Professional Documents

Culture Documents

Pump

Uploaded by

facebookshopOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump

Uploaded by

facebookshopCopyright:

Available Formats

PUMP

TM - FTTM

Pump (pendahuluan)

Pumps have a prime of uses in the oilfield.

Large pumps provide the pressure driving

force needed to move oil through piping

from point to point during its gathering,

processing, and pipeline transport.

Pump

Crude oil is stabilized by stage separation

to or near atmospheric pressure for

transportation and storage, before

pumping.

Main-line oil (MLO) pumps are required

for pipeline transport or transfer pumps for

delivery into other carrier or storage.

Background

Large pumps are also needed for injection

water and produced brine transport and

disposal.

Background

In the life of the field. Produced water must

also be transported in the production

facilities and possibly re-injected.

Basically, Pumps convert the rotary motion

of a prime mover into the linear motion of

the liquid in the piping.

As a secondary function, pumps

occasionally serve to mix fluids.

Background

There are two basic classes of pumps: positive

displacement and centrifugal.

Positive displacement pumps trap a portion of the liquid

in a fixed volume and deliver it mechanically to a higher

pressure. The entrapment may be done by a reciprocating

piston or plunger in a cylinder, or by a rotating sliding

vane, or gear, or screw.

Head

o Significance of using Head instead of

Pressure

o Pressure to Head Conversion formula

o Static Suction Head, hS

o Static Discharge Head, hd

o Friction Head, hf

Double Action Stroke in a

Duplex Pump

Suction Suction

Discharge Discharge

LIQUID

LIQUID

Single-action Stroke in a

Triplex Pump

Suction

Discharge

Liquid

L

S

Background

Centrifugal pumps propel liquid in a

smooth, uninterrupted stream.

Centrifugal pumps accelerate the liquid by

impellers and convert the induced kinetic

energy of the liquid into pressure energy by

an increase in cross-section.

Liquid flow path inside a

centrifugal pump

Units

In English engineering units, th. capacity

of a pump is expressed in gpm (U. S.

gallons per minute) at flow conditions.

Work per unit mass is expressed in ft-

lbf/lbm or ft or 'head.

In SI unit, flows are expressed in cubic

meters per second (m

3

/s), work per unit

mass in kJ/kg, and work per unit time in

W.

Centrifugal Pumps

The most common type of pump used in field handling of

crude oil.

Centrifugal pumps operate reliably, require low

maintenance, and are well-suited for automatic control.

They produce smooth output flow and operate safely

against partially closed control Valves safely against a

closed valve for short time periods.

Centrifugal pumps operate flexibly over a wide range of

flow rates (from a few gpm to 100,000 bpd) at heads

ranging from a few psi to 3,000 psi.

Sectional View of a Centrifugal Pump (Jackson, 1973)

General Components of Centrifugal Pump

General Components of Centrifugal Pump

Cut-away of a Pump Showing Volute Casing

Solid Casing

Suction and Discharge Nozzle Location

Horizontal

Centrifugal Pump

Cross Section

Typical Centrifugal-Pump Curves

Centrifugal Pump Performance Curve

Typical performance curve for centrifugal pumps

Characteristic Curves for 11 in Impeller

Operating Point for Centrifugal Pump in a Piping System

Horizontal Multistage Centrifugal Pump, GPSA 1987

Parallel Pumps

Centrifugal pumps may be operated in parallel at the

same head to provide greater capacity than a single

pump.

Parallel flows are additive at the same head. Extreme

care must be exercised that parallel pumps have

identical, or nearly identical, performance curves.

Pumps connected in parallel / in series

Parallel Operation Matched

Centrifugal Pumps

Parallel Operation mismatched

Centrifugal Pumps

No Diameter Change

Only

Speed Change Only Diameter & Speed Change

1

2

3

|

|

.

|

\

|

=

1

2

1 2

D

D

Q Q

|

|

.

|

\

|

=

1

2

1 2

N

N

Q Q

|

|

.

|

\

|

=

1

2

1

2

1 2

N

N

x

D

D

Q Q

2

1

2

1 2

D

D

H H

|

|

.

|

\

|

=

2

1

2

1 2

N

N

H H

|

|

.

|

\

|

=

2

1

2

1

2

1 2

N

N

x

D

D

H H

|

|

.

|

\

|

=

3

1

2

1 2

D

D

bhp bhp

|

|

.

|

\

|

=

3

1

2

1 2

N

N

bhp bhp

|

|

.

|

\

|

=

3

1

2

1

2

1 2

N

N

x

D

D

bhp bhp

|

|

.

|

\

|

=

IInitial Capacity, Head, break horse

power, Diameter, Speed

New Capacity, Head, break horse

power, Diameter, Speed

1 1 1 1 1

N , D , bhp , H , Q

2 2 2 2 2

N , D , bhp , H , Q

Series / parallel Combinations Centrifugal Pumps

2 Pumps in Series

One Pump

2 Pumps in Parallel

H

e

a

d

-

F

e

e

t

Series and parallel operation of Centrifugal Pumps

Net Positive Suction Head Required

(NPSHR)

An important consideration in pump selection is

the so called net positive suction head required

(NPSHR), which is the head that must be supplied

at the pump inlet in order to avoid or minimize

cavitation.

TANK

A

t

m

.

P

r

e

s

s

Vapor

Pressure

Liquid (Water)

Centrifugal Pump

Static Head

NPSH

Required

NPSH at Tank

Tank Farm Line Sizing

NPSH Available NPSH Required by the Pump

Net Positive Suction Head Required

(NPSHR)

If the pressure in the eye of the impeller falls below the

vapor pressure of the fluid, some vaporization occurs. At a

subsequent point in the pump, the pressure rises and

these bubbles collapse, creating sound pressure waves

(cavitation) that erode the pump impeller. Mechanical

damage may also be possible.

Flow Rate

N

P

S

H

R

P

a

P

Z

Water

Level

PUMP

Outlet

L

Typical PD pumping system

Diameter

Centrifugal Pump performance data for speed

TANK

A

t

m

.

P

r

e

s

s

Vapor

Pressure

Liquid (Water)

Centrifugal Pump

Static Head

NPSH

Required

NPSH at Tank

Tank Farm Line Sizing

NPSH Available NPSH Required by the Pump

TANK

A

t

m

.

P

r

e

s

s

Vapor

Pressure

Liquid (Water)

Centrifugal Pump

Static Head

NPSH

Required

NPSH at Tank

Tank Farm Line Sizing

s.g

2.31 x P

- (ft) Press Static

s.g

2.31 x P

-

s.g

2.31 x P

FRIC V atm

A

|

|

.

|

\

|

|

|

.

|

\

|

=

NPSH

Available

Pump by the required NPSH >

TANK

A

t

m

.

P

r

e

s

s

Vapor

Pressure

Liquid (Water)

Centrifugal Pump

Static Head

NPSH

Required

NPSH at Tank

Tank Farm Line Sizing

Vapor Press NPSH Available Meningkat

Pipa semakin panjang NPSH Available Menurun

Viscosity Liquid NPSH Available Menurun

Static Head NPSH Available Meningkat

No of Pump Operating Flow Rate

3 100 %

2 75 %

1 50 %

Flow Rate NPSH

100 % 15 feet

75 % 20 feet

50 % 27 feet

Pump combination produce the

following rates :

NPSH available :

TANK

0.5 PSIA

Water at 80 F

NPSH

Available

Absolute

Press,(ft)

Vapor

Press. (ft)

Line

Loss, (ft)

Difference in

elevation, ft

=

_ _

Line Loss

= 3 ft

10 ft - 0

Atmosphere

14.7 psia

NPSH CALCULATION FOR

SUCTION LIFT

Gravity Specific

2.31 x psia) Pressure, (

(Feet) Pressure =

Feet 19.7

10 - 3 - 12 - 33.9

10 - 3 -

1.0

(2.31) (0.5)

-

1.0

(2.31) (14.7)

=

=

=

NPSH

Available

NPSH available must be greater than NPSH

Required by the PUMP

GAS

PRESSURE

52.2 PSIA

N-BUTHANE

AT 100

O

F

Gauge Reading, 37.5 psi

8

f

e

e

t

-

0

Line Loss = 2.5 Ft

NPSH CALCULATION FOR LIQUID AT BOILING POINT

Specific gravity of N-Butane at 100 F = 0.56

Absolute Pressure = Gauge Pressure + Atmosphere Pressure

= Gauge Pressure + 14.7

NPSH = Absolute - Vapor - Line Difference in

Available Press, Ft Press, ft Loss, ft Elevation, Ft.

Feet 5.5

8 - 2.5 - 215.3 - 215.3

8 2.5 -

0.56

(2.31) (52.2)

-

(0.56)

2.31 14.7) - (37.5

=

=

+ =

NPSH

Available

NPSH available must be greater than NPSH

Required by the PUMP

Air

PRESSURE

0.5 PSIA

N-BUTHANE

AT 100

O

F

Gauge Reading, 10 psi

5

f

e

e

t

-

0

Line Loss = 45 Ft

NPSH CALCULATION FOR LIQUID AT BOILING POINT

Specific gravity of Water = 1.0

Absolute Pressure = Gauge Pressure + Atmosphere Pressure

= Gauge Pressure + 14.7

NPSH = Absolute - Vapor - Line Difference in

Available Press, Ft Press, ft Loss, ft Elevation, Ft.

Feet 59.828

5 45 - 2.06 - 101.8875

5 45 -

0.56

(2.31) (0.5)

-

(0.56)

2.31 14.7) (10

=

+ =

+

+

=

NPSH

Available

NPSH available must be greater than NPSH

Required by the PUMP

g

g

W -

g

g

F

g 2

) V - (V

) Z - (Z

) P - (P

c

s

c

2

1

2

2

1 2

1 2

= + + +

h

pr

+ h

st

+ h

v

+ h

f

= h

p

Pressure

Head

Static

Head

Velocity

Head

Friction

Head

Pump

Head

g

g

W -

g

g

F

g 2

) V - (V

) Z - (Z

) P - (P

c

s

c

2

1

2

2

1 2

1 2

= + + +

h

pr

+ h

st

+ h

v

+ h

fric

= h

p

Pressure

Head

Static

Head

Velocity

Head

Friction

Head

Pump

Head

Friction Loss : h

fric

g 2

V

K

D

L f

g

g

F h

2

i

c

fric

|

|

.

|

\

|

+ = =

f = Friction factor

L = Length of straight pipe

D = ID of pipe

K = summation of resistance coefficients for all valve and fittings

V = velocity

g

g

W -

g

g

F

g 2

) V - (V

) Z - (Z

) P - (P

c

s

c

2

1

2

2

1 2

1 2

= + + +

h

pr

+ h

st

+ h

v

+ h

fric

= h

p

Pressure

Head

Static

Head

Velocity

Head

Friction

Head

Pump

Head

c

2

s

2

d

fs fd s d

f

1 2

g 2

) V - (V

) h (h ) h - (h

SG

2.31 x ) P - (P

H + + + + =

H = Total Differential Head

E x 3960

gravity specific x H x Q

bhp =

Q = Capacity, gpm

H = Total Head, ft

Bhp = break horse power

Where HL = head loss due to friction, ft

L = length, ft

C = 140 for new steel pipe

= 130 for new cast iron pipe

= 100 for riveted pipe

d = pipe ID, in.

gpm = liquid flow rate, gallons/minute

Q1 = liquid flow rate, bpd

85 . 1 87 . 4

85 . 1

1

L

H

C d

L Q

=

L

d

gpm

C

85 . 1

87 . 4

85 . 1

L

100

0.00208 H

|

.

|

\

|

|

.

|

\

|

=

Hazen-Williams formula

P

2

= 50 psig

P

1

= 0 psig

Liquid Level,

Hs1

Liquid Level,

Hs2

h = 35 ft

hd = 45 ft

hs = 10 ft

hs = - 10 ft

NPSHa = P1 + hs hvp - hfs

H = (P2 P1) x 2.31 / Sp.g + (hd- hs) + Hf + (V

d

2

V

s

2

) / 2g

c

The tank is open to atmosphere, 0 psig = 34 ft water = P1, pumping water at

70F, hvp = 0.36 psi = 8 ft; from hs1 = ft.

NPSHa = 34 + 10 0.8 1 = 42.2 ft

Water

Water

Advantages of Centifugal Pump

A centrifugal pump can be multistages

Discharge pressure may be increased by

increasing pump speed.

Increasing pump speed may increase

pump rate, if the pressure is held constant.

If the rate is held constant, a speed

increase will cause the pressure to

increase.

Pump Application Sketch

E x 3960

SG x H(ft) x Q(gpm)

bhp =

E x 3960

SG x H(ft) x Q(gpm)

bhp =

P

2

= 50 psig

P

1

= 0 psig

Liquid Level,

Hs1

Liquid Level,

Hs2

h = 35 ft

hd = 45 ft

hs = 10 ft

hs = - 10 ft

NPSHa = P1 + hs hvp - hfs

H = (P2 P1) x 2.31 / Sp.g + (hd- hs) + Hf + (V

d

2

V

s

2

) / 2g

c

The tank is open to atmosphere, 0 psig = 34 ft water = P1, pumping water at

70F, hvp = 0.36 psi = 8 ft; from hs1 = 10 ft, Hf

s

= 6 ft

NPSHa = 34 8 + 10 6 = 30 ft

Water

Water

P

2

= 50 psig

P

1

= 0 psig

Liquid Level,

Hs1

Liquid Level,

Hs2

h = 35 ft

hd = 45 ft

hs = 10 ft

hs = - 10 ft

NPSHa = P1 + hs hvp - hfs

H(ft) = (P2 P1) x 2.31 / Sp.g + (hd- hs) + HF + (V

d

2

V

s

2

) / 2g

c

Water

Water

E x 3960

SG x H(ft) x Q(gpm)

bhp =

85 . 1 87 . 4

85 . 1

1

F

C d

L Q

H =

You might also like

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Industrial Plant Engineering Reviewer Complete PDFDocument93 pagesIndustrial Plant Engineering Reviewer Complete PDFNovaCastillo100% (2)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Document5 pagesStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruNo ratings yet

- Un 3790-31 PDFDocument9 pagesUn 3790-31 PDFfacebookshopNo ratings yet

- Pressure Vessel Design CalculationsDocument127 pagesPressure Vessel Design Calculationsajayghosh314086% (22)

- Un 3790-31 PDFDocument9 pagesUn 3790-31 PDFfacebookshopNo ratings yet

- Metric Properties of Structural Shapes - AISCDocument52 pagesMetric Properties of Structural Shapes - AISCalmeteck100% (7)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- A - Piping Joint HandbookDocument161 pagesA - Piping Joint HandbookCharles Tauk100% (30)

- Chapter 6 Exercise Short QuestionsDocument2 pagesChapter 6 Exercise Short Questionsirtaza ch100% (5)

- ASTM D323 - 15a TVRDocument11 pagesASTM D323 - 15a TVREliasNo ratings yet

- TurbomachineDocument41 pagesTurbomachineshailendra_236No ratings yet

- 2013lect4 Pumping System of FluidDocument30 pages2013lect4 Pumping System of Fluidmustikaaryanti100% (1)

- Pumps Chapter 11Document91 pagesPumps Chapter 11Muhammad Usman100% (1)

- Pump Basics1Document34 pagesPump Basics1Surendra ReddyNo ratings yet

- 2 Pump-Pipeline SysDocument39 pages2 Pump-Pipeline SysAdelChNo ratings yet

- Centrifugal Pump Sizing, Selection and Design Practices (Hay)Document77 pagesCentrifugal Pump Sizing, Selection and Design Practices (Hay)Scribd_del75% (8)

- Pumps PresentationDocument44 pagesPumps Presentationoida_adNo ratings yet

- Pumps and Compressors: Week 7Document20 pagesPumps and Compressors: Week 7ednsmnNo ratings yet

- Fluid Mechanics II (Chapter4)Document15 pagesFluid Mechanics II (Chapter4)حيدر محمدNo ratings yet

- Hydraulic MachineryDocument60 pagesHydraulic MachinerygetsweetNo ratings yet

- ChE354 PumpsDocument36 pagesChE354 PumpsFA AyNo ratings yet

- XI. Turbomachinery: General ClassificationDocument19 pagesXI. Turbomachinery: General ClassificationAditya GargNo ratings yet

- NPSH and CavitationDocument29 pagesNPSH and CavitationEarl Josh ManansalaNo ratings yet

- Fluid Mechanics II (Chapter 4)Document20 pagesFluid Mechanics II (Chapter 4)sarmadNo ratings yet

- Pump PerformanceDocument33 pagesPump PerformanceHASSAN MERNo ratings yet

- GPM8-E Complete CDDocument147 pagesGPM8-E Complete CDGuztavo Nm G0% (1)

- System Curves-Pump CurvesDocument87 pagesSystem Curves-Pump CurvesChandaKundaNo ratings yet

- PumpsDocument115 pagesPumpsMehmet Yılmaz100% (1)

- Chapter Five: Piping System, Cavitaions, and Net Positive Suction HeadDocument30 pagesChapter Five: Piping System, Cavitaions, and Net Positive Suction HeadKaren SantosNo ratings yet

- Conversion TableDocument6 pagesConversion TableDoctorObermanNo ratings yet

- Engineering Lesson Guide 4: Pumps, Valves, and FansDocument34 pagesEngineering Lesson Guide 4: Pumps, Valves, and FansNader Ragab AmmarNo ratings yet

- Chapter 5 Pump and Control Devices PDFDocument68 pagesChapter 5 Pump and Control Devices PDFRana G100% (2)

- PumpsDocument32 pagesPumpsAngela Paul PeterNo ratings yet

- Goulds-Pumps Fundamentals PDFDocument140 pagesGoulds-Pumps Fundamentals PDFAgustinus Made Theo Dwijaya100% (2)

- PE-System Hydraulic Design of Liquid or Water Pumping CircuitDocument25 pagesPE-System Hydraulic Design of Liquid or Water Pumping CircuitAqeel BismaNo ratings yet

- Experiment No 7+8+9Document32 pagesExperiment No 7+8+9Muhammad kamran AmjadNo ratings yet

- Hydraulic MachineryDocument60 pagesHydraulic MachinerySushil Kumar Singh100% (1)

- GPM RevDocument138 pagesGPM RevJuan Cortes TorizNo ratings yet

- Automatic Water Flow ControlDocument18 pagesAutomatic Water Flow ControlssgjmlimNo ratings yet

- CR 0701 ApaDocument2 pagesCR 0701 ApaVenkatramanan SubramaniyanNo ratings yet

- Bahan Tugas 3 Buat EXCEL Perhitungan PompaDocument37 pagesBahan Tugas 3 Buat EXCEL Perhitungan PompaIhsan Wiratama100% (1)

- Pump Basics1Document34 pagesPump Basics1MeetNo ratings yet

- Libro de BombasDocument260 pagesLibro de BombasBoris SalazarNo ratings yet

- Single Acting-Simplex Reciprocataing Piston Pump: How It Works (p.11 of Hand-Outs)Document6 pagesSingle Acting-Simplex Reciprocataing Piston Pump: How It Works (p.11 of Hand-Outs)Ariel GamboaNo ratings yet

- Pompa HidrolikDocument30 pagesPompa HidrolikIon_RiswanNo ratings yet

- Pump NPSH (Net Positive Suction Head)Document8 pagesPump NPSH (Net Positive Suction Head)farhan_katpar1838No ratings yet

- Pump System CurveDocument133 pagesPump System Curvemohamed abd eldayem0% (1)

- PumpsDocument57 pagesPumpsJai Acharya100% (1)

- Pump Basics1Document34 pagesPump Basics1sambasivammeNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Un 3790-33Document10 pagesUn 3790-33facebookshopNo ratings yet

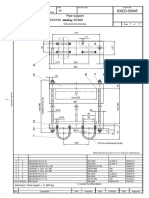

- KXEO-00045: CSC010A 25/460 Pipe SupportDocument1 pageKXEO-00045: CSC010A 25/460 Pipe SupportfacebookshopNo ratings yet

- Un 3790-41Document14 pagesUn 3790-41facebookshopNo ratings yet

- Un 3790-44Document8 pagesUn 3790-44facebookshopNo ratings yet

- Un 3790-39Document8 pagesUn 3790-39facebookshopNo ratings yet

- HAX053A 80/1250 Pipe Support: KXEO-00045Document1 pageHAX053A 80/1250 Pipe Support: KXEO-00045facebookshopNo ratings yet

- 1.standard Drawing R01 PDFDocument1,690 pages1.standard Drawing R01 PDFfacebookshopNo ratings yet

- Pde Pip G00 Ec 0137 000 00 DPP 1Document3 pagesPde Pip G00 Ec 0137 000 00 DPP 1facebookshopNo ratings yet

- Pipeline BasicsDocument12 pagesPipeline Basicsgerrydl100% (2)

- Procedures of Plant Layout N Piping-RILDocument123 pagesProcedures of Plant Layout N Piping-RILfacebookshopNo ratings yet

- Process Piping Welding T-IDocument188 pagesProcess Piping Welding T-IfacebookshopNo ratings yet

- Piping SpecificationsDocument10 pagesPiping SpecificationssmithallenNo ratings yet

- Piping Training CourseDocument446 pagesPiping Training CoursefacebookshopNo ratings yet

- Practical Piping CurseDocument46 pagesPractical Piping Cursemsaad2100% (1)

- Piping DesignDocument122 pagesPiping Designfacebookshop100% (9)

- Piping Application GuideDocument36 pagesPiping Application GuidefacebookshopNo ratings yet

- Piping and Pipe Support SystemsDocument178 pagesPiping and Pipe Support Systemssaisssms9116No ratings yet

- Prediction of Standard Pipe PressureDocument5 pagesPrediction of Standard Pipe PressurefacebookshopNo ratings yet

- Maximum Piping Operating PressureDocument8 pagesMaximum Piping Operating PressurefacebookshopNo ratings yet

- Part 1 Piping SystemsDocument22 pagesPart 1 Piping SystemsfacebookshopNo ratings yet

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- General Piping and ValvesDocument184 pagesGeneral Piping and Valvesfacebookshop100% (2)

- Flange TypesDocument1 pageFlange TypesHadi UtomoNo ratings yet

- FM PPT 4Document22 pagesFM PPT 4sagar mittalNo ratings yet

- 3 Cazimierz Conder 101YearsSuperconductivityFinalDocument42 pages3 Cazimierz Conder 101YearsSuperconductivityFinalAnonymous BMsQJZWBB8No ratings yet

- VCRSDocument24 pagesVCRSgultoogultoo2No ratings yet

- Polar Bonds and Polar MoleculesDocument18 pagesPolar Bonds and Polar MoleculesGlenn ClementeNo ratings yet

- Versión 1.5 Orifice Gasflow Calcule - ExcelDocument5 pagesVersión 1.5 Orifice Gasflow Calcule - ExceledwinmenaNo ratings yet

- ACTAIR 3 To 200 Selection ChartDocument12 pagesACTAIR 3 To 200 Selection Chartedark2009No ratings yet

- External Column Balances (W4)Document13 pagesExternal Column Balances (W4)Tle SupawidNo ratings yet

- HIGHVOLTAGE - L11 - BreakdownDocument39 pagesHIGHVOLTAGE - L11 - Breakdownrezasirjani1No ratings yet

- 02 Atomic Structure and Interatomic BondingDocument76 pages02 Atomic Structure and Interatomic BondingNorell TolentinoNo ratings yet

- Energy Resources Conversion and Utilization: Liq-Liq Extract. & Other Liq-Liq Op. and EquipDocument3 pagesEnergy Resources Conversion and Utilization: Liq-Liq Extract. & Other Liq-Liq Op. and EquipyanyanNo ratings yet

- Perancangan Dan Analisis Alat Microbubble Generator (MBG) Untuk Aerasi Kolam Ikan Tipe Nozzel VenturiDocument7 pagesPerancangan Dan Analisis Alat Microbubble Generator (MBG) Untuk Aerasi Kolam Ikan Tipe Nozzel VenturiMochammad IzzaNo ratings yet

- Increasing Water Evaporation Rate by Magnetic Field: September 2013Document9 pagesIncreasing Water Evaporation Rate by Magnetic Field: September 2013Moon SunNo ratings yet

- Measurement and Application of Zeta-Potential: Branko SALOPEK, Dragan and Suzana FILIPOVIDocument5 pagesMeasurement and Application of Zeta-Potential: Branko SALOPEK, Dragan and Suzana FILIPOVIgusuchihaNo ratings yet

- WPP Chem IX-QDocument3 pagesWPP Chem IX-QAjay KumarNo ratings yet

- Periodic Table Trends Worksheet CDPDocument4 pagesPeriodic Table Trends Worksheet CDPaḵeělaḧ ,No ratings yet

- 3Document6 pages3Petrus Jese Patarmatua PardedeNo ratings yet

- Flash Calculation: SeaderDocument24 pagesFlash Calculation: SeaderaaaNo ratings yet

- Fluid Mechanics Sample ExamDocument4 pagesFluid Mechanics Sample ExamNiña VictoriaNo ratings yet

- Unit IV CrystallographyDocument17 pagesUnit IV Crystallographyswapniljawadwar1No ratings yet

- Improvement of Adhesion Properties of Glass Prepared Using SiC-deposited Graphite Mold Via Low-Temperature Chemical Vapor DepositionDocument7 pagesImprovement of Adhesion Properties of Glass Prepared Using SiC-deposited Graphite Mold Via Low-Temperature Chemical Vapor DepositionheheNo ratings yet

- ENGR 2213 Thermodynamics: F. C. Lai School of Aerospace and Mechanical Engineering University of OklahomaDocument20 pagesENGR 2213 Thermodynamics: F. C. Lai School of Aerospace and Mechanical Engineering University of OklahomaSebastián SantarrosaNo ratings yet

- Basic Refrigeration CycleDocument12 pagesBasic Refrigeration CycleApet GriffinNo ratings yet

- 2.1 Transition Metals General Properties MSDocument11 pages2.1 Transition Metals General Properties MSJesulayomi BolajiNo ratings yet

- Ideal Gas LawDocument1 pageIdeal Gas LawIsko XDNo ratings yet

- Ch11fluidsonline 101013121349 Phpapp01Document107 pagesCh11fluidsonline 101013121349 Phpapp01naefmubarakNo ratings yet

- Air Conditioning and RefrigerationDocument21 pagesAir Conditioning and Refrigerationrajnikanth pNo ratings yet

- Effect of Droplet Collisions On Evaporation in Spraydrying PDFDocument16 pagesEffect of Droplet Collisions On Evaporation in Spraydrying PDFgerpo123No ratings yet

- Accepted Manuscript: RSC - Li/njcDocument15 pagesAccepted Manuscript: RSC - Li/njcRikardo Pino RiosNo ratings yet