Professional Documents

Culture Documents

Plate Heat Exchangers Slide

Uploaded by

Ha PijiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plate Heat Exchangers Slide

Uploaded by

Ha PijiCopyright:

Available Formats

It uses metal plates as a medium to transfer heat

between two f luids composed of multiple, thin, slightly separated plates that have very large surface areas and f luid f low passages for heat transfer The f luids are exposed to a much larger surface area as the f luids spread out over the plates The plate heat exchanger has a major advantage over a conventional heat exchanger This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger

The plate heat exchanger (PHE) is a specialized design well

suited to transferring heat between medium and low pressure fluids In place of a pipe passing through a chamber, there are instead two alternating chambers, usually thin in depth, separated at their largest surface by a corrugated metal plate The plates used in a plate and frame heat exchanger are obtained by one piece pressing of metal plates. Stainless steel is a commonly used metal for the plates The plates are spaced by rubber sealing gaskets

The plates are pressed to form troughs at right

angles to the direction of flow of the liquid which runs through the channels in the heat exchanger. These troughs are arranged so that they interlink with the other plates which forms the channel with gaps of 1.31.5 mm between the plates. The troughs create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved. The plates are compressed together in a rigid frame to form an arrangement of parallel flow channels with alternating hot and cold fluids.

The plates produce an extremely large surface area, which

allows for the fastest possible transfer. Making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved

Plate and frame heat exchangers The components consist of a fixed end plate, connections and a loose pressure plate, with carrier bars mounted between them These heat exchangers are normally of the gasket type to allow periodic disassembly, cleaning, and inspection.

A brazed plate heat exchanger is small, light and

compact It does not need gaskets. Instead, it is brazed together using copper to give a strong, compact construction This heat exchanger is especially suitable for pressures up to 50 bar and temperatures from -196C to +550C.

You might also like

- Heat Exchanger BasicsDocument59 pagesHeat Exchanger BasicsPassionNo ratings yet

- TEMA Type Heat Exchangers PDFDocument4 pagesTEMA Type Heat Exchangers PDFkinjalpatel123450% (1)

- Tube To Tube SheetDocument9 pagesTube To Tube Sheetcmpatel_00100% (2)

- ASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFDocument8 pagesASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFLisa MaloneNo ratings yet

- S&T HeDocument32 pagesS&T HeArpit Sharma100% (1)

- 7180833Document10 pages7180833DdNak Ydk SubangNo ratings yet

- Design and Analysis of Above-Ground Full Containment LNG Storage TanksDocument6 pagesDesign and Analysis of Above-Ground Full Containment LNG Storage TanksrodrigoperezsimoneNo ratings yet

- Pressure Vessel Design As Per Asme CodeDocument24 pagesPressure Vessel Design As Per Asme CodearunyogNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- Floating Roof Check PointsDocument3 pagesFloating Roof Check PointsSajeev NarayananNo ratings yet

- FRP TanksDocument1 pageFRP TanksMakrand SakpalNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Document18 pagesPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNo ratings yet

- A.3 Sequence of Operation Fuel SystemDocument9 pagesA.3 Sequence of Operation Fuel SystemPLC Swa100% (2)

- Storage TanksDocument2 pagesStorage Tanksarif99pakNo ratings yet

- Water SprayDocument2 pagesWater SpraySaba SamankanNo ratings yet

- Boiler Inspection PDFDocument2 pagesBoiler Inspection PDFsajuhereNo ratings yet

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Jsa For Roof Air LiftDocument2 pagesJsa For Roof Air LiftKoshy Thankachen100% (1)

- Bolier Inspection ReportDocument4 pagesBolier Inspection ReportHadi AlloucheNo ratings yet

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesNo ratings yet

- Nozzle LoadDocument8 pagesNozzle LoadDam VoNo ratings yet

- Pipe Spacing From Perisher Handbook PG 194Document8 pagesPipe Spacing From Perisher Handbook PG 194Asif Haq100% (1)

- Client Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved byDocument7 pagesClient Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved bySARSAN NDTNo ratings yet

- Air Cooled Condenser - A Dry Cooling TowerDocument6 pagesAir Cooled Condenser - A Dry Cooling TowerGmail44No ratings yet

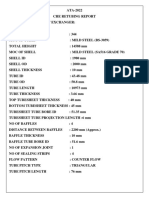

- CHE Retubing ReportDocument29 pagesCHE Retubing ReportRajesh KtrNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- List of Itp新 for HrsgDocument16 pagesList of Itp新 for HrsgzhangNo ratings yet

- Hydro Testing + Post Weld Heat TreatmentDocument20 pagesHydro Testing + Post Weld Heat TreatmentRafia ZafarNo ratings yet

- Foam Chamber Data SheetDocument6 pagesFoam Chamber Data Sheetadilmomin45No ratings yet

- Astm D 2657 - 97Document9 pagesAstm D 2657 - 97Walther LaricoNo ratings yet

- Air Cooled Condenser ACC PDFDocument3 pagesAir Cooled Condenser ACC PDFHoney TiwariNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- SHT ExchangerDocument55 pagesSHT ExchangerCc12 22tNo ratings yet

- Heat Exchanger PresentationDocument39 pagesHeat Exchanger PresentationZia UlmananNo ratings yet

- Air-Cooled Heat Exchangers: LectureDocument39 pagesAir-Cooled Heat Exchangers: LectureBaraa Shurbaji No 111No ratings yet

- Vortex Gasket PDFDocument13 pagesVortex Gasket PDFmansurudinNo ratings yet

- External Floating Roof Tank - WikipediaDocument2 pagesExternal Floating Roof Tank - WikipediaalphadingNo ratings yet

- Air Cooled Heat Exchanger !Document17 pagesAir Cooled Heat Exchanger !RehinaNo ratings yet

- 125 - Performance Guarantee - Maan - R4Document4 pages125 - Performance Guarantee - Maan - R4Ahmad ShekhNo ratings yet

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNo ratings yet

- U-Tube Heat ExchangerDocument9 pagesU-Tube Heat Exchangerhirenpatel_62No ratings yet

- Globe ValvesDocument7 pagesGlobe ValvesAngela IlaganNo ratings yet

- Butterfly Valve Catalogue PDFDocument25 pagesButterfly Valve Catalogue PDFPriyanka rajpurohitNo ratings yet

- ISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108Document1 pageISO 15614-1 0 Bilfinger Salamis 19.11.2018. ISO 15614-1 N/A BIS-DK Form Number: BIS-DK-F 108TomasPavlovicNo ratings yet

- Storage CalorifiersDocument5 pagesStorage CalorifiersVishnu ThampiNo ratings yet

- Hydrostatic & Pneumatic Test For PipingDocument12 pagesHydrostatic & Pneumatic Test For PipingFaqih Alaina FilhasmiNo ratings yet

- Corrosion Damage in Waste Heat Boilers Major Root Causes and RemediationDocument10 pagesCorrosion Damage in Waste Heat Boilers Major Root Causes and Remediationvaratharajan g rNo ratings yet

- Boilers and Thermic Fluid HeatersDocument42 pagesBoilers and Thermic Fluid HeatersArvind ShuklaNo ratings yet

- Air Receiver DesignDocument3 pagesAir Receiver DesigngksakthiNo ratings yet

- Foot Valve Catalog PDFDocument4 pagesFoot Valve Catalog PDFFabio MiguelNo ratings yet

- Plate Heat Ex ChangersDocument5 pagesPlate Heat Ex Changersmuftah faragNo ratings yet

- Design of Plate and Frame Heat ExchangersDocument3 pagesDesign of Plate and Frame Heat ExchangersJiten Kumar BiswalNo ratings yet

- of HXEDocument31 pagesof HXEetayhailuNo ratings yet

- Heat ExchangersDocument29 pagesHeat ExchangersSruthish SasindranNo ratings yet

- Experiment Test MatrixDocument19 pagesExperiment Test MatrixVishal KhandelwalNo ratings yet

- Plate Type Heat ExchangerDocument28 pagesPlate Type Heat ExchangerJagadeesan Sai100% (1)

- Heat Exchanger TypesDocument15 pagesHeat Exchanger TypesDanish BaigNo ratings yet

- Ahmad PHTDocument12 pagesAhmad PHTEngineer TalhaNo ratings yet

- Norton Scan 12212Document4 pagesNorton Scan 12212Saurabh KumarNo ratings yet

- Ultra ETK20910Document2 pagesUltra ETK20910emil gasimovNo ratings yet

- Selangor-Physics P2-Trial SPM 2009Document24 pagesSelangor-Physics P2-Trial SPM 2009kamalharmozaNo ratings yet

- 1 - ERDAS IMAGINE Viewer PDFDocument20 pages1 - ERDAS IMAGINE Viewer PDFRahmad KurniawanNo ratings yet

- CraftDocument15 pagesCraftImamMukhri100% (1)

- Understanding The Harmony Information in The Preset DisplayDocument2 pagesUnderstanding The Harmony Information in The Preset DisplaymileroNo ratings yet

- Stainless Steel Wire Mesh and Wire ClothDocument3 pagesStainless Steel Wire Mesh and Wire ClothStela LjevarNo ratings yet

- NAJRAN Quarter 4 NAJRAN Quarter 4 DDT Report DDT Report: December 2012 December 2012Document50 pagesNAJRAN Quarter 4 NAJRAN Quarter 4 DDT Report DDT Report: December 2012 December 2012Shaheryar KhanNo ratings yet

- Medellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFDocument16 pagesMedellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFajay d1212No ratings yet

- Ditch Excavation Procedure - C01Document8 pagesDitch Excavation Procedure - C01Toreson OfuafoNo ratings yet

- Aprilia SR 50 Factory Owners ManualDocument88 pagesAprilia SR 50 Factory Owners ManualAnna RyanNo ratings yet

- Perry 02Document2 pagesPerry 02Thaly MejiaNo ratings yet

- Instruction ManualDocument462 pagesInstruction ManualCaraluaNo ratings yet

- WPT PresentationDocument23 pagesWPT PresentationSyed Safiur RahmanNo ratings yet

- Alfonso, Michael John Agaser 202005047MN0 Bachelor of Science in Electrical Engineering Enrolled SubjectsDocument1 pageAlfonso, Michael John Agaser 202005047MN0 Bachelor of Science in Electrical Engineering Enrolled SubjectsMJA.AlfonsoNo ratings yet

- Guide For High Performance CoatingsDocument34 pagesGuide For High Performance Coatingsro snNo ratings yet

- BAJA RULES 2020 Rev B 2020-01-26Document129 pagesBAJA RULES 2020 Rev B 2020-01-26baja100% (2)

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocument23 pagesPPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANNo ratings yet

- Mapping of Human BrainDocument31 pagesMapping of Human BrainParag RabadeNo ratings yet

- Manual Daiwa Tanacom 500 PDFDocument37 pagesManual Daiwa Tanacom 500 PDFHenrique BelliniNo ratings yet

- Eurotherm 605 Drive ManualDocument222 pagesEurotherm 605 Drive Manualodnanref00No ratings yet

- Building Completion Certificate: Certificate Number Plot Number Initial Issue DateDocument2 pagesBuilding Completion Certificate: Certificate Number Plot Number Initial Issue DateAbrar AbbasiNo ratings yet

- S BlockDocument27 pagesS BlockAditya BansalNo ratings yet

- Electric SystemDocument78 pagesElectric SystemHarry Wart Wart100% (2)

- VGP - Book1Document94 pagesVGP - Book1Chirag DesaiNo ratings yet

- Web Pacs Viewer 2008Document68 pagesWeb Pacs Viewer 2008Devair VieiraNo ratings yet

- Parts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachineDocument39 pagesParts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachinePericoNo ratings yet

- EZ-FRisk V 7.52 User Manual PDFDocument517 pagesEZ-FRisk V 7.52 User Manual PDFJames IanNo ratings yet

- IMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicDocument10 pagesIMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicatommotaNo ratings yet

- BMW E46 RearlightDocument4 pagesBMW E46 RearlightLiviu CasuneanuNo ratings yet