudyDocument17 pagesBoiler Case StudyAbu FaizNo ratings yet

- Furnace: Mohamed Mosaad Ahmed Mohamed RagabDocument33 pagesFurnace: Mohamed Mosaad Ahmed Mohamed RagabMohamed Mosaed100% (2)

- Gas Turbine - Combustion Chamber. MaykDocument69 pagesGas Turbine - Combustion Chamber. MaykAlvaro Vicente100% (3)

- Experiment No.5 To Study The Simple Gas Turbine Engine. ObjectiveDocument3 pagesExperiment No.5 To Study The Simple Gas Turbine Engine. Objectivefarah nazNo ratings yet

- Experiment No.5 To Study The Simple Gas Turbine Engine. ObjectiveDocument3 pagesExperiment No.5 To Study The Simple Gas Turbine Engine. Objectivefarah nazNo ratings yet

- Gas Turbine Power Plant ExplainedDocument21 pagesGas Turbine Power Plant ExplainedBiniam Nega100% (1)

- Automotive Turbocharged Gas Turbine.Document48 pagesAutomotive Turbocharged Gas Turbine.Santanu ChakrabortyNo ratings yet

- Primary Air SystemDocument4 pagesPrimary Air SystemShahNo ratings yet

- Essentials of Steam Power Plant EquipmentDocument102 pagesEssentials of Steam Power Plant EquipmentPrakhar Shukla100% (1)

- Boiler DraughtDocument22 pagesBoiler DraughtPolavarapu Srinivasa RaoNo ratings yet

- Increase power plant efficiency with an air preheaterDocument8 pagesIncrease power plant efficiency with an air preheaterabhishek01raiNo ratings yet

- Regenerative Air PreheaterDocument19 pagesRegenerative Air PreheaterTejas T S Tejas100% (2)

- Major Heat Losses in BoilerDocument2 pagesMajor Heat Losses in BoilerSanjay GodaraNo ratings yet

- 30 MW Power Generation ProcessDocument11 pages30 MW Power Generation ProcessMohan PNo ratings yet

- 34 Boiler Acce 2Document12 pages34 Boiler Acce 2Swaraj TodankarNo ratings yet

- 1 212 Air PreheaterDocument5 pages1 212 Air Preheaterhanafy_arnandaNo ratings yet

- Design of Gas Turbine Combustion ChamberDocument11 pagesDesign of Gas Turbine Combustion ChamberSai Rahul100% (1)

- Introduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesDocument9 pagesIntroduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesTahir MuneebNo ratings yet

- Auto Thermal Reactor Process for Methanol ProductionDocument6 pagesAuto Thermal Reactor Process for Methanol ProductionAtif MehfoozNo ratings yet

- Lec 3 BoilerDocument20 pagesLec 3 BoilerRajiv SharmaNo ratings yet

- Gas Turbine Power PlantDocument42 pagesGas Turbine Power PlantMuralikrishnan GM100% (3)

- Gas Turbine ReportDocument13 pagesGas Turbine Reportwaleed100% (1)

- Economiser Air Pre-HeaterDocument22 pagesEconomiser Air Pre-Heaterahmedimam508No ratings yet

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (1)

- Jagan Steam Power PlantDocument101 pagesJagan Steam Power PlantMahender VangalaNo ratings yet

- Module 5 Aircraft Propulsion notesDocument48 pagesModule 5 Aircraft Propulsion notesPratham M JariwalaNo ratings yet

- Reformer Convection Coils Explained PT 1 X 0Document7 pagesReformer Convection Coils Explained PT 1 X 0David PierreNo ratings yet

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 pagesGas Turbine - Traning Report Bhel - 14 PageVivek PatelNo ratings yet

- Generation of Electric PowerDocument108 pagesGeneration of Electric Powermausam sharmaNo ratings yet

- Vinayaka Vratha KalpamDocument4 pagesVinayaka Vratha KalpamPurnima GunturuNo ratings yet

- Unit - I Steam Power PlantsDocument32 pagesUnit - I Steam Power Plantsrsankarganesh MECH-HICET100% (1)

- BoilersDocument41 pagesBoilersojoo sharmaNo ratings yet

- Gas Turbine Start UpDocument131 pagesGas Turbine Start UpBaharudin Bin Kamarul Baharin100% (3)

- Introduction To Boiler 2023Document1 pageIntroduction To Boiler 2023yohannesNo ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- SSAA Power Station-Boiler Auxiliary Cooling Water SystemDocument115 pagesSSAA Power Station-Boiler Auxiliary Cooling Water Systemsudhirkumar99No ratings yet

- Nuclear Operator Job PreviewDocument16 pagesNuclear Operator Job Previewsudhirkumar99No ratings yet

- 335 Variable-Pitch Axial Flow Fans For Thermal Power StationsDocument14 pages335 Variable-Pitch Axial Flow Fans For Thermal Power Stationssudhirkumar99100% (1)

- EPRI 1000987 Mechanical Seal Maintenance and Application GuideDocument190 pagesEPRI 1000987 Mechanical Seal Maintenance and Application Guidesudhirkumar99No ratings yet

- Puts You in Control: L&T Valves LimitedDocument4 pagesPuts You in Control: L&T Valves Limitedsudhirkumar99No ratings yet

- EPRI Mill MaintenanceDocument308 pagesEPRI Mill Maintenancesprotkar100% (1)

- IhtDocument3 pagesIhtsudhirkumar99No ratings yet

- HTRWDocument17 pagesHTRWsudhirkumar99No ratings yet

- EPRI Mill MaintenanceDocument308 pagesEPRI Mill Maintenancesprotkar100% (1)

- CV1Document20 pagesCV1Murugavel VenkatNo ratings yet

- Boiler Aux.Document58 pagesBoiler Aux.Best KvansNo ratings yet

- Puts You in Control: L&T Valves LimitedDocument4 pagesPuts You in Control: L&T Valves Limitedsudhirkumar99No ratings yet

- Puts You in Control: L&T Valves LimitedDocument4 pagesPuts You in Control: L&T Valves Limitedsudhirkumar99No ratings yet

- Optimized Title for PGR Installation DocumentDocument72 pagesOptimized Title for PGR Installation Documentsudhirkumar99No ratings yet

- AVU II Skill Development 2008 09 PDFDocument43 pagesAVU II Skill Development 2008 09 PDFsudhirkumar99No ratings yet

- Urea Production ReportDocument58 pagesUrea Production Reportsudhirkumar99No ratings yet

- 335 Variable-Pitch Axial Flow Fans For Thermal Power StationsDocument14 pages335 Variable-Pitch Axial Flow Fans For Thermal Power Stationssudhirkumar99100% (1)

- Urea Production ReportDocument58 pagesUrea Production Reportsudhirkumar99No ratings yet

- Urea Production ReportDocument58 pagesUrea Production Reportsudhirkumar99No ratings yet

- Rotating Machines in BoilersDocument23 pagesRotating Machines in Boilerssudhirkumar99No ratings yet

- HPGCL27395Document24 pagesHPGCL27395sudhirkumar99No ratings yet

- Despatch Status of Commissioning Procedures1Document93 pagesDespatch Status of Commissioning Procedures1sudhirkumar99No ratings yet

- D Nit-65 3Document0 pagesD Nit-65 3sudhirkumar99No ratings yet

- Rotating Machines in BoilersDocument23 pagesRotating Machines in Boilerssudhirkumar99No ratings yet

- YgytvbDocument1 pageYgytvbsudhirkumar99No ratings yet

- HPGCL27395Document24 pagesHPGCL27395sudhirkumar99No ratings yet

- Rich Text Editor FileDocument1 pageRich Text Editor Filesudhirkumar99No ratings yet

- Jhby YgDocument1 pageJhby Ygsudhirkumar99No ratings yet

- Cv-Morten Christian MelaaenDocument19 pagesCv-Morten Christian MelaaenbbeeNo ratings yet

- Evaporation in Porous Media With Large Evaporation RatesDocument26 pagesEvaporation in Porous Media With Large Evaporation Ratesdaniel parraNo ratings yet

- Pipe Tester Valve: Pressure Tests Pipe Above The Valve While Running in HoleDocument1 pagePipe Tester Valve: Pressure Tests Pipe Above The Valve While Running in HoleluisNo ratings yet

- Rig 350 Ipn SpecificationDocument8 pagesRig 350 Ipn SpecificationBambang PermanaNo ratings yet

- Equipo Carrier 38aks028-044Document82 pagesEquipo Carrier 38aks028-044sybreed88No ratings yet

- McCabe-Thiele Distillation Column Design For A Methanol-Propanol SystemDocument12 pagesMcCabe-Thiele Distillation Column Design For A Methanol-Propanol SystemPeyton EllenNo ratings yet

- 4130-C Parker Check Valves, August 2005Document8 pages4130-C Parker Check Valves, August 2005jbjb2000No ratings yet

- Numerical Simulation of Cavity Flow Induced NoiseDocument6 pagesNumerical Simulation of Cavity Flow Induced Noise潘子豪No ratings yet

- Water TreatmentDocument45 pagesWater TreatmentSarim ChNo ratings yet

- Optimum Design of Wind Tunnel Contractions MikhailDocument7 pagesOptimum Design of Wind Tunnel Contractions MikhailsekharsamyNo ratings yet

- Unit 1 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inDocument13 pagesUnit 1 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inFno FnoNo ratings yet

- PARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGDocument26 pagesPARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGsegunju50% (2)

- DN Diametre Nominal-NPS Size ChartDocument5 pagesDN Diametre Nominal-NPS Size ChartSankar CdmNo ratings yet

- FM Global Property Loss Prevention Data SheetsDocument52 pagesFM Global Property Loss Prevention Data SheetsBototo EscobarNo ratings yet

- Integrated Design Project: CDB 2013 Separation Process I CDB 2043 Reaction EngineeringDocument34 pagesIntegrated Design Project: CDB 2013 Separation Process I CDB 2043 Reaction EngineeringMuhammad AnwarNo ratings yet

- Bernoulli ApparatusDocument4 pagesBernoulli ApparatusDarul Imran Azmi0% (1)

- Rheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageDocument7 pagesRheological Characteristics of Arabic Gum Suspension and Plantago Seeds MucilageTalha HabibNo ratings yet

- Convection Heat TransferDocument31 pagesConvection Heat TransferVuiKuanNo ratings yet

- K 442 Original MasterlogDocument5 pagesK 442 Original MasterlogAhmedNo ratings yet

- KINETICDocument9 pagesKINETICGabriel BonciuNo ratings yet

- CH306 Transport PhenomenaDocument2 pagesCH306 Transport PhenomenaMallikarjunachari GangapuramNo ratings yet

- 26 RefrigerantsDocument14 pages26 RefrigerantsPRASAD326100% (5)

- SB41Document1 pageSB41bhaaskarNo ratings yet

- PPT 02Document52 pagesPPT 02Dickson LeongNo ratings yet

- Argohytoslr PDFDocument874 pagesArgohytoslr PDFdonnyNo ratings yet

- Shengji Group Product Catalog2018Document24 pagesShengji Group Product Catalog2018SIMON S. FLORES G.No ratings yet

- Analysis and Prediction of Pumping Characteristics of High Strength ConcreteDocument300 pagesAnalysis and Prediction of Pumping Characteristics of High Strength Concreteسامح الجاسمNo ratings yet

- Pipe CNS 05Document42 pagesPipe CNS 05maria katherine pantojaNo ratings yet

- Some Notes About Corrosion Coupons InstallationDocument23 pagesSome Notes About Corrosion Coupons InstallationHadi VeyseNo ratings yet

- Operações Untárias C - Exercícios Torres de ResfriamentoDocument5 pagesOperações Untárias C - Exercícios Torres de ResfriamentoVeronica Perote SouzaNo ratings yet