Professional Documents

Culture Documents

Perforating Basics

Uploaded by

Khalid Waheed ShaikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Perforating Basics

Uploaded by

Khalid Waheed ShaikhCopyright:

Available Formats

1

Perforating Basics

2

Perforating Basics

Basic Concepts

Factors Affecting Gun Performance

Perforation x Production

Perforation and Completion Types

Perforation Techniques

Intelligent Perforation

3

Basic Concepts

Perforation in Well Completion

Explosives

Shaped Charges

Perforating Guns

4

Production

Zone

Cement

Casing or

Liner

Well Completion

Perforating is a critical part of well completion

Determinant for well productivity

Safety

Lower Cost

Pressure Relation:

Overbalance;

Underbalance;

Extreme Overbalance.

5

Explosives

Explosives Types:

Low Explosives:

High Explosives

Primary Explosives: Electric and Percussion Detonators;

Secondary Explosives: Detonating Cord, Boosters and

Shaped Charges.

Affected by temperature

6

Liner Position

Shaped Charges

Components:

Outer Case;

Primer Explosive;

Main Explosive;

Liner

7

4 sec

Shaped Charges

Detonation Mechanics:

1. Detonation Cord -

Primer Explosive - Main

Explosive

2. Liner collapses -

perforating jet

8

9.4 sec

16.6 sec

Shaped Charges

Detonation Mechanics:

1. Detonation Cord -

Primer Explosive - Main

Explosive

2. Liner collapses -

perforating jet

3. Jet impacts casing

surface (100 GPA )

4. Jet passes through

casing wall, cement and

formation

9

Perforating Guns

Divided in:

Capsule Guns:

Enerjet* and Pivot*

Carrier Guns: High

Density, HEGS*,

Scallope

Expendable or

Retrievable

Debris are concern

Clearance x standoff

10

Perforating Guns

Divided in:

Capsule Guns:

Enerjet and Pivot

Carrier Guns: High

Density, HEGS,

Scallope

Expendable or

Retrievable

Debris are concern

Clearance x standoff

11

Gun Performance

Direct Influence well production

Performance affected by:

Gun Design

Downhole Parameters

12

Gun Design Factors

Standoff

Scallop Thickness

Small effect in deep penetration than in Big Hole

charges

Charge packed in the gun

Charge to charge interference;

13

Downhole Parameters

Clearance

Casing Strength

Effective Formation Strength

Wellbore Fluid

Temperature

14

Perforation x Productivity

Productivity Laws

Skin

Perforation Parameters

Skin due to Perforation

15

q =

kh (Pe - Pwf)

141.2 | (In

re

rw

+ S)

PI =

q

P P

kh

141.2 ln

r

r

e wf

e

w

=

+

|

\

|

.

| | S

Productivity Laws

Darcys Law

Productivity Index

16

Skin

Divided in

Mechanical Skin:

Drilling, Completion fluids

Perforation damage

Pseudo Skin:

Completion improper diameter;

Shot density

Turbulence

Perforation plugging

17

Perforation Parameters

Geometry factors

Importance related to

completion type and

formation conditions

Shot density more

important than shot

penetration

18

Skin due to Perforation

Skin due to:

Perforation Length

Shot Density

Crushed Zone Permeability

Thickness

Optimum Underbalance

19

Completion Types

Natural Completion

Stimulated Completion

Fracturing;

Acidizing;

STIMPAC*

Extreme Overbalance

Perforation affecting Sand Control and Fracturing

20

Perforation x Sand Control

Perforation Efficiency - Permeability

Factors:

Gravity

Sand debries are difficult to remove

Stable Arcs

Multiple Perforations

Gravel mixed to Sand Debries tends to reduce

permeability

21

Perforation x Sand Prevention

Three main objectives:

Acceptable sand production

Minimize formation stress

Optimum flow rate

Recommended Perforation Design:

Underbalance

Deep Penetration

Optimum gun phase

Shot density by Critical Flow

Oil as wellbore fluid

22

Perforation x Fracture

Objectives:

Minimize Wellbore Pressure Drops

Perforation Friction

Microannulus

Side Fractures

Tortuosity

Lab Results:

180 phase with 30 degrees offset PFP

Hole diameter: Saucier Method

23

Perforation Techniques

Through-Tubing Perforating

HyperDome*, Enerjet* or Pivot* - Carrier Guns

Completion tested, Underbalance, Rigless

Limited Interval - 30 ft

Casing Gun/ High Shot Density Guns

Port Plug Guns, HEGS* and HSD guns

Gun size limited by casing size

Wireline conveyed in overbalance: larger interval

(60 ft)

Low Debries Guns

24

Perforation Techniques

Wireline :

Faster and Economic

Limited Intervals - Deviated Wells

Tubing Conveyed Perforation

Long and multizone intervals

Through tubing and casing/ HSD advantages

Underbalance Perforation

Wide variety of firing systems

Expendable guns can be drop allowing through

tubing operations

25

Perforation Techniques

Guns

Enerjet*

Pivot*

HSD*

Big Shot

Release Mechanisms

WAXR*

SXAR*

MAXR*

26

PerfPAC*

Perforation Techniques

Completion without Killing

FIV*

CIRP*

PERFPAC*

GunStack

27

Custom design each completion based on

formation properties to optimize production

Intelligent Perforating.Completion Design

Intelligent Perforating

28

Reservoir

Description

Completion

Design

Hardware Treatment

Gun

Deployment

Job

Design

Execution

(Optimize)

Seismic

Logs...

Perforating

Parameters

Simulators

Nodal, SPAN*..

Monobore

Multiple..

Performance Data Base

Field Specific

Intelligent Perforating

29

Natural Completions

Formation Damage

Deep Penetrating Charges

Anisotropy

High Shot Density

Phasing

Perforation Skin

Underbalance

TCP

Through-Tubing

FIV, X-Tools

CIRP, Stackable

Long Intervals

TCP, CT

FIV, X-Tools

CIRP, Stackable

Deep/Hot Wells

HPHT, HNS/HTX

Wireline

Through-Tubing

Hard Formations

Hard-Rock Charges

30

Sand Control

Gravel Placement & Skin Reduction

Area-Open-to-Flow (AOF)

Shot Density and Big-Hole Charges

Phasing

Reduction of Perforation Skin

(Underbalance/Clean-up)

Efficiency

PERFPAC

IRDV, SXAR, HSD Guns, Quantum Packer

31

Sand Prevention

Retain Structural Integrity

Deep Penetrating Charges

High Shot Density

Optimum Phasing (Maximize Perf-to-Perf

Spacing)

Limit Drawdown

Custom Gun Designs

7-in. 27 spf HSD Gun

3 3/8-in. 4 spf 99

32

Hydraulic Stimulation - Frac

Pressure Drop

Perforation Hole Size

Interval Length

Number of Shots

Tortuosity & Leakoff

Phasing (180, 60 , 120)

Orientation

Micro Annulus or Multiple Fractures

Deviation

33

Deviated/Horizontal Wells

Debris

CleanSHOT*, CleanPACK* Charges

Bigshot 21*

Skin

Gun Orientation

Special Guns (Top-side Shooting)

Efficiency

Coiled Tubing Perforating

FIV*, LTIV*

34

References Jan 99

Schlumberger WL & Testing Perforating Services

Manual

You might also like

- Perforating Gun TypesDocument32 pagesPerforating Gun TypesSadiq HusayniNo ratings yet

- IDPT - 10 - Casing Seat SelectionDocument14 pagesIDPT - 10 - Casing Seat SelectionDaymas Arangga Radiandra100% (1)

- Part 5 Perforating TechniquesDocument46 pagesPart 5 Perforating Techniquesamir_ahmed_27100% (1)

- PerforationDocument27 pagesPerforationmemos2011No ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Fracturing For Sand ControlDocument37 pagesFracturing For Sand ControlkmelloistakenNo ratings yet

- C4 PerforatingDocument40 pagesC4 PerforatingNguyễnTrườngNo ratings yet

- IDPT - 12 - Casing Design PrinciplesDocument12 pagesIDPT - 12 - Casing Design PrinciplesDaymas Arangga RadiandraNo ratings yet

- "Fishing Operation ": Drilling EngineeringDocument28 pages"Fishing Operation ": Drilling EngineeringLulav Barwary100% (1)

- Tubing Conveyed Perforating Systems PDFDocument8 pagesTubing Conveyed Perforating Systems PDFVishwanath BanerjieNo ratings yet

- Spe 30364 Seebty Ofpotrebum Endnws: Platform Concept OutlineDocument12 pagesSpe 30364 Seebty Ofpotrebum Endnws: Platform Concept Outlinebr_fdm1604100% (1)

- CompletionsDocument78 pagesCompletionsHamed GeramiNo ratings yet

- Offshore Well Construction - Casing DesignDocument77 pagesOffshore Well Construction - Casing DesigntduyhaoNo ratings yet

- Introduction of Gravel Pack With Inflow Control Completions in BrazilDocument26 pagesIntroduction of Gravel Pack With Inflow Control Completions in BrazilMujtabaNo ratings yet

- 11 CL-1.Primary Cementing 1Document45 pages11 CL-1.Primary Cementing 1Eslam Atif AzkolNo ratings yet

- Drill String DesignDocument12 pagesDrill String Designnikhil_barshettiwatNo ratings yet

- Perforating Technology: China National Logging CorpDocument39 pagesPerforating Technology: China National Logging Corpdarryl_gilbertNo ratings yet

- LinerDocument19 pagesLinerHakan Özkara100% (1)

- 13 Remedial SqueezeDocument26 pages13 Remedial SqueezeLenin DiazNo ratings yet

- UGM JDS - 9 Casing Design Load Case ExerciseDocument15 pagesUGM JDS - 9 Casing Design Load Case ExercisedidikhartadiNo ratings yet

- Tubing SelectionDocument51 pagesTubing SelectionImam Zulkifli SNo ratings yet

- Completion Equipment1Document32 pagesCompletion Equipment1MUHAMMAD AKRAMNo ratings yet

- Tubing Length Change CalculationsDocument33 pagesTubing Length Change CalculationsOmer Khalid100% (2)

- 14 PackersDocument45 pages14 PackersJuan Carlos Gonzalez L100% (1)

- ERD RecommendationsDocument25 pagesERD Recommendationsvictor_n333100% (2)

- Sand Control MethodsDocument17 pagesSand Control MethodsKamran Haider Tunio100% (1)

- Perf - Presentation AiymDocument32 pagesPerf - Presentation AiymNaief Javaheri100% (1)

- Perforation: ReviewDocument7 pagesPerforation: ReviewVG100% (1)

- AADE/Fluids Management Group: Advances in Deepwater FluidsDocument15 pagesAADE/Fluids Management Group: Advances in Deepwater FluidsBarry TrettNo ratings yet

- Advanced Drilling Practices - Casing Design PDFDocument92 pagesAdvanced Drilling Practices - Casing Design PDFAnonymous H9n5g3aaCENo ratings yet

- Section 05 Tripping Backreaming PracticesDocument68 pagesSection 05 Tripping Backreaming PracticesSpeculeNo ratings yet

- CSG Type & DesignDocument45 pagesCSG Type & Designcrown212100% (2)

- Permanent+vs+retrievable+packer 00076711.desbloqueadoDocument16 pagesPermanent+vs+retrievable+packer 00076711.desbloqueadoSalomon Rached FerrerNo ratings yet

- Uses of PackersDocument13 pagesUses of Packersmohamed_sahnoun_enisNo ratings yet

- Side Tracking Cased HolesDocument45 pagesSide Tracking Cased HolesNehomar Jose Brito Guerra100% (4)

- HPHT Solutions Drilling and EvaluationDocument41 pagesHPHT Solutions Drilling and EvaluationJohnSmithNo ratings yet

- Formation Damage ExamplesDocument89 pagesFormation Damage ExamplesLaurensius Raymond SanjayaNo ratings yet

- Well Completion Techniques-2 (Well Perforation)Document74 pagesWell Completion Techniques-2 (Well Perforation)NIRAJ DUBEY67% (3)

- Well Plugging & Abandonment GuidelineDocument11 pagesWell Plugging & Abandonment GuidelineAry Rachman100% (1)

- Well Control PresentationDocument57 pagesWell Control PresentationmissaouiNo ratings yet

- Kick Tolerance CalculationDocument5 pagesKick Tolerance Calculationi oNo ratings yet

- Well CementingDocument8 pagesWell CementingNima MoradiNo ratings yet

- Casing and Cement ManualDocument248 pagesCasing and Cement ManualAnonymous ocBLoeAOh467% (3)

- Liner Hanger SystemsDocument22 pagesLiner Hanger SystemsVJHJHVJHNo ratings yet

- USIT CBL Microannulus PDFDocument6 pagesUSIT CBL Microannulus PDFAnkit SharmaNo ratings yet

- Principles and ProceduresDocument236 pagesPrinciples and ProceduresMurtda AL-SayadNo ratings yet

- GRAVEL Packer Tool OperationDocument7 pagesGRAVEL Packer Tool OperationCerón Niño Santiago100% (2)

- Casing DesignDocument28 pagesCasing DesignTarek Hassan100% (2)

- Drilling and Completion Egy Petroleum Engineer PDFDocument208 pagesDrilling and Completion Egy Petroleum Engineer PDFRahma MejriNo ratings yet

- Determine Hole Cleaning Requirement in Deviated WellsDocument22 pagesDetermine Hole Cleaning Requirement in Deviated WellsCut Fanni Ayutaya100% (1)

- Sand Control FINALDocument90 pagesSand Control FINALAbdelHamid Abdo100% (1)

- Petroleum Engineering - Well ControlDocument43 pagesPetroleum Engineering - Well ControlJeffrey100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Principles of Enhanced Oil Recovery: by Engr. Hassan AzizDocument83 pagesPrinciples of Enhanced Oil Recovery: by Engr. Hassan AzizKhalid Waheed ShaikhNo ratings yet

- List of Nominated Faculty & Students For Ats & E 2019 (Islamabad)Document1 pageList of Nominated Faculty & Students For Ats & E 2019 (Islamabad)Khalid Waheed ShaikhNo ratings yet

- Visit at Core Lab PPLDocument1 pageVisit at Core Lab PPLKhalid Waheed ShaikhNo ratings yet

- BOBI OIL COMPLEX LetterDocument1 pageBOBI OIL COMPLEX LetterKhalid Waheed ShaikhNo ratings yet

- Production Assignment 1Document4 pagesProduction Assignment 1Khalid Waheed ShaikhNo ratings yet

- Updated Timetable of 18 PGDocument1 pageUpdated Timetable of 18 PGKhalid Waheed ShaikhNo ratings yet

- TABLE S1: Compressibility Factors, Z, of The Pure Components Helium, Xenon, Z Z ZDocument5 pagesTABLE S1: Compressibility Factors, Z, of The Pure Components Helium, Xenon, Z Z ZKhalid Waheed ShaikhNo ratings yet

- Oil and Gas Well CompletionsDocument93 pagesOil and Gas Well CompletionsKhalid Waheed Shaikh100% (3)

- OzoneDocument1 pageOzonebolsjhevikNo ratings yet

- Mic Electronics Research ReportDocument17 pagesMic Electronics Research ReportSudipta BoseNo ratings yet

- Frax22b Frax22d Drx32ddlmanualDocument18 pagesFrax22b Frax22d Drx32ddlmanualPawel Vlad LatoNo ratings yet

- Catalog Solar-PV String Inverters Hopewind V4.3.1Document14 pagesCatalog Solar-PV String Inverters Hopewind V4.3.1Atiq SaberNo ratings yet

- ProMax 3 BrochureDocument20 pagesProMax 3 BrochureNila Gama100% (2)

- Barracuda Lite 19 WS RegularDocument2 pagesBarracuda Lite 19 WS RegularcarlosorizabaNo ratings yet

- GUF RDH4 SpecificationsDocument4 pagesGUF RDH4 SpecificationstachetacheNo ratings yet

- Class 9 Science Study Material Chapter 12Document16 pagesClass 9 Science Study Material Chapter 12rajman1990No ratings yet

- BHEL - Agitator Specification PDFDocument68 pagesBHEL - Agitator Specification PDFRiyaz100% (1)

- Get Big Stay LeanDocument87 pagesGet Big Stay LeanMatheus Buniotto100% (1)

- 31 Getting Your Refrigerator To RDocument19 pages31 Getting Your Refrigerator To Rraypower2004No ratings yet

- MF1547Electric Panel PDFDocument24 pagesMF1547Electric Panel PDFAhmad Ali NursahidinNo ratings yet

- PDS655S 404 405Document59 pagesPDS655S 404 405Naing Min HtunNo ratings yet

- GT ManualDocument10 pagesGT Manualsoldatbr4183No ratings yet

- CREW Radon 1 ReportDocument26 pagesCREW Radon 1 ReportDragos MihaiNo ratings yet

- Tài liệu bộ chỉnh lực căng (Tension Controller Mitsubishi) LE-40MTA-EDocument54 pagesTài liệu bộ chỉnh lực căng (Tension Controller Mitsubishi) LE-40MTA-ENguyễn Văn Dũng50% (2)

- A Novel High-Gain DC-DC Converter Applied in Fuel Cell VehiclesDocument13 pagesA Novel High-Gain DC-DC Converter Applied in Fuel Cell Vehiclesrock starNo ratings yet

- 250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt InverterDocument3 pages250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt Invertertaner56No ratings yet

- PHYSICS/FILIPINODocument2 pagesPHYSICS/FILIPINOMaLou Temblique EscartinNo ratings yet

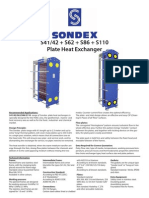

- S41/42 + S62 + S86 + S110 Plate Heat ExchangerDocument2 pagesS41/42 + S62 + S86 + S110 Plate Heat ExchangerTrần Khắc ĐộNo ratings yet

- 16operation StartingadieselengineDocument76 pages16operation StartingadieselengineVijay HanchinalNo ratings yet

- IT Chem F5 Mid-Year Examination (E)Document10 pagesIT Chem F5 Mid-Year Examination (E)Norzawati NoordinNo ratings yet

- ATP-Oil A4 Brochure Proof 4aDocument33 pagesATP-Oil A4 Brochure Proof 4aDavid PomaNo ratings yet

- PWM Control IC: BM1P107FJDocument30 pagesPWM Control IC: BM1P107FJArokiaraj RajNo ratings yet

- Ponchon Savarit MethodDocument34 pagesPonchon Savarit Methodppga410100% (7)

- Temperature Measurement Lab Report PDFDocument13 pagesTemperature Measurement Lab Report PDFSyafiiqahNo ratings yet

- Project On Global WarmingDocument22 pagesProject On Global WarmingHilda DsouzaNo ratings yet

- TechnicalPaper PDFDocument30 pagesTechnicalPaper PDFJimmy HaddadNo ratings yet

- MC 10206242 0001Document8 pagesMC 10206242 0001Yang MaNo ratings yet

- Subsea Pipeline Design Report.Document26 pagesSubsea Pipeline Design Report.Luke6nNo ratings yet