Professional Documents

Culture Documents

Furnaces and Refractories

Uploaded by

Mostafa MohamedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Furnaces and Refractories

Uploaded by

Mostafa MohamedCopyright:

Available Formats

Training Session on Energy Equipment

Furnaces and Refractories

Presentation from the Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

1 UNEP 2006

Training Agenda: Steam

Introduction

Type of furnaces and refractory materials

Assessment of furnaces

Energy efficiency opportunities

2 UNEP 2006

Introduction

What is a Furnace?

Equipment to melt metals

Casting Change shape Change properties

Type of fuel important

Mostly liquid/gaseous fuel or electricity

Low efficiencies due to

High operating temperature Emission of hot exhaust gases

3 UNEP 2006

Introduction

Chimney: remove combustion gases

Burners: raise or maintain chamber temperature

Furnace Components

Furnace chamber: constructed of insulating materials Hearth: support or carry the steel. Consists of refractory materials

Charging & discharging doors for loading & unloading stock

(The Carbon Trust)

4 UNEP 2006

Introduction

What are Refractories:

Materials that

Withstand high temperatures and sudden changes Withstand action of molten slag, glass, hot gases etc Withstand load at service conditions Withstand abrasive forces Conserve heat Have low coefficient of thermal expansion Will not contaminate the load

5 UNEP 2006

Introduction

Refractories

Refractory lining of a furnace arc

Refractory walls of a furnace interior with burner blocks

(BEE India, 2005)

6 UNEP 2006

Introduction

Properties of Refractories

Melting point

Temperature at which a test pyramid (cone) fails to support its own weight

Size

Affects stability of furnace structure

Bulk density

Amount of refractory material within a volume (kg/m3) High bulk density = high volume stability, heat capacity and resistance

7 UNEP 2006

Introduction

Properties of Refractories

Porosity

Volume of open pores as % of total refractory volume Low porosity = less penetration of molten material

Cold crushing strength

Resistance of refractory to crushing

Creep at high temperature

Deformation of refractory material under stress at given time and temperature

8 UNEP 2006

Introduction

Properties of Refractories

Pyrometric cones

Used in ceramic industries to test refractoriness of refractory bricks Each cone is mix of oxides that melt at specific temperatures

(BEE India, 2004)

Pyrometric Cone Equivalent (PCE)

Temperature at which the refractory brick and the cone bend Refractory cannot be used above this temp

9 UNEP 2006

Introduction

Properties of Refractories

Volume stability, expansion & shrinkage

Permanent changes during refractory service life Occurs at high temperatures

Reversible thermal expansion

Phase transformations during heating and cooling

10 UNEP 2006

Introduction

Properties of Refractories

Thermal conductivity

Depends on composition and silica content Increases with rising temperature

High thermal conductivity:

Heat transfer through brickwork required E.g. recuperators, regenerators

Low thermal conductivity:

Heat conservation required (insulating refractories) E.g. heat treatment furnaces

11 UNEP 2006

Training Agenda: Steam

Introduction

Type of furnaces and refractory materials

Assessment of furnaces

Energy efficiency opportunities

12 UNEP 2006

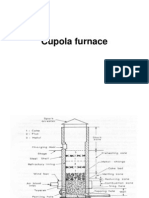

Type of Furnaces and Refractories

Type of Furnaces

Forging furnaces Re-rolling mill furnaces Continuous reheating furnaces

Type of Refractories Type of Insulating Materials

13 UNEP 2006

Type of Furnaces and Refractories

Classification Combustion Furnaces

Classification method

1. Type of fuel used

Types and examples

Oil-fired Gas-fired Coal-fired

2. Mode of charging materials

Intermittent / Batch Periodical Forging Re-rolling (batch/pusher) Pot Continuous Pusher Walking beam Walking hearth Continuous recirculating bogie furnaces Rotary hearth furnaces

3. Mode of heat transfer

Radiation (open fire place) Convection (heated through medium)

4. Mode of waste heat recovery

Recuperative Regenerative

14 UNEP 2006

Type of Furnaces and Refractories

Forging Furnace

Used to preheat billets/ingots Use open fireplace system with radiation heat transmission Temp 1200-1250 oC Operating cycle

Heat-up time Soaking time Forging time

Fuel use: depends on material and 15 number of reheats UNEP 2006

Type of Furnaces and Refractories

Re-rolling Mill Furnace Batch type

Box type furnace

Used for heating up scrap/ingots/billets

Manual charge / discharge of batches

Temp 1200 oC

Operating cycle: heat-up, re-rolling Output 10 - 15 tons/day Fuel use: 180-280 kg coal/ton material

16 UNEP 2006

Type of Furnaces and Refractories

Re-rolling Mill Furnace Continuous pusher type

Not batch, but continuous charge and discharge

Temp 1250 oC Operating cycle: heat-up, re-rolling Output 20-25 tons/day

Heat absorption by material is slow, steady, uniform

17 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

Continuous material flow

Material temp 900 1250 oC

Door size minimal to avoid air infiltration Stock kept together and pushed

Pusher type furnaces

Stock on moving hearth or structure

Walking beam, walking hearth, continuous recirculating bogie, rotary hearth furnaces

18 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

1. Pusher Furnace

Pushers on skids (rails) with water-cooled support push the stock Hearth sloping towards discharge end Burners at discharge end or top and/or bottom Chimney with recuperator for waste heat recovery

(The Carbon Trust, 1993) 19 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

2. Walking Beam Furnace

Stock placed on stationary ridges Walking beams raise the stock and move forwards Walking beams lower stock onto stationary ridges at exit Stock is removed Walking beams return to furnace entrance

(The Carbon Trust, 1993)

20 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

3. Walking Hearth Furnace

Refractory blocks extend through hearth openings Stock rests on fixed refractory blocks Stock transported in small steps walking the hearth Stock removed at discharge end

(The Carbon Trust, 1993)

21 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

4. Continuous Recirculating Bogie Furnace

Shape of long and narrow tunnel Stock placed on bogie (cart with wheels) with refractory hearth Several bogies move like train Stock removed at discharge end Bogie returned to entrance

(The Carbon Trust, 1993)

22 UNEP 2006

Type of Furnaces and Refractories

Continuous Reheating Furnaces

5. Rotary Hearth Furnace

Walls and roof remain stationary Hearth moves in circle on rollers Stock placed on hearth Heat moves in opposite direction of hearth Temp 1300oC

(The Carbon Trust, 1993)

23 UNEP 2006

Type of Furnaces and Refractories

Classification of Refractories

Classification method Chemical composition

ACID, which readily combines with bases BASIC, which consists mainly of metallic oxides that resist the action of bases NEUTRAL, which does not combine with acids nor bases Special Silica, Semisilica, Aluminosilicate Magnesite, Chrome-magnesite, Magnesitechromite, Dolomite Fireclay bricks, Chrome, Pure Alumina Carbon, Silicon Carbide, Zirconia Blast furnace casting pit

Examples

End use

Method of manufacture

Dry press process, fused cast, hand moulded, formed normal, fired or chemically bonded, unformed (monolithics, plastics, ramming mass, gunning castable, spraying)

24 UNEP 2006

Type of Furnaces and Refractories

Fireclay Refractories

Common in industry: materials available and inexpensive Consist of aluminium silicates Decreasing melting point (PCE) with increasing impurity and decreasing AL2O3

High Alumina Refractories

45 - 100% alumina

High alumina % = high refractoriness

Applications: hearth and shaft of blast furnaces, ceramic kilns, cement kilns, glass tanks

25 UNEP 2006

Type of Furnaces and Refractories

Silica Brick

>93% SiO2 made from quality rocks Iron & steel, glass industry Advantages: no softening until fusion point is reached; high refractoriness; high resistance to spalling, flux and slag, volume stability

Magnesite

Chemically basic: >85% magnesium oxide

Properties depend on silicate bond concentration

High slag resistance, especially lime and iron

26 UNEP 2006

Type of Furnaces and Refractories

Chromite Refractories

Chrome-magnesite

15-35% Cr2O3 and 42-50% MgO Used for critical parts of high temp furnaces Withstand corrosive slags High refractories

Magnesite-chromite

>60% MgO and 8-18% Cr2O3 High temp resistance Basic slags in steel melting Better spalling resistance

27 UNEP 2006

Type of Furnaces and Refractories

Zirconia Refractories

Zirconium dioxide ZrO2

Stabilized with calcium, magnesium, etc.

High strength, low thermal conductivity, not reactive, low thermal loss Used in glass furnaces, insulating refractory

Oxide Refractories (Alumina)

Aluminium oxide + alumina impurities Chemically stable, strong, insoluble, high resistance in oxidizing and reducing atmosphere Used in heat processing industry, crucible shaping 28

UNEP 2006

Type of Furnaces and Refractories

Monolithics

Single piece casts in equipment shape

Replacing conventional refractories

Advantages

Elimination of joints Faster application Heat savings Better spalling resistance Volume stability Easy to transport, handle, install Reduced downtime for repairs

29 UNEP 2006

Type of Furnaces and Refractories

Insulating Materials Classification

Material with low heat conductivity: keeps furnace surface temperature low Classification into five groups

Insulating bricks Insulating castables and concrete Ceramic fiber Calcium silicate Ceramic coatings (high emissivity coatings)

30 UNEP 2006

Type of Furnaces and Refractories

Castables and Concretes

Consist of

Insulation materials used for making piece refractories Concretes contain Portland or high-alumina cement

Application

Monolithic linings of furnace sections Bases of tunnel kiln cars in ceramics industry

31 UNEP 2006

Type of Furnaces and Refractories

Ceramic Fibers

Thermal mass insulation materials

Manufactured by blending alumina and silica

Bulk wool to make insulation products

Blankets, strips, paper, ropes, wet felt etc

Produced in two temperature grades

32 UNEP 2006

Type of Furnaces and Refractories

Ceramic Fibers

Remarkable properties and benefits

Low thermal conductivity Light weight Lower heat storage Thermal shock resistant Chemical resistance Mechanical resilience Low installation costs Ease of maintenance Ease of handling Thermal efficiency Lightweight furnace Simple steel fabrication work Low down time Increased productivity Additional capacity Low maintenance costs Longer service life High thermal efficiency Faster response

33 UNEP 2006

Type of Furnaces and Refractories

High Emissivity Coatings

Emissivity: ability to absorb and radiate heat Coatings applied to interior furnace surface:

emissivity stays constant Increase emissivity from 0.3 to 0.8 Uniform heating and extended refractory life Fuel reduction by up to 25-45%

34 UNEP 2006

Type of Furnaces and Refractories

High Emissivity Coatings

(BEE India, 2005)

35 UNEP 2006

Training Agenda: Steam

Introduction

Type of furnaces and refractory materials

Assessment of furnaces

Energy efficiency opportunities

36 UNEP 2006

Assessment of Furnaces

Heat Losses Affecting Furnace Performance

Heat input FURNACE

Heat in stock

Flue gas

Moisture in fuel

Hydrogen in fuel

Openings in furnace

Furnace surface/skin

Other losses

37 UNEP 2006

Assessment of Furnaces

Instruments to Assess Furnace Performance

Parameters to be measured

Furnace soaking zone temperature (reheating furnaces) Flue gas temperature

Location of measurement

Soaking zone and side wall

Instrument required

Pt/Pt-Rh thermocouple with indicator and recorder Chromel Alummel Thermocouple with indicator Hg in steel thermometer Low pressure ring gauge

Required Value

1200-1300oC

In duct near the discharge end, and entry to recuperator After recuperator Near charging end and side wall over the hearth

700oC max.

Flue gas temperature Furnace hearth pressure in the heating zone

300oC (max) +0.1 mm of Wc

Oxygen in flue gas

In duct near the discharge end

Fuel efficiency monitor for oxygen and temperature

5% O2

Billet temperature

Portable

Infrared pyrometer or optical pyrometer

38 UNEP 2006

Assessment of Furnaces

Calculating Furnace Performance

Direct Method

Thermal efficiency of furnace = Heat in the stock / Heat in fuel consumed for heating the stock Heat in the stock Q:

Q = m x Cp (t1 t2)

Q = Quantity of heat of stock in kCal m = Weight of the stock in kg Cp= Mean specific heat of stock in kCal/kg oC t1 = Final temperature of stock in oC 39 t2 = Initial temperature of the stock before it enters the furnace in oC UNEP 2006

Assessment of Furnaces

Calculating Furnace Performance

Direct Method - example

Heat in the stock Q =

Efficiency =

Heat loss = 100% - 25% = 75%

m = Weight of the stock = 6000 kg Cp= Mean specific heat of m x Cp (t1 t2) stock = 0.12 kCal/kg oC 6000 kg X 0.12 X (1340 40) t1 = Final temperature of 936000 kCal stock = 1340 oC t2 = Initial temperature of the stock = 40 oC (heat input / heat output) x 100 Calorific value of oil = 10000 [936000 / (368 x 10000) x 100 = 25.43% kCal/kg Fuel consumption = 368 kg/hr 40 UNEP 2006

Assessment of Furnaces

Calculating Furnace Performance

Indirect Method Heat losses

a) Flue gas loss = 57.29 %

b) Loss due to moisture in fuel

c) Loss due to H2 in fuel d) Loss due to openings in furnace e) Loss through furnace skin Total losses

= 1.36 %

= 9.13 % = 5.56 % = 2.64 % = 75.98 %

Furnace efficiency =

Heat supply minus total heat loss

100% 76% = 24%

41 UNEP 2006

Assessment of Furnaces

Calculating Furnace Performance

Typical efficiencies for industrial furnaces

Furnace type

1) Low Temperature furnaces

a. 540 980 oC (Batch type) b. 540 980 oC (Continous type) c. Coil Anneal (Bell) radiant type d. Strip Anneal Muffle 20-30 15-25 5-7 7-12

Thermal efficiencies (%)

2) High temperature furnaces

a. Pusher, Rotary b. Batch forge 7-15 5-10

3) Continuous Kiln

a. Hoffman b. Tunnel 25-90 20-80

4) Ovens

a. Indirect fired ovens (20 oC 370 oC) b. Direct fired ovens (20 oC 370 oC) 35-40 35-40

42 UNEP 2006

Training Agenda: Steam

Introduction

Type of furnaces and refractory materials

Assessment of furnaces

Energy efficiency opportunities

43 UNEP 2006

Energy Efficiency Opportunities

1. Complete combustion with minimum excess air 2. Proper heat distribution 3. Operation at the optimum furnace temperature 4. Reducing heat losses from furnace openings 5. Maintaining correct amount of furnace draft

6. Optimum capacity utilization

7. Waste heat recovery from the flue gases 8. Minimize furnace skin losses

9. Use of ceramic coatings

10.Selecting the right refractories

44 UNEP 2006

Energy Efficiency Opportunities 1. Complete Combustion with Minimum Excess Air

Importance of excess air

Too much: reduced flame temp, furnace temp, heating rate Too little: unburnt in flue gases, scale losses

Indication of excess air: actual air / theoretical combustion air Optimizing excess air

Control air infiltration Maintain pressure of combustion air Ensure high fuel quality Monitor excess air

45 UNEP 2006

Energy Efficiency Opportunities

2. Proper Heat Distribution

When using burners

Flame should not touch or be obstructed

No intersecting flames from different burners Burner in small furnace should face upwards but not hit roof More burners with less capacity (not one big burner) in large furnaces Burner with long flame to improve uniform heating in small furnace

46 UNEP 2006

Energy Efficiency Opportunities

3. Operate at Optimum Furnace Temperature

Operating at too high temperature:

heat loss, oxidation, decarbonization, refractory stress

Automatic controls eliminate human error

Slab Reheating furnaces 1200oC

Rolling Mill furnaces Bar furnace for Sheet Mill

Bogie type annealing furnaces

1200oC 800oC

650oC 750oC

47 UNEP 2006

Energy Efficiency Opportunities

4. Reduce Heat Loss from Furnace Openings

Heat loss through openings

Direct radiation through openings Combustion gases leaking through the openings Biggest loss: air infiltration into the furnace

Energy saving measures

Keep opening small Seal openings Open furnace doors less frequent and shorter

48 UNEP 2006

Energy Efficiency Opportunities

5. Correct Amount of Furnace Draft

Negative pressure in furnace: air infiltration Maintain slight positive pressure Not too high pressure difference: air ex-filtration

Heat loss only about 1% if furnace pressure is controlled properly!

49 UNEP 2006

Energy Efficiency Opportunities

6. Optimum Capacity Utilization

Optimum load

Underloading: lower efficiency Overloading: load not heated to right temp

Optimum load arrangement

Load receives maximum radiation Hot gases are efficiently circulated Stock not placed in burner path, blocking flue system, close to openings

Optimum residence time

Coordination between personnel

Planning at design and installation

50 stage UNEP 2006

Energy Efficiency Opportunities

7. Waste Heat Recovery from Flue Gases

Charge/Load pre-heating

Reduced fuel needed to heat them in furnace

Pre-heating of combustion air

Applied to compact industrial furnaces Equipment used: recuperator, selfrecuperative burner Up to 30% energy savings

Heat source for other processes

Install waste heat boiler to produce steam Heating in other equipment (with care!)

51 UNEP 2006

Energy Efficiency Opportunities

8. Minimum Furnace Skin Loss

Choosing appropriate refractories

Increasing wall thickness

Installing insulation bricks (= lower conductivity) Planning furnace operating times

24 hrs in 3 days: 100% heat in refractories lost 8 hrs/day for 3 days: 55% heat lost

52 UNEP 2006

Energy Efficiency Opportunities

9. Use of Ceramic Coatings

High emissivity coatings Long life at temp up to 1350 oC Most important benefits

Rapid efficient heat transfer Uniform heating and extended refractory life Emissivity stays constant

Energy savings: 8 20%

53 UNEP 2006

Energy Efficiency Opportunities

10. Selecting the Right Refractory

Selection criteria

Type of furnace

Type of metal charge Presence of slag Structural load of furnace

Stress due to temp gradient & fluctuations

Chemical compatibility

Area of application

Working temperatures Extent of abrasion and impact

Heat transfer & fuel conservation

Costs

54 UNEP 2006

Training Session on Energy Equipment

Furnaces and Refractories

THANK YOU FOR YOUR ATTENTION

55 UNEP 2006

Disclaimers and References

This PowerPoint training session was prepared as part of the project Greenhouse Gas Emission Reduction from Industry in Asia and the Pacific (GERIAP). While reasonable efforts have been made to ensure that the contents of this publication are factually correct and properly referenced, UNEP does not accept responsibility for the accuracy or completeness of the contents, and shall not be liable for any loss or damage that may be occasioned directly or indirectly through the use of, or reliance on, the contents of this publication. UNEP, 2006. The GERIAP project was funded by the Swedish International Development Cooperation Agency (Sida) Full references are included in the textbook chapter that is available on www.energyefficiencyasia.org

56 UNEP 2006

You might also like

- RefractoriesDocument31 pagesRefractoriesChandra Shekar Reddy Yelety100% (2)

- Insulation - RefractoriesDocument32 pagesInsulation - RefractoriesSantosh ThapaNo ratings yet

- Furnaces and RefractoriesDocument54 pagesFurnaces and RefractoriesYuvaraj ChinthNo ratings yet

- Furnace and Rferactory CalculationsDocument210 pagesFurnace and Rferactory Calculationsfsijest100% (2)

- 4.12.1 Types and Classification of Different FurnacesDocument7 pages4.12.1 Types and Classification of Different FurnacesSheikh Muhammad Sikandar100% (1)

- Furnaces and Refractories: 6. WorksheetsDocument36 pagesFurnaces and Refractories: 6. WorksheetsDHSanjNo ratings yet

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyFrom EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- Combustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsFrom EverandCombustion and Mass Transfer: A Textbook with Multiple-Choice Exercises for Engineering StudentsRating: 3 out of 5 stars3/5 (1)

- Induction FurnaceDocument7 pagesInduction FurnaceDeepak Velusamy100% (2)

- Reheating Furnace.3Document8 pagesReheating Furnace.3Zulfa Ilham BasyarahilNo ratings yet

- Types of Reheating FurnacesDocument4 pagesTypes of Reheating FurnacesziadNo ratings yet

- Hot Transport - HTVDocument2 pagesHot Transport - HTVAnton SoewitoNo ratings yet

- Furnace DesignDocument30 pagesFurnace DesignTARIQ46767% (3)

- Furnaces and RefractoriesDocument68 pagesFurnaces and RefractoriesSachith Praminda Rupasinghe0% (1)

- Continuos Steel Reheating Furnaces: Specification, Design and EquipmentDocument68 pagesContinuos Steel Reheating Furnaces: Specification, Design and EquipmentVishal Duggal83% (12)

- Refractory workshop – Castable selection and installation guideDocument37 pagesRefractory workshop – Castable selection and installation guideElwathig Bakhiet100% (4)

- Study Material On RefractoriesDocument6 pagesStudy Material On RefractoriesSoumalyaBhowmikNo ratings yet

- Overview of RefractoriesDocument54 pagesOverview of Refractoriesssmith2007No ratings yet

- Design of Refractory LiningDocument31 pagesDesign of Refractory Liningabdulscribd100% (12)

- Refractory Installation Drying and Heating GuideDocument24 pagesRefractory Installation Drying and Heating GuideAnonymous NxpnI6jC100% (2)

- Midrex NGDocument8 pagesMidrex NGMohsen ArdestaniNo ratings yet

- 4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFDocument5 pages4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFSatria PurwantoNo ratings yet

- Heat Treating FurnacesDocument63 pagesHeat Treating FurnacesNawaz KhanNo ratings yet

- Boiler and FurnaceDocument42 pagesBoiler and FurnaceEr Bali PandhareNo ratings yet

- Refractory BricksDocument19 pagesRefractory BricksNael100% (3)

- How fiber addition affects properties of low cement castablesDocument4 pagesHow fiber addition affects properties of low cement castablesAndrian Hadiana100% (1)

- Industrial Burners HandbookDocument47 pagesIndustrial Burners HandbookLeydi HernandezNo ratings yet

- Furnace: Mohamed Mosaad Ahmed Mohamed RagabDocument33 pagesFurnace: Mohamed Mosaad Ahmed Mohamed RagabMohamed Mosaed100% (2)

- Shell CorrosionDocument33 pagesShell CorrosionManekGorisNo ratings yet

- Cold Bonding of Iron Ore Concentrate PelletsDocument7 pagesCold Bonding of Iron Ore Concentrate PelletsJaq Plin PlinNo ratings yet

- 2012 Lecture BKC Insulations & RefractoryDocument30 pages2012 Lecture BKC Insulations & Refractorydeb_bratapalNo ratings yet

- Design Modifications in Coal-Based Sponge Iron Plant Using Modified Pinch ApproachDocument264 pagesDesign Modifications in Coal-Based Sponge Iron Plant Using Modified Pinch ApproachAmit Kumar SinghNo ratings yet

- RHI MR Services Bulletin 1 2012-DataDocument64 pagesRHI MR Services Bulletin 1 2012-DataSuphi Yüksel100% (1)

- RDCIS introduction energy efficient refractories reheating furnacesDocument24 pagesRDCIS introduction energy efficient refractories reheating furnacescet.ranchi7024No ratings yet

- Furnace Design FundamentalsDocument9 pagesFurnace Design FundamentalsnastaranbNo ratings yet

- 2.assessment of FurnacesDocument16 pages2.assessment of FurnacesDeepak JayNo ratings yet

- MME 2506 Refractory Materials 6Document47 pagesMME 2506 Refractory Materials 6dibyendu ChakrabartyNo ratings yet

- Catalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908Document188 pagesCatalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908iMiklaeNo ratings yet

- Direct From MidrexDocument10 pagesDirect From MidrexLekhamani YadavNo ratings yet

- Ironmaking SSDocument459 pagesIronmaking SSAnjaniAkulaNo ratings yet

- Refractory Thk. Cal.Document1 pageRefractory Thk. Cal.Pradeep Kothapalli100% (1)

- Ladle RefractoryDocument26 pagesLadle RefractoryRavindra Kashyap100% (2)

- Alternative Fuels and RefractoriesDocument43 pagesAlternative Fuels and RefractoriesMehmet CNo ratings yet

- Magnalenz Induction Furnace Benefits Lower Cost Cleaner MeltingDocument31 pagesMagnalenz Induction Furnace Benefits Lower Cost Cleaner Meltingassar_metalNo ratings yet

- Neutral Refractories 2021Document36 pagesNeutral Refractories 2021Daniel AppuingNo ratings yet

- Blast Furnace Water Recirculation SystemDocument19 pagesBlast Furnace Water Recirculation SystemDaniel Seixas Breda100% (1)

- Advances in Modern Refractory CastableDocument12 pagesAdvances in Modern Refractory CastableBagas Prasetyawan Adi Nugroho100% (1)

- Study of Blast Furnace Cooling StaveDocument7 pagesStudy of Blast Furnace Cooling StavecaapasaNo ratings yet

- PDF ST Nanobond e - 04 2019.en.22Document8 pagesPDF ST Nanobond e - 04 2019.en.22Henry Sunarko100% (1)

- Optimisation of Reheat Furnace - Air PreheaterDocument6 pagesOptimisation of Reheat Furnace - Air PreheaterLTE002No ratings yet

- Factors Affecting Coke Rate in A Blast Furnace - Ispatguru PDFDocument3 pagesFactors Affecting Coke Rate in A Blast Furnace - Ispatguru PDFWallisson Mendes OsiasNo ratings yet

- Fluxes For MetallurgyDocument15 pagesFluxes For Metallurgyramau619No ratings yet

- Refractory Materials IntroductionDocument25 pagesRefractory Materials IntroductionTaha KhanNo ratings yet

- Mathios Refractories Catalog Web EditionDocument102 pagesMathios Refractories Catalog Web EditionEvangelos TentisNo ratings yet

- Sintering of Iron Ore PDFDocument32 pagesSintering of Iron Ore PDFDhiraj KadheNo ratings yet

- Blast Furnace RunnersDocument39 pagesBlast Furnace Runnershengki100% (4)

- Rotary KilnDocument12 pagesRotary KilnNasjilah Muhayati100% (1)

- SIC Refractory CastableDocument5 pagesSIC Refractory CastableJagadeesh GuttiNo ratings yet

- PlumbingDocument1 pagePlumbingPam Ingenieria Construyendo IdeasNo ratings yet

- HIT RE 500 Underwater ApplicationsDocument5 pagesHIT RE 500 Underwater Applicationsdaniel0% (1)

- Non Food Manufacturing Plant ChecklistDocument17 pagesNon Food Manufacturing Plant ChecklistJo YabotNo ratings yet

- Sparing PhilosophyDocument1 pageSparing PhilosophyKevin J. Mills100% (2)

- Annual Barangay Youth Investment Program Cy: 2022 Center of Participation: EducationDocument6 pagesAnnual Barangay Youth Investment Program Cy: 2022 Center of Participation: EducationArman Bentain100% (1)

- Q1-M1 - Information Gathering For Everyday Life UsageDocument37 pagesQ1-M1 - Information Gathering For Everyday Life UsageAillen SumagaysayNo ratings yet

- Plastics and RubbersDocument11 pagesPlastics and RubbersChin-Chin AbejarNo ratings yet

- Packaging Functions OverviewDocument25 pagesPackaging Functions OverviewRami AbdelaalNo ratings yet

- CPVC ModelDocument1 pageCPVC ModelZhu Chen ChuanNo ratings yet

- Project Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Document47 pagesProject Sustainable Design Management: Methodology For Sustainable Solutions (BIM Book)Nhan DoNo ratings yet

- LEED v4.1 BD+CDocument164 pagesLEED v4.1 BD+CYash MalaniNo ratings yet

- Product and Service Design: Mcgraw-Hill/IrwinDocument16 pagesProduct and Service Design: Mcgraw-Hill/IrwinAnaya MalikNo ratings yet

- A Proposed Five Storey School Building With The Use of Fly AshDocument101 pagesA Proposed Five Storey School Building With The Use of Fly AshJJ TevesNo ratings yet

- Anti-Tarnish Packaging Paper and Film Protects Silver-Plated PartsDocument2 pagesAnti-Tarnish Packaging Paper and Film Protects Silver-Plated PartsPR.comNo ratings yet

- DLL - English 6 - Q3 - W1Document9 pagesDLL - English 6 - Q3 - W1Romeo MercadoNo ratings yet

- Heat RecoveryDocument8 pagesHeat RecoveryPrashantNo ratings yet

- Softener 2Document8 pagesSoftener 2Tri FebriyaniNo ratings yet

- Space User Furniture Breakdown and Circulation CalculationsDocument3 pagesSpace User Furniture Breakdown and Circulation CalculationsCali RetuyaNo ratings yet

- Operating Manual: Eagleburgmann Mechanical Seal (M.S.)Document22 pagesOperating Manual: Eagleburgmann Mechanical Seal (M.S.)kiranNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance and CompanyDocument7 pagesSafety Data Sheet: 1. Identification of The Substance and CompanyMariaJoseHernandezHurtadoNo ratings yet

- Military Preservation GuideDocument296 pagesMilitary Preservation GuideCAP History LibraryNo ratings yet

- Environmental Survey: The Search For ActionDocument7 pagesEnvironmental Survey: The Search For ActionKabayanNo ratings yet

- Oman Construction Industry Prospective On Cause of Construction Material WasteDocument10 pagesOman Construction Industry Prospective On Cause of Construction Material WasteYosie MalindaNo ratings yet

- Shree Cement LTD.: An Energy & Environment Conscious, Sustainable & Prosperous OrganizationDocument47 pagesShree Cement LTD.: An Energy & Environment Conscious, Sustainable & Prosperous Organizationshashank nutiNo ratings yet

- Mimaki JFX200-2513 Operations ManualDocument158 pagesMimaki JFX200-2513 Operations ManualWES ATKINSONNo ratings yet

- Value Stream MappingDocument21 pagesValue Stream MappingmpvoNo ratings yet

- Collective Nouns For UPSR English PupilsDocument3 pagesCollective Nouns For UPSR English PupilsPizza4080% (5)

- Upstream c1 Essay Writing 5063713895279Document10 pagesUpstream c1 Essay Writing 5063713895279Loredana Cătălina SpoialăNo ratings yet

- BASIC STOCK CONTROL AND COMPOSTING PROCEDURESDocument23 pagesBASIC STOCK CONTROL AND COMPOSTING PROCEDURESRenz renzNo ratings yet

- Autoclave - Definition, Parts, Principle, Procedure, Types, UsesDocument22 pagesAutoclave - Definition, Parts, Principle, Procedure, Types, UsesDeep AnuNo ratings yet