Professional Documents

Culture Documents

Ee 4314 Comphnvhvn

Uploaded by

SALIMSEIF10 ratings0% found this document useful (0 votes)

27 views26 pagesThis document contains examples of compensator design for control systems. It discusses stability margins like gain margin and phase margin. It then provides examples of designing lead and lag compensators using root locus analysis and frequency response methods. The examples show how to select compensator parameters to meet specifications for rise time, overshoot, phase margin, etc. Compensators are designed for systems using proportional, lead, and double lead configurations.

Original Description:

bhjgbj

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains examples of compensator design for control systems. It discusses stability margins like gain margin and phase margin. It then provides examples of designing lead and lag compensators using root locus analysis and frequency response methods. The examples show how to select compensator parameters to meet specifications for rise time, overshoot, phase margin, etc. Compensators are designed for systems using proportional, lead, and double lead configurations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views26 pagesEe 4314 Comphnvhvn

Uploaded by

SALIMSEIF1This document contains examples of compensator design for control systems. It discusses stability margins like gain margin and phase margin. It then provides examples of designing lead and lag compensators using root locus analysis and frequency response methods. The examples show how to select compensator parameters to meet specifications for rise time, overshoot, phase margin, etc. Compensators are designed for systems using proportional, lead, and double lead configurations.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 26

EE 4314

Examples on Compensator Design

Spring 2011

Stability Margins

Gain margin: (GM): Factor

by which the gain can be

raised before instability

results

Phase margin (PM):

Amount by which the

phase of G(j) exceeds

-180 when |KG(j)|=1

Stability Margins

GM and PM are measures

of how close the Nyquist

plot comes to encircling

the -1 point

Lead Compensator Design Summary

Lag Compensator Design Summary

Design Example Root Locus (p. 261)

G s

( )

=

u s

( )

o

e

s

( )

=

160 s + 2.5

( )

s + 0.7

( )

s

2

+ 5s + 40

( )

s

2

+ 0.03s + 0.06

( )

The transfer function between the

elevator input and the pitch attitude

is

where

is the pitch angle* (degrees)

is the elevator angle (degrees)

u

o

e

Design the controller so that

1. Rise time of 1 sec or less

2. Overshoot less than 10%

* see sec 10.3 for details

Design Example Root Locus

According to the specifications:

From (3.60) p.116:

t

r

~

1.8

e

n

From (3.64) p.118:

M

p

= e

t, / 1,

2

e

n

>1.8 rad/sec

, >0.6

As a result, desired closed-loop pole should be at:

p =o je

d

where

o =, e

n

e

d

=e

n

1,

2

(3.56) p.112

Design Example Root Locus

Lets look at open loop response of the system, by using Matlab:

>> num = 160 .* conv([1 2.5], [1 0.7]);

>> den = conv([1 5 40], [1 0.03 0.06]);

>> sysOl = tf(num, den);

>> step(sysOl)

Design Example Root Locus

Now, look at the root locus of the system:

>> Wn = 1.8;

>> DR = 0.6;

>> sigma = DR * Wn;

>> Wd = Wn * sqrt(1 - DR^2);

>> p = -sigma + j*Wd;

>> q = -sigma - j*Wd;

>> rlocus(sysOl)

>> hold on

>> plot(p, '*')

>> plot(q, '*')

>> grid on

Design Example Root Locus

Root Locus Plot

Design Example Root Locus

Using rlocfind command to find the gain K that yield the closed-loop

poles that locate as close to the desired poles location as possible:

>> rlocfind(sysOl)

Select a point in the graphics window

selected_point =

-0.9755 + 0.4105i

ans =

0.3260

Use K = 0.3260

Design Example Root Locus

Use proportional gain K = 0.326 to see if it gives satisfactory close-

loop response:

>> sysClP = feedback(0.326*sysOl, 1)

Transfer function:

52.16 s^2 + 166.9 s + 91.28

--------------------------------------------

s^4 + 5.03 s^3 + 92.37 s^2 + 168.4 s + 93.68

>> step(sysClP)

The overshoot is greater than

10 %, rise time is okay.

Design Example Root Locus

Since proportional control is not enough, we can use lead

compensator as a lead compensator would shift the root locus

further to the left (lowering rise time and decreasing the transient

overshoot (p. 249).

From p. 250, the zero of the lead compensator should be placed in

the neighborhood of the desired closed-loop Wn, and the pole

of the lead compensator should be 5 to 20 times of the value of the

zero. Lets pick z = 2 (as Wn = 1.8) and p = 2 * 10 = 20.

D s

( )

= K

s + 2

s + 20

Design Example Root Locus

Now pick gain K of the lead compensator:

>> lead = tf([1 2], [1 20]);

>> sysLead = lead * sysOl;

>> rlocus(sysLead)

>> hold on

>> plot(p, '*')

>> plot(q, '*')

>> grid on

>> hold off

>> rlocfind(sysLead)

Select a point in the graphics window

selected_point =

-8.7708 +14.3523i

ans =

1.7599

Design Example Root Locus

Simulate the step response of the new closed-loop system:

>> sysClLead = feedback(1.7599 * sysLead, 1)

Transfer function:

281.6 s^3 + 1464 s^2 + 2295 s + 985.5

------------------------------------------------------

s^5 + 25.03 s^4 + 422.4 s^3 + 2270 s^2 + 2327 s + 1034

>> step(sysClLead)

Design Example Root Locus

D s

( )

=1.7599

s + 2

s + 20

Design Example Compensator Design from Freq. Response

Example 6.17 (p. 358) a Type 1 Servomechanism System

KG s

( )

= K

10

s s/2.5 +1

( )

s/6 +1

( )

Design a lead compensator so that the PM = 45 and Kv = 10.

From p. 356:

Step 1: Pick K to satisfy error constant

from p. 181

K

v

= lim

s0

sK G s

( )

= K

10

0 +1

( )

0 +1

( )

K =1

Design Example Compensator Design from Freq. Response

Step 2: Evaluate the PM of the uncompensated system using K

obtained from step 1

>> Gs = tf(10, conv([1 0], conv([1/2.5 1], [1/6 1])))

Transfer function:

10

----------------------------

0.06667 s^3 + 0.5667 s^2 + s

>> [mag, phase, w] = bode(Gs);

>> [GM, PM, Wcg, Wcp] = margin(mag, phase, w)

GM =

0.8540

PM =

-4.1158

Wcg =

3.8730

Wcp =

4.1910

Design Example Compensator Design from Freq. Response

Step 3: Add extra margin (about 5-10) and determine the phase lead

|

max

= 45

o

+ 5

o

(4

o

)

= 54

o

Step 4: Determine from (6.40) p. 349:

o

o =

1sin|

max

1+ sin|

max

o = 0.1

Step 5: Pick at the crossover frequency:

e

max

1/T =e

max

o

T ~ 0.5

D s

( )

=

Ts+1

oTs+1

=

0.5s +1

0.05s +1

Design Example Compensator Design from Freq. Response

Step 6: Draw the compensated frequency response and check the PM:

>> lead = tf([0.5 1], [0.05 1]);

>> sysLead = lead * Gs;

>> [mag, phase, w] = bode(sysLead);

>> [GM, PM, Wcg, Wcp] = margin(mag, phase, w)

GM =

2.3204

PM =

22.9367

Wcg =

11.5132

Wcp =

7.2994

Design Example Compensator Design from Freq. Response

We can use sisotool command to find GM, PM, Wcp, Wcg:

>> sisotool(sysLead)

Design Example Compensator Design from Freq. Response

Step 6: Iterate on the design until all specifications are met.

Add an additional lead compensator if necessary.

We can see that with only on lead compensator, we can only get the

PM of 23.

So, we need to repeat Step 1 Step 5 again to add additional lead

compensator.

Assuming the second iteration gives:

D s

( )

=

Ts+1

oTs+1

=

0.25s +1

0.025s +1

Design Example Compensator Design from Freq. Response

Lets check the PM new compensated system:

>> secondLead = tf([0.25 1], [0.025 1]);

>> sysDoubleLead = secondLead * sysLead;

>> [mag, phase, w] = bode(sysDoubleLead);

>> [GM, PM, Wcg, Wcp] = margin(mag, phase, w)

GM =

3.8669

PM =

45.6362

Wcg =

30.7887

Wcp =

13.7805

Design Example Compensator Design from Freq. Response

The overall compensator becomes:

D s

( )

=

0.5s +1

(0.05s +1)

0.25s +1

(0.025s +1)

Lets take a look at the step responses of the compensated system:

>> sysLeadCl = feedback(sysLead, 1);

>> sysDoubleLeadCl = feedback(sysDoubleLead, 1);

>> step(sysLeadCl)

>> hold on

>> step(sysDoubleLeadCl)

>> hold off

>> grid on

>> legend('Single Lead Compensator', 'Double Lead Compensator')

Design Example Compensator Design from Freq. Response

Step responses of the single lead compensator system vs double

lead compensator system

Compensator Design Conclusion

Lead Compensator => PD Controller

Speed up system response

Lowering the rise time

Decreasing the overshoot

Lag Compensator => PI Controller

Improve steady-state accuracy

You might also like

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Lab 1 To Study The Lead Compensator DesignDocument6 pagesLab 1 To Study The Lead Compensator DesignMuhammad AsaadNo ratings yet

- Eee 336 L7Document48 pagesEee 336 L7Rezwan ZakariaNo ratings yet

- Control Stystem PDFDocument33 pagesControl Stystem PDFArdrick BoscoNo ratings yet

- E24Document8 pagesE24ROHITCHOURASIYANo ratings yet

- PD, PI, PID Compensation: M. Sami Fadali Professor of Electrical Engineering University of NevadaDocument42 pagesPD, PI, PID Compensation: M. Sami Fadali Professor of Electrical Engineering University of NevadaAsghar AliNo ratings yet

- Lecture 8: From Analog To Digital Controllers, PID Control Design ApproachesDocument10 pagesLecture 8: From Analog To Digital Controllers, PID Control Design ApproachesarafatasgharNo ratings yet

- Compensator Design II PDFDocument37 pagesCompensator Design II PDFMani Vannan SoundarapandiyanNo ratings yet

- 1 - Compensator Design Procedure - Lead - Lag - With ExamplesDocument12 pages1 - Compensator Design Procedure - Lead - Lag - With ExamplesMadhav SNo ratings yet

- AV 315 Control System: Raman Chawla SC12B042Document37 pagesAV 315 Control System: Raman Chawla SC12B042Raman ChawlaNo ratings yet

- E24 PDFDocument8 pagesE24 PDFadil_farooq_6No ratings yet

- Tutorial 2 SolutionsDocument12 pagesTutorial 2 SolutionsZhouDaiNo ratings yet

- EE 4343/5329 - Control System Design Project: EE 4343/5329 Homepage EE 4343/5329 Course OutlineDocument14 pagesEE 4343/5329 - Control System Design Project: EE 4343/5329 Homepage EE 4343/5329 Course OutlineAkmaral NauryzgalievaNo ratings yet

- Assignment 1: Answer.1 Syms T P (T) T 2+2 t+1Document24 pagesAssignment 1: Answer.1 Syms T P (T) T 2+2 t+1tommy merlynNo ratings yet

- Control System Assignment ReportDocument6 pagesControl System Assignment ReportAamodh KuthethurNo ratings yet

- Ee481 p11 Root Locus DesignDocument77 pagesEe481 p11 Root Locus DesignDwi Ika BasithaNo ratings yet

- Lab Manual # 12 (LCS) (2018-CPE-07)Document7 pagesLab Manual # 12 (LCS) (2018-CPE-07)Momel FatimaNo ratings yet

- hw2 SolDocument11 pageshw2 SolSaied Aly SalamahNo ratings yet

- Processcontrol Topic13 PidtuningDocument15 pagesProcesscontrol Topic13 Pidtuningmuthukumartharani100% (1)

- Assignment 02: PES2UG19EC097Document25 pagesAssignment 02: PES2UG19EC097PavanKumar DaniNo ratings yet

- Assignment No: 01Document3 pagesAssignment No: 01Sudhakar KumarNo ratings yet

- Assignment No: 01Document3 pagesAssignment No: 01Sudhakar KumarNo ratings yet

- Sist Control I - Informe Nº7Document9 pagesSist Control I - Informe Nº7Rodolfo Vasquez CortezNo ratings yet

- Assignment-4: %assignment Submitted by %name: Jeswin Tom Joseph %roll - No: CH17B052Document14 pagesAssignment-4: %assignment Submitted by %name: Jeswin Tom Joseph %roll - No: CH17B052Jeswin Tom Joseph ch17b052No ratings yet

- Homewrok #1 SolutionDocument5 pagesHomewrok #1 SolutionStoyan StoyanovNo ratings yet

- B.Divya Sudha 19EE10015 Cs Session 7 Report Given PlotsDocument13 pagesB.Divya Sudha 19EE10015 Cs Session 7 Report Given PlotsDivya SudhaNo ratings yet

- Assignment 2 CONTROL SYSTEMS Name: Prateeth Rao SRN: PES2UG19EC103Document24 pagesAssignment 2 CONTROL SYSTEMS Name: Prateeth Rao SRN: PES2UG19EC103PavanKumar DaniNo ratings yet

- Practical: 1 Unit Impulse Response: Num (0 0 1) Den (1 0.2 1) Impulse (Num, Den) Grid TitleDocument20 pagesPractical: 1 Unit Impulse Response: Num (0 0 1) Den (1 0.2 1) Impulse (Num, Den) Grid TitlealwaysharshNo ratings yet

- Assignment 1 ContinuedDocument13 pagesAssignment 1 ContinuedPavanKumar DaniNo ratings yet

- From The Whole System Detailed Block DiagramDocument11 pagesFrom The Whole System Detailed Block DiagramMotasem MrwanNo ratings yet

- Ritik Dubey - Ritik Dubey-1Document10 pagesRitik Dubey - Ritik Dubey-1Saurabh KumarNo ratings yet

- 陈俊杰 10460348745 Control System Modeling Assesment 04Document19 pages陈俊杰 10460348745 Control System Modeling Assesment 04CharithNo ratings yet

- Controller Design Based On Transient Response CriteriaDocument20 pagesController Design Based On Transient Response CriteriaGapuk MaboekNo ratings yet

- Examen Control 2Document25 pagesExamen Control 2Carla SierraNo ratings yet

- The Transportation Lag: X (T) X (T-X (S) X(S)Document9 pagesThe Transportation Lag: X (T) X (T-X (S) X(S)nm2007kNo ratings yet

- Assignment 1 Design of Lead Compensator: ECTE942 Computer Controlled System: Assignment 1Document10 pagesAssignment 1 Design of Lead Compensator: ECTE942 Computer Controlled System: Assignment 1suryolNo ratings yet

- OvershootDocument13 pagesOvershootEngr Ali Sarfraz SiddiquiNo ratings yet

- Project Based Learning IcsDocument14 pagesProject Based Learning IcsAvinash YadavNo ratings yet

- CDS 101, Lecture 9.2 R. M. Murray, CaltechDocument7 pagesCDS 101, Lecture 9.2 R. M. Murray, Caltechtidjani86No ratings yet

- Transformasi Fungsi Diskrit MatlabDocument6 pagesTransformasi Fungsi Diskrit MatlabAlya SyafiiNo ratings yet

- S S TF: 3. Controller Design CalculationsDocument6 pagesS S TF: 3. Controller Design CalculationsJoy MatiwaneNo ratings yet

- E102 Using MATLAB in Feedback Systems Part I. Classical DesignDocument18 pagesE102 Using MATLAB in Feedback Systems Part I. Classical DesignLê Tuấn Minh100% (1)

- Stability of Linear Feedback SystemDocument49 pagesStability of Linear Feedback SystemNANDHAKUMAR ANo ratings yet

- Wan Amir Fuad Wajdi Othman Room: PPKEE 3.25 Ext: 6062 Email: Eeamirfuad@eng - Usm.myDocument11 pagesWan Amir Fuad Wajdi Othman Room: PPKEE 3.25 Ext: 6062 Email: Eeamirfuad@eng - Usm.myBruce ChanNo ratings yet

- CSD Practical MannualDocument35 pagesCSD Practical MannualitsurturnNo ratings yet

- Lab Manual Talha Faizan PNO:50799 Second Year Electronics Communication SystemDocument23 pagesLab Manual Talha Faizan PNO:50799 Second Year Electronics Communication SystemRamsha TariqNo ratings yet

- Project Report Linear SystemsDocument39 pagesProject Report Linear SystemsMd.tanvir Ibny GiasNo ratings yet

- DC DrivesDocument50 pagesDC DrivesjvilasisNo ratings yet

- Antenna Azimuth Position Control System Modelling, AnalysisDocument30 pagesAntenna Azimuth Position Control System Modelling, AnalysisMbongeni Maxwell100% (3)

- Ee3304 hw1 SLNDocument11 pagesEe3304 hw1 SLNzerocoderNo ratings yet

- KashoocontrollDocument5 pagesKashoocontrollMuhammadwaqasnaseemNo ratings yet

- Mathematical Modelling& Various Control System Models & Responses Using MatlabDocument45 pagesMathematical Modelling& Various Control System Models & Responses Using MatlabJagabandhu KarNo ratings yet

- DC Motor Speed: Digital Controller Design: Eng Mohamed DobaDocument20 pagesDC Motor Speed: Digital Controller Design: Eng Mohamed DobaEng. Ibrahim Abdullah AlruhmiNo ratings yet

- The Frecuency-Response Design Method: Universidad Politecnica SalesianaDocument28 pagesThe Frecuency-Response Design Method: Universidad Politecnica SalesianaFabiola ChachaNo ratings yet

- Compte Rendu TP1 Automatique Linéaire: - Hicham Elfarissi - Abdessamad Guessous - QmsiDocument21 pagesCompte Rendu TP1 Automatique Linéaire: - Hicham Elfarissi - Abdessamad Guessous - QmsiAbdessamad GuessousNo ratings yet

- Pre Lab Tasks:: Task 1Document13 pagesPre Lab Tasks:: Task 1Hammad SattiNo ratings yet

- Analysis and Design of Linear Control Systems, 06thDocument6 pagesAnalysis and Design of Linear Control Systems, 06thNikola MicicNo ratings yet

- A Instrument Landing System AccountingDocument13 pagesA Instrument Landing System AccountingvasudhaaaaaNo ratings yet

- Automatic Voltage RegulatorsDocument35 pagesAutomatic Voltage RegulatorsAlejandroHerreraGurideChileNo ratings yet

- Control System Performance PDFDocument18 pagesControl System Performance PDFChibueze EzeokaforNo ratings yet

- Brembo CatalogDocument24 pagesBrembo CatalogMr.JohnNo ratings yet

- TimelineDocument1 pageTimelineSALIMSEIF1No ratings yet

- TimelineDocument1 pageTimelineSALIMSEIF1No ratings yet

- Data TiresDocument0 pagesData TiresSALIMSEIF1No ratings yet

- Ceng Ebook PDFDocument14 pagesCeng Ebook PDFMahnooranjumNo ratings yet

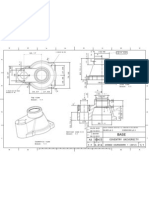

- Said Salim 205med Cw1 Tech DrawingDocument1 pageSaid Salim 205med Cw1 Tech DrawingSALIMSEIF1No ratings yet

- Vem BrochureDocument8 pagesVem BrochureVamshi Krishnam Raju NadimpalliNo ratings yet

- Revised Malaysian Code of Practice For Structural Use of TimberDocument6 pagesRevised Malaysian Code of Practice For Structural Use of Timbermcwong_98No ratings yet

- Master Antenna Television System and Satellite SystemDocument6 pagesMaster Antenna Television System and Satellite SystemMHEP_DANIELNo ratings yet

- UAMDocument35 pagesUAMVishnu R PuthusseryNo ratings yet

- Flight DynamicsDocument57 pagesFlight DynamicsDexto100% (2)

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 pagesInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNo ratings yet

- SMD Resistor ExamplesDocument5 pagesSMD Resistor Examplesmarcbuss100% (1)

- DUNAN Fan Coil UnitDocument14 pagesDUNAN Fan Coil UnitDjordjeNo ratings yet

- SAX Brochure - Web ReadyDocument4 pagesSAX Brochure - Web ReadyEng-Ahmad Abo-AledousNo ratings yet

- 02 Chain Surveying PDFDocument47 pages02 Chain Surveying PDFch_nadeemhussain50% (2)

- Mix Design Practice For Bituminous MixDocument49 pagesMix Design Practice For Bituminous MixAshwani KesharwaniNo ratings yet

- Java SampleExamQuestionsDocument18 pagesJava SampleExamQuestionshmasryNo ratings yet

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)SonratNo ratings yet

- Oilon 4A Monox en StandardDocument16 pagesOilon 4A Monox en StandardWilbert Consuelo CotrinaNo ratings yet

- Welding ProceduresDocument11 pagesWelding ProceduresnamasralNo ratings yet

- A C +Haier+12000+BTUDocument51 pagesA C +Haier+12000+BTUfox7878No ratings yet

- EWF2703 TV EmersonDocument57 pagesEWF2703 TV EmersonEriksson Miguel Tapia SolisNo ratings yet

- VNX Unified Storage ManagementDocument3 pagesVNX Unified Storage ManagementNicoleNo ratings yet

- HHW 35 m6 GBDocument6 pagesHHW 35 m6 GBSuper WhippedNo ratings yet

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- How To Build Pyramids and Other Orgone GeneratorsDocument6 pagesHow To Build Pyramids and Other Orgone GeneratorsGuy Jones100% (2)

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Document26 pagesDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilNo ratings yet

- Astm A769 PDFDocument5 pagesAstm A769 PDFCristian OtivoNo ratings yet

- Uponor Dop Klett CPR 20 Ic 251 V 001Document3 pagesUponor Dop Klett CPR 20 Ic 251 V 001jamppajoo2No ratings yet

- IMDSDocument13 pagesIMDSJohn OoNo ratings yet

- Update Notifikasi Depkes FEB 18Document6 pagesUpdate Notifikasi Depkes FEB 18pratistanadia_912023No ratings yet

- Digital Pressure Gauge XP2i PSI Data Sheet USDocument5 pagesDigital Pressure Gauge XP2i PSI Data Sheet USAbdurrachman JalaludinNo ratings yet

- How To Fix - External Disk Drive Suddenly Became RAWDocument96 pagesHow To Fix - External Disk Drive Suddenly Became RAWAntonio Marcano0% (1)

- Use of Multimeter TextDocument76 pagesUse of Multimeter Textprueba1100% (2)

- PDRXDocument4 pagesPDRXNeel AdwaniNo ratings yet