Professional Documents

Culture Documents

Piston

Uploaded by

Bhupender RamchandaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piston

Uploaded by

Bhupender RamchandaniCopyright:

Available Formats

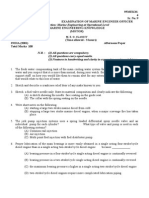

BBC/PISTON/GE

PISTON

PISTON MATERIAL

LIGHT & STRONG, CONDUCT HEAT WELL, EXPAND ONLY

SLIGHTLY, RESIST WEAR & LOW IN COST.

EARLIER MADE OF CAST IRON, TODAY ALLOY CAST IRON

WHICH OFFERS GREATER HEAT RESISTANCE & BETTER

WEARING QUALITIES.

ALUMINIUM ALLOY ARE LIGHT WEIGHT, USED IN HIGH

SPEED ENGINES TO REDUCE INERTIA FORCE.

THEY EXPAND CONSIDERABLY WHEN HEATED.

COMPOSITE PISTONS : FORGED STEEL CROWNS & CAST

IRON SKIRTS USED IN LARGE ENGINES.FOR STRENGTH &

HEAT RESISTANCE IN UPPER SECTION, GOOD WEARING

PROPERTIES OF CAST IRON IN THE LOWER SECTION.

CONSTRUCTION

THE PISTONWITH ITS RINGS , SEALS THE CYLINDER &

TRANSMITS THE GAS PRESSURE TO THE CONNECTING

ROD.

IT ABSORBS HEAT FROM GAS, WHICH SHOULD BE

CARRIED AWAY.

IN LARGE TWO-STROKE ENGINES , PISTONS ARE COOLED

BY OIL OR WATER.

BBC/PISTON/GE

THE CROWN IS MADE WITH SLIGHT TAPER TO TAKE CARE

OF EXPANSION, & CARRIES COMPRESSION RINGS.

SKIRT TAKES SIDE THRUST OF CONNECTING ROD &

PREVENTS ROCKING OF PISTON , & CARRIES LOWER SET

OF OIL CONTROL RINGS. THEY REMOVE EXCESS OIL

FROM THE LINER.

PISTON SKIRT BECOMES THINNER ON THE LOWER SIDE.

INTERIOR RIBS ARE USED TO STIFFEN THE SKIRT OF CAST

PISTONS.

THE RUNNING CLEARANCE BETWEEN SKIRT & LINER

MUST BE SMALL.

PISTON COOLING FOR TRUNK PISTON

MEDIUM IS LUB OIL.

LUB OIL IS FORCED THROUGH THE HOLLOW

CONNECTING RODTO THE UPPER END OF THE ROD.

PART OF THE OIL LUBRICATES THE GUDGEON PIN

BEARING, & REMAINDER PASSES THROUGH THE NOZZLE

IN THE END OF THE ROD & SPRAYS AGAINST THE

UNDERSIDE OF THE PISTON CROWN.

AFTER ABSORBING HEAT FROM THE METAL, THE OIL DRIPS

DOWN THE PISTON & FALLS BACK TO THE CRANKCASE.

THE OIL CIRCULATES THROUGH AN ENCLOSED SPACE

UNDER THE CROWN.

OIL IS CONDUCTED FROM THE CONNECTING ROD BOTTOM-

END UP A PSSAGE INTO THE ROD & SO INTO THE PISTON PIN

THROUGH PASSAGES IN THE PISTON PIN AND TO THE

COOLING COIL IN PISTON.

BBC/PISTON/GE

IT CIRCULATES THROUGH THE PISTON BOSS THEN

PISTON PIN & RETURNS DOWN THE ROD BY A SIMILAR

PASSAGE AS THAT OF SUPPLY.

PISTON FOR LARGE CROSSHEAD- TYPE MAIN ENGINE

PISTON IS CAST OF HEAT RESISTING ALLOY STEEL

CONTAINING CHROMIUM & MOLYBDENUM TO MAINTAIN

STRENGTH AT HIGH TEMP & RESIST CORROSION.

THE PISTON CROWN IS THIN TO ENSURE ADEQUATE

COOLING & STRONG ENOUGH TO RESIST THE HIGH

PRESSURE GAS LOAD.

IT IS SHAPED TO ASSIST FLOW DIRECTION OF GASES

DURING SCAVENGING, & IS SUPPORTED & FURTHER

COOLED BY INTERNAL RIBS.

THE CYLINDRICAL WALL OF THE PISTON IS SHAPED

INTERNALLY TO ENSURE COOLING BUT IS THICKENED TO

ACCOMMODATE THE PISTON GROOVES .

THE EXTERNAL SHAPE IS TAPERED SLIGHTLY ABOVE THE

TOP RING GROOVE TO ALLOW SOME DISTORTION DURING

COMBUSTION CONDITIONS.

THERE ARE FIVE PISTON RING GROOVES EACH OF WHICH

HAS ITS LOWER WEAR SURFACE CHROMIUM PLATED TO

RESIST WEAR.

THE PISTON IS WATER COOLED INTERNALLY WITH

FRESH WATER WHICH ENTERS & LEAVES THROUGH

RECIPROCATING PIPES & GLANDS.

THE WATER OUTLET IN THE PISTON IS SET NEAR THE

CROWN TO ENSURE THAT THE PISTON REMAINS FULL OF

WATER AT ALL TIMES.

BBC/PISTON/GE

DRAINAGE CONNECTIONS ARE MADE FROM THE WATER

GLANDS TO PREVENT ANY WATER LEAKAGE FROM

ENTERING THE CYLINDER OR CRANKCASE.

THE PISTON COOLING SPACE IS CLOSED BY A BOLTED

COVER FITTED WITH RUBBER SEAL RINGS TO PREVENT

LEAKAGE.

RUBBER SEAL RINGS ARE ALSO FITTED AT THE

ATTACHMENTS OF RECIPROCATING COOLING PIPES &

BETWEEN PISTON & THE PISTON ROD FLANGE.

A SHORT CAST IRON PISTON SKIRT IS SECURED BETWEEN

THE PISTON ROD FLANGE & THE UNDERSIDE OF THE

PISTON A SPIGOT & RUBBER RING SEALING THIS

JUNCTION.

THE SKIRT IS UNCOOLED & ACTS AS A GUIDE WITHIN THE

LINER.

IT HAS TWO LEADED BRONZE WEARING RINGS CAULKED

INTO GROOVES TO PREVENT POSSIBLE DAMAGE

BETWEEN SKIRT & LINER.

THE LOWER EDGE OF THE SKIRT ALSO REDUCES LOSS OF

SCAVENGE AIR TO EXHAUST PORTS.

FRESH WATER COOLING HAS THE ADVANTAGE OF

GREATER THERMAL CAPACITY THAN OIL. IT MAY ALSO

SUSTAIN HIGHER OUTLET TEMP.

INHIBITORS ARE NECESSARY TO PREVENT CORROSION IN

THE SYSTEM & ADEQUATE VENTING MUST BE

MAINTAINED.

LEAKAGE FROM SEALS IS A PROBLEM.

BBC/PISTON/GE

PISTON

Manufacturing and materials

Materials

Piston crowns attain a running temperature of about

450oC and in this zone there is a need for high

strength and minimum distortion in order to

maintain resistance to gas loads and maintain the

attitude to the rings in relation to the liner.

The heat flow path from the crown must be uniform

otherwise thermal distortion will cause a non-

circular piston resulting in reduced running

clearance or even possible contact with the liner

wall.

In addition to this thermal stress they are also

subject to compressive stress from combustion and

compression loads, as well as inertial loads.

Materials such as pearlitic, flake and spheroidal cast

iron, alloy cast irons containing Nickel and

chromium, and aluminium alloys may be used.

The determining factor is the design criteria for the

engine.

BBC/PISTON/GE

PISTON

For a modern slow speed engine steel forging

or castings of nickel-chrome steel or

molybdenum steel are common. The weight of

the material is not normally a governing factor

in this type of engine although resistance to

thermal stress and distortion is. Efficient

cooling is a required to ensure the piston

retains sufficient strength to prevent distortion.

For medium and high speed engines the weight

of the material becomes important to reduce

the stresses on the rotating parts. The high

thermal conductivity of aluminium alloys

allied to its low weight makes this an ideal

material. To keep thermal stresses to a

reasonable level cooling pipes may be cast into

the crown, although this may be omitted on

smaller engines. Where cooling is omitted, the

crown is made thicker both for strength and to

aid in the heat removal from the outer surface.

Hard landings are inserted into the ring groves

to keep wear rated down. Composite pistons

may be used consisting of an cast alloy steel

crown with an aluminium-alloy or cast iron

body.

BBC/PISTON/GE

PISTON

Annealing

After casting or forging the

component is formed of

different material thicknesses.

The thinner parts will cool more

quickly thereby setting up

internal stresses. Annealing

removes or reduces these stress

as well as refining the grain

structure.

BBC/PISTON/GE

PISTON

Water Cooled

High specific heat capacity therefore

removes more heat per unit volume

Requires chemical conditioning

treatment to prevent scaling

Larger capacity cooling water pump

or separate piston cooling pump and

coolers although less so than with oil

Special piping required to get

coolant to and from piston without

leak

Coolant drains tank required to

collect water if engine has to be

drained.

Pistons often of more complicated

design

Cooling pumps may be stopped

more quickly after engine stopped

BBC/PISTON/GE

PISTON

Oil Cooled

Low specific heat capacity

Does not require chemical treatment

but requires increased separate and

purification plant

Larger capacity Lube oil pump,

sump quantity and coolers

No special means required and

leakage not a problem with less risk

of hammering and bubble

impingement.

Increased capacity sump tank

required Thermal stresses in piston

generally less in oil cooled pistons

Large volumes of oil required to

keep oxidation down and extended

cooling period required after engine

stopped to prevent coking of oil

BBC/PISTON/GE

PISTON

Wear rings

Wear rings are found on some slow

speed engines employing loop or

cross flow scavenging although they

may be found in most designs.

They are made of a low coefficient

of friction material and serves two

main purposes. To provide a rubbing

surface and to prevent contact

between the hot upper surfaces of

the piston and the liner wall.

In trunk piston engines wear rings to

negate the distortion effect caused by

the interference fit of the gudgeon

pin .

The ring may be inserted in two

pieces into the groove then lightly

caulked in with good clearance

between the ends.

BBC/PISTON/GE

PISTON

B&W LMC oil cooled piston

The piston has a concave top. This is near self

supporting and reduces the need for internal

ribbing. It prevents the cyclic distortion of the top

when under firing load. This distortion can lead to

fatigue and cracking

BBC/PISTON/GE

PISTON

Pistons may be cooled by oil or water.

Oil has the advantage that it may be

supplied simply from the lubrication

system up the piston rod.

Its disadvantage are that maximum

temperatures is relatively low in order to

avoid oxidised deposits which build up on

the surfaces.

In addition the heat capacity of oil is much

lower than that of water thus a greater flow

is required and so pumps and pipework

must be larger.

Also, if the bearing supply oil is used as is

mainly the case a greater capacity sump is

required with more oil in use.

Water does not have these problems, but

leakage into the crankcase can cause

problems with the oil (such as Micro Biol-

Degradation).

The concave or dished piston profile is

used for most pistons because it is stronger

than the flat top for the same section

thickness

BBC/PISTON/GE

PISTON

Sulzer watercooled piston (RND)

Increasing section thickness would result in higher

thermal stress.

Sulzer piston require a flat top because of the

scavenging and exhaust flow arrangement (loop

scavenging of RND etc). in order to avoid thicker

sections internal support ribs are used.

BBC/PISTON/GE

PISTON

However these ribs cause problems

in that coolant flow is restricted.

The flow of water with an RD

piston is directed to and from the

piston by telescopic pipes.

The outlet is positioned higher than

the inlet within the cooling cavity

and on the opposite side of the

support rib in order to ensure

positive circulation.

BBC/PISTON/GE

PISTON

With highly rated engines overheating

occurred in stagnant flow areas between

the ribs and so a different form of

cooling was required.

The cocktail shaker effect has air as well

as water in the cooling cavity as the

piston reciprocates water washes over

the entire inner surface of the piston just

as in a cocktail shaker.

Unfortunately air bubbles become

trapped in the water and flow to outlet

reducing the air content and removing

the cocktail shaker effect.

To avoid this problem air must be

supplied to the piston some engine

builders use air pumps feeding air to the

inlet flow.

The sulzer engine allows air to be drawn

into the flow at a specially designed

telescopic transfer system.

BBC/PISTON/GE

PISTON

The telescopic arrangement is designed

to prevent leakage and allows air to be

drawn into the coolant flow to maintain

the cocktail shaker effect.

Consider the inlet telescopic, a double

nozzle unit is fitted to the top of the

standpipe.

Small holes allow connection from the

main seal to the space between the

nozzles.

Water flowing through the lower nozzle

is subject to pressure reduction and a

velocity increase.

The space between the nozzles is

therefore at a lower pressure than other

parts of the system.

Any water which leaks past the main seal

is drawn through the radial holes into the

low pressure region and hence back into

the coolant flow.

BBC/PISTON/GE

PISTON

The pumping action of the telescopic

draws air past the lower seal and this

is also drawn through the radial

holes into the coolant flow.

This maintains the air quantity in

the piston and so maintains the

cocktail shaker effect.

The sulzer water cooled piston

differs from that of the Oil cooled

variety by the method it uses for

distributing the cooling medium.

In this case the piston is not

continually flooded but instead

contains a level governed by the

outlet weir.

Cooling of the crown occurs during

change of direction at the top of the

stroke by so called 'Cocktail shaker'

action.

BBC/PISTON/GE

PISTON

BBC/PISTON/GE

PISTON

Composite pistons

With medium speed and higher speed engines considerable

inertia forces are placed on the conn rod and bearings as

the piston changes direction at the ends of the stroke. The

amount of force is a factor of the speed and rotating mass.

To reduce this force whilst maintaining the same engine

speed it is necessary to reduce this rotating mass.

BBC/PISTON/GE

PISTON

Aluminium, with its lower density

than steel is used when alloyed with

silicon for extra strength.

Even alloyed the aluminium has less

mechanical strength than the steel,

therefore damage is possible due to

gas pressure acting on crown and

piston rings.

The piston could deform sufficiently

to prevent proper operation of the

rings in their grooves.

Some engine manufacturers fit cast

iron inserts into the grooves but

more generally the piston is made in

two parts with a cast steel crown

containing two grooves.

BBC/PISTON/GE

PISTON

Aluminium has a better coefficient

of heat transfer than steel thus

overheating is not a problem.

Its lower coefficient of friction

avoids the problems of fitting bushes

for the gudgeon pin, thus a floating

gudgeon pin may be used.

The higher coefficient of expansion

could lead to the need for greater

piston/liner clearance.

However, as the main body is not

subject to the high temperatures of

combustion this expansion is not a

problem.

BBC/PISTON/GE

PISTON

Sulzer rotating piston

BBC/PISTON/GE

PISTON

This piston rotates as it reciprocates.

The rotation being brought about by

the swing of the con rod.

This causes two spring loaded palls

located in the spherical top end to

oscillate.

These palls engage with a toothed

rim which is connected to the piston

by means of a compensating spring.

As the conrod swings the palls act

on the toothed rim causing it, and

hence the piston, to rotate.

The amount of rotation is limited to

one tooth pitch every engine rev and

the action is similar to that of a

ratchet mechanism.

BBC/PISTON/GE

PISTON

The advantage of this is that local

overheating of the piston or the liner

due to blow past is prevented.

Running in characteristics are

improved and liner wear are

improved.

There is a better spread of oil

brought about by the piston rotation.

A spherical top end is required but

this provides better support for the

piston which does not distort as

much as one fitted with a gudgeon

pin.

Piston to liner clearance may

therefore be reduced.

BBC/PISTON/GE

PISTON

Transfer of gas loads from crown

to piston rod

Is usually transmitted from the

reinforced crown to the piston rod by

internal mechanism avoiding possible

distortion of the ring belt.

The tops of pistons are made dome

shaped or have strong internal

ribbing.

Thermal distortion of Piston

BBC/PISTON/GE

PISTON

Anti-Polishing rings

High topland ( the 1st piston ring is positioned

well below the upper surface of the piston) with

associated reduced ring heat load has given

better ring pack performance by improving

working conditions for the cylinder lube oil.

BBC/PISTON/GE

PISTON

The disadvantage of this system is

that a coke build up can occur above

the piston which leads to 'bore

polishing'. This polishing reduces the

ability of the cylinder lube oil to

'key' into the liner therefore

increased cylinder lube oil

consumption/increased liner wear

can result.

To combat this piston cleaning

rings are incorporated into the liner.

These slightly reduce the bore

removing the deposits.

BBC/PISTON/GE

PISTON

Modern Design

The top piston ring is moved further down the

piston. This allows the crown to enter deeper into

the crown reducing temperature and pressure on

the liner. The top piston ring is a 'Controlled

Pressure relief' (CPR) ring.

This design has several oblique shallow grooves

in the piston ring face allowing some gas presure

to pass through to the 2nd ring thereby reducing

load on the top ring. To reduce blowpast an 'S'

type joint is formed n the ring ends

BBC/PISTON/GE

PISTON

BBC/PISTON/GE

PISTON

BBC/PISTON/GE

PISTON

BBC/PISTON/GE

PISTON

BBC/PISTON/GE

PISTON

You might also like

- P 57Document7 pagesP 57Bhupender RamchandaniNo ratings yet

- ArticlDocument11 pagesArticlBhupender RamchandaniNo ratings yet

- Ship security levels and duties guideDocument10 pagesShip security levels and duties guideBhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: EFC InternationalDocument5 pagesMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: Videocon d2h HD OfferDocument7 pagesMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNo ratings yet

- Marine engineering exam questionsDocument3 pagesMarine engineering exam questionsBhupender RamchandaniNo ratings yet

- ArticrlDocument9 pagesArticrlBhupender RamchandaniNo ratings yet

- 95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairDocument2 pages95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairBhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: Videocon d2h HD OfferDocument6 pagesMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No2Document2 pages95 MEKM4 SR No2Bhupender RamchandaniNo ratings yet

- Marine Engineering Study Materials: Wall Paints in HD ShadesDocument7 pagesMarine Engineering Study Materials: Wall Paints in HD ShadesBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- Marine engineering exam questionsDocument3 pagesMarine engineering exam questionsBhupender RamchandaniNo ratings yet

- 95MEKM-4 Marine Engineer Officer Exam QuestionsDocument3 pages95MEKM-4 Marine Engineer Officer Exam QuestionsBhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No4Document3 pages95 MEKM4 SR No4Bhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument2 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No5Document3 pages95 MEKM4 SR No5Bhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No5Document3 pages95 MEKM4 SR No5Bhupender RamchandaniNo ratings yet

- 95 MEKM4 SR No.7Document3 pages95 MEKM4 SR No.7Bhupender RamchandaniNo ratings yet

- 95 MEKM SR No.3Document3 pages95 MEKM SR No.3Bhupender RamchandaniNo ratings yet

- Marine Engineer Exam QuestionsDocument4 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo10Document3 pages95MEKM4 SrNo10Bhupender RamchandaniNo ratings yet

- Marine Engineer Exam QuestionsDocument4 pagesMarine Engineer Exam QuestionsBhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo8Document3 pages95MEKM4 SrNo8Bhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo6Document3 pages95MEKM4 SrNo6Bhupender RamchandaniNo ratings yet

- Examination of Marine Engineer Officer - MotorDocument3 pagesExamination of Marine Engineer Officer - MotorBhupender RamchandaniNo ratings yet

- 95MEKM4 SrNo2Document3 pages95MEKM4 SrNo2Bhupender RamchandaniNo ratings yet

- Function: Marine Engineering at Operational LevelDocument3 pagesFunction: Marine Engineering at Operational LevelBhupender RamchandaniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Engine Failure Cause PDFDocument5 pagesEngine Failure Cause PDFRohmanNo ratings yet

- Toyota D-4D 2nd Generation Common-rail Diesel SystemDocument16 pagesToyota D-4D 2nd Generation Common-rail Diesel SystemCarlos QuispeNo ratings yet

- 3 Jaw Chuck and 4 Jaw Chuck Difference - Google SearchDocument1 page3 Jaw Chuck and 4 Jaw Chuck Difference - Google SearchCIV2169Akash kumar MeenaNo ratings yet

- GSX s150m1Document77 pagesGSX s150m1andres parragaNo ratings yet

- Two Stroke Top EndDocument66 pagesTwo Stroke Top EndPete MoonNo ratings yet

- Jet Engine Types, Functions and ConstructionDocument10 pagesJet Engine Types, Functions and ConstructionTushar ShingadeNo ratings yet

- Se 120RDocument19 pagesSe 120Rserg_bushNo ratings yet

- 1322805Document2 pages1322805Dmicalio SimNo ratings yet

- CC CCCC: Y Y Y YyDocument24 pagesCC CCCC: Y Y Y YyRavi KantNo ratings yet

- Pump NotesDocument10 pagesPump NotesSasmita SahooNo ratings yet

- H2000 5 10t Service and Operation Manual PDFDocument111 pagesH2000 5 10t Service and Operation Manual PDFJavier Ignacio Briones CapiccelliNo ratings yet

- 1.8T 5V (Awm)Document413 pages1.8T 5V (Awm)Vladimir Socin ShakhbazyanNo ratings yet

- CFM International CFM56: HistoryDocument24 pagesCFM International CFM56: HistoryĐoàn Hồng NgọcNo ratings yet

- MT XR190L (62K79B0) 2017 OkDocument128 pagesMT XR190L (62K79B0) 2017 OkJaime Vasquez MedinaNo ratings yet

- Job Profile Chart & Competency UnitDocument13 pagesJob Profile Chart & Competency UnitMohd FadhliNo ratings yet

- Parts 4121225 (D222) H PM US EN (07 2019)Document1,102 pagesParts 4121225 (D222) H PM US EN (07 2019)Erisson100% (1)

- Fuel Injection SystemsDocument17 pagesFuel Injection Systemsअभिषेक ओझा100% (1)

- Load Calculation For CNG Station (Software Park) Utilisation Factor Connected Load (KW)Document5 pagesLoad Calculation For CNG Station (Software Park) Utilisation Factor Connected Load (KW)vinay1999No ratings yet

- Gas Turb 10Document224 pagesGas Turb 10Mohammad Ali AkhtardaneshNo ratings yet

- Piston and Ring Failures 2001Document5 pagesPiston and Ring Failures 2001Abdelrahman MagdyNo ratings yet

- 1 4 132 KW TSI EngineDocument205 pages1 4 132 KW TSI EngineAdrian Todea100% (8)

- Illustrated Spare Parts List for DV12 Power Generator EngineDocument125 pagesIllustrated Spare Parts List for DV12 Power Generator EngineMECHO STORENo ratings yet

- Komatsu - E.H - PC1250-11 - 6.70 m3Document20 pagesKomatsu - E.H - PC1250-11 - 6.70 m3JC VargNo ratings yet

- Senior Design Midterm Report 3Document14 pagesSenior Design Midterm Report 3SheruNo ratings yet

- IS-6 Intake Installation GuideDocument14 pagesIS-6 Intake Installation GuideEd MoralesNo ratings yet

- Industrial and Genset Technical Data Issue 8Document59 pagesIndustrial and Genset Technical Data Issue 8q8peoplesNo ratings yet

- Manual de Taller - Yamaha Crux 2005Document0 pagesManual de Taller - Yamaha Crux 2005Insomnia Dj ChileNo ratings yet

- Zadatak 1. Trofazna Četvoropolna Kliznokolutna Asinhrona MašinaDocument19 pagesZadatak 1. Trofazna Četvoropolna Kliznokolutna Asinhrona MašinaAA RRNo ratings yet

- 101401-9271 Doowon Test PlanDocument5 pages101401-9271 Doowon Test Planmurillo_rodriguez8382100% (1)

- Data For Tightening Torque: LubricantDocument5 pagesData For Tightening Torque: LubricantAtanasio PerezNo ratings yet