Professional Documents

Culture Documents

1988 Piper Alpha Oil Rig Ablaze

Uploaded by

Hamdan YusoffCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1988 Piper Alpha Oil Rig Ablaze

Uploaded by

Hamdan YusoffCopyright:

Available Formats

1988: Piper Alpha Oil Rig

Ablaze

CHEN 655 Project:

Syed Quraishy

Tasmia Tahsin Priyanka

Piper Alpha-Location

At around 110 miles north-east of Aberdeen in the North

Sea.

Claymore and Tartan were the two other platforms

connected to Piper which were also operated by

Occidental.

http://www.brighthubengineering.com/marine-history/116049-piper-alpha-oil-rig-disaster

Piper Alpha-Background

Owned by a consortium consisting of

-Occidental Petroleum (Caledonia)

-Texaco Britain Ltd

-International Thomson Plc

-Texas Petroleum Ltd

Oil Production in 1976 about 250,000 barrels

per day increasing to 300,000 barrels later.

In 1980 a gas recovery module was installed .

Production declined to 125,000 in the year

1988.

Piper Alpha-Background

The production deck level consisted of four

Modules:

Module A: Well head

Module B: Oil Separation

Module C: Gas compression

Module D: Power generation and Utilities

Piper Alpha-Background

Piper Alpha Platform: West

Elevation

(Lees Loss Prevention in Process industries, Volume 3)

Piper Alpha Platform: Production deck on 84 feet level

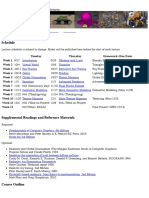

Piper Alpha-Timeline

Incident Investigation

1 hr. 35 min before disaster:

All gas alarm came from

module C

Captain in one of the nearby

ship had seen a blue flame

coming underneath the module

C

Convinced the investigator that

module C was starting point of

the explosion

Analyzing 3 products of Piper

Alpha they were confirmed that

condensate started the fire.

Incident Investigation

Analyzed the pattern of the gas

alarm & suspected a condensate

release in the eastern end of

module C.

Only source of condensate in

module C is two PSVs; designed

to withstand twice the operating

pressure.

PSV-504 was taken out for a

maintenance work, replaced by a

blind flange/metal disk

Incident Investigation

Workers had installed the metal disk by

hand tight.

PSV-504 was connected with a condensate

pump which was shut down for an

overhauling job.

Standby pump (Pump-B) tripped that night

and the lead operator (unaware about the

PSV maintenance work) had swapped the

pump & introduced condensate for priming

before startup.

Later when they had started the pump the

leak was larger and triggered multiple gas

alarms including the High gas alarm

1 hr. 30 min before disaster:

Module C was protected by fire walls

designed to resist intense flames up

to 6 hrs. but not explosion proof.

Destroyed the fire panels of the fire

walls which had flown like projected

missiles.

Damaged another condensate

pipeline in module B.

This leak aided a second explosion

which was an oil explosion resulted

in an evanescent fire ball.

Incident Investigation

Incident Investigation

1 hr. 10 min before disaster:

Colossal explosion from the bottom of

module B had shaken the platform

Oil was dripping below the module B did

not dripped directly to the sea but it

settled

Divers placed rubber matting over the

gratings to avoid the sharp edge on their

bare feet

Dripped oil had formed a small pool and

this pool fire had heated up a high

pressure gas line from Piper alpha to

another rig named Tartan.

The pool fire, weak metal, high pressure

heated up gas caused the huge

explosion and around 150m (as per

Cullen Report) fire ball

Incident Investigation

HP gas pipeline to Claymore destroyed

Living quarter dislodged to the sea with

all the crew

Failure Analysis & Mitigation

PTW System

Multiple PTW should be kept at a common place

Proper hand over between shifts

Effective site auditing regarding specialized permit

Appropriate equipment specific isolation procedure

Fire wall and

Layout

Conducting a design safety review before any

modification and analyzing the requirement of passive

fire protection (blast proof walls) due to the new

modification.

Conducting Explosion Overpressure Study to check

the extent to which the walls could withstand

explosion

Failure Analysis & Mitigation

Automatic

water deluge

system

Putting the critical safety equipment always on

automatic mode

Production-

Safety Conflict

People > Environment > Asset > Revenue

OSHA PSM Elements Failure

The 14 key elements of OSHA PSM are as

follows:

Employee participation

Process safety information

Process hazard analysis (PHA)

Operating procedures

Training

Contractors

Pre-start up safety review

Mechanical integrity

Hot work permits

Management of change

Incident investigations

Emergency planning and response

Audits

Trade secrets

OSHA PSM Elements Failure

The 14 key elements of OSHA PSM are as

follows:

Employee participation

Process safety information

Process hazard analysis (PHA)

Operating procedures

Training

Contractors

Pre-start up safety review

Mechanical integrity

Hot work permits

Management of change

Incident investigations

Emergency planning and response

Audits

Trade secrets

Accidents and disasters are

common events in chemical, oil

& gas, manufacturing, and

nuclear industry.

Piper Alpha Disaster was

initiated & propagated by faulty

actions of human.

In our study of this incident we

have focused on Human Error.

Our Approach

Human Error

Departure from acceptable or desirable

practice on the part of an individual that can

result in unacceptable or undesirable results

1

Intentional & unintentional manmade mistakes

that cause injury to people, environment

pollution, economical loss and reputational

damage.

It is a concept for explaining breakdowns,

accidents or other inadvertent consequences .

1

Bea, Holdsworth, and Smith, Human and Organization Factors in the Safety of Offshore Platforms

Human error includes:

Failing to execute or omitting a task

Accomplishment of the task inaccurately

Performing an additional or non-required

task

Performing tasks out of sequence

Failing to perform the task within time limit

linked with it

Failing to respond effectively to an

emergency

Human Error

Human Error Classification

Unsafe Acts

Intended Action

unintended Action

Slip

Laps

Mistake

Violation

Attentional Failure

Intrusion

Omission

Reversal

Misordering

Mistiming

Memory Failure

Omitted Planned items

Place-losing

Forgetting intensions

Rule-based Mistakes

Misapplication of good rule

Application of bad rule

Knowledge-based Mistakes

Many variable forms

Routine Violation

Exceptional Violation

Art based mistakes

Fig. 1: Unsafe Acts taxonomy (Reason 1990)

Slips: Errors associated with the execution of faulty action.

Lapses: Errors is caused by memory failure.

Mistakes: Error occurs perfect execution of a task but wrong

planning.

Violations: Errors associated with deliberately avoiding

organizational rules and regulations.

Human Error Classification

Human Error Classification

Human Error

Handling Error

Maintenance Error

Assembly Error

Design Error

Installation Error

Inspection Error

Operator Error

Control Error

Fig. 2: Human Error in Different Phase of a Project

Contributors to Human Error

Performance requirements that exceed

human capability

Design that promotes fatigue

Inadequate facilities or information

Difficult/ Dangerous/ Unpleasant/

Repetitive tasks

Tasks at odds with the person's aptitude

Stress, Illness, Sleep Deprivation, Injury.

Human Error Management

Reduce error vulnerabilities to tasks/task

elements

Determine, asses & eliminate error

producing factors within the workplace

Identify organizational factors that create

error producing conditions within the

individual, team, task & workplace

Enhance error detection

Increase the error tolerance of the system

Improve the organization resistance to

human fallibility

HEART: Human Error Assessment &

Reduction Technique

Established by J.C. Williams (1986)

Procedural technique that attempts to

calculate human error.

Data based structured approach to human

error quantification

Uses its own values of reliability & also

factors of effect for a certain number of

error producing conditions

Start

Analyze task by

using HTA

Take the first/next

task step from the

HTA

Assign a HEART

generic category to

the task step in

question

Assign a nominal

human error

probability (HEP) to

the task step in

question

Select any relevant

error producing

conditions (EPCs)

Take the first/next

EPC

Determine the

assessed proportion

of effect of the EPC

on the nominal HEP

Are there any

more EPCs?

Y

N

Calculate the final

HEART HEP for the

task step in question

Are there any

more task steps?

N Y

Stop

HEART Methodology

Step 1: Categorized task

Analysis (HTA)

Step 2: The HEART Selection

Process

Step 3: Classification of task

unreliability

Step 4: Identifying Error

Producing Conditions (EPC)

Step 05: Assessed proportion

of effect

Step 06: Explanation of

remedial measures

Step 07: Documentation

Human Errors in Piper Alpha

Performing a maintenance work without

following appropriate procedure

Faulty warning system & read out problems

in the control board panel due to design of

the panels or action of board operator

Put the automatic (electricity driven)

firefighting pumps turned off

Philosophy of production first rather than

safety first

Action of a less trained people as major

decision maker

Assumed Scenario

A key overhauling work, already in backlog

No practice of cross referencing between

works

Possibility weather condition change

Complacent attitude in the auditing &

inspection practice.

Non redundant methanol system (hydrate

inhibitor) needs troubleshooting

Recently promoted OIM having no

experience in managing crisis condition as

an incident commander.

General task category

Type of task (E)

Routine, highly practiced, rapid task Involving

relatively low level of skill

Nominal Human Unreliability 0.02

Error Producing Conditions

EPC HEART

effect (E)

Assessed Proportion

(P)

Assessed effect

A.E=((E-1) x P) + 1

No means of conveying spatial

and functional information to

operators(in this case

maintenance crew) in a form

which they can readily assimilate

X 8.0 0.15 2.05

The need to transfer specific

knowledge from task to task

without loss

X 5.5 0.2 1.9

Little or no independent

checking or testing of output

X 3.0 0.5 2

Ambiguity in the required

performance standards

X 2.5 0.35 1.525

A need for absolute judgments

which are beyond the

capabilities/experience of the

performer

X 1.6 0.25 1.150

No obvious way to keep track of

progress during an activity

X 1.4 0.5 1.2

Human Error Probability

Nominal likelihood of failure

P = 0.02 2.05 1.90 2.0 1.525

1.150 1.2 = 0.3279

Calculated Human Error Probability (HEP) is

nearly 33% for this particular task

Remedial Measures

Spatial & Functional Incompatibility Such incompatibilities should not occur. If there is any doubt

expert opinion should be obtained to run the task in

appropriate manner

Knowledge Transfer Reliance should not be placed on operators transferring

their previous knowledge without loss of precision or

meaning-if such perfect transfer is required suitable job aids

should be provided as reference.

Inadequate Checking When high reliability is paramount, independent checking on

a proper accuracy level by people & systems that do not

have any vested interest in the success/failure of an

individual. Blame game is strictly prohibited.

Ambiguity It needs to be ensured that all the performers of a particular

task are well aware of the codes & standards. There should

not be any chance of relying on substandard information

Requirement of absolute judgment Task performer should not be placed in the position of

taking decision about issues which are outside the span of

their experience. Task analysis will help to figure out the

time when this sort of situation arises & management should

have contingency plan. Brain storming or problem solving

sessions can help to tackle this bizarre condition.

Lack of progress tracking Job aids (checklist/electronic mimic) need to be supplied in

order to ensure that performers do not go out of step with

the task in hand.

HEART at a glance

HEART method was used for error

probability assessment & error reduction.

HEART provided valued awareness

regarding industrial parameter

Aided to figure out appropriate defenses

against human error in both qualitative &

quantitative level.

Aftermath

Immediate wide ranging assessments of the installation

and management system carried.

Official public inquiry of the disaster was done by Lord

Cullen came up with 106 recommendations.

The Offshore Installations (Safety Case) Regulations

came into effect 1992

The Offshore Installation and Pipeline Works

(Management and Administration) Regulations 1995

The Offshore Installations (Prevention of Fire and

Explosion, and Emergency Response) Regulations 1995

(PFEER)

The Offshore Installations and Wells (Design and

Construction, etc) Regulations 1996

Survivors Psychology

Professor David Alexander carried out a study

on the long-term psychological and social

effects of Piper Alpha on the survivors.

Around 70% survivors had psychological and

behavioral symptoms of post-traumatic stress

disorder.

They had difficulty in finding employment.

Employers regarded Piper Alpha survivors as

Jonahs bringers of bad luck.

Family members of the dead and survived

victims suffered psychological and social

problems.

Piper Alpha Today

Platform that used to produce 10 percent of the North Seas

oil , today only a wreck buoy of it is all that is visible.

A memorial sculpture showing three oil workers was

founded in the Rose Garden within Hazlehead Park in

Aberdeen.

A scholarship was launched on April 20th 2011 by Industry

Skills and Safety Body OPTIO as a tribute to the heroes of

Piper Alpha who lost their lives.

Pound for Piper Memorial was launched on the 28th of

May 2012 to raise 1m for maintenance of the Piper Alpha

Memorial garden.

A three-day event to be held at Aberdeen which will be

chaired by Oil & Gas UK chief executive, Malcolm Webb to

mark 25 years of Piper Alpha disaster

This Presentation is dedicated to all the

survivors- When I stand before thee at the day's

end, thou shalt see my scars and know that I had my

wounds and also my healing.-Rabindranath Tagore

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Forensic Science: Written By: Jennifer HansenDocument31 pagesForensic Science: Written By: Jennifer HansenHamdan YusoffNo ratings yet

- Manufacture of Formaldehyde From Methanol-LibreDocument51 pagesManufacture of Formaldehyde From Methanol-LibreHamdan YusoffNo ratings yet

- Case Study Batch Reaction Lesson 1Document43 pagesCase Study Batch Reaction Lesson 1Hamdan YusoffNo ratings yet

- Dajjal Book EngDocument79 pagesDajjal Book EngHamdan YusoffNo ratings yet

- The Fall of MalaccaDocument4 pagesThe Fall of MalaccaHamdan YusoffNo ratings yet

- Engineering at Food Manufacturing Plant Premised On Haccp OperationDocument11 pagesEngineering at Food Manufacturing Plant Premised On Haccp OperationHamdan YusoffNo ratings yet

- Case Study On Materials Selection MedicalForcepsDocument6 pagesCase Study On Materials Selection MedicalForcepsHamdan YusoffNo ratings yet

- Khmer Dan MalayDocument51 pagesKhmer Dan MalayHamdan YusoffNo ratings yet

- AP1999 ArticleDocument30 pagesAP1999 ArticleHamdan YusoffNo ratings yet

- Piping Codes, Standards, and Specifications 1Document5 pagesPiping Codes, Standards, and Specifications 1Manish KumarNo ratings yet

- Universal Marine: Welcome To Our One Stop Marine ServicesDocument8 pagesUniversal Marine: Welcome To Our One Stop Marine Serviceshoangtruongson1111No ratings yet

- Compose Testing CheatsheetDocument1 pageCompose Testing CheatsheetEstampados SIn ApellidoNo ratings yet

- Jicable DAS For Power Industry Applications 2015-A3-4Document6 pagesJicable DAS For Power Industry Applications 2015-A3-4Richard KluthNo ratings yet

- Valery 1178Document22 pagesValery 1178valerybikobo588No ratings yet

- CV Rafi Cargill, GAR, MCR, AM GROUP and Consultancy EraDocument6 pagesCV Rafi Cargill, GAR, MCR, AM GROUP and Consultancy EranorulainkNo ratings yet

- Functions and Uses of CCTV CameraDocument42 pagesFunctions and Uses of CCTV CameraMojere GuardiarioNo ratings yet

- CS 148 - Introduction To Computer Graphics and ImagingDocument3 pagesCS 148 - Introduction To Computer Graphics and ImagingMurtaza TajNo ratings yet

- Water Quality Management For Production of Freshwater Ornamental SHDocument14 pagesWater Quality Management For Production of Freshwater Ornamental SHVarun KNo ratings yet

- VAT (Chapter 8 Compilation of Summary)Document36 pagesVAT (Chapter 8 Compilation of Summary)Dianne LontacNo ratings yet

- Shareholder Agreement 06Document19 pagesShareholder Agreement 06Josmar TelloNo ratings yet

- Consumer Research ProcessDocument78 pagesConsumer Research ProcessShikha PrasadNo ratings yet

- 9a Grundfos 50Hz Catalogue-1322Document48 pages9a Grundfos 50Hz Catalogue-1322ZainalNo ratings yet

- Magicolor2400 2430 2450FieldSvcDocument262 pagesMagicolor2400 2430 2450FieldSvcKlema HanisNo ratings yet

- Electrical NTPCDocument24 pagesElectrical NTPCSenthil KumarNo ratings yet

- Vehicle Detection and Identification Using YOLO in Image ProcessingDocument6 pagesVehicle Detection and Identification Using YOLO in Image ProcessingIJRASETPublicationsNo ratings yet

- Pac All CAF Subject Referral Tests 1Document46 pagesPac All CAF Subject Referral Tests 1Shahid MahmudNo ratings yet

- Unilever Financial PerformanceDocument9 pagesUnilever Financial PerformanceAbdul QayumNo ratings yet

- LIC Form - Intimation of Death Retirement Leaving ServiceDocument1 pageLIC Form - Intimation of Death Retirement Leaving ServicekaustubhNo ratings yet

- 2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP GlycerinDocument1 page2B. Glicerina - USP-NF-FCC Glycerin Nutritional Statement USP Glycerinchristian muñozNo ratings yet

- BPI vs. Posadas, G.R. No. L - 34583, 1931Document8 pagesBPI vs. Posadas, G.R. No. L - 34583, 1931Nikko AlelojoNo ratings yet

- Past Simple and Continuous - When - While Worksheet - Live WorksheetsDocument4 pagesPast Simple and Continuous - When - While Worksheet - Live WorksheetsSaraí CaracúnNo ratings yet

- Ara FormDocument2 pagesAra Formjerish estemNo ratings yet

- 11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsDocument6 pages11 - Savulescu Et Al (2020) - Equality or Utility. Ethics and Law of Rationing VentilatorsCorrado BisottoNo ratings yet

- Latitude 5424 Rugged Spec SheetDocument5 pagesLatitude 5424 Rugged Spec SheetHaitemNo ratings yet

- Inkt Cables CabinetsDocument52 pagesInkt Cables CabinetsvliegenkristofNo ratings yet

- Emergency Communication Procedures Communication Equipment Wake TurbulenceDocument38 pagesEmergency Communication Procedures Communication Equipment Wake TurbulenceRaluca StoicaNo ratings yet

- 4439 Chap01Document28 pages4439 Chap01bouthaina otNo ratings yet

- Pub 005940 PDFDocument31 pagesPub 005940 PDFkurniaNo ratings yet

- Logbook) Industrial Attachment Brief To Students-3Document6 pagesLogbook) Industrial Attachment Brief To Students-3geybor100% (1)

- Global Grants Community Assessment FormDocument3 pagesGlobal Grants Community Assessment Formlalitya xavieraNo ratings yet