Professional Documents

Culture Documents

Types of Treatments: Anand

Uploaded by

Anand Dubey0 ratings0% found this document useful (0 votes)

32 views26 pagestreatment of surfaces

Original Title

Treatments

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttreatment of surfaces

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views26 pagesTypes of Treatments: Anand

Uploaded by

Anand Dubeytreatment of surfaces

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 26

anand

Finishing and Polishing covered previously

Coatings

Conversion Coatings (oxidation, anodizing)

Thermal Coatings (carburizing flame spraying)

Metal Coatings (electrochemical, electroless)

Deposition

Physical Vapor Deposition

Chemical Vapor Deposition

Organic

Oxidation

Phosphate Coatings

Chrome Coatings

Oxidation

Not all oxides are

detrimental many are

tightly adhering leading

to passivation and

hardening of surface

Al

2

O

3

Chromium in Stainless

steel rapidly corrodes to

passivate the surface

Gun-bluing

Heat steel to 700 deg F in

steam or oil

Blue coating offers some

corrosion resistance, but little

wear benefit

Chemical Baths similar in

nature to gun-bluing

Black Oxide chemical

application

Typically applied to steel,

copper and stainless steel

Anodizing electrochemical

conversion

Usually done to Aluminum

2-25 mm thick typically

Multiple colors possible

Improved Corrosion and Wear

Resistance

Immersion in a Zn-P bath with Phosphoric acid

causes growth of a crystalline zinc phosphate

layer

Iron, Zinc or Manganese Phosphate layer formed

Typically applied to C-steel, low alloy steel and

cast irons

Sometimes applied to Zinc, Cadmium, Aluminum

and Tin

Typically very thin ~ 2.5 mm

Food cans

Immersion in a chromic acid bath (pH ~ 1.8)

with other chemicals to coat surface

Known carcinogen chemicals used, so

alternatives are currently under research

Molybdate chemicals currently best subsititute for

aluminum coatings

Very good to minimize atmospheric corrosion

Many household goods screws, hinges (yellow

brown appearance)

Typically very thin < 2.5 mm

Surface Heat Treatment

Diffusion Coating

Hot-Dip Coatings

Weld Overlay Coatings

Basic concept is to heat the surface to

austenitic range, then quench it to form surface

martensite - workpiece is steel

Heating Methods

Flame Treatment

Induction Heating

Copper coil wraps around part to heat by induction

Electron Beam or Laser Beam Hardening

Typically heat small area and allow the bulk solid heat

capacity to quench the small heated area

With low carbon steel, the surface can be enriched by

diffusion of C or N into surface

Carburizing

Heat steel to austenitic range (850-950 C) in a carbon rich

environment, then quench and temper

Nitriding

Nitrogen diffusion into steels occurs around 500-560 C to form

a thin hard surface

Good for Cr, V, W, and Mo steels. Will embrittle surface of

Aluminum.

Metal Diffusion

Chromizing Chromium diffuses into surface to form corrosion

resistant layer.

Take care with carbon steels as surface will decarburize

Aluminizing Used to increase the high temperature corrosion

resistance of steels and superalloys

These coatings are used for corrosion protection

Galvanizing

Parts are dipped into a molten zinc bath

Galv-annealing

Galvanized parts are then heat treated to ~500 C to form Fe-Zn inter-

metallic

Used for metals that need spot welded to protect copper electrode from

alloying with zinc and reducing its life

Zn-Al Coatings

Gives a different corrosion protect and a more lustrous appearance

(can greatly reduce spangles easily observed on galvanized parts)

Aluminum Coatings

Alloyed with Si

Coatings used on steel for high temperature applications that need a

lustrous appearance

Example Automobile exhaust

Typically used to improve wear resistance by creating a

hard surface over a tough bulk body

Hard Facing

Weld buildup of parts alloy composition controls final

properties

Examples cutting tools, rock drills, cutting blades

Cladding of material for corrosion resistance

Thermal spraying

Molten particle deposition a stream of molten metal particles

are deposited on the substrate surface

Major difference from hard facing is that the surface of the

substrate is not subjected to welding. Instead it just undergoes

a bonding process with the molten particles.

Electroplating

Electroless Coatings

Metallizing of Plastics and Ceramics

Used to increase wear and corrosion resistance

Electrochemical process used to create a thin coating

bonding to substrate

Process is slow so coating thickness can be closely

controlled (10-500 mm)

Applications

Tin and Zinc are deposited on steel for further working

Zinc and Cadmium are deposited on parts for corrosion

resistance (Cadmium is toxic and can not be used for food

applications)

Copper is deposited for electrical contacts

Nickel for corrosion resistance

Chromium can be used to impart wear resistance to dies and

reduce adhesion to workpieces such as aluminum or zinc

Precious metals for decoration or electronic devices

Part is submerged into an aqueous bath

filled with metal salts, reducing agents

and catalysts

Catalysts reduce metal to ions to form the

coating

Excellent for complex geometries as

deposition is uniform across surface

regardless of geometry (except very

sharp corners (0.4 mm radii))

Has the appearance of

stainless steel

Autocatalytic immersion

process

Key characteristics:

Heat treatable coating (to

68 Rc) very hard

Non-porous

Corrosion resistant

.001 thick typical

Withstand load to 45 ksi

Can be applied to:

steel and stainless steel,

iron, aluminum, titanium,

magnesium, copper,

brass, bronze, and nickel

ELECTROLESS NICKEL HARD CHROME

METAL DISTRIBUTION VERY GOOD POOR

CORROSION RESISTANCE

1,000 HOURS

ASTM B117

400 HOURS

ASTM B117

HARDNESS:

AS DEPOSITED

HEAT TREAT

48-52 Rc

70 Rc

64-69 Rc

48-52 Rc

MELTING POINT 1800

o

F 2900

o

F

WEAR RESISTANCE GOOD VERY GOOD

CO-EFFICIENT OF FRICTION:

DYNAMIC

STATIC

0.19

0.20

0.16

0.17

DUCTILITY 1-2% Very Low Almost 0

EFFLUENT COST RELATIVELY LOW HIGH

DEPOSITION RATE

(PER HOUR PER HOUR)

.0002 - .0003 .001 - .002

EFFECTIVE OF HYDROGEN

EMBRITTLEMENT ON PLATED

COMPONENTS

FAIR/NOT SERIOUS USUALLY SERIOUS

Metal Coatings

Metallizing of Plastics and

Ceramics

Poor adhesion is the major challenge (As

in all coating processes, however it is

more challenging in this case.)

Applications

Decorative (plumbing fixtures, automotive

parts), reflectivity (headlights), electrical

conduction (electronic touchpads), and EMF

shielding

Physical Vapor Deposition (PVD)

Thermal PVD

Sputter Deposition

Ion plating

Chemical Vapor Deposition (CVD)

Thermal PVD also called Vacuum Deposition

Coating material (typically metal) is evaporated by

melting in a vacuum

Substrate is usually heated for better bonding

Deposition rate is increased though the use of a DC

current (substrate is the anode so it attracts the

coating material)

Thin ~0.5 mm to as thick as 1 mm.

Physical Vapor Deposition

Sputter Deposition

Vacuum chamber is usually backfilled with Ar gas

Chamber has high DC voltage (2,000-6,000 V)

The Ar becomes a plasma and is used to target the

deposition material. The impact dislodges atoms from

the surface (sputtering), which are then deposited on

the substrate anode

If the chamber is full of oxygen instead of Ar, then the

sputtered atoms will oxidize immediately and an oxide

will deposit (called reactive sputtering)

Combination of thermal PVD and

sputtering

Higher rate of evaporation and deposition

TiN coating is made this way (Ar-N

2

atmosphere)

The gold looking coating on many cutting

tools to decrease the friction, increase the

hardness and wear resistance

Deposition of a compound (or element) produced by a

vapor-phase reduction between a reactive element and

gas

Produces by-products that must be removed from the process

as well

Process typically done at elevated temps (~900C)

Coating will crack upon cooling if large difference in thermal

coefficients of expansion

Plasma CVD done at 300-700C (reaction is activated by

plasma)

Typical for tool coatings

Applications

Diamond Coating, Carburizing, Nitriding, Chromizing,

Aluminizing and Siliconizing processes

Semiconductor manufacturing

Enamels

Form film primarily by solvent evaporation

30 % Volatile Organic Content (VOC)

Lacquers solvent evaporation

Water-base paints water evaporation,

therefore much better

Powder Coating superior more detail

to follow

Fully formulated

paint ground into a

fine powder

Powder is sprayed

onto part, retained by

static electricity

Heat cured onto part

Can virtually

eliminate VOCs

Sprayed, dipped or

tumbled to coat,

followed by heating

to bond

Key characteristics:

Low friction coefficient

(0.02 0.08)

Can sustain load of

250 ksi

Dont overlook coatings importance to

overall product performance

Coating technology is very specialized

get a couple of expert opinions before

committing

You might also like

- 2010-12 600 800 Rush Switchback RMK Service Manual PDFDocument430 pages2010-12 600 800 Rush Switchback RMK Service Manual PDFBrianCook73% (11)

- GORE Automotive Vents Exterior Lighting Datasheet ENDocument4 pagesGORE Automotive Vents Exterior Lighting Datasheet ENAaron HuangNo ratings yet

- Surface Treatment-An OverviewDocument20 pagesSurface Treatment-An OverviewGuru SamyNo ratings yet

- Coating Din4762Document10 pagesCoating Din4762motiNo ratings yet

- Guidelines For Alloy Selection For Waters and Waste Water Service PDFDocument6 pagesGuidelines For Alloy Selection For Waters and Waste Water Service PDFssgentisNo ratings yet

- Compatibilidad Materiales Corrosion - TableDocument20 pagesCompatibilidad Materiales Corrosion - TableYaíma Casañola SuárezNo ratings yet

- Din en 10111Document14 pagesDin en 10111aldairlopesNo ratings yet

- C Arrays and Pointers: - in Java, Pointers Are Easy To Deal WithDocument16 pagesC Arrays and Pointers: - in Java, Pointers Are Easy To Deal WithJamali NagamoraNo ratings yet

- Multivariable Notes PDFDocument233 pagesMultivariable Notes PDFFitri AzizaNo ratings yet

- Why Stainless Steel Rust - Corrosion - Part 2 - Other CorrosionDocument12 pagesWhy Stainless Steel Rust - Corrosion - Part 2 - Other CorrosionViệt Đặng XuânNo ratings yet

- 20-01 Design Din en Iso enDocument19 pages20-01 Design Din en Iso enIbhar Santos MumentheyNo ratings yet

- En 60745-1 - 2009-A11 - 2010Document4 pagesEn 60745-1 - 2009-A11 - 2010Vuk OgiNo ratings yet

- Iso 12944 Brochure PDFDocument21 pagesIso 12944 Brochure PDFCristian CisternasNo ratings yet

- Chemical Resistance Chart: Sodium Hydroxide - Tartaric AcidDocument1 pageChemical Resistance Chart: Sodium Hydroxide - Tartaric AcidAbdullah FahmiNo ratings yet

- 3 1 Eight Forms CorrosionDocument20 pages3 1 Eight Forms CorrosionIbraheem KhressNo ratings yet

- Lecture Notes For Physics 229: Quantum Information and ComputationDocument321 pagesLecture Notes For Physics 229: Quantum Information and ComputationIsai Angel RungasamyNo ratings yet

- Yao D.D., Zheng S.-Dynamic Control of Quality in Production-Inventory Systems-Springer (2002)Document229 pagesYao D.D., Zheng S.-Dynamic Control of Quality in Production-Inventory Systems-Springer (2002)Vsauce FansNo ratings yet

- A Review of Steel and Its Interaction With Hydrogen Diana M. Ayala Valderrama, Yinela A. Young MosqueraDocument22 pagesA Review of Steel and Its Interaction With Hydrogen Diana M. Ayala Valderrama, Yinela A. Young MosquerayinelaNo ratings yet

- Galvanic CorrDocument6 pagesGalvanic CorrdhlinvaNo ratings yet

- Wet Gas MeterDocument4 pagesWet Gas MeterFareez JamaliNo ratings yet

- Modern Control Theory - Ad DamenDocument163 pagesModern Control Theory - Ad Damenjonastibola100% (1)

- Calculation of Correction Factors For Variable Area Flow MetersDocument5 pagesCalculation of Correction Factors For Variable Area Flow MetersgeorgehvaNo ratings yet

- Applying Matlab - Simulink To Study Calculation of NOx Efficiency of The SCRDocument5 pagesApplying Matlab - Simulink To Study Calculation of NOx Efficiency of The SCRMaxNo ratings yet

- Pitting CorrosionDocument29 pagesPitting Corrosionatikahj_3No ratings yet

- 2015 - 07094934Document9 pages2015 - 07094934mjimenezgNo ratings yet

- Radial Fan Conical Vs Parallel Impeller Casing AnalysisDocument10 pagesRadial Fan Conical Vs Parallel Impeller Casing AnalysisvirgilioNo ratings yet

- Melchert Duijve - MSC Thesis - LCA Insulation Materials - 2012Document139 pagesMelchert Duijve - MSC Thesis - LCA Insulation Materials - 2012Julian Andres Garcia BohorquezNo ratings yet

- Tds Fire Clay Brick Sk30 enDocument1 pageTds Fire Clay Brick Sk30 enjcljeNo ratings yet

- General Tolerances - DIN - IsO - 2768Document2 pagesGeneral Tolerances - DIN - IsO - 2768Pasca GheorgheNo ratings yet

- Cak D1 1211Document342 pagesCak D1 1211sergey sergeevNo ratings yet

- Fundamentals of Radiation Thermometry: Klaus Anhalt Klaus - Anhalt@ptb - deDocument17 pagesFundamentals of Radiation Thermometry: Klaus Anhalt Klaus - Anhalt@ptb - deAshish DubeyNo ratings yet

- Jeida Farm Supply Corporation Catalog 2014Document10 pagesJeida Farm Supply Corporation Catalog 2014Taj Deluria100% (3)

- Steel Coating SystemsDocument39 pagesSteel Coating Systemsmzarei_1982No ratings yet

- KAT A 1332 G Gu Lug CEREX300 L Cast Iron Gas Edition8 03.07.2018 enDocument4 pagesKAT A 1332 G Gu Lug CEREX300 L Cast Iron Gas Edition8 03.07.2018 enCarlos Alfaro GuerraNo ratings yet

- Corrosion of Water Walls and Superheaters in Wte MSW PlantsDocument114 pagesCorrosion of Water Walls and Superheaters in Wte MSW Plantsvijay_nani124No ratings yet

- En P 01 PrinciplesOfBrazingTechnologyDocument14 pagesEn P 01 PrinciplesOfBrazingTechnologySyed Noman AhmedNo ratings yet

- Information - Roofing SheetDocument5 pagesInformation - Roofing SheetRajeev RanjanNo ratings yet

- Galvanizing Defects RectificationsDocument28 pagesGalvanizing Defects RectificationslakshanNo ratings yet

- Latest Date For Receipt of Comments: 31 July 2013: Form 36Document15 pagesLatest Date For Receipt of Comments: 31 July 2013: Form 36Popeye William CapthandsomeNo ratings yet

- Slag GrranulationDocument2 pagesSlag Grranulationnishanth132No ratings yet

- Understanding UL 94 Certifications and LimitationsDocument2 pagesUnderstanding UL 94 Certifications and LimitationsLakshmi PrasannaNo ratings yet

- Company Name Weld Procedure SpecificationDocument2 pagesCompany Name Weld Procedure SpecificationAekJayNo ratings yet

- PROFITank Sample Structural CalculationDocument26 pagesPROFITank Sample Structural CalculationAndrea Castillo100% (1)

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNo ratings yet

- Waste Heat Recovery Vinay ShuklaDocument31 pagesWaste Heat Recovery Vinay ShuklaVnyNo ratings yet

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDocument6 pagesE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanNo ratings yet

- Arvedi First Thin Slab Endless CastingDocument10 pagesArvedi First Thin Slab Endless CastingprasenjitsayantanNo ratings yet

- Chemical Resistance ChartDocument11 pagesChemical Resistance Chartdpick1No ratings yet

- BS en 26704-1991 (1999) Iso 6704-1982Document12 pagesBS en 26704-1991 (1999) Iso 6704-1982GT-LUCAS BARCINo ratings yet

- Kina25317enn 002 PDFDocument115 pagesKina25317enn 002 PDFfahrgeruste3961No ratings yet

- 229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFDocument2 pages229-79577 - EN - 10204 - Type - 3 - 2 - Certification - Services.2 Inspection Certification PDFBranza TelemeaNo ratings yet

- Seawater Flue Gas DesulphurisationDocument2 pagesSeawater Flue Gas DesulphurisationNestramiNo ratings yet

- ELEC3320 - Lecture Notes 1Document36 pagesELEC3320 - Lecture Notes 1Aneketh GurumurthiNo ratings yet

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Structure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsFrom EverandStructure and Properties of Inorganic Solids: International Series of Monographs in Solid State PhysicsNo ratings yet

- Surface Coatings1Document16 pagesSurface Coatings1bathinsreenivasNo ratings yet

- Surface Engineering Part 1Document71 pagesSurface Engineering Part 1Prasanth M Cool100% (1)

- Topic 2 Property Enhancing and Surface Processing Operations 2017Document87 pagesTopic 2 Property Enhancing and Surface Processing Operations 2017lim50% (2)

- DevashishDocument43 pagesDevashishDevashish JoshiNo ratings yet

- Materials Selection For Wear ResistanceDocument28 pagesMaterials Selection For Wear ResistanceRECEP ÇETİNKAYANo ratings yet

- Golden Peacock Innovative Product/Service Award (Gpipsa) : Guidelines-cum-Application FormDocument11 pagesGolden Peacock Innovative Product/Service Award (Gpipsa) : Guidelines-cum-Application FormAnand DubeyNo ratings yet

- 5 Leave RuleDocument5 pages5 Leave RuleAnand DubeyNo ratings yet

- Supreme Court DecisionsDocument2 pagesSupreme Court DecisionsAnand DubeyNo ratings yet

- Writ Petition (Civil) No. 176 of 2009 and I.A. No. 1 of 2009 (Under Article 32 of The Constitution of India)Document4 pagesWrit Petition (Civil) No. 176 of 2009 and I.A. No. 1 of 2009 (Under Article 32 of The Constitution of India)Anand DubeyNo ratings yet

- 7qt 8Document6 pages7qt 8Anand DubeyNo ratings yet

- Leave Rules 7Document4 pagesLeave Rules 7Anand DubeyNo ratings yet

- Leave Rule 2Document5 pagesLeave Rule 2Anand DubeyNo ratings yet

- Leave Rule1Document4 pagesLeave Rule1Anand DubeyNo ratings yet

- Leave Rules3Document5 pagesLeave Rules3Anand DubeyNo ratings yet

- Global Warming: The Greenhouse EffectDocument4 pagesGlobal Warming: The Greenhouse EffectAnand DubeyNo ratings yet

- Causes of Environmental DegradationDocument4 pagesCauses of Environmental DegradationAnand DubeyNo ratings yet

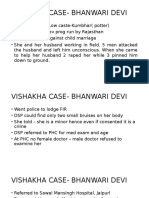

- Vishakha Case-Bhanwari DeviDocument4 pagesVishakha Case-Bhanwari DeviAnand DubeyNo ratings yet

- Environmental Management System (Ems) & Related StandardsDocument4 pagesEnvironmental Management System (Ems) & Related StandardsAnand DubeyNo ratings yet

- Sexual Harassment of Women at Workplace (Prevention, Prohibition and Redressal) Act, 2013Document4 pagesSexual Harassment of Women at Workplace (Prevention, Prohibition and Redressal) Act, 2013Anand DubeyNo ratings yet

- Sexual Harrassment PartDocument4 pagesSexual Harrassment PartAnand DubeyNo ratings yet

- Population IncreaseDocument4 pagesPopulation IncreaseAnand DubeyNo ratings yet

- Vishakha Case-Bhanwari Devi: - Dist Court Judgement in Nov 1995Document6 pagesVishakha Case-Bhanwari Devi: - Dist Court Judgement in Nov 1995Anand DubeyNo ratings yet

- Attitude & Human Behaviour: Lakshman Singh Ex Jwm/OfilknDocument49 pagesAttitude & Human Behaviour: Lakshman Singh Ex Jwm/OfilknAnand DubeyNo ratings yet

- Sexual Harassment of Women at Workplace (Prevention, Prohibition and Reddressal) ACT 2013Document4 pagesSexual Harassment of Women at Workplace (Prevention, Prohibition and Reddressal) ACT 2013Anand DubeyNo ratings yet

- Efficiency Gap JMS 2Document7 pagesEfficiency Gap JMS 2Anand DubeyNo ratings yet

- 6 Gender SensitivityDocument65 pages6 Gender SensitivityAnand DubeyNo ratings yet

- What Are Control Charts?: Comparison of Univariate and Multivariate Control DataDocument3 pagesWhat Are Control Charts?: Comparison of Univariate and Multivariate Control DataAnand DubeyNo ratings yet

- Water Cooled Chiller (SHUBAILY GRAND MALL)Document40 pagesWater Cooled Chiller (SHUBAILY GRAND MALL)kdpmansiNo ratings yet

- SRV1 Q4-05 PDFDocument484 pagesSRV1 Q4-05 PDFalexNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- D-Intro To Programming With RAPTORDocument13 pagesD-Intro To Programming With RAPTORmarkecbNo ratings yet

- Service Brake: Model FB (Air Over Hydraulic Brake)Document97 pagesService Brake: Model FB (Air Over Hydraulic Brake)Komatsu Perkins HitachiNo ratings yet

- Math5 Q4 Mod11 OrganizingDataInTabularFormAndPresentingThemInALineGraph V1Document45 pagesMath5 Q4 Mod11 OrganizingDataInTabularFormAndPresentingThemInALineGraph V1ronaldNo ratings yet

- 253 968 2 SPDocument16 pages253 968 2 SPAlvin MRNo ratings yet

- AL8860EV2 User GuideDocument8 pagesAL8860EV2 User GuideHans ClarinNo ratings yet

- Laboratory Investigations On The Causes of Road Failures Constructed AlongDocument8 pagesLaboratory Investigations On The Causes of Road Failures Constructed AlongMulugeta DessieNo ratings yet

- DV-08-UK (Oct-07)Document28 pagesDV-08-UK (Oct-07)hepcomotionNo ratings yet

- Capacitors and Dielectrics: Major PointsDocument18 pagesCapacitors and Dielectrics: Major Points陳慶銘No ratings yet

- Reasoning Calendar Questions Finding Day or Date, Concepts, Shortcuts ExplainedDocument8 pagesReasoning Calendar Questions Finding Day or Date, Concepts, Shortcuts ExplainedManish KumarNo ratings yet

- CLT2Document13 pagesCLT2Yagnik KalariyaNo ratings yet

- Alkali MetalsDocument12 pagesAlkali MetalsSaki Sultana LizaNo ratings yet

- Binomial Theorem: Theory and Exercise BookletDocument8 pagesBinomial Theorem: Theory and Exercise BookletEr. Narender SinghNo ratings yet

- Second Periodical ExamDocument19 pagesSecond Periodical ExamMaynard Lee Estrada GomintongNo ratings yet

- Datasheet Solis 110K 5GDocument2 pagesDatasheet Solis 110K 5GAneeq TahirNo ratings yet

- ISO 3384 2005-Stress RelaxationDocument18 pagesISO 3384 2005-Stress RelaxationshashaNo ratings yet

- A1 - Full Papers PS1 10834 2022Document18 pagesA1 - Full Papers PS1 10834 2022DmitryNo ratings yet

- Engine Removal and DisassemblyDocument12 pagesEngine Removal and DisassemblyMinh MinhNo ratings yet

- Foundation Design RequirementsDocument18 pagesFoundation Design RequirementsDanyal AhmedNo ratings yet

- ORM-II Theory+exercise+ Answer PDFDocument58 pagesORM-II Theory+exercise+ Answer PDFGOURISH AGRAWALNo ratings yet

- Maintenance Manual Training Presentation - R.ADocument232 pagesMaintenance Manual Training Presentation - R.AYasir Ammar100% (3)

- Kenelm Digby On Quantity As Divisibility PDFDocument28 pagesKenelm Digby On Quantity As Divisibility PDFvalexandrescuNo ratings yet

- General Systems Theory A Mathematical ApproachDocument385 pagesGeneral Systems Theory A Mathematical Approachselotejp7100% (4)

- PD Measurements On Power TransformersDocument3 pagesPD Measurements On Power TransformersJuan Sebastian Juris ZapataNo ratings yet

- Ee 434L Manual (5-12)Document45 pagesEe 434L Manual (5-12)Saleemullah KhanNo ratings yet

- Structural SteelDocument17 pagesStructural SteelliNo ratings yet

- MFTDocument63 pagesMFTvenkatwsNo ratings yet